A small scale prototype of a low-cost scalable design that uses four servo motors to control the display of two seven-segment digits.

Finished small-scale scoreboard prototype. This version had 6.5 inch tall digits.

(c) R. Scott Zitek 2014 Permission granted for experimental and personal use. License for commercial sale available from R. Scott Zitek. ---------------------------------------- Contact: rzitek (at) lorainccc (dot) edu

Typical mechanical scoreboards control each segment in the display independently. By controlling the visibility of each of the seven segments the various digits 0-9 can be created. With electro-mechanical displays this is typically accomplished by "flipping" the segments so that they physically display either a light or dark surface. This often requires seven actuators per digit, one for each segment.

Current solid state scoreboards usually employ LEDs to selectively illuminate each segment as needed. LEDs are becoming brighter and less expensive but larger scoreboards require either very bright LEDs or many "standard" LED. So larger LED based scoreboards are often prohibitively expensive.

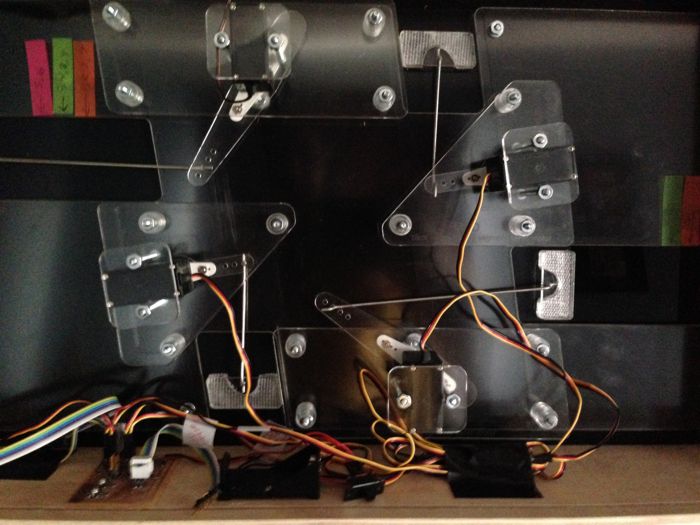

I have designed a low-cost scalable scoreboard that using sliding parts to control multiple segments with the same actuator. This prototype uses just four actuators to control 14 different display segments. This means that it can display all of the digits from 00 to 99 using only four actuators.

This approach:

One of the challenges of this design is that a slide with all the segment combinations needed had to be very long. I wanted the scoreboard to be portable but my initial designs needed large cabinets to give room for the slides to move through their entire range of motion. I also had issues with not being able to put two digits close enough together.

The solution was take advantage of patterns in the display combinations. For example, I was able to use the slide segment that controls the right upper segment of the most significant digit (MSD) digit to also control the left upper segment of the least significant digit (LSD) for another combination. It was challenging to design but the pattern is easy to make once it was figured out. I also tried to optimize the sequence of the patterns to reduce the movement needed from one number to the next. This is appreciated when you see how quickly the system can cycle from one digit to the next.

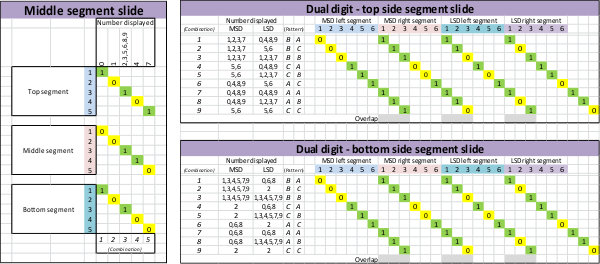

This is a chart I created to document the different segment combinations for each slide.

