Computer-Controlled Cutting

In this assignment, I focused on understanding and working with computer-controlled cutting tools. I started by completing the lab safety training and characterizing the laser cutter by testing key parameters such as focus, power, speed, frequency, kerf, joint clearance, and different joint types. I also completed the individual assignments by cutting a design on the vinyl cutter and designing, laser cutting, and documenting a parametric construction kit. The design was developed to be assembled in multiple ways and to include non-flat elements, using both engraving and cutting throughout the process.

CAM (Computer-Aided Manufacturing) converts digital designs into machine instructions for precise manufacturing.

CNC (Computer Numerical Control) machines use G-code to control movement, speed, and operations such as cutting, milling, printing, and engraving, including tools like laser cutters and 3D printers.

G-code defines axis movement (X, Y, Z), toolpaths, and tool activation, allowing the machine to execute the design accurately.

In conclusion, CAM connects the digital design to the CNC machine by translating the model into G-code that the machine can interpret and execute.

Nesting is the process of arranging parts within the machine's cutting area to use the material as efficiently as possible.

By optimizing the layout, nesting reduces empty spaces, minimizes material waste, and improves cutting time. In this case, the nesting is done manually, carefully positioning the pieces inside the laser cutter workspace before sending the file to the machine.

Even though I had already received safety training at my home university, Universidad del Pacífico, the training at Fab Lab ULima was essential. It helped me realize that there are many physical and technical differences between laser cutters.

For this week's assignments, we worked with the C4V Laser 16100 Pro IA, learning its main characteristics, safety considerations, and working area, which was key to understanding how to properly prepare files and operate the machine.

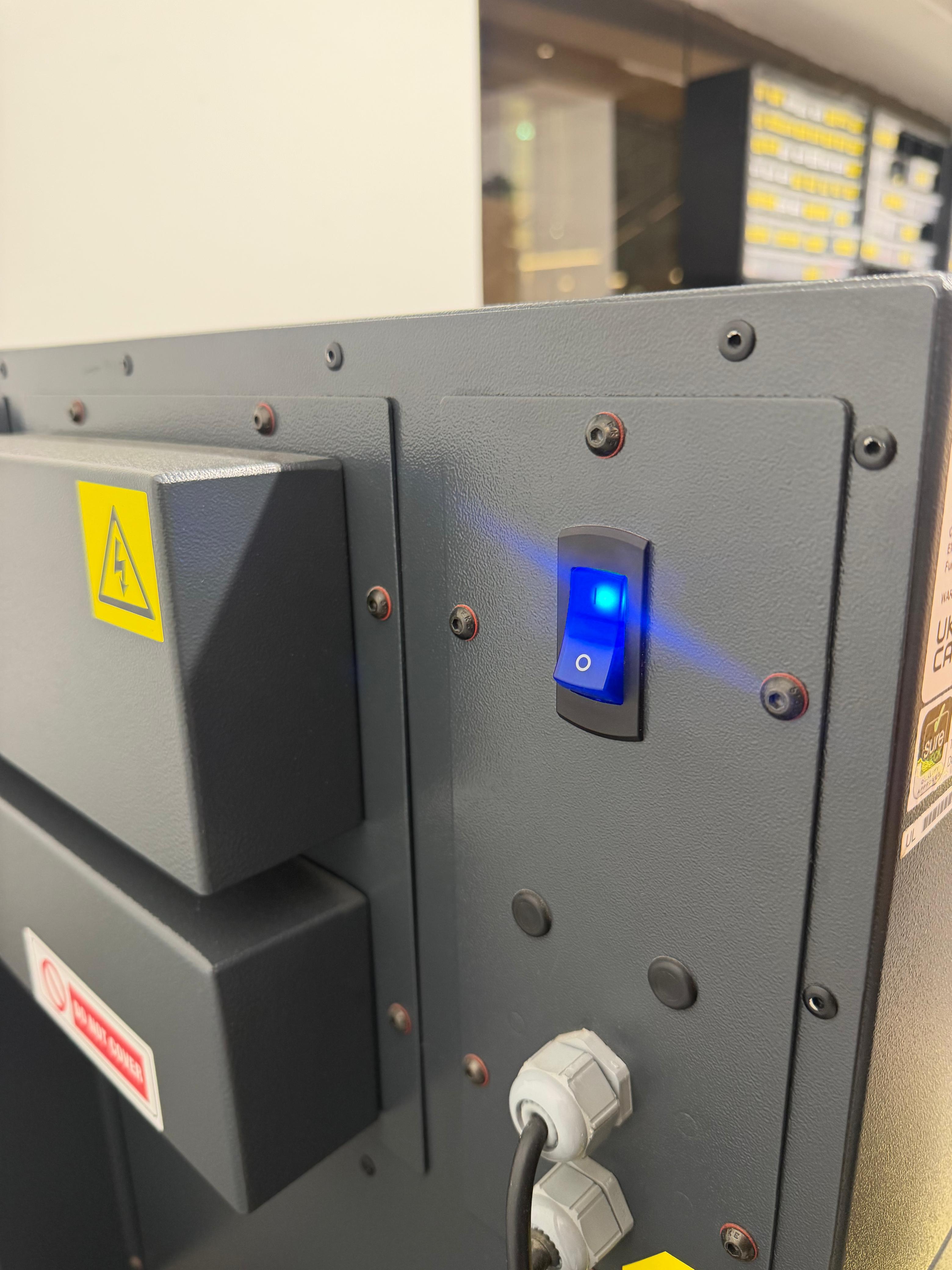

Now we explored the support equipment that allows the laser cutter to work properly and remain in good condition. On the left side of the laser cutter, there are two important machines that must be turned on when operating the laser.

The first one is the industrial chiller, which prevents the laser cutter from overheating. The coolant should be replaced every three to four months, and the chiller is turned on using the front power button.

The second support system is the particle filtration unit, whose main function is to filter the smoke and fine particles generated when the laser cutter processes different materials.

Unlike basic ventilation systems that only extract air, a particle filter is designed to capture solid particles and contaminants, improving air quality and protecting both the machine and users. This is especially important when cutting or engraving materials that produce dense smoke or residues.

The unit is powered on using the blue rear button. However, the front control button is used to activate the filtration process, which is noticeably loud, and should only be turned on while the laser cutter is operating.

To turn on the laser cutter, the emergency stop button must first be released by twisting it, and then the green power button should be pressed.

