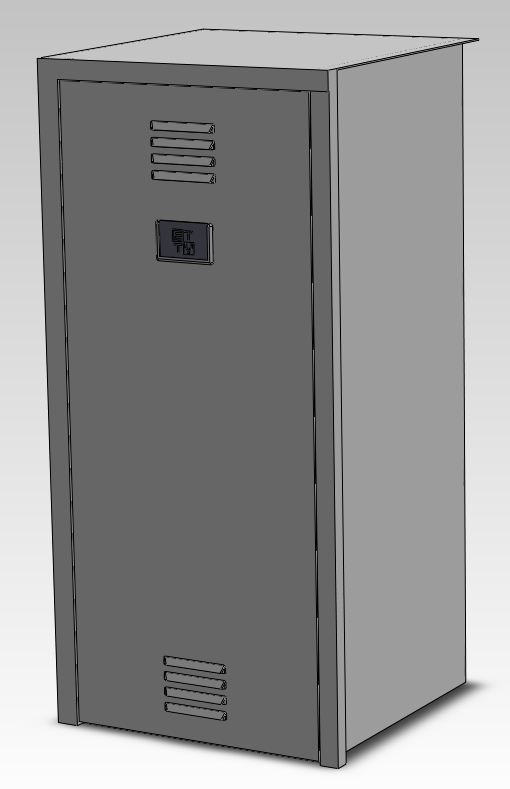

In the Fab Lab UNI, all the people who are in the Fab Academy program has a locker. My own is one of the biggers and I have a lot of things inside are realy disordered. I detect the problem, the locker need to be like a shelf...

Materials & Equipments

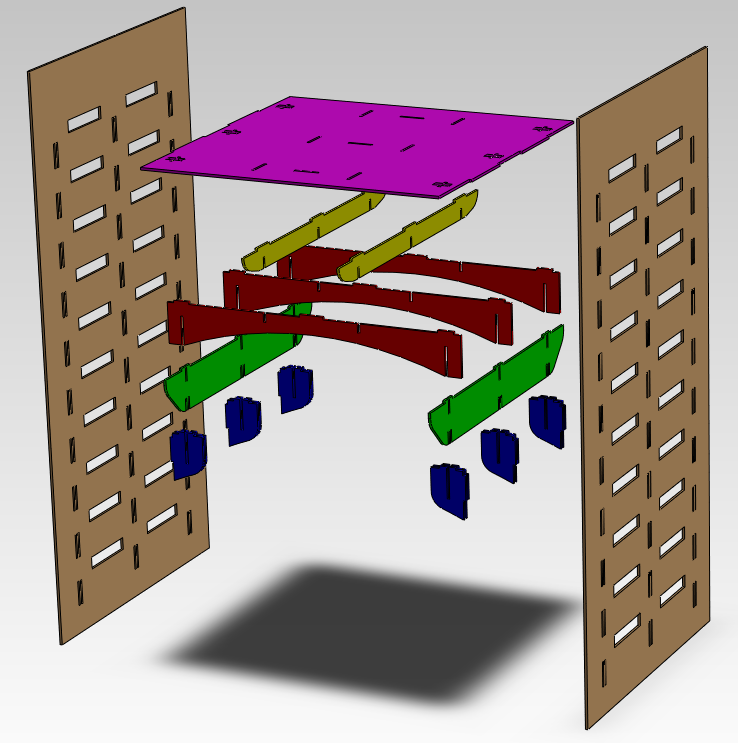

Design

First of all I need to take the inside dimentions of the locker: Length = 365mm, Height = 700mm (I considered the space under the bar for hang clothes), Width = 380mm.

With the dimentions I start drawing the locker, to get a better vision of the locker in the software.