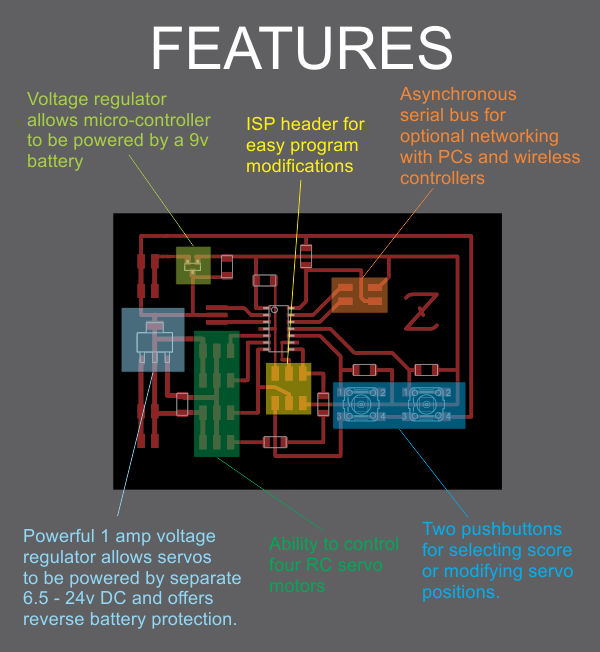

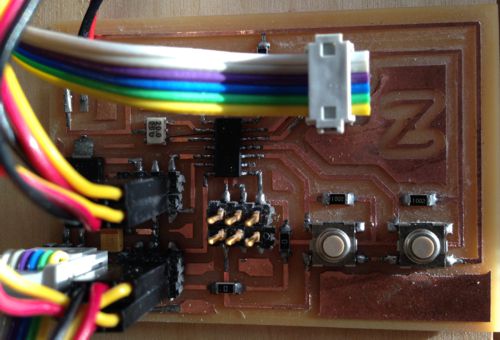

I used Eagle CAD to create a custom circuit board that integrated together all of the features that I needed.

The stand-alone custom designed circuit board with network interface for connectivity.

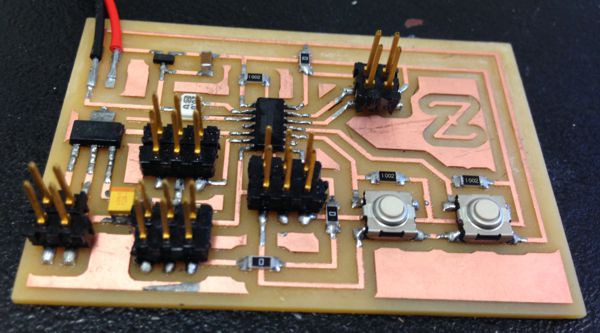

I cut the board on the Modela mill and soldered all of the components.

The finished circuit board.

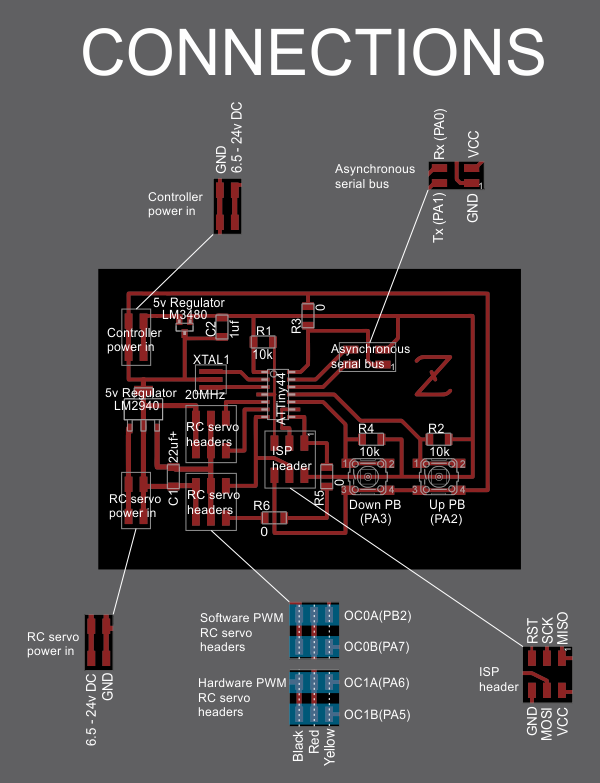

Since this circuit board does so many things, I made a diagram to label all of the components, headers, and power connections.

The circuit board utilizes numerous connection headers and two separate power supplies.

This is what the circuit board looks like when everything is connected (except the ISP connector which is only needed to modify the program).

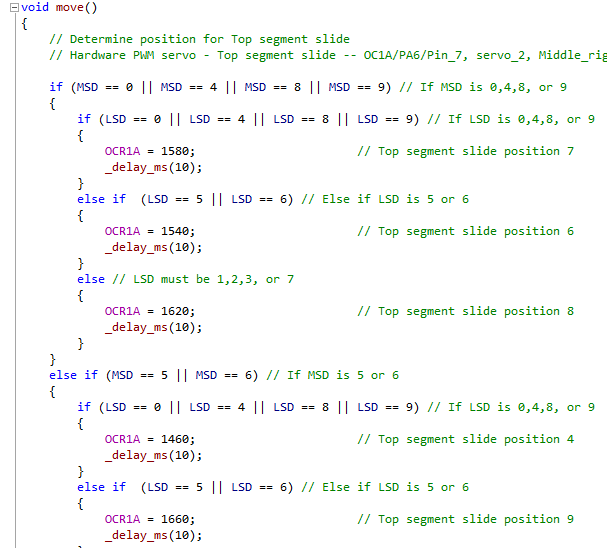

I programmed the circuit board using Atmel Studio 6.2 and AVR GCC C. The program uses hardware PWM to position the two side-to-side slides and uses software PWM to position the two up-down middle segment slides.

