Computer-Aided Design

In this week, I explored 2D and 3D modeling using different software tools to develop a possible final project. I evaluated and selected the tools based on precision and workflow, starting from 2D sketches and progressing to 3D models. I also documented my process by properly compressing images and videos for web publication, and shared all design files on this page on the "Download resources".

Computer-Aided Design (CAD) is the use of computers to assist in the creation, modification, analysis, and optimization of designs. CAD includes both 2D and 3D tools, which are used depending on the design requirements.

CAD can be categorized by the way it represents space, such as 2D drawings, parametric solid modeling, surface modeling, and mesh-based modeling, each suited for different design and fabrication purposes.

Parametric modeling is based on dimensions and parameters that define the geometry. It allows controlled and editable designs in both 2D and 3D, where changes in parameters automatically update the model.

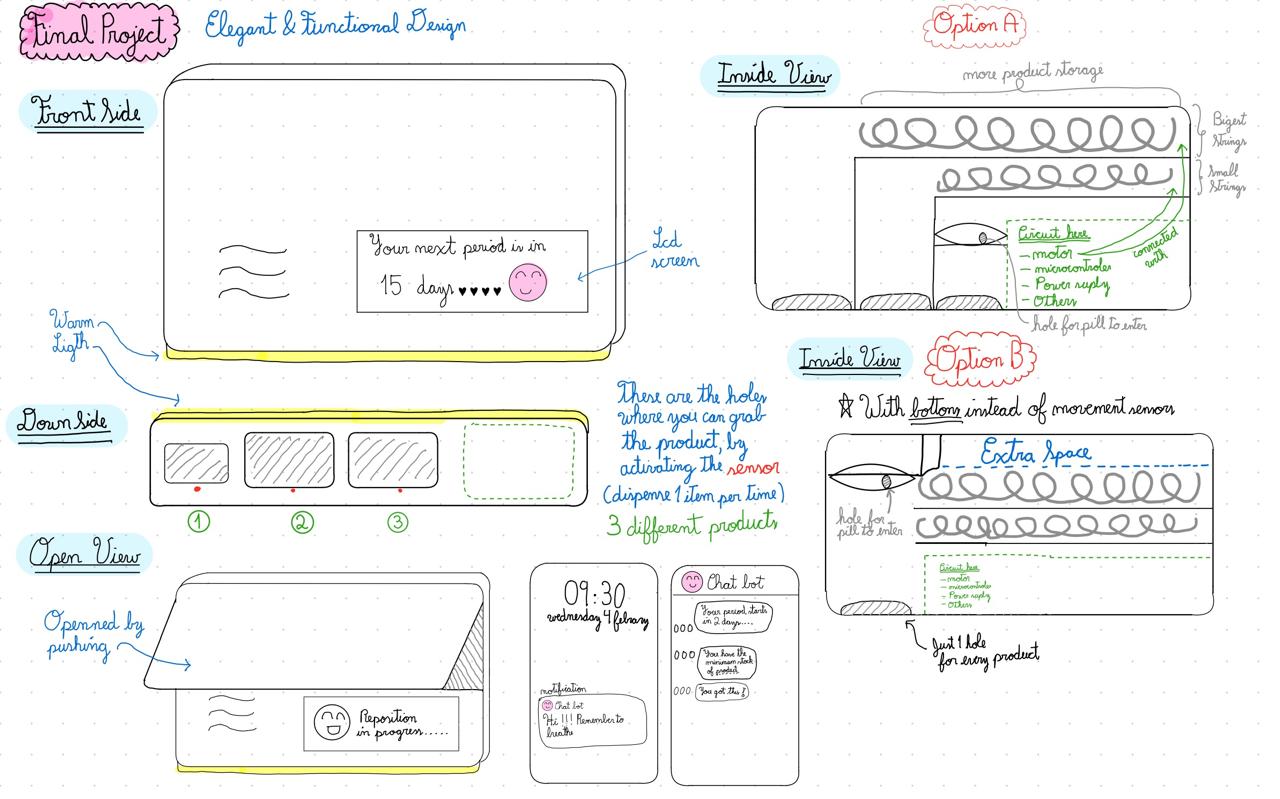

The idea was to create an intelligent menstrual cycle dispenser for personal use. To do this, I first needed to build a clear structure in my mind. In order to organize my ideas and imagine how the product would work and look, I started by drawing it using raster graphics, then vector graphics, and finally modeling it in 3D. In other words, the sketch I made in Week 1 was brought to life in both 2D and 3D.