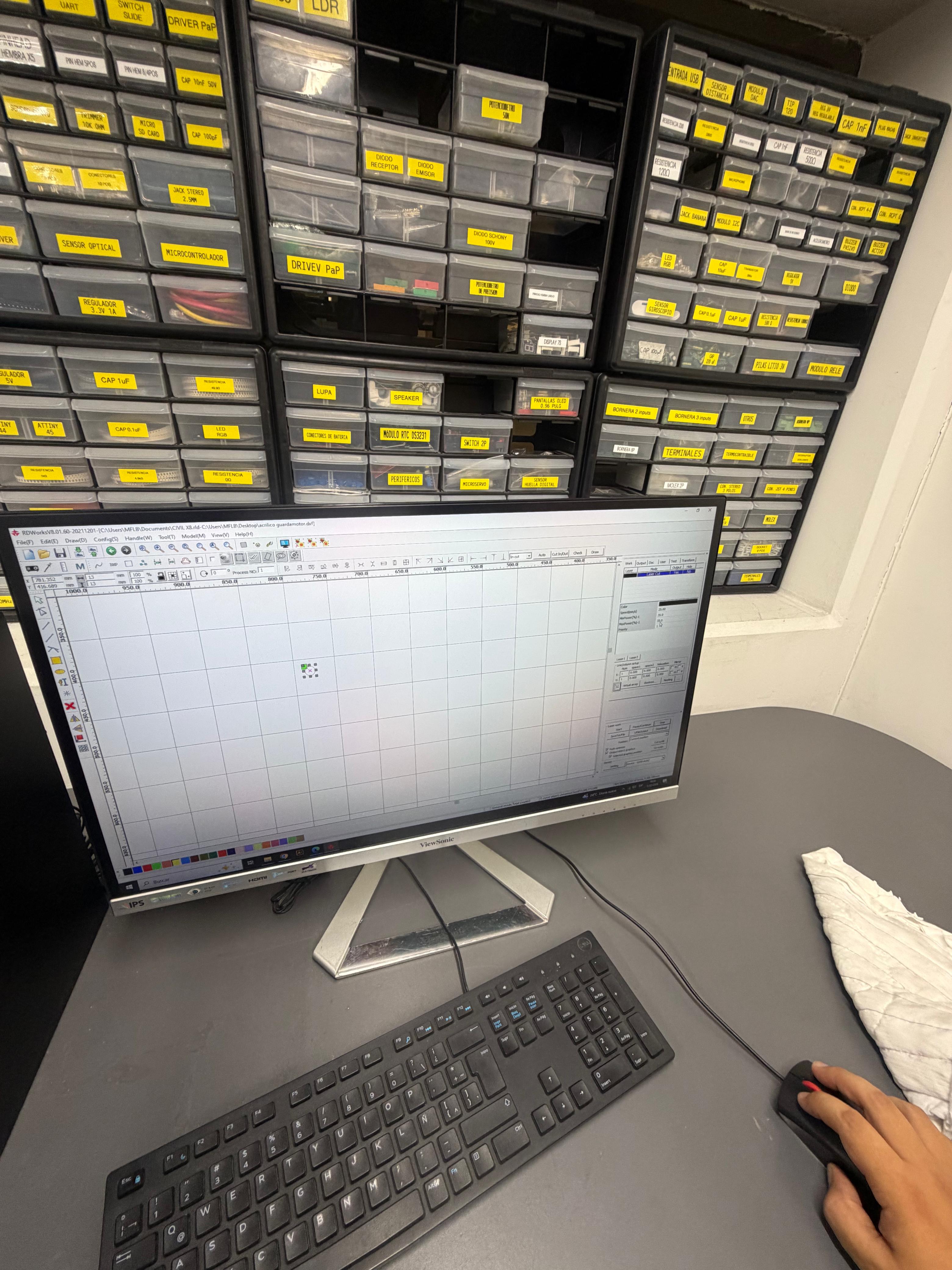

The software used to operate the laser cutter is RDWorks (RDXSolids).

⚠️ Safety note: As a safety measure, I tied my hair back to avoid accidents while operating the laser cutter.

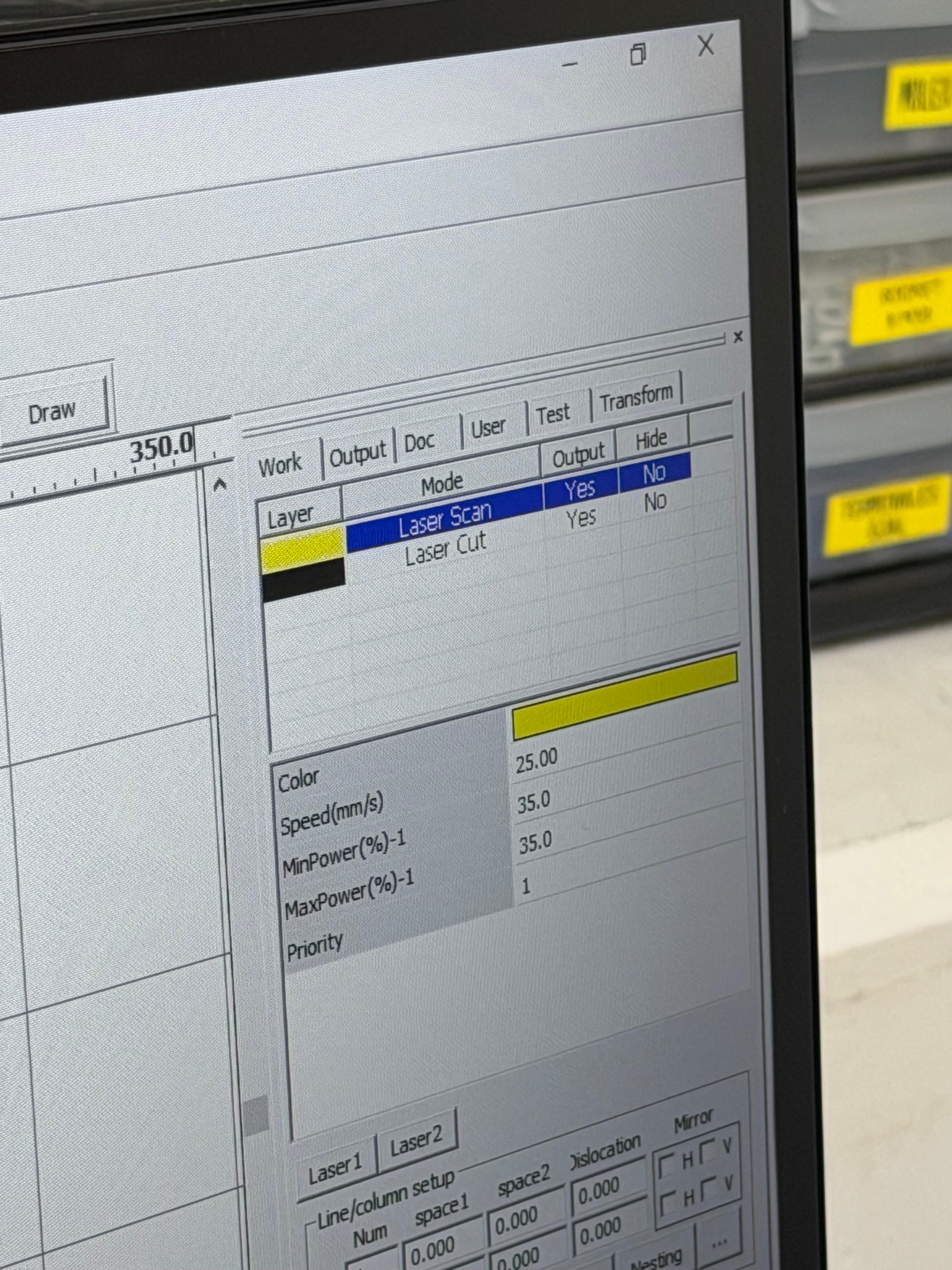

In RDWorks, it is possible to create shapes and engrave text. Different colors can be assigned to define specific cutting and engraving parameters such as power and speed, which will be explained in more detail during the group assignment.

Finally, I decided that my first laser cut would be a simple circle engraved with the word "Hola" in Spanish.

Check out the group assignment page for details of the work with Nicolas Mamani at Fab Lab Ulima here.

In this assignment, we explored the main parameters that affect the laser cutting process and how each variable directly influences the final result. Understanding these settings is essential to achieve clean cuts, dimensional accuracy, and good material performance.

Laser cutting depends on key parameters: focus, power, speed, pulse repetition rate (rate), kerf, and joint clearance.

Focus is the distance between the laser lens and the material surface. It determines how concentrated the beam is. A correct focus produces a small, intense point for clean and precise cuts. If the focus is incorrect, the cut becomes wider, less defined, or may not fully penetrate the material.

Power is the amount of energy delivered to the material, expressed as a percentage of the machine's capacity. In many laser cutters, the minimum effective cutting power starts around 12%, and the maximum is 100%. Higher power increases cutting ability but may cause burning if excessive. Lower power is typically used for engraving or thin materials.

Speed refers to how fast the laser head moves across the material, also expressed as a percentage (1% = very slow, 100% = very fast). Lower speed increases heat input and cutting depth, while higher speed reduces penetration and is suitable for engraving. Power and speed must be balanced together.

Pulse Repetition Rate is the number of laser pulses emitted per second, measured in Hz.

Joint Clearance is the intentional space between two fitting parts. It compensates for kerf and material tolerances, ensuring proper assembly without being too tight or too loose. If the joint is too small, it doesn't grab properly and lacks enough friction to hold the pieces together. If the joint is too big, it becomes loose or difficult to assemble correctly.

Kerf is the amount of material that a laser cutter removes or vaporizes during the cutting process. This material loss directly affects the dimensional accuracy of the final parts.

The kerf value is not fixed; it varies depending on the laser cutter, the material, and the cutting parameters such as power, speed, and focus. For this reason, kerf must be measured for each specific machine and material combination.

To calculate the kerf, we use the following formula:

Kerf = (measured empty space) / (number of squares + 1)

In our experiment, we laser-cut multiple 20 mm squares, measured the total gap between them, and also verified the square dimensions. We then calculated an average value to obtain a more accurate kerf measurement.

The final kerf value obtained was 0.05 mm. This is relatively low, possibly because the machine is only two years old and still maintains good calibration and beam quality.

