John O'Keefe

Week 5 - Electronics Production

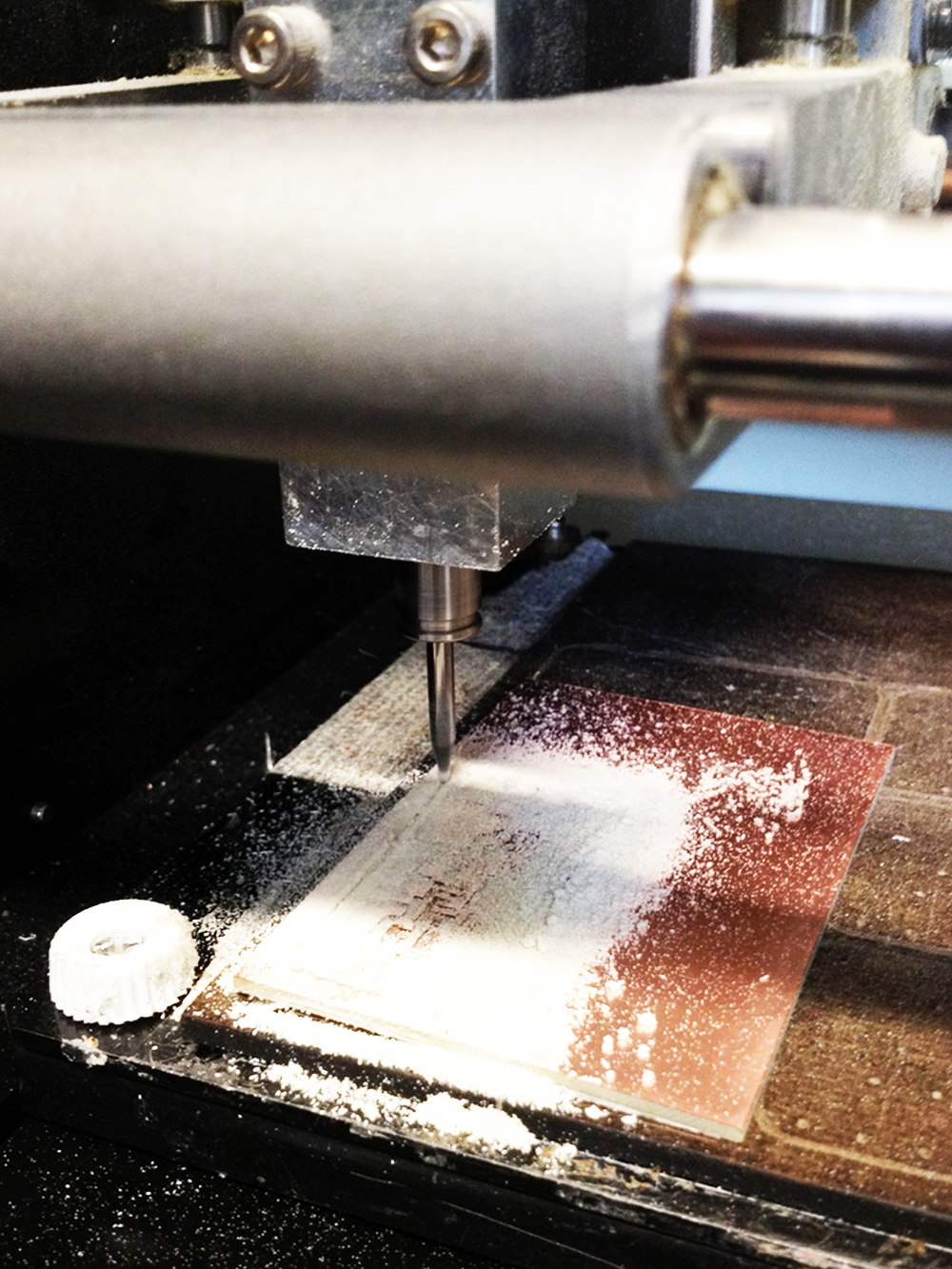

Milling Board with Roland Modela CNC

Milled the Fab ISP out of a copper plated, compressed paper board. Board came out pretty good, though next time will use stronger tape - the edges were pretty ragged and need

to be sanded down (you can see it sticking up a bit above).