And to keep everything organized, I created a dedicated project folder, so that all files were easily accessible as I worked on the modeling within the software.

2D design focuses on creating flat representations using width and height. It is commonly used for sketches, technical drawings, vector graphics, and layouts that serve as the foundation for fabrication processes such as laser cutting, CNC machining, and as a base for 3D modeling.

In this week's class, I learned that raster and vector graphics differ in how images are defined and scaled. Each one also has a different minimum unit: raster graphics are based on pixels, while vector graphics are based on points.

During this week, I also tried to sketch my final project using both methods.

And as a fun fact for laser cutting applications:

Raster graphics are composed of pixels, so they lose quality and become pixelated when zooming in. Raster design is more freeform and suitable for artistic or image-based work. GIMP and Krita are examples of raster-based software used for 2D design.

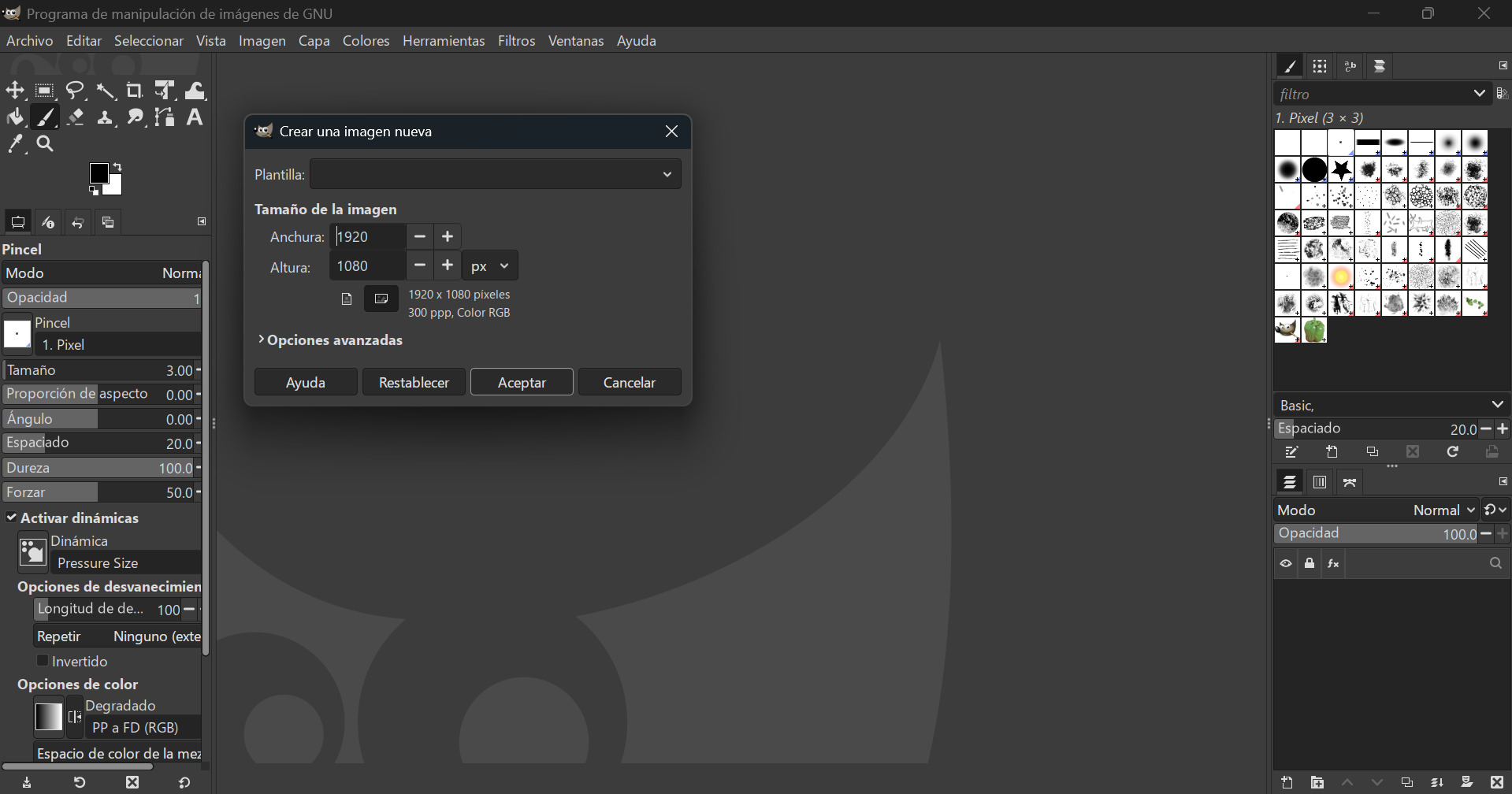

First, I opened GIMP and selected "New" >> "New…". Then, I chose the image dimensions I wanted to create. In this case, I left the standard measurements shown in the image.