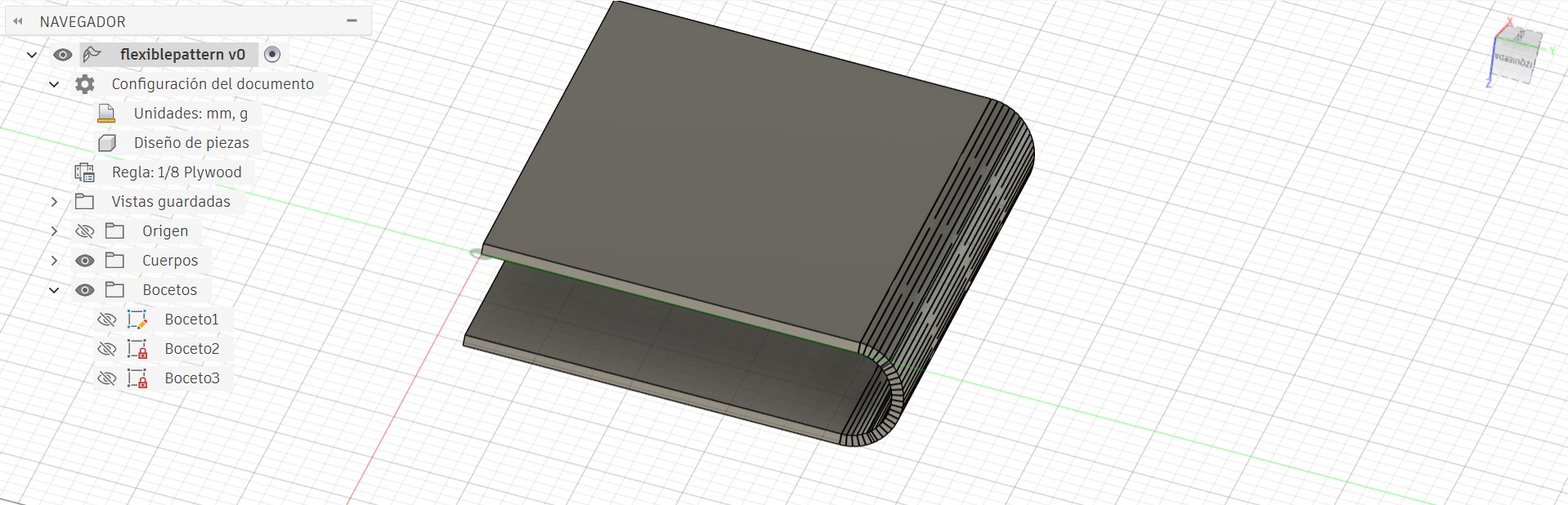

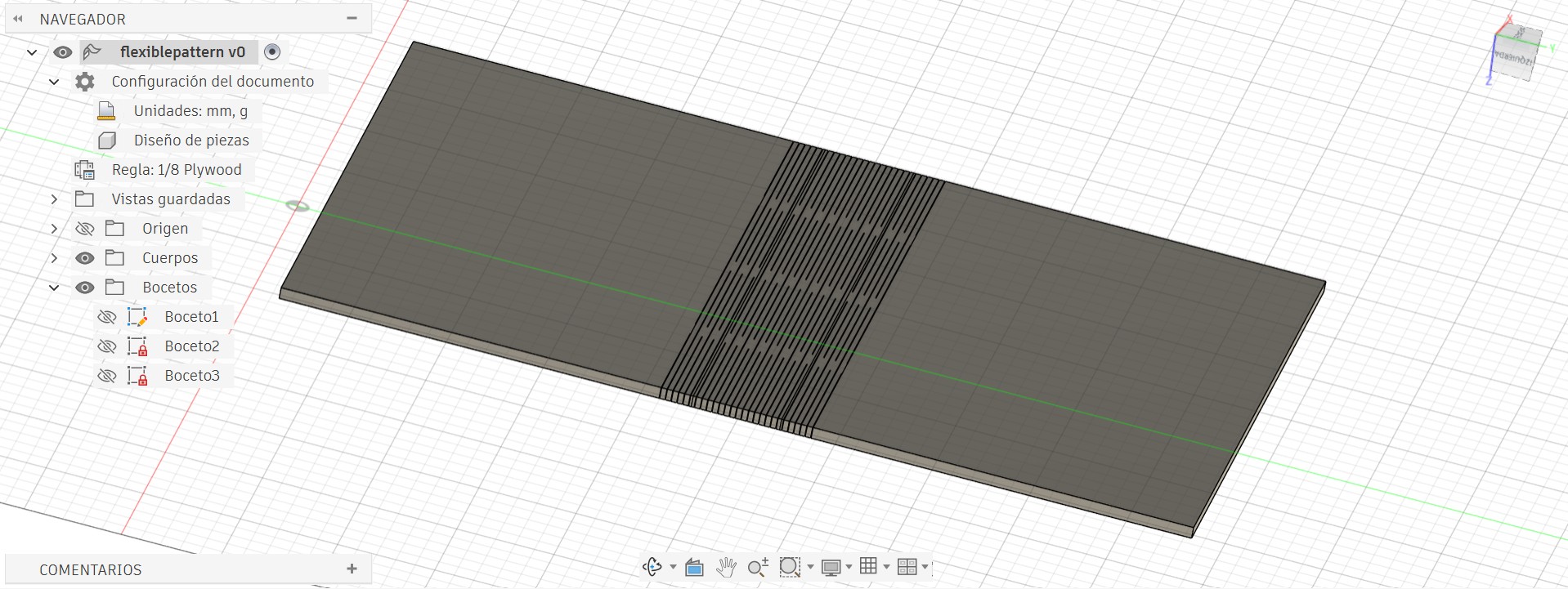

In the final project, I contributed by designing and implementing a special laser-cut pattern that allows a solid material like MDF to become flexible. This technique is commonly known as a flexible hinge or living hinge.

I also contributed by helping determine the kerf value using the square-gap measurement method described earlier. By cutting test pieces and calculating the kerf, we were able to adjust our designs more precisely, ensuring better fitting joints and improved overall accuracy in the final assembly.

Our initial goal was to create an MDF book that could open and close using a flexible (living hinge) pattern. However, we encountered a complication in the final stage. Even though the full-scale version did not work as expected, the experience allowed us to understand the tools and theory necessary to later develop a smaller and more refined version.

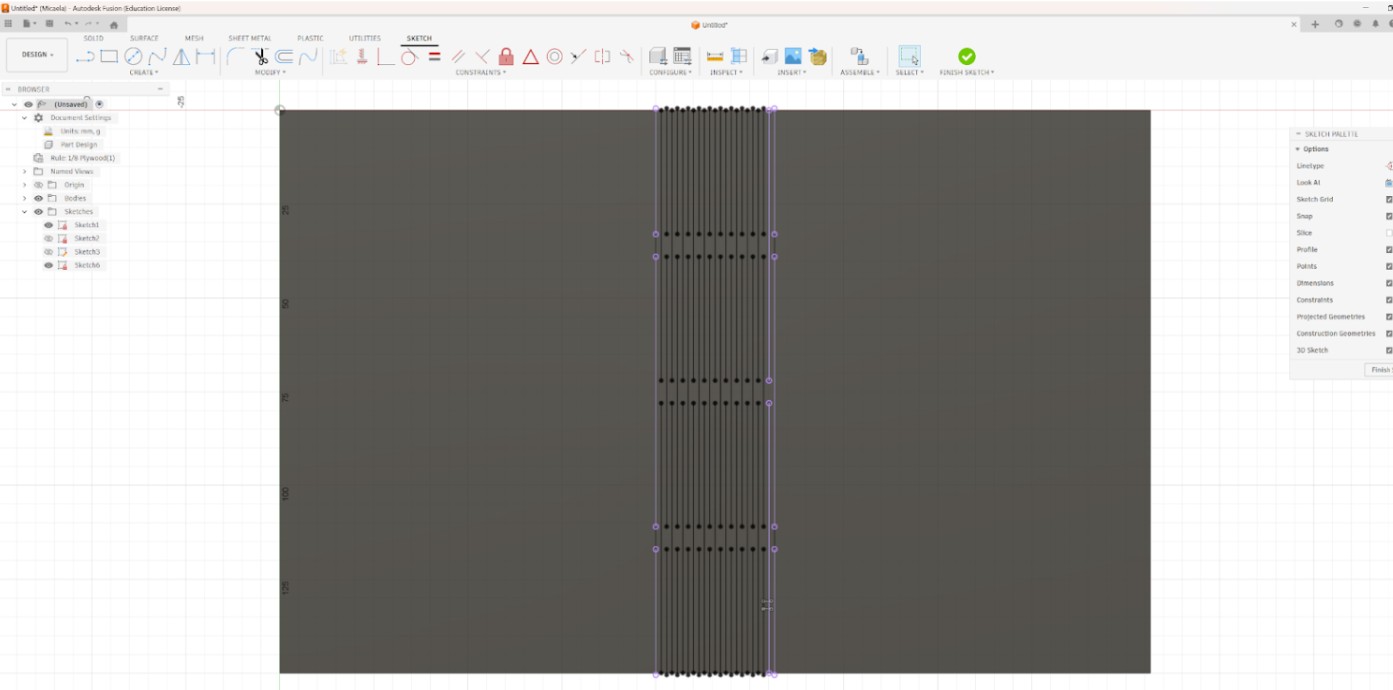

First, it is important to clearly define this type of cut. A living hinge is created from a pattern of precise cuts that transform rigid MDF into a bendable structure without breaking it. The material remains continuous, but its stiffness is reduced in a controlled area, allowing flexibility. This technique is especially useful for curved surfaces, enclosures, and dynamic components. Its effectiveness depends on spacing, pattern geometry, material thickness, and proper laser calibration.