Milled the Fab ISP out of a copper plated, compressed paper board. Board came out pretty good, though next time will use stronger tape - the edges were pretty ragged and need

to be sanded down (you can see it sticking up a bit above).

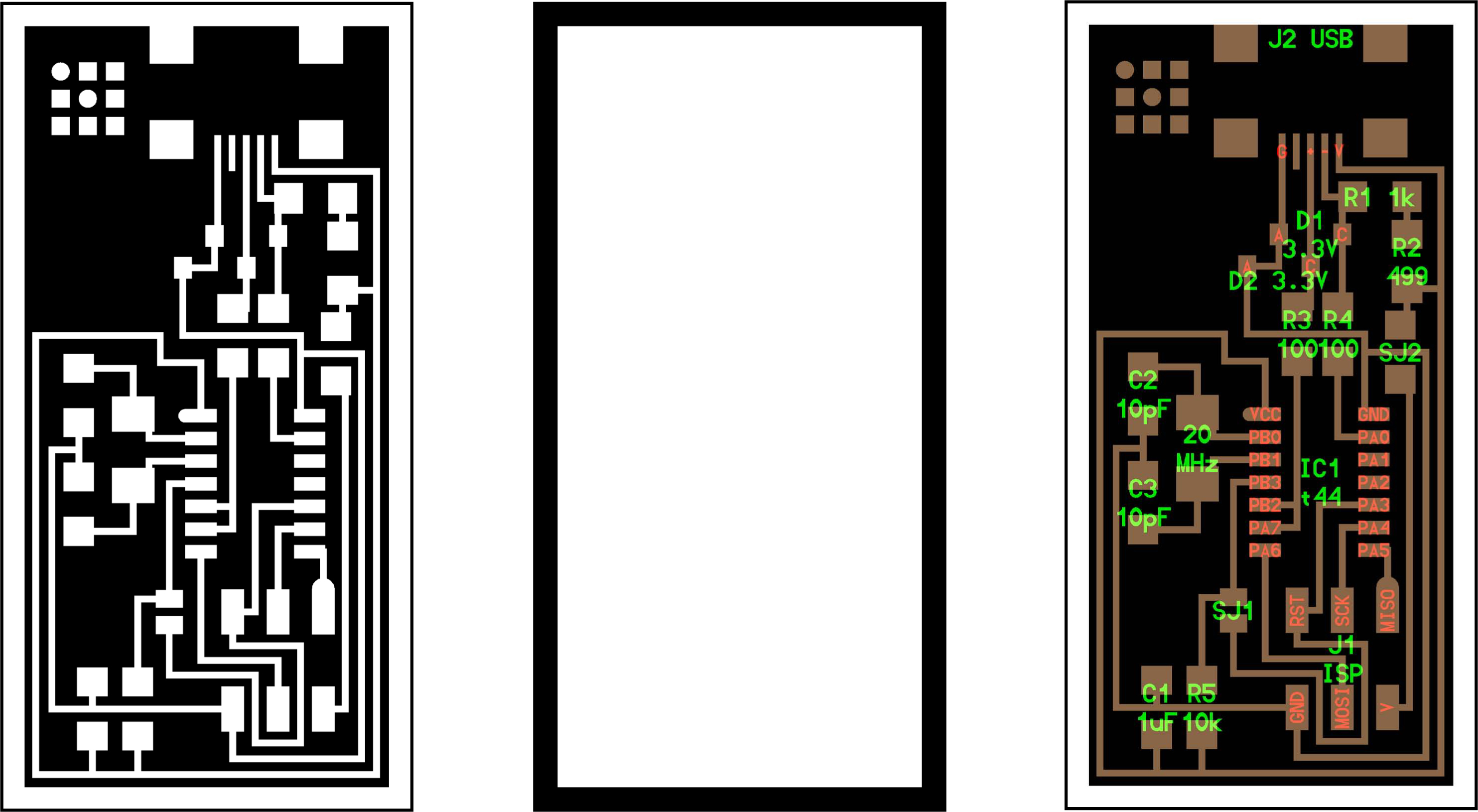

.PNG's

Used first .PNG, Fab Module trace default settings, and 1/64" bit to mill traces. Once traces were completed, second .PNG was loaded into the Fab Modules, paths were made, bit and settings were

changed to 1/32" and the board outline was cut through. The third .PNG was used to guide selection and placement of components on the board. SJ1 and SJ2 are jumpers which

must be removed after the board is initially programmed.

