|

|

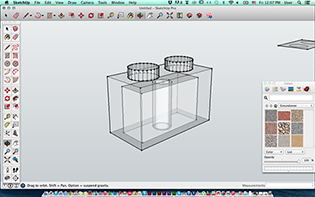

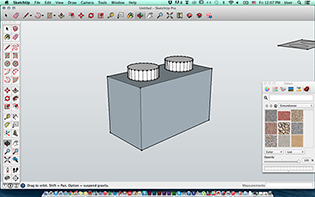

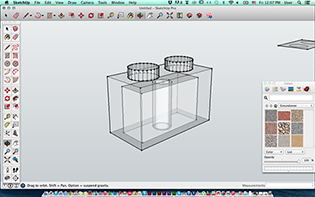

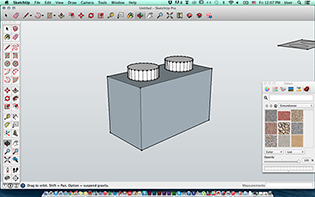

Using Sketch Up

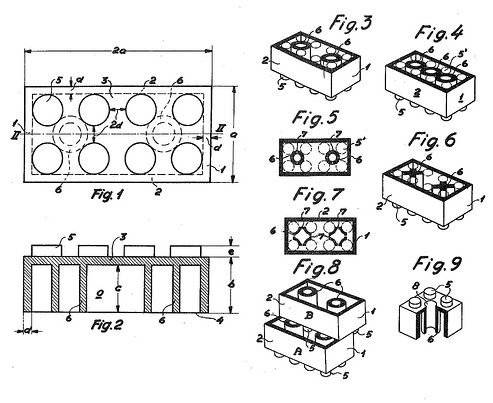

First i thought of a mold that can be replicated and be useful or used as decoration in a toy shop, so i thought of a piece of lego.

Process:

1- Get or generate the dimensions of the part

2- Design the part just as you want it to be casted

3-

Design the 3D mold

Design

using Sketch up

|

|

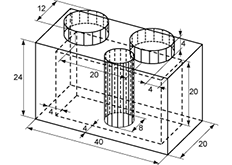

Dimensions

(found online)

|

|

Using the milling machine (Modela)

Margins 6 mm

Slope

The margins are important to give u a rigid block for casting.

The slope is eaqually important to get an easy grab of the part when casting

The milling process took 2 hours to finish the wax mold

using silicon

After milling the wax mold, I had to make its negative to be able to cast parts of the lego out of it. The silicon is used in this case because it suits the properties of epoxy and will tolerate its suspension. The silicon is inserted into the wax and left for 3 to 4 days to dry. Because the lego mold is deep, the silicon took too long to dry completely. After pulling the silicon mold out, it's time now to cast some lego parts!

This is the tricky part, below I will present you the process of preparation of the epoxy and some tips to get a smooth and clear surface.

NOTE: Try to keep the silicon mold and clean and smooth as possible otherwise the epoxy will get through every detail in the silicon mold and solidify. So if the silicon mold is not clean enough, bumpy, or textured, you will come up with a similar quality of the epoxy cast.

using Epoxy & Hardener

To prepare the mixture you need to be wearing gloves and preferably an apron and a mask. The ratio of the epoxy to the hardener is 2:1 as written in the instructions on the bottle.

Mix the two materials gently and slowly in order not to generate small bubbles that you don't want in your cast.

Air bubbles will cause unclear cast so be aware especially if you are seeking a glassy transparent object.

As you can see, the cast is bumpy because when I tried to pull the silicon mold out of the wax, it had not been completely dry especially at the very bottom. So this caused a bumpy surface in the silicon mold which appears clearly in the cast.

mariamwaelgado@gmail.com mariamwaelgado@gmail.com |

mariam-wael |