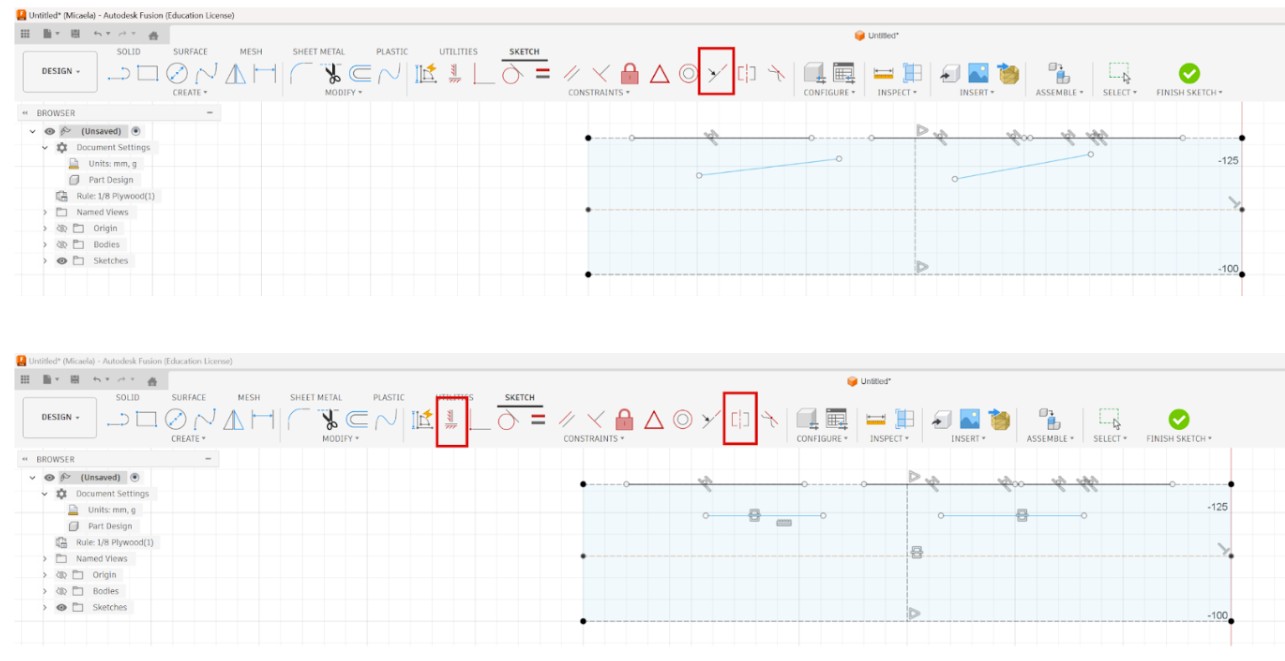

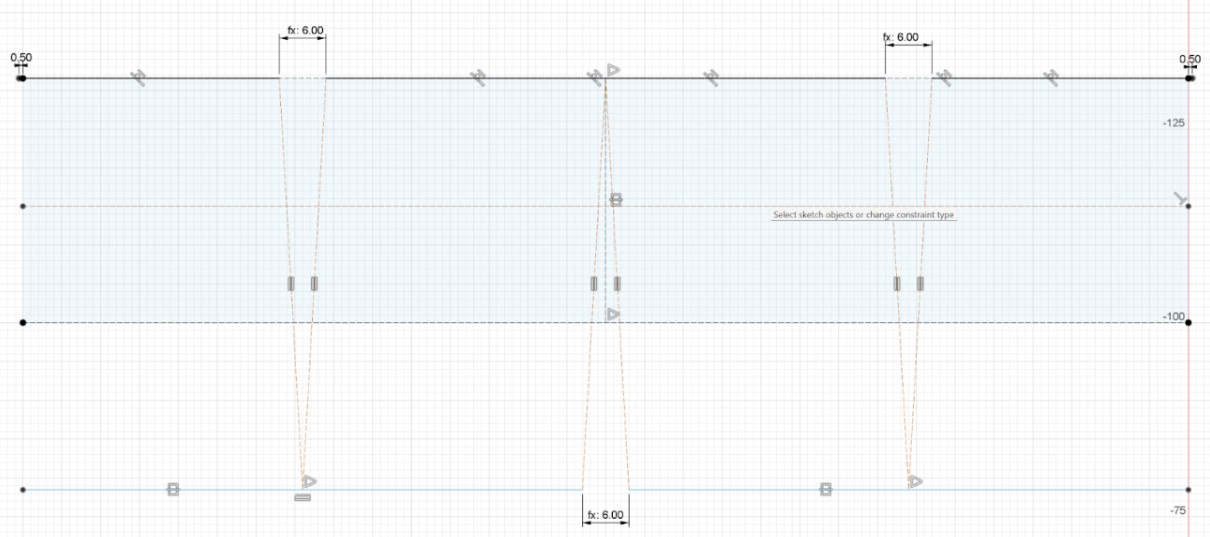

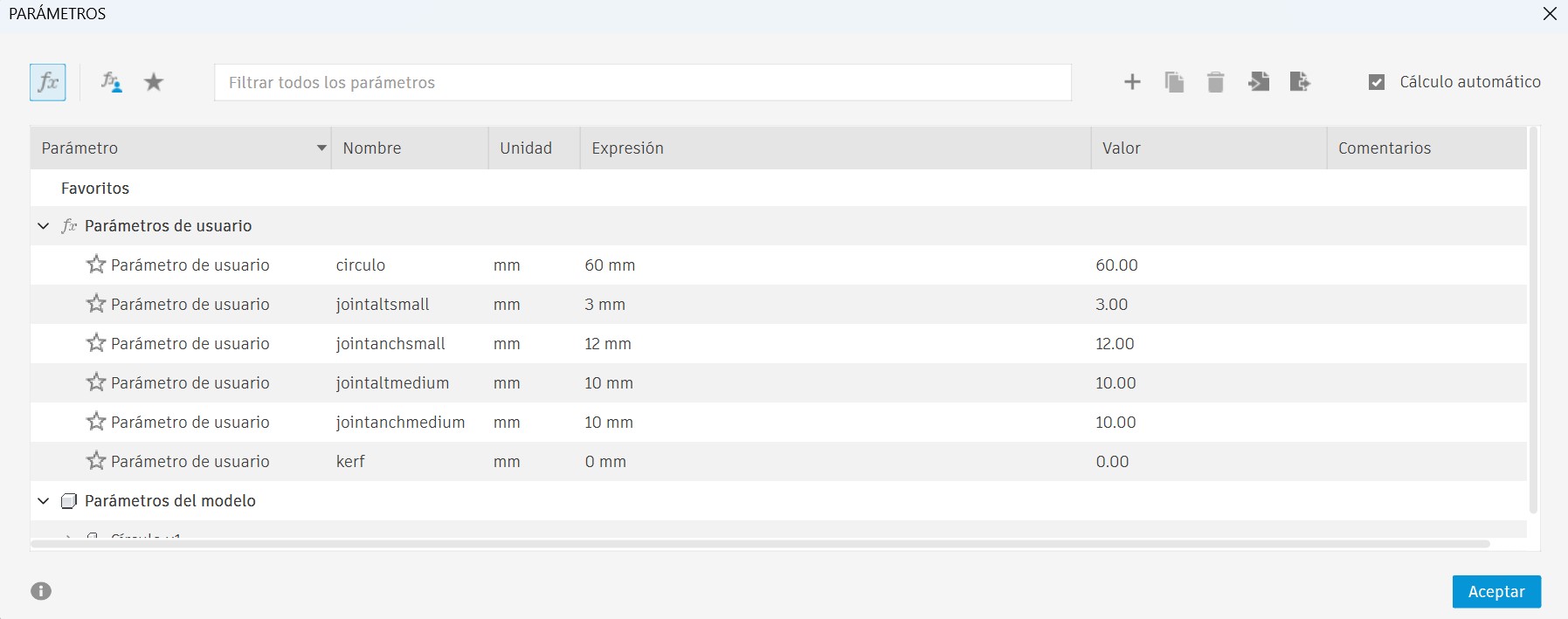

To design it, I followed the tutorial "Autodesk Fusion 360 Tutorial: Mastering Living Hinges for Laser Cutting." In this process, I learned how to create the pattern using a structured and parametric workflow in Fusion 360. I began by understanding the relationship between cut length, spacing, and material thickness, since these proportions directly control how much the MDF can bend without failing.