Used first .PNG, Fab Module trace default settings, and 1/64" bit to mill traces. Once traces were completed, second .PNG was loaded into the Fab Modules, paths were made, bit and settings were

changed to 1/32" and the board outline was cut through. The third .PNG was used to guide selection and placement of components on the board. SJ1 and SJ2 are jumpers which

must be removed after the board is initially programmed.

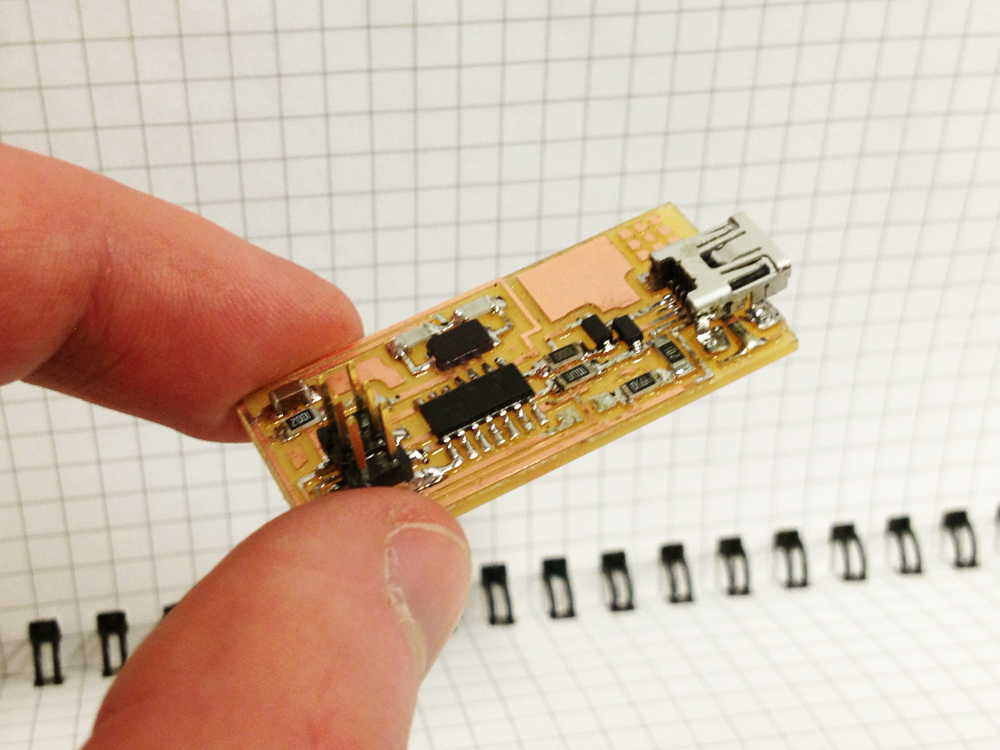

Fab ISP Programmer

"Stuffed" the board with components - resistors, capacitors, etc. using a soldering iron. Had to go back several times and tighten things up (there was a short indicated

by an error message that the board was drawing too much power when connected to the computer) by reflowing solder on some "cold" looking joints, and disconnecting joined pins on the mini USB

header using copper desoldering braid. I feel like a smaller tip on the soldering iron would help a lot but flux and desoldering braid for wicking excess worked pretty well.

"Stuffed" the board with components - resistors, capacitors, etc. using a soldering iron. Had to go back several times and tighten things up (there was a short indicated

by an error message that the board was drawing too much power when connected to the computer) by reflowing solder on some "cold" looking joints, and disconnecting joined pins on the mini USB

header using copper desoldering braid. I feel like a smaller tip on the soldering iron would help a lot but flux and desoldering braid for wicking excess worked pretty well.