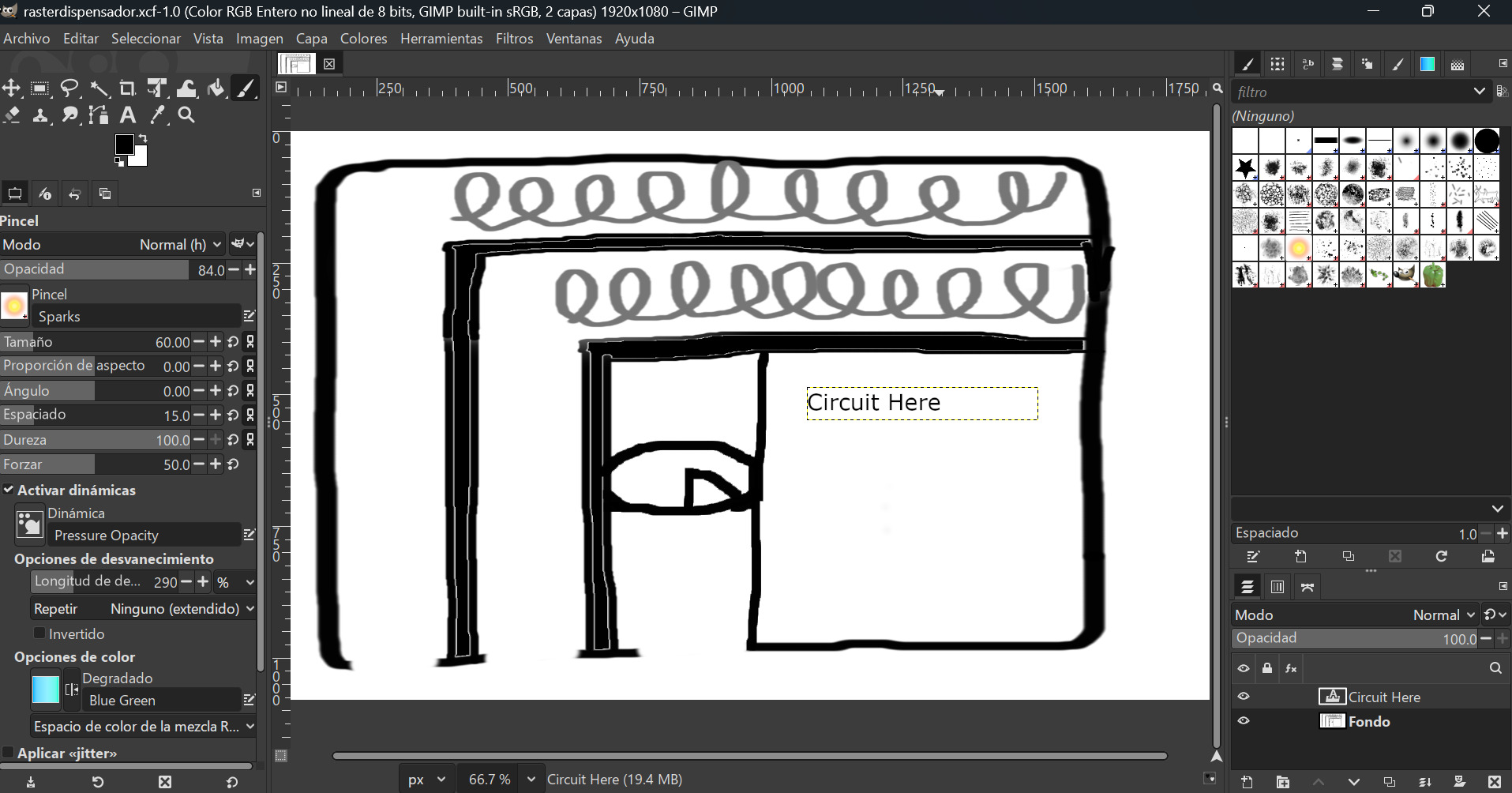

GIMP has an interface mainly divided into three areas: on the left is the toolbox, where you can select, draw, move, transform, or erase, and below it are the options for the active tool; in the center is the canvas, and on the right are the panels, especially the Layers panel, which is the most important, along with Channels and Paths. These panels are used to organize the image and control opacity, order, and visibility.