Example of part of program used to position one of the servos.

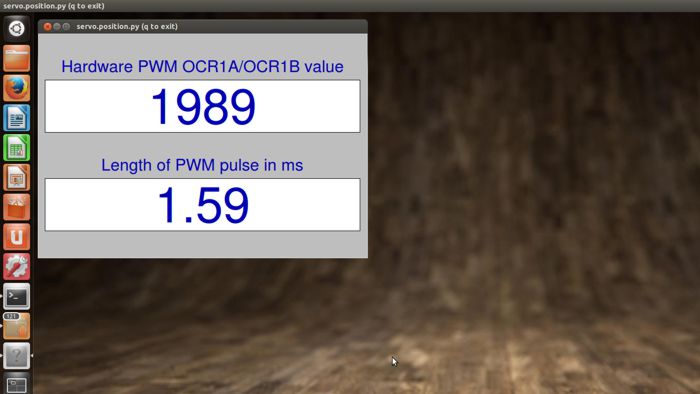

I also created a different program that sends the servo position value via the FTDI interface to a PC where a custom python interface displays the value in near real-time. See week 15 for more information.

The graphical user interface showing the needed information for precisely programming the servo positions.

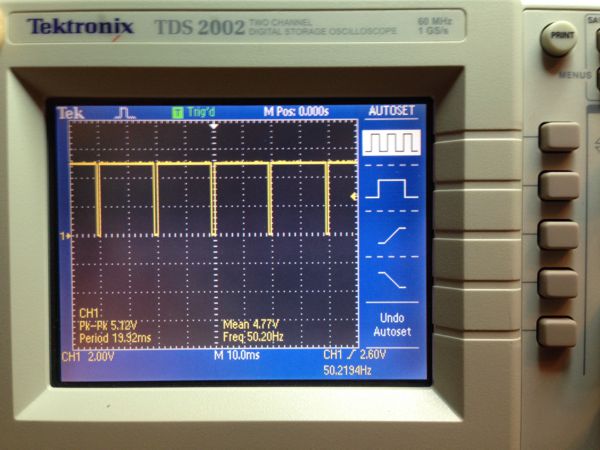

I hooked up an oscilloscope to see what the control signal really looked like. It is amazing that we can do this with a microcontroller that costs less than two dollars.

PWM signal to control RC servo as seen on an oscilloscope.

I spent most of my time working on the mechanical aspect of the scoreboard, how to assemble it, and how to move the slides with the RC servos.

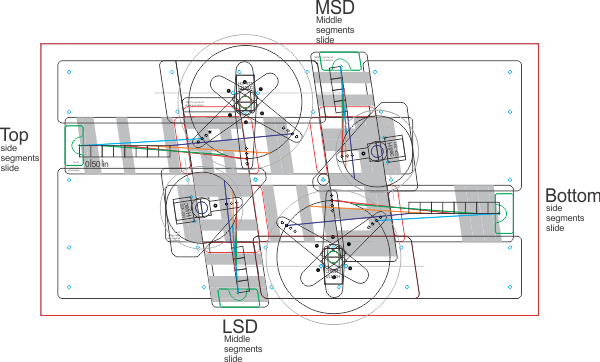

CAD diagram of the overall assembly as seen from the back.

I used CAD software extensively to work out the details of the design, to work out rotational to linear movement, and to avoid interference among all the different moving parts.

