Design

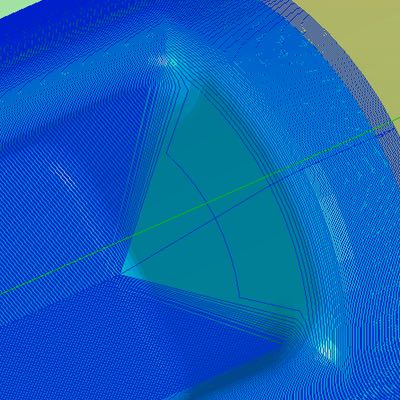

I have used Solidworks to design and partially simulate the function of my first dispenser, in this case designed to dispense AA batteries, the design will dispense one battery each time a dispensing rotor pivots through approximately 120°, actuated by a sub-micro hobby servo motor.

I opted to use a rotary dispenser over a sliding tray or similar to reduce cost and complexity, rotational motion is very easily achieved and controlled using inexpensive parts with little to no complex mechanical linkage required.

Process

I opted to manufacture the rotor using a 4-Axis CNC machining process on the Roland MDX-40A, I am making the initial prototype out of wood, specifically Tasmanian Oak with a view to using a polymer such as HDPE in the final version.

Hiccup #1

Enter the first hiccup, whilst working on generating toolpaths in SRP Player I ran into the fact that SRP Players 4 axis toolpaths are not really 4 axis, they are a 3.5 axis toolpath allowing either the Y, Z and A axis to operate simultaneously but not the X or the X, Y and Z axis to operate continuously with indexing on the A axis.

The Workaround

The trick was to generate 2 separate jobs, the first milling out the pocket using the 'Block Workpiece' mode in SRP Player and restricting the machined area to the pocket and its immediate surrounds, this did result is some time machining the air around the part but ultimately did work.

Finishing the Machining

Final machining took approximately 6 hours, I used the SRP player defaults for hardwood machining however due to the relatively small remaining material connecting the finished part to the unmachined portion I did slow the feedrate down a bit once it had removed the bulk of the material.

Assembly

Files

Note: These are the manufacturing files for this component only, for the design files for my entire project see the summary page.