After many servomotors hacked, I want to show us the diferent ways to trick a servomotor and convert it to contiuos rotation.

Introduction

A common servomotor can't turn more than a couple complete turns. Commonly it can turn only half or a quarter turn.

How it function

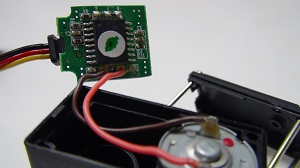

Inside de servomotor has four principal parts, a DC motor (actuator) a potentiometer (sensor), a gear box (torque multiplier), and an electronic board (control). These board, control the angle of the axis, using a proportional control; what this mean?, the speed to reach a certain position is proportional to the travel angle, so if you need to turn a great angle the speed of turning will be very high at first, and meanwhile the angle decrease the turn speed also decreases.

Also you can find continuos rotation servomotor, these kind of servos has two resistances of the same value instead of the potentiometer, of course the mechanical block doesn't exist inside this kind of servomotors.

|

|

Disassembly

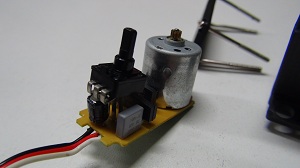

Take out the four screws at the bottom. Then you can separate the servomotor housing in 3 parts: on top you can find the gear train, on the bottom we find the motor, the potentiometer and electronic board.

Mechanical Hack

Some servomotors has metallic pin or plastic tab on the final gear to avoid the continuous rotation and protect the potentiometer from over turns.

For the mechanical hack, you could cut the plastic tab with a knife or a chisel.

Or remove/cut the metallic pin. In some cases the pin doesn't exist (but it's rare).

In other cases the last gear is incomplete toothed (the gear part that turns has teeth); these kinds of servo motors are impossible to hack if this gear don't be replaced.

Electronic Hack

The idea is to convert the potentiometer to a non-variable resistance, to deceive the control board that the axis is always in the middle position; so when the angle signal is sent the control board will try to change the position, and will set the speed proportional to the angle set in the signal (90° = zero speed / 0° or 180° = top speed ).

To hack the electronics, you have three options:

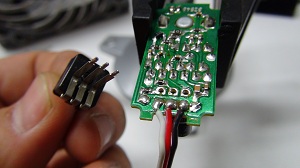

A. Swap the potentiometer with a pair of resistances of the same value

With SMD resistors With SMD resistors |

With THD resistors With THD resistors |

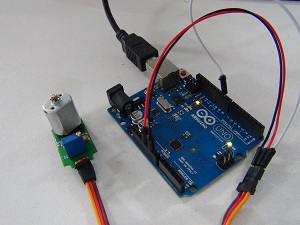

B. Cut the axis of the original potentiometer and then calibrate it in the middle position, with use of a 90° signal (could use an Arduino).

C. Change the original potenciometer with a trimpot (more acurate potentiometer) and then calibrate it in the middle position using a 90° signal (could use an Arduino).

The first option need a very accurate resistance value, last two options needs precision at calibration. Of course the option A. and C. needs soldering skills. The last is the better option (in my opinion).

Reassembly

For reassembly take care if you use THD resistances or a big trimpot, maybe could not enter inside the servomotor case.