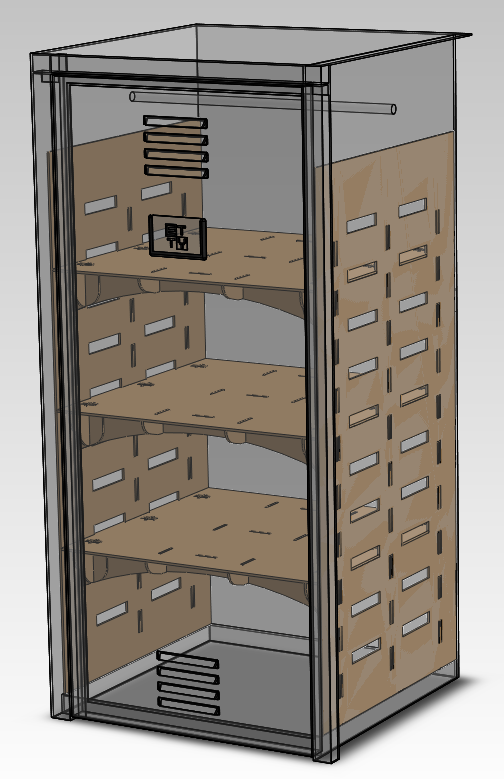

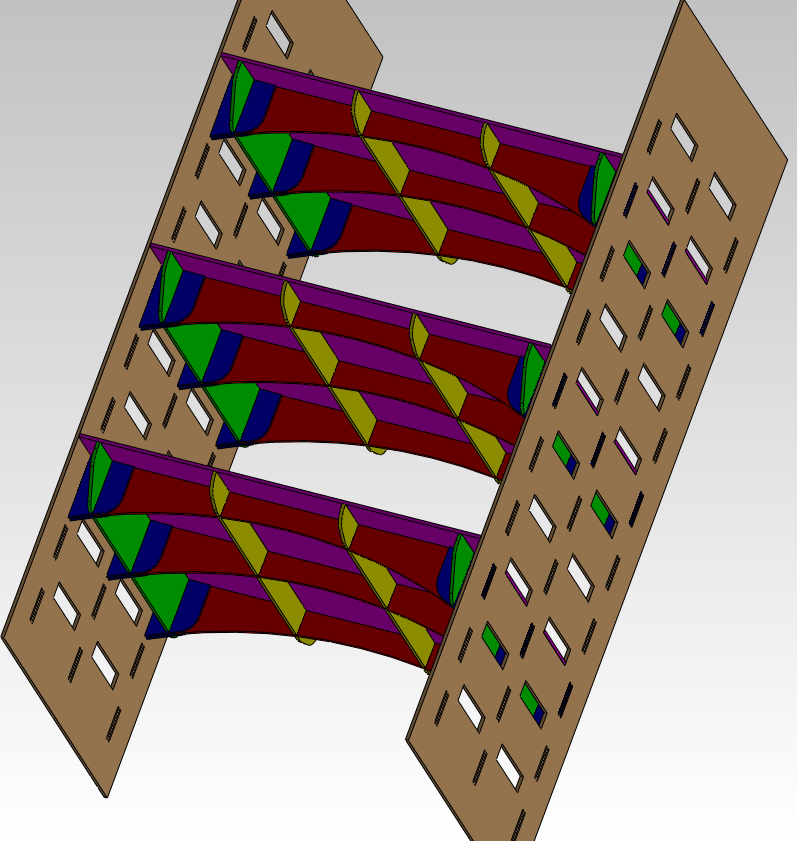

I started putting 2 walls (brown parts in the left picture) to support the rack's structure. The locker sides will support this walls (without glue or other kind of joint element). Also the racks could be put in any height.

Each rack, use 3 beams (red) that will been supported by 6 tabs (blue) to each wall of the shelf (total 12 tabs by rack), this tabs needs a tab-connector (green) to coupling to the beam.

In the middle of the beams I put 2 cross-beams (yellow) to increase the rigidity of the structure and suporte the rack board (violet)

Part List (for one rack)

*Is easiest to understand all the design looking the assembly section.

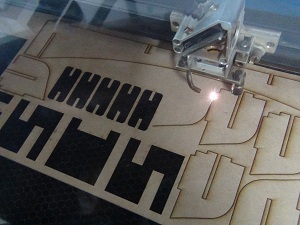

Cutting

For this part we have the CNC Laser Cutter Epilog Legend 36EXT with a 60W laser cannon.

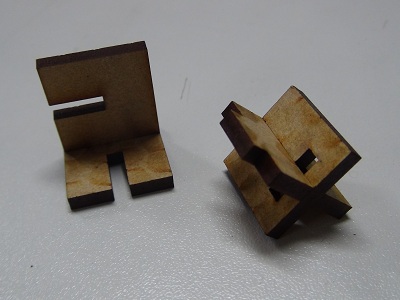

Before the cutting, I need to made some tests with the material that I will use, the 3mm MDF; sometimes it don't has exactly 3mm (use the vernier to take measure). Normally I cut small scuares with hole or canal to test.

A good press-fit joint is when you can assemble only with your hands effortless and when you hang the joint in the air by one of the parts, the other doesn't falls.

For 3mm MDF that we have in Lima, the parameters for the laser cutter are:

- Power = 100%

- Speed = 20%-22%

- Frecuency = 2500Hz

NOTE: If the parameters varied the press-fit could fail. Each setting parameters are for each type of board (thickness / brand).

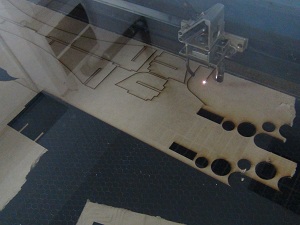

For cutting the small parts I prefere to use MDF scraps, that normally are throwed to the trash can, because are more dificult to setup the cut file on it. It take more time but is better for the planet (like I said: "reuse all than you can").

* Notice that the holes of the boards are from other works (scrap pieces).

* Notice that the holes of the boards are from other works (scrap pieces).

Assembly

|

|

|

|

|

|

Result

Now my locker is in order and clean.

Before the shelf |

With the Shelf |