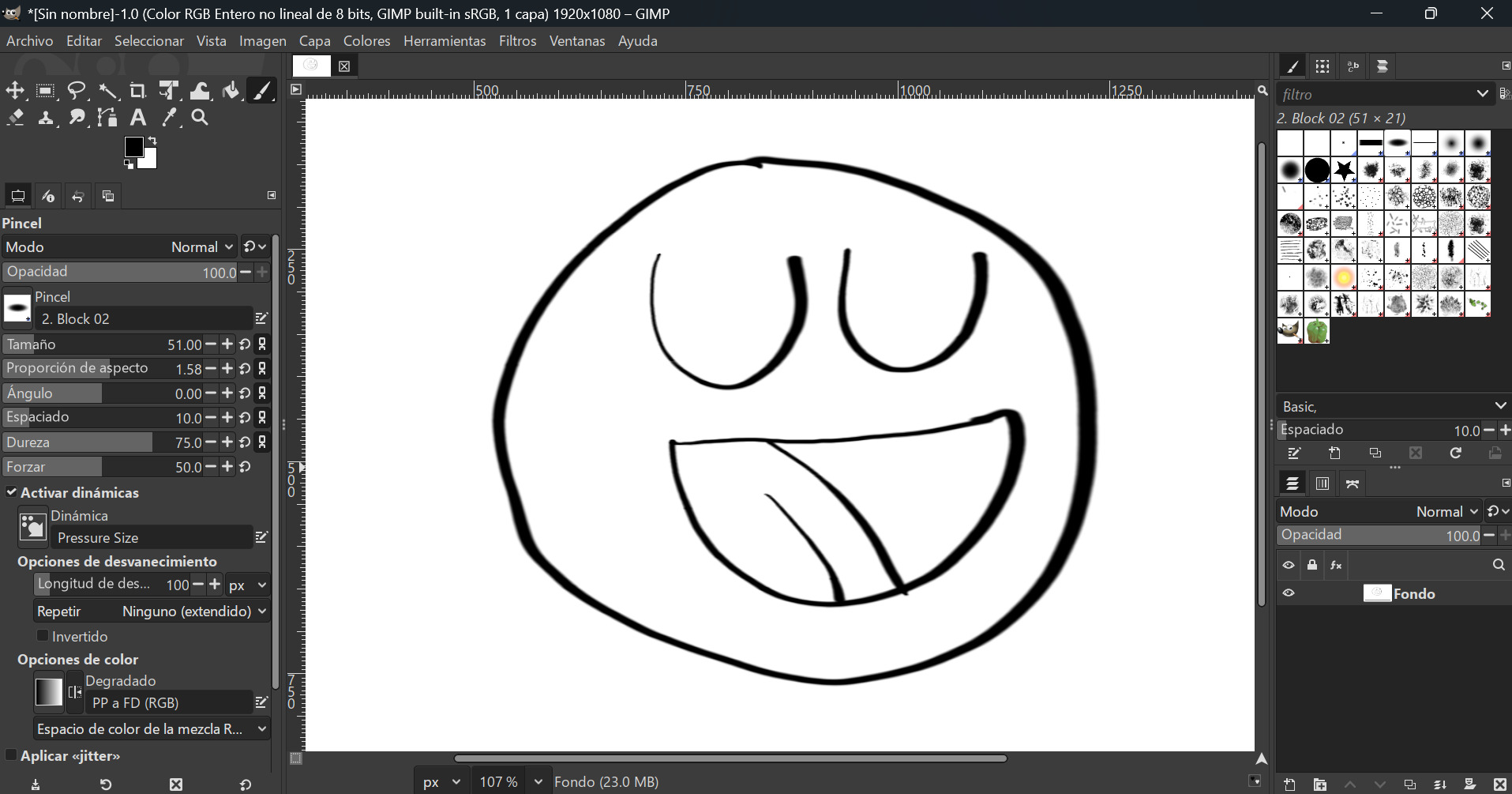

I tested the raster function by drawing a simple smiley face.