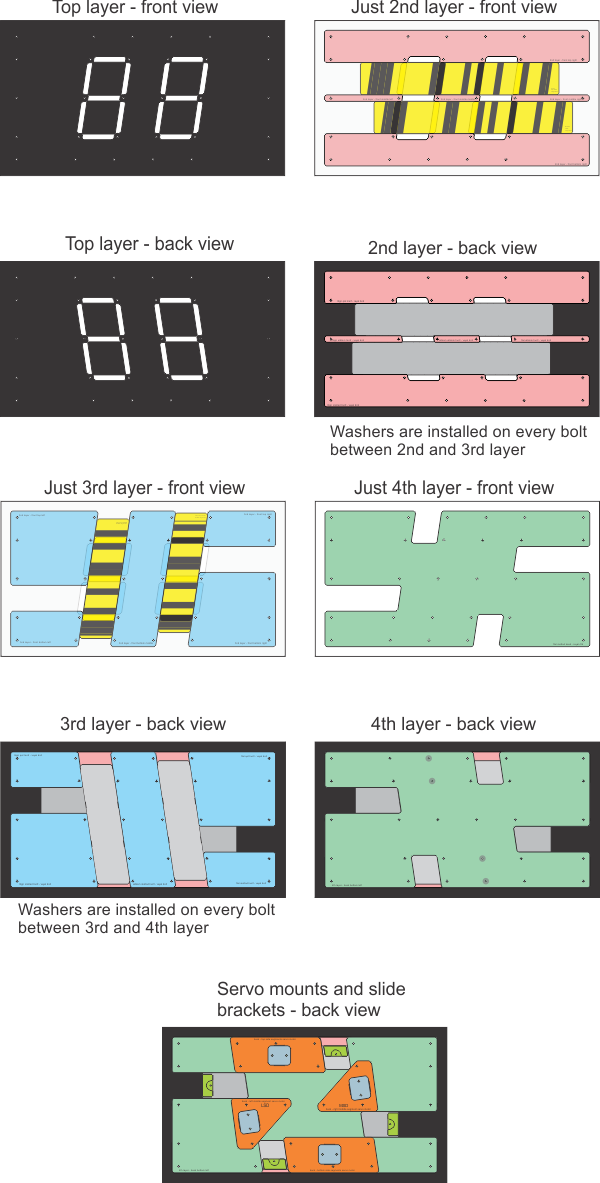

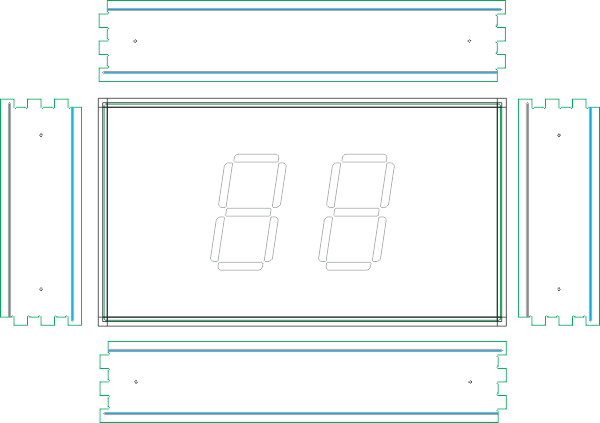

CAD diagrams showing the different layers of the assembly.

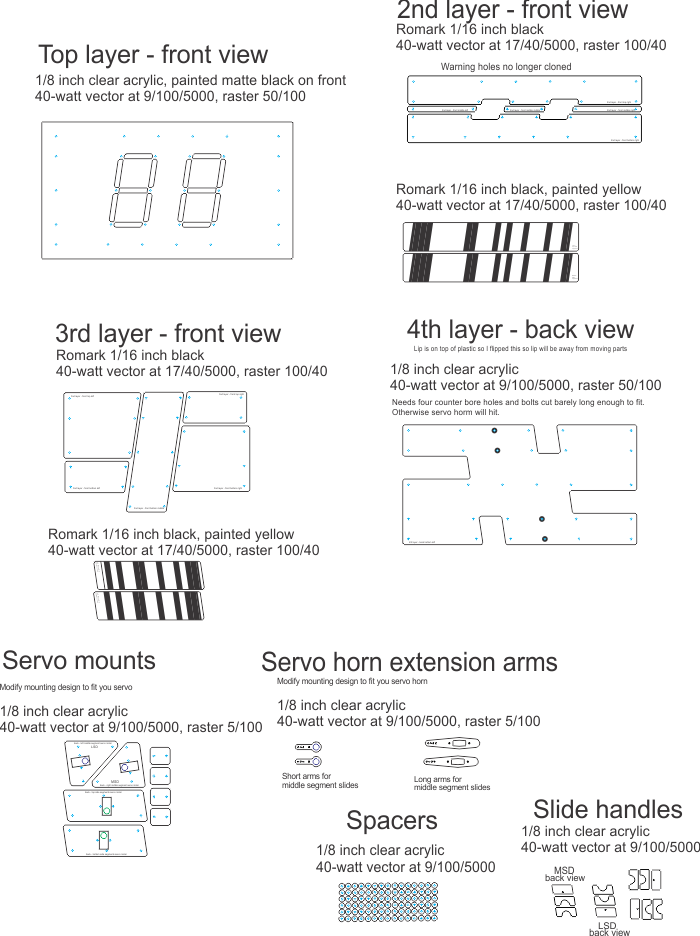

I had to precisely draw many parts, laser cut, and then assemble them.

