|

|

Using the Auto Cad & Corel draw

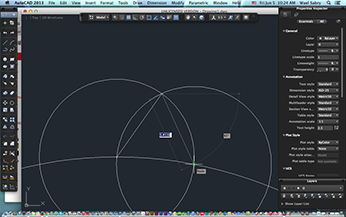

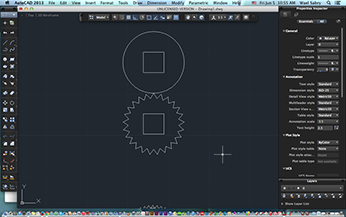

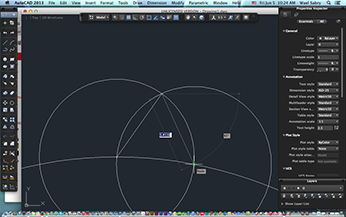

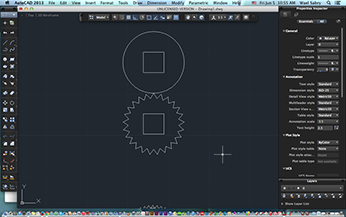

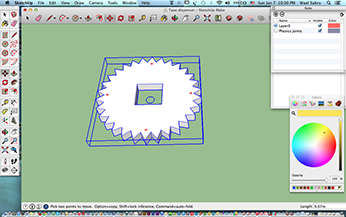

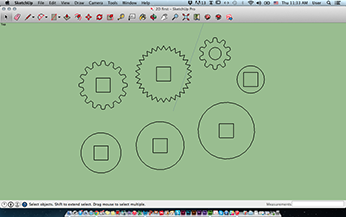

I chose AutoCad to design the drums because AutoCad is accurate. I needed to create a centric shape of copied acute angles and that was easily accomplished using AutoCad smart tools.

|

|

Using Sketch up

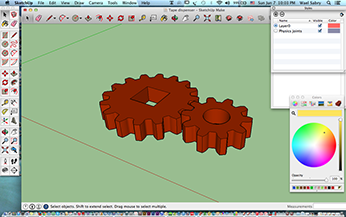

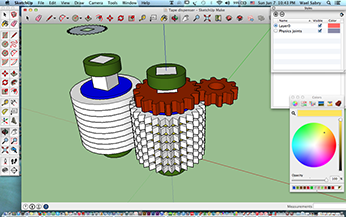

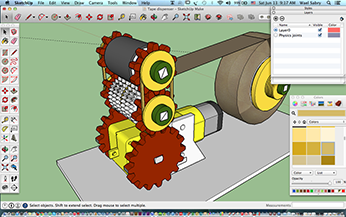

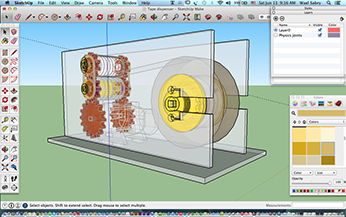

After designing the gears and drums it's time now to bring them in shape! I started pulling up the gears into the tickness of the acrylic sheets and i stacked everything together to view it in 3D without actually fabricating it.

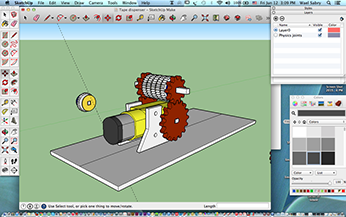

When it comes to 3D, everything changes and new things are discovered such as missing parts, wrong counts of parts needed, and illogical design in some cases. After modification the pictured tured out to be clear and finaly teh whole idea is visualized.

Now what's next?

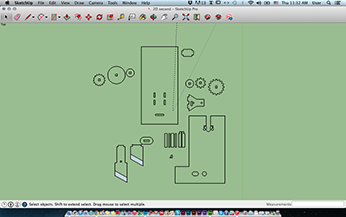

Let's bring it in real life - fabrication. But in order to fabricate or laser cut those parts they need to be transformed into 2D drawings once more.

|

|

|

|

|

|

On sketch up, I chose the cutting outline of each part and placed them in parallel on the same plan and chose the top view, then I exported it as a DXF file format. As shown in teh image below, this is the top view after eliminating all unwanted lines and keeping the outlines to be cut on the laser cutter soon.

|

|

And finally what i have been designing is now in hands. Here are all the parts I will need to build up the tape dispenser.

mariamwaelgado@gmail.com mariamwaelgado@gmail.com |

.png) http://mariamwaelgado.wix.com/ http://mariamwaelgado.wix.com/mariam-wael |