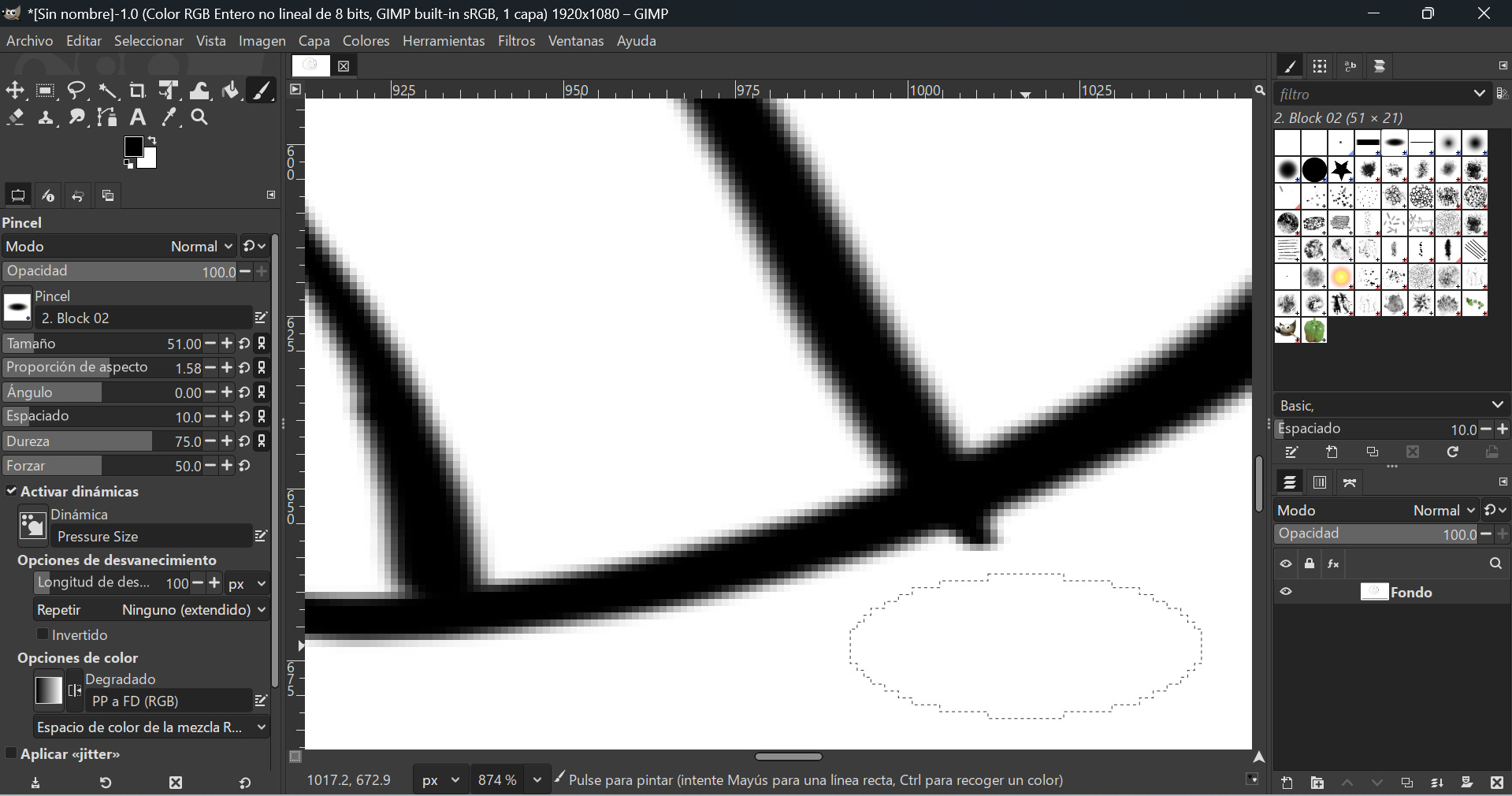

Then I zoomed in, and it was clear that the pixels became visible and the smooth pencil finish had disappeared.

I started by drawing the inner part of my dispenser, specifically the container area, because this is the component that gives life and functionality to the entire machine. At this stage, I focused on defining how the internal spaces would work and interact. I experimented with the different brushes available in GIMP and explored several tools, such as the bucket fill tool, which allowed me to color closed shapes easily, as well as text boxes and other drawing options. This experimentation helped me better visualize the internal structure and refine my initial idea.

Vector graphics describe images using mathematical definitions of geometric shapes, which allows them to scale without losing quality. Vector-based design relies on precise lines, constraints, and dimensions. Commonly used vector design software includes Inkscape and Adobe Illustrator.

I chose Inkscape because it downloaded quickly from the official website (https://inkscape.org/es/) and its interface felt very user-friendly and easy to understand.