Inside the Sketch environment, I applied constraints such as Coincident, Horizontal/Vertical, Parallel, Equal, and dimensional constraints to fully define the geometry. This ensured alignment, consistency, and precision.

The Rectangular Pattern tool was essential, as it allowed me to replicate a single cut line evenly across the surface, guaranteeing uniform spacing and alignment.

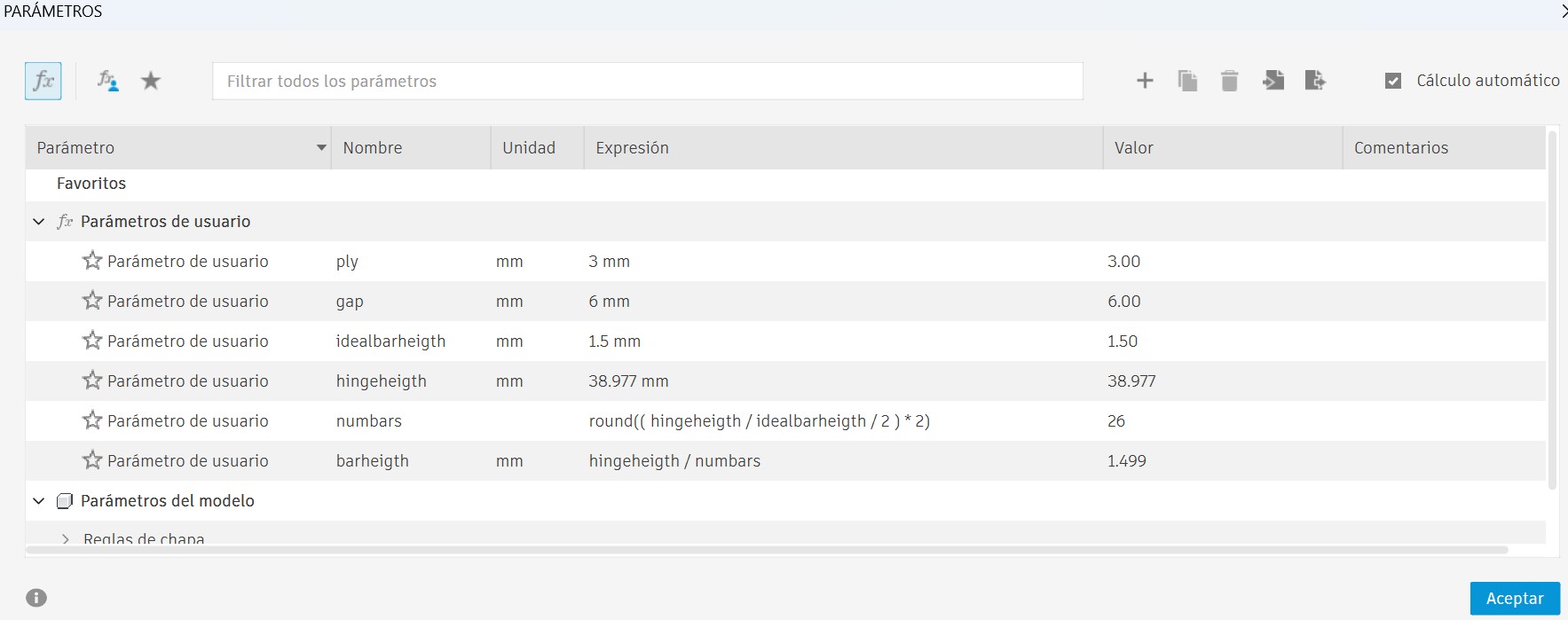

Through Modify → Change Parameters, I created a user parameter called "gap" = 6 mm to control the spacing between lines. This introduced me to parametric modeling, where dimensions are driven by variables rather than fixed numbers. If the gap value changes, the entire pattern updates automatically. This is crucial in living hinge design because spacing directly affects flexibility.

I also used the Project tool to reference edges into the sketch and maintain accurate alignment.

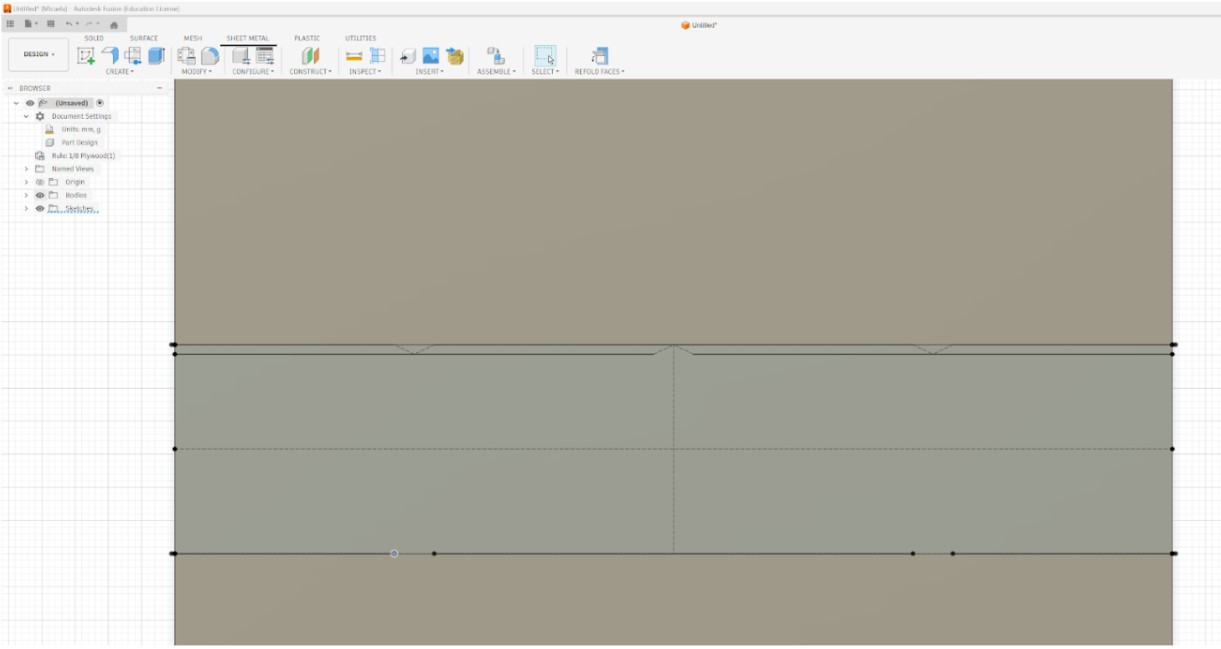

Additionally, I explored Sheet Metal tools, specifically Fold and Refold, to simulate bending along a defined line. Although folding functions belong to the Sheet Metal workspace, the parametric logic itself is built in the Sketch and Parameters section and then applied to features like patterns and folds.

Finally, when exporting the design for laser cutting, a problem appeared. The original extruded body contained internal lines that were interpreted as cut paths by the laser software. When sending the file to the machine, these extra lines interrupted the hinge pattern. To solve this, I attempted to clean the geometry using other platforms such as Rhino and AutoCAD in order to remove the unnecessary lines before final cutting.

Despite the final complication, this process strengthened my understanding of parametric design, pattern creation, and digital fabrication workflow, giving me the foundation to successfully redesign the project at a smaller scale.

After gaining experience with the flexible hinge project, I felt confident enough to develop my own construction kit. I wanted to design something minimalistic yet functional — a dynamic system that could easily connect and adapt to different configurations.

