Home Work

The job is to design a "Big Thing" , and then send it to the big milling machine to make it. We'll use OSB board, 1,25m x 2,5m with a 15mm thickness. Well, when mesuring it, the real thickness is more 14,3mm.

We will try to make a table with the following feature :

- form of the African continent

- no use of glue or screw

- corect size to have 2 people working at the same time

Before starting drawing, we start doing some design thinking :

- we first take some mesure of the area , giving us a size of 1,6m x 1,3m

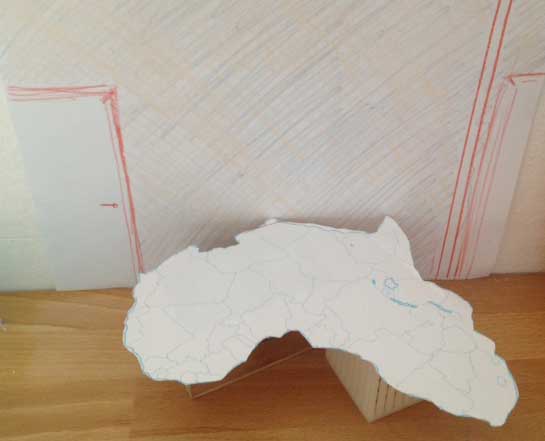

- then we do a paper simulation to check how to rotate the shape : a continent is probably not the best idea for a table, but anyway we'll try it.

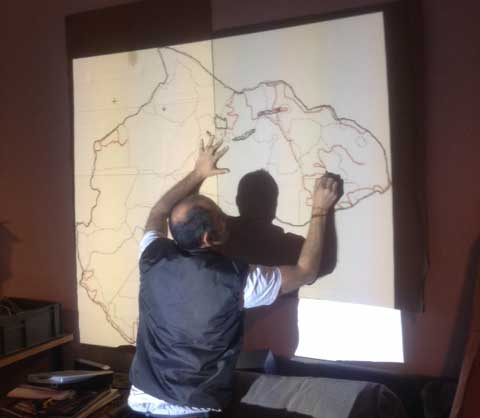

Then we decide to made a cardboard version at scale 1:1, in order to be sure it would be a more o less usefull furniture. Because the lasercutter was not available, I use another way to have the corect shape of Africa :

- I project africa on a wall with a projector , mooving it until reaching the 1,6m length I need

- then I place the cardboard, and draw following the line

- you just then have to cut it and place it to test what would be the more confortable way to rotate this strange form.

I like design thinking using cardboard !

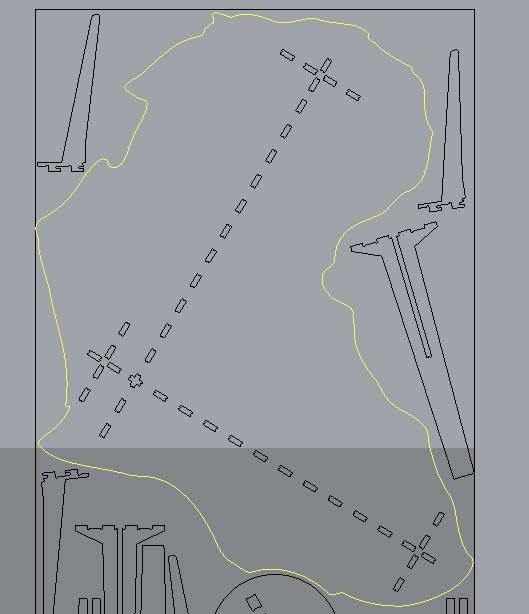

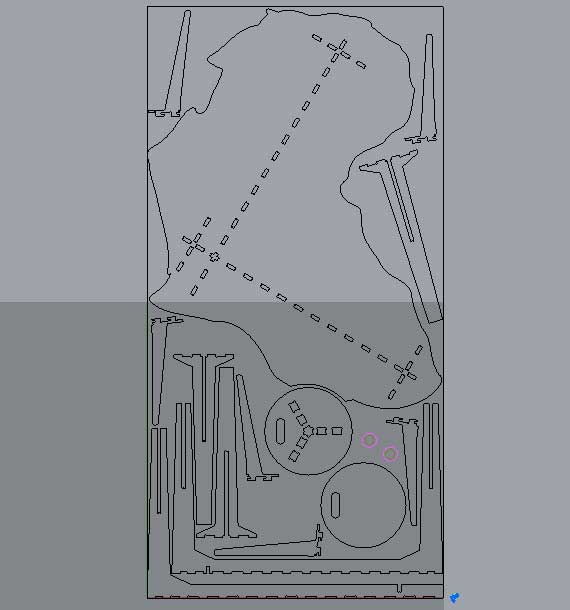

We realize the support will be a critical decision : having 4 is not confortable for 2 people, but having only 3 , using a so thin material as OSB for such a big piece, could be a point of failure. After looking many options, we decide to try the one sho at the image below (I prefere the very nice one Luciano showed us, but I dismiss because it's too complex for my skills...)