3D design is the process of creating digital three-dimensional models that represent real or conceptual objects. Unlike 2D design, which only shows height and width, 3D design includes depth, allowing designers to visualize, simulate, and fabricate physical objects.

There are different CAD platforms used for 3D modeling, such as Onshape, Fusion 360, Inventor, and SolidWorks, each offering different tools and workflows depending on project needs.

While Onshape and SolidWorks offer strong parametric flexibility, Fusion 360 and Inventor focus on creating closed and consistent solid models, which reduces fabrication errors and improves export reliability. For this reason, I decided to work mainly with Fusion 360 and Inventor.

For this assignment, I decided to model the spring mechanism because it is the core element of the system. The spring must be sized according to the product it holds. One of its main advantages is that it ensures only one product is dispensed at a time while keeping each item organized individually.

To achieve this, I measured the width of a sanitary pad (the main product) using a vernier caliper. This allowed me to simulate the gripping mechanism and determine the spacing required for the spring system to properly dispense the product. The measurement taken at that point gave an approximate width of 4.5 cm.

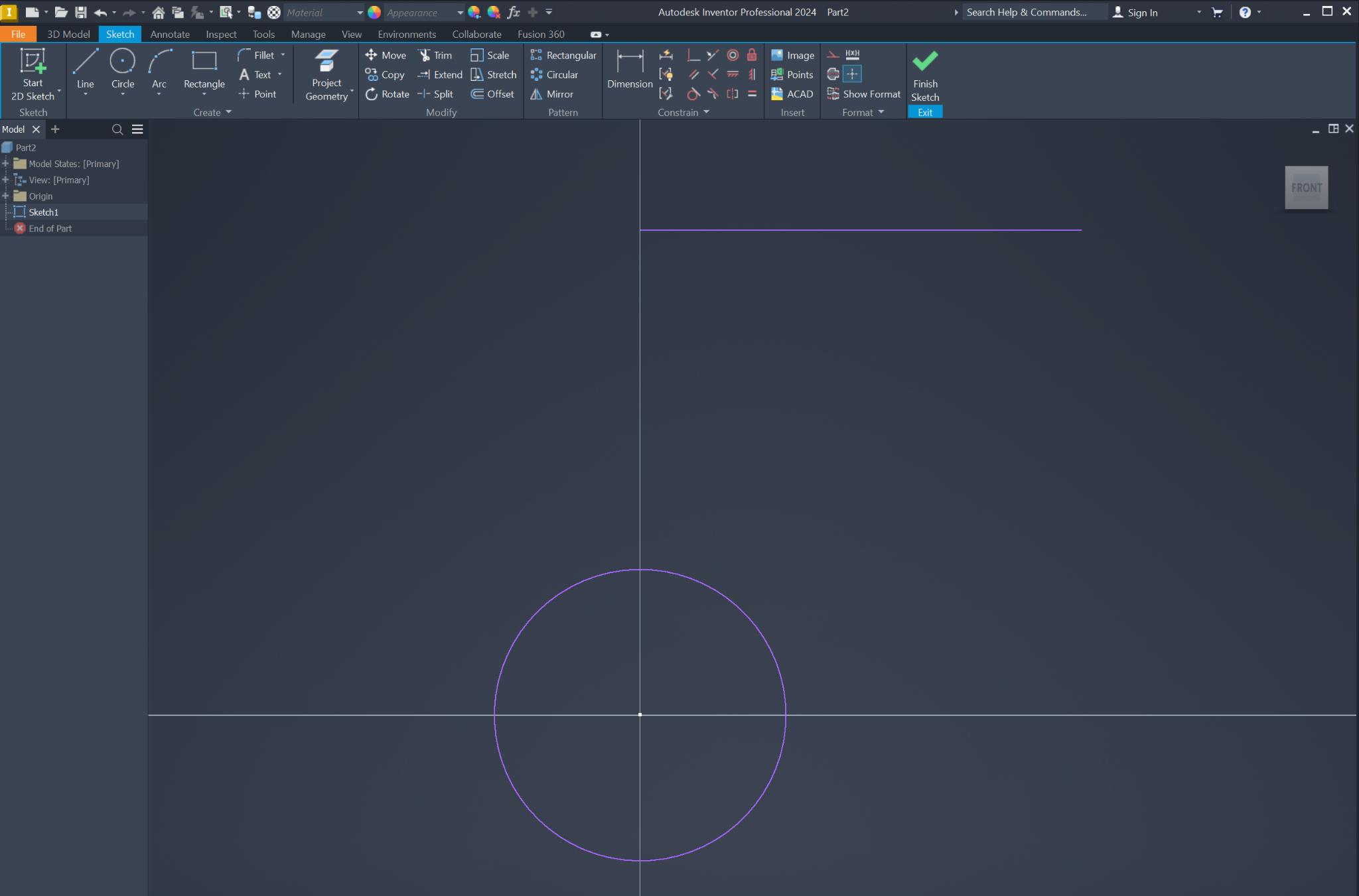

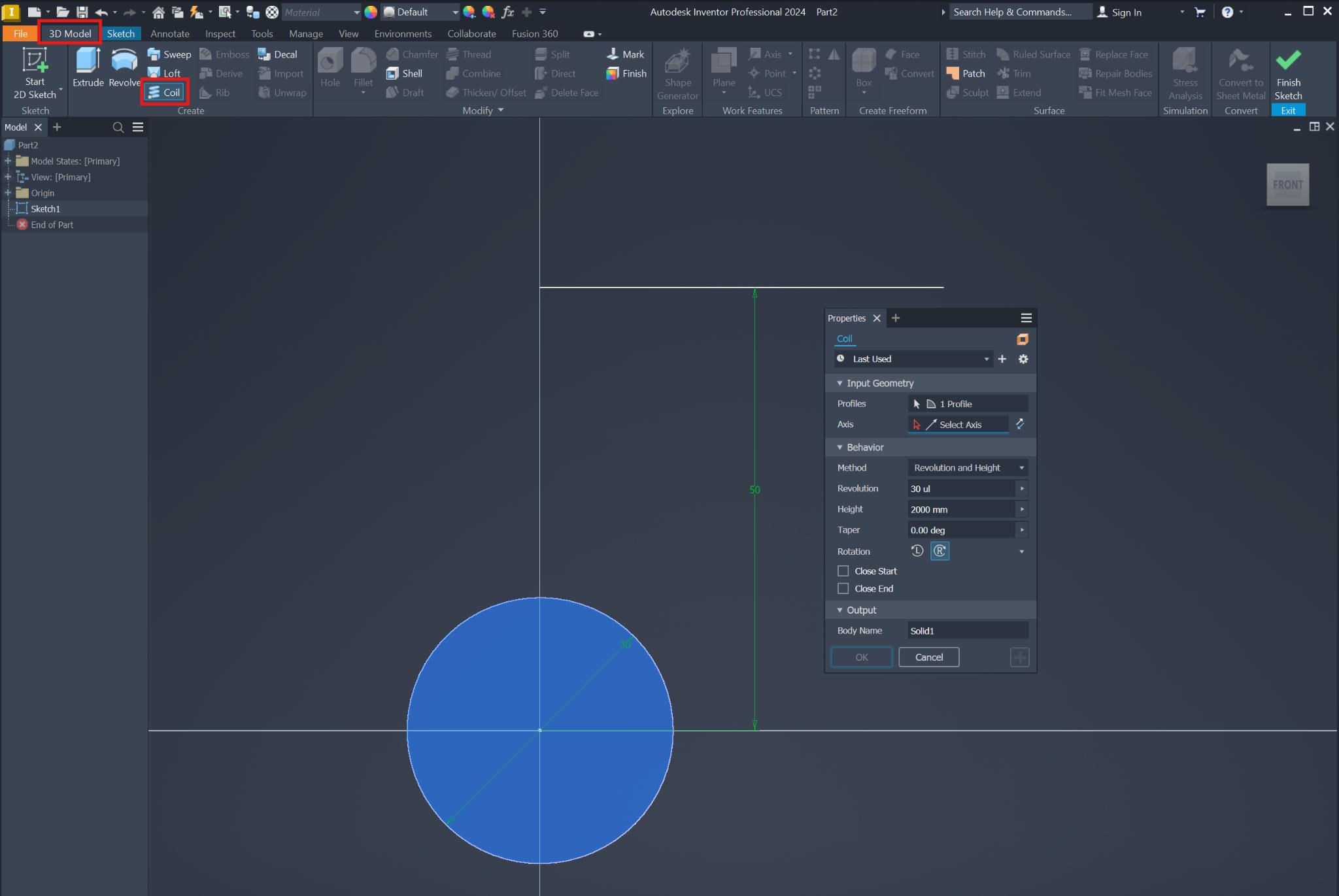

First, I used Autodesk Inventor, selected the XY plane, and created a new 2D sketch, which serves as the base for the 3D model. I created a circle, and then, following the Y axis, I drew a horizontal line at the top to be used as a reference axis.