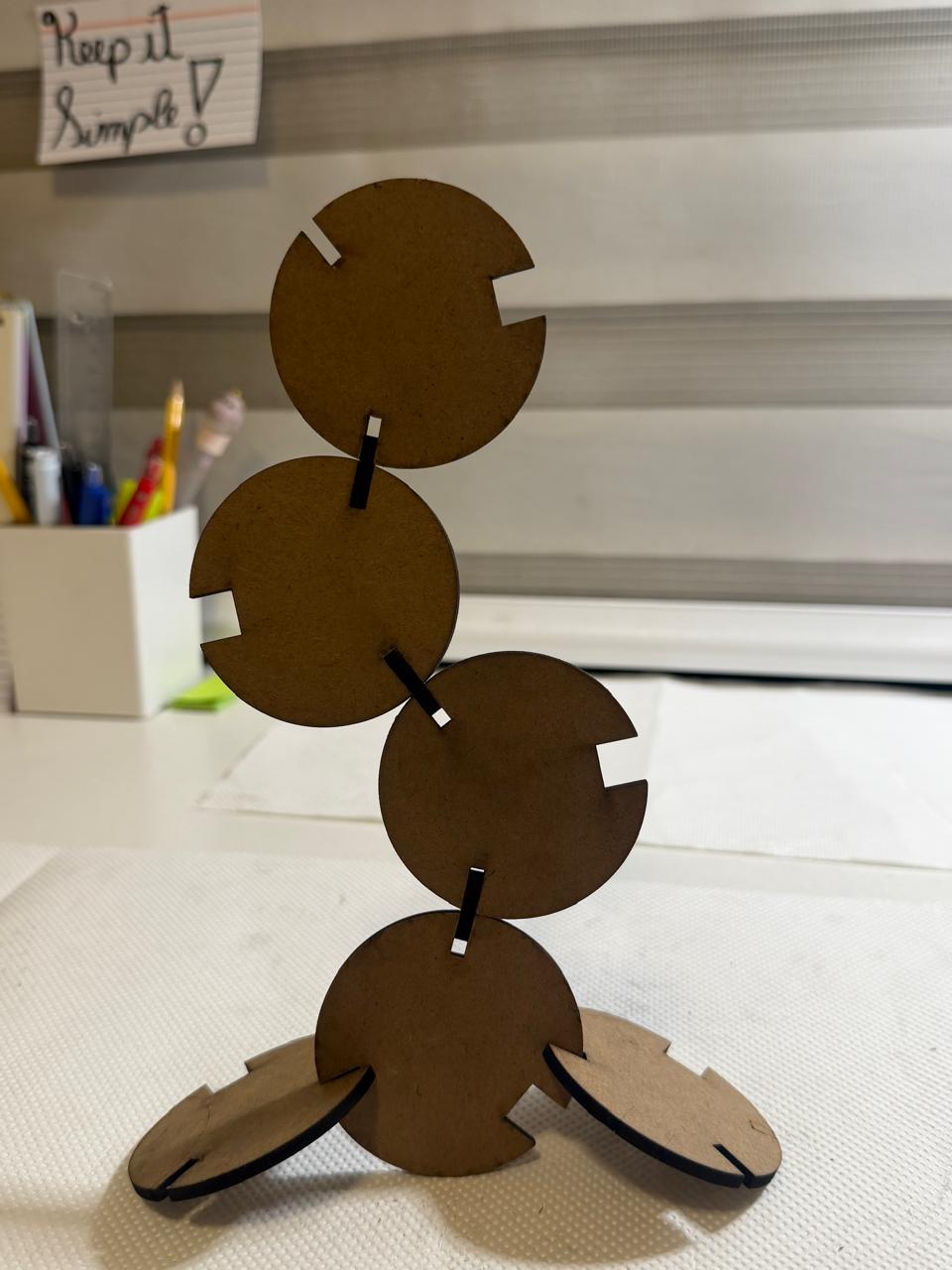

The concept was to create a circular base piece with three different slot connections, allowing multiple assembly possibilities. This simple geometry provides versatility, enabling the pieces to be combined in various ways while maintaining structural stability. The goal was not only aesthetic simplicity, but also modularity and interaction.

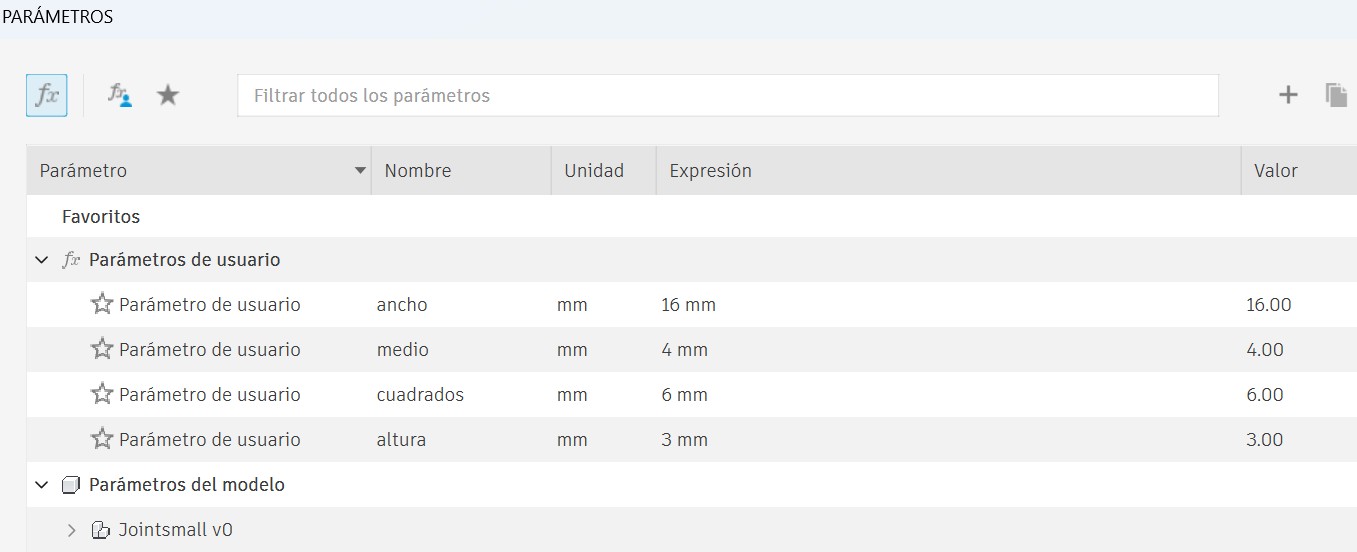

In this process, I applied the parametric design skills I had previously learned. By defining dimensions through parameters instead of fixed values, I was able to maintain consistent measurements and precise tolerances throughout the entire design process. This approach allowed me to easily adjust thickness, slot width, and spacing while ensuring that all parts remained compatible.

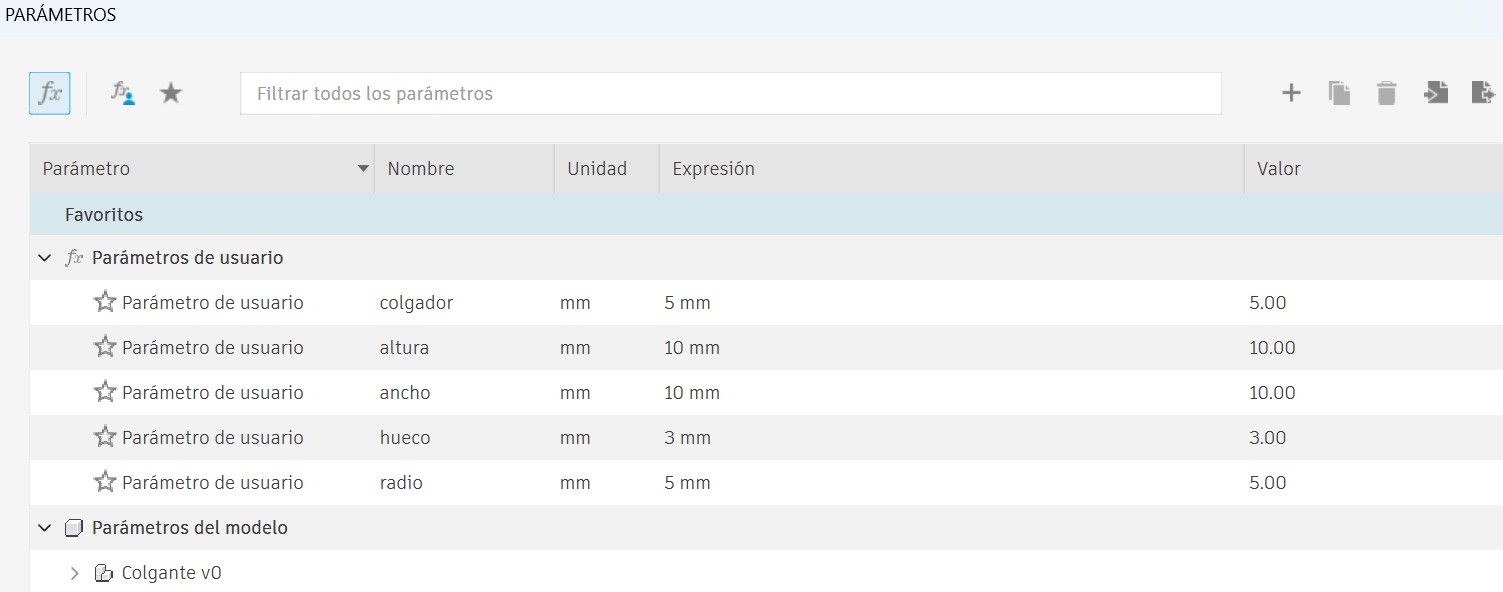

On this occasion, I used Fusion 360 to develop the kit. The complete set consists of four different pieces, whose dimensions vary according to the parameters defined by the user. This means that by modifying a parameter, all related dimensions update automatically, maintaining proportionality and correct fit between parts. In the first piece, for example, the slot width, thickness, and overall diameter were all controlled through user-defined parameters.