CAD diagrams showing all the different laser cut parts.

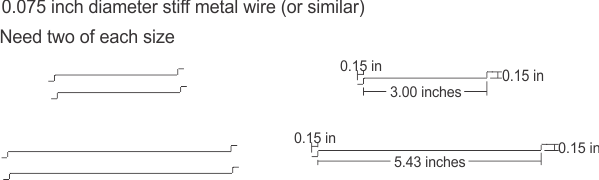

I tried to use all standard Fab Lab Inventory materials. However, I needed to make pushrods to connect between the rotating arm of the servos and the handle that attached to the linear slides.

Dimensions for push rods.

The push rods are made from 0.075" stiff wire that can easily be bent by hand. I found a iny pair of channel locks that were perfect for the job.

This is what the ends of the push rods should be bent to look like.

For the most part, everything is held together with common nuts and bolts. Washers are used as spacers where needed. There is two exceptions. The enclosure which is press fit and the slide handles. I needed a way to attach the push rods to the sliding pieces. Since the sliding pieces in this small-scale prototype are only 1/16" thick, I ended up attaching a "slide handle". It consists of three pieces of 1/8" acrylic that are solvented together. I then attached them to the slides using double-sided carpet tape.

Example of a slide handle. These are used to attach the rotating arm of the servo to linearly move the slides.

When assembling the arms on the servos, make sure the servo is in the center position. This can be done by running the ftdi-hardware-pwm.c program and holding down the Up and Down buttons together. After assembly, it is ready to have the positions fined tuned in the program. See week 15 for more information.

This is what the back of the assembled prototype looks like.

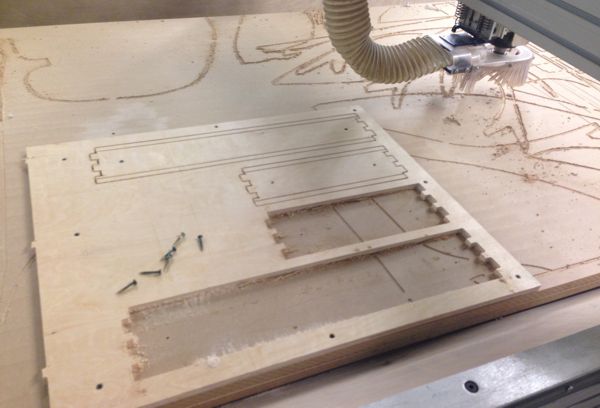

The enclosure ended up being the easiest part. I made the enclosure on the Shopbot from 1/2" thick plywood. I cut everything using only one tool, a 1/8" flat end-mill that was barely long enough to cut 1/2" deep.

I made the design using CAD and then imported it into Aspire to generate the part program.

You may notice that there are two small holes in each board. That is where I held the boards down with screws while they were being cut out on the Shopbot. It was fast and eliminated the need to add tabs. I made one Shopbot program to spot drill, using the 1/8" end-mill, where the hold-down screws go. This eliminates the guess work of where to put the hold-down screws and reduces the chances of crashing the tool into a hold-down screw.

I then generated a program to cut along the line for the slots and around the outside of the profile for everything else.

CAD design for the enclosure.

The enclosure is press fit held together only by the friction of the fingers being pushed together. It was fast and easy to design and cut. It was easy to assemble, looks pretty nice, and holds together well. The joints can be glued if a permanent joint is desired. In this case, I might need to take it apart someday.

Removing the enclosure parts after they were finished being cut on the Shopbot.

Picture of the finger joints on one of the corners of the enclosure.

Here is a video of the first time I tested the scoreboard. It works very well. The display is very easy to read and holds the postions well. It is also very responsive and the digits update faster than I expected with standard servos running on only 5 volts.

(c) R. Scott Zitek 2014 Permission granted for experimental and personal use. License for commercial sale available from R. Scott Zitek. ---------------------------------------- Contact: rzitek (at) lorainccc (dot) edu