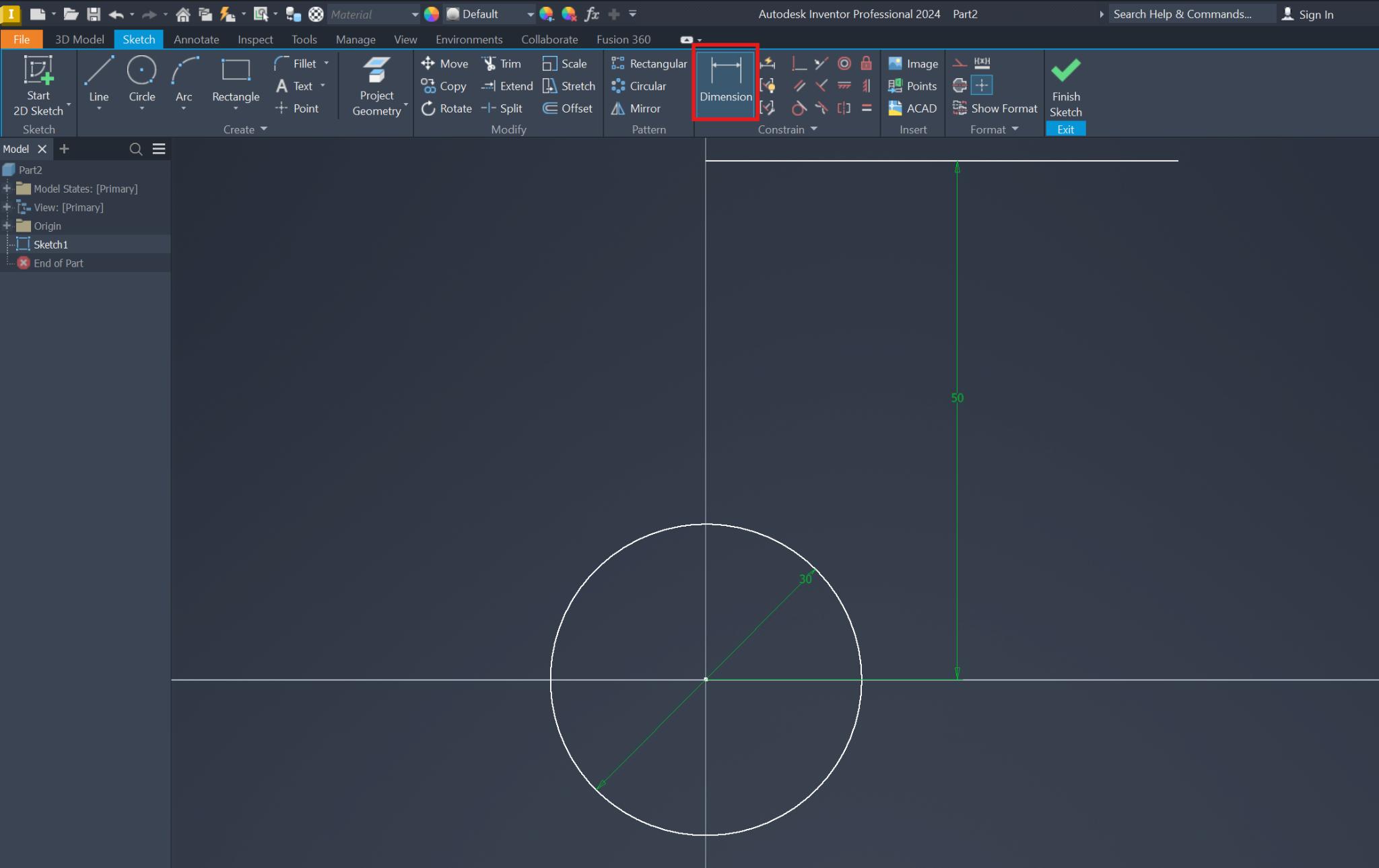

On the computer where I created the design, the interface was set to dark mode, which made it easier to see the sketch lines. Next, I added dimensions to both sketches. For the line, I defined its distance from the center of the circle, and for the circle, I defined its radius, using only the Dimension tool.

In this case, I chose a radius of 30 mm for the circle and a distance of 50 mm between the line and the center of the circle. The importance of this step is related to the final size of the spring, which will be explained later.

Then, I went to the 3D Model tab, where I found the Coil tool. This tool creates a helical shape by wrapping a 2D profile around an axis, giving form to the spring but not defining its final dimensions by itself.