To create user-defined parametric dimensions in Fusion 360, we go to the Solid tab, then select Modify, and choose Change Parameters.

The main piece, including its defined dimensions. This circular base acts as the core structural element of the kit, and all its measurements were controlled parametrically to ensure accurate fitting with the other components.

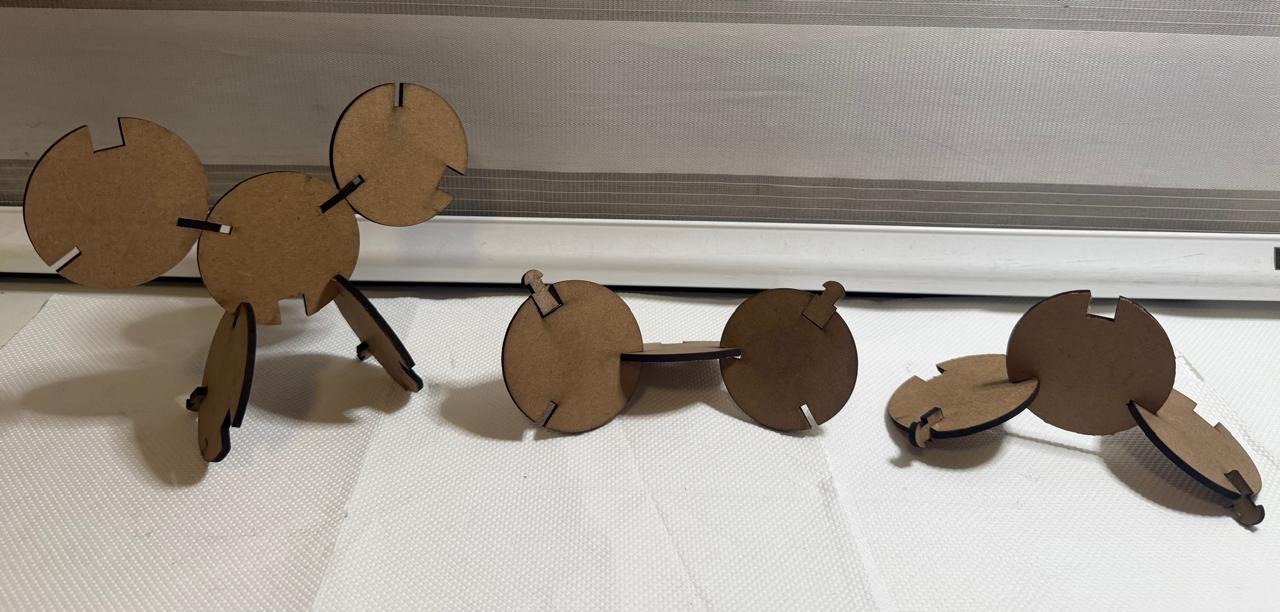

Next, the medium joint. This piece was not only decorative but also functional: it works as a stabilizer and helps the assembled structures stand upright. Its dimensions were carefully adjusted to provide balance without interfering with the overall minimal aesthetic.

Here we have the small joint, designed to perfectly connect the circular pieces. Its slot width was defined according to the material thickness parameter, ensuring a precise press-fit connection.

Finally, the earring extension, which allows the circular modules to transform into wearable pieces. This addition expands the kit's functionality, turning it from a construction system into an accessory design as well.

Below, you can see some of the different figures and compositions I was able to assemble using this modular kit.

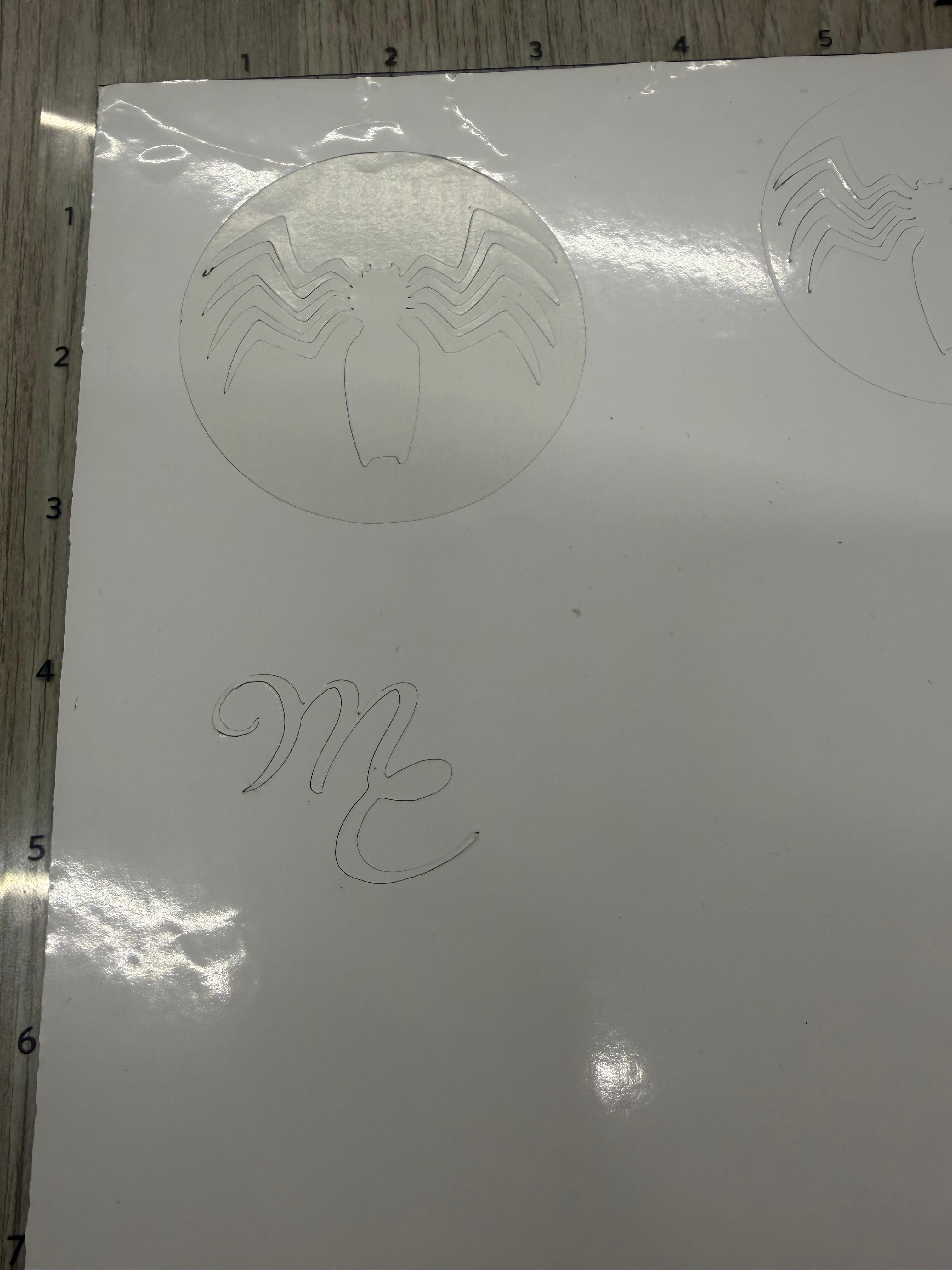

For this assignment, I decided to use my personal website logo, which I designed myself. I wanted to test whether my custom lettering would work properly as a vinyl sticker. Since the original drawing was created in raster format, I first imported it into Inkscape and vectorized it.

This step was essential because raster images would be interpreted as small points by the vinyl cutter, producing dotted or irregular cuts. By converting the logo into vector format, I ensured clean, continuous strokes suitable for cutting.