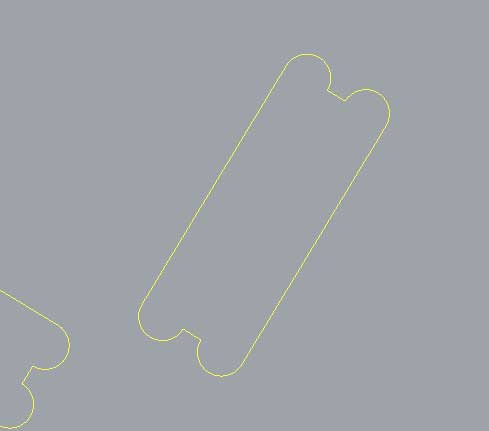

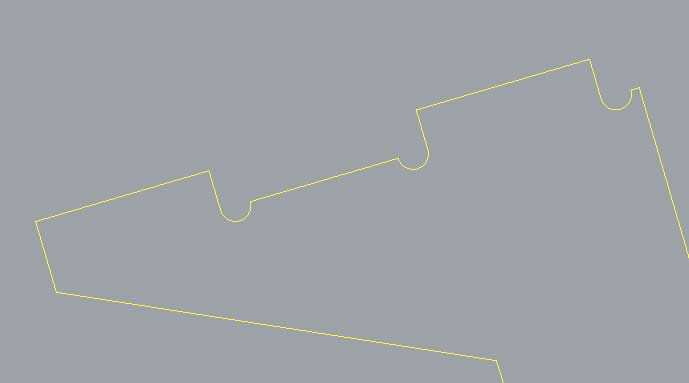

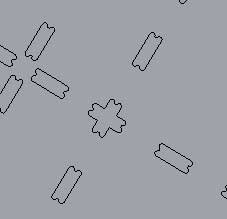

I try to use Inventor Fusion to do it, but there is no way to import anything, even a Illustador file ! Incredible. After trying to do it with the interesting MOI software, I finally go for using Rhino in 2D mode. It was paintfull, especially because my very poor skills relating to Rhino. The union will be "unvisible", carving 8mm in the 14mm thick OSB. We'll use a 6mm drill, so I draw the tipical "mickey'ear" for each part of the union. For the intersection of the 2 conectors, Luciano advise me to center the 2 hole, making a cross.

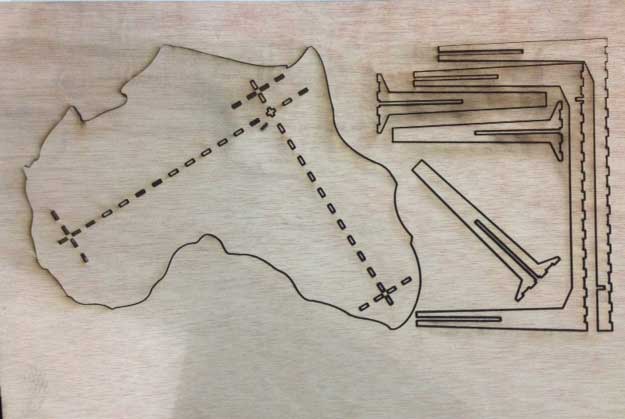

Because we are many student here, around 15, there is a long wait to be able to use the ruter. I use it to make a reduce version of the table, using the Epilog Lasercuter, in order to check all the union were corect. Good news, all this time suffering Rhino was not wasted, it work :

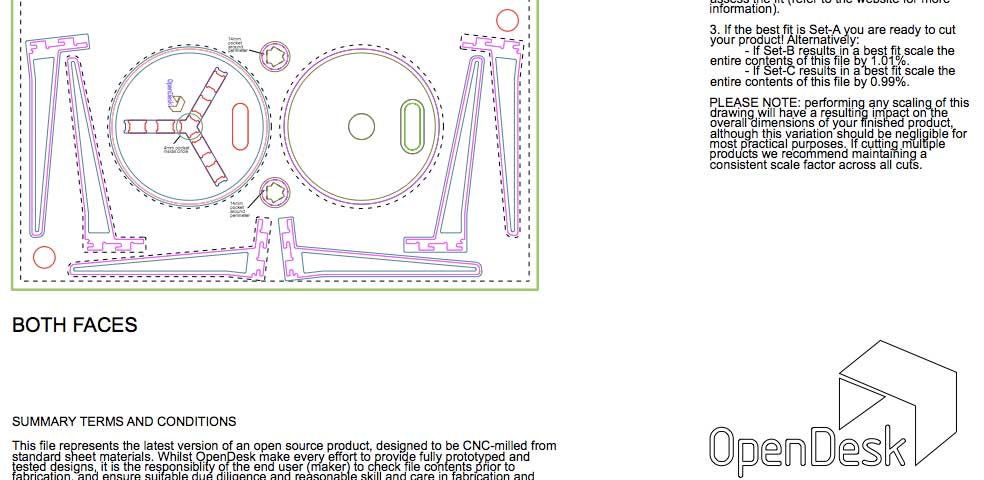

Then come the real job, but before I wanted not loose material , and I import a stool from the nice www.opendesk.cc website :

I was ready to mill, when Luciano ask me "did you check if the width of the opendesk design is the same than the OSB board we are using ? ..." I forget this ! I am a Padawan... => OK , I had to erase the stool, next time "think before acting" .

Starting the milling process, we'll see the result in 2 hours ..

And the final result is quite good, but some part of the structure are too narrow and have breaked. But my kids are happy ; next step is to make it corecting the errors, and using a better material like plywood.