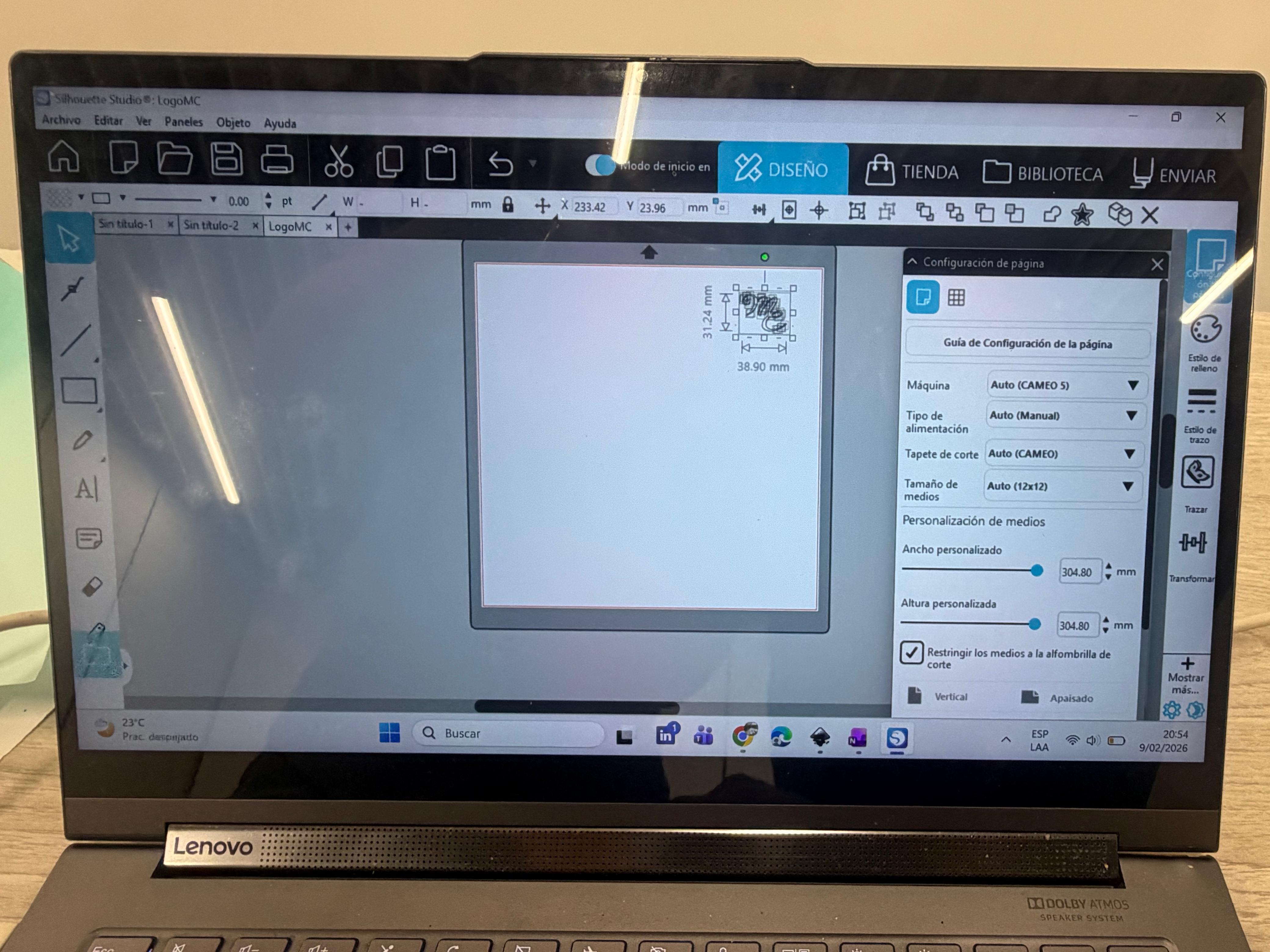

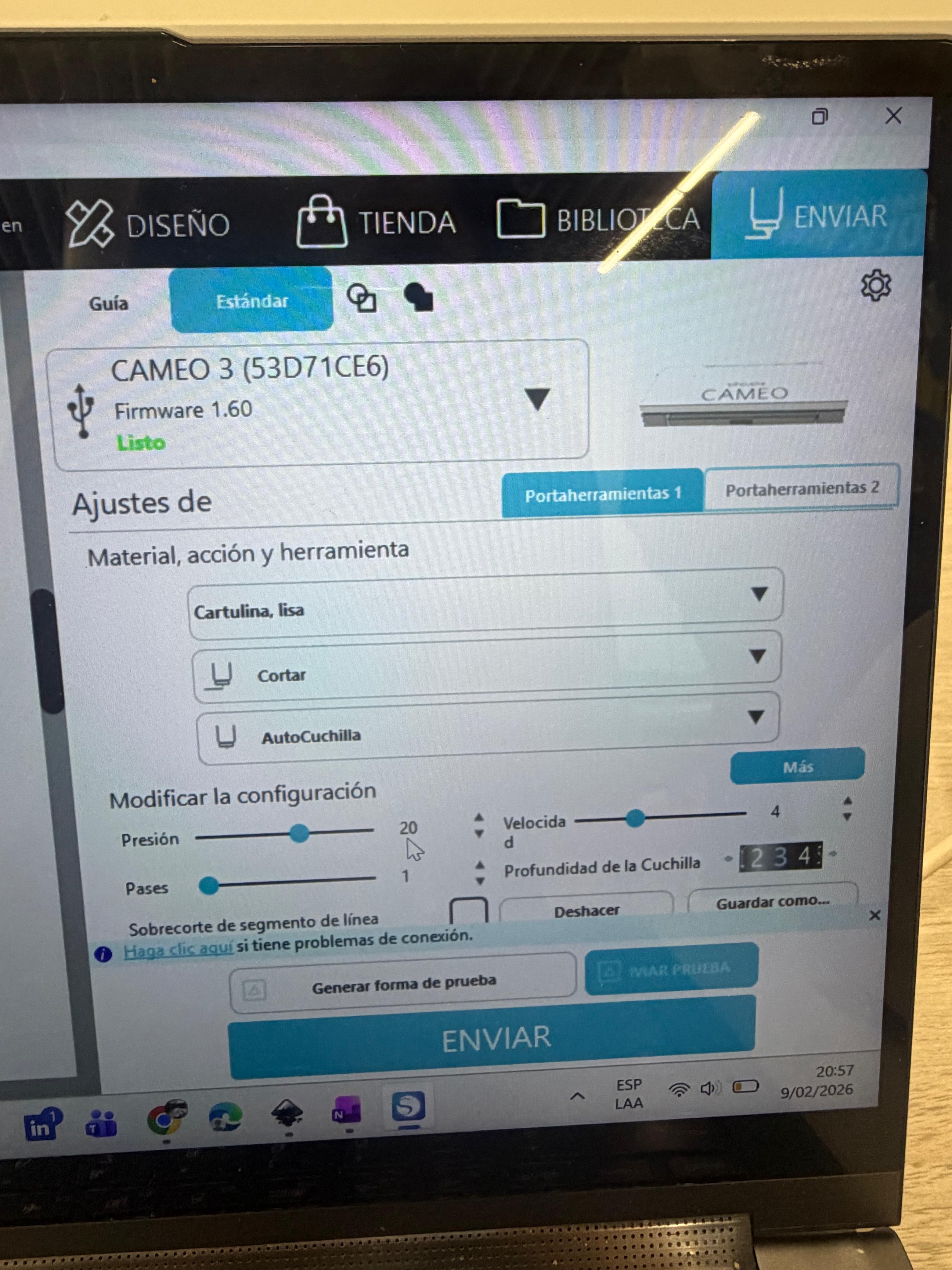

The vinyl cutter available in the lab is the Silhouette CAMEO, and to manage the cutting process I downloaded Silhouette Studio. I imported the strokes in .DXF format, centered the design on the workspace, and selected the correct material settings. In this case, I used glossy vinyl, with a blade depth of 3. Unlike the laser cutter, where power and speed must be carefully calibrated, here I kept the default speed and force settings since they were appropriate for vinyl.

To prepare the machine, I inserted the vinyl sheet, carefully aligning it with the blue arrows on the cutter. While holding the material in place, I pressed the load button so the machine could grip and align it properly. After confirming placement in Silhouette Studio, I sent the design to cut.

These were the settings:

After cutting, I applied transfer tape (vinyl transfer film) over the sticker so it would adhere to the tape and could be moved easily. I then positioned it on my phone case, pressed firmly using a card to distribute pressure evenly across the surface, and slowly removed the transfer tape. The vinyl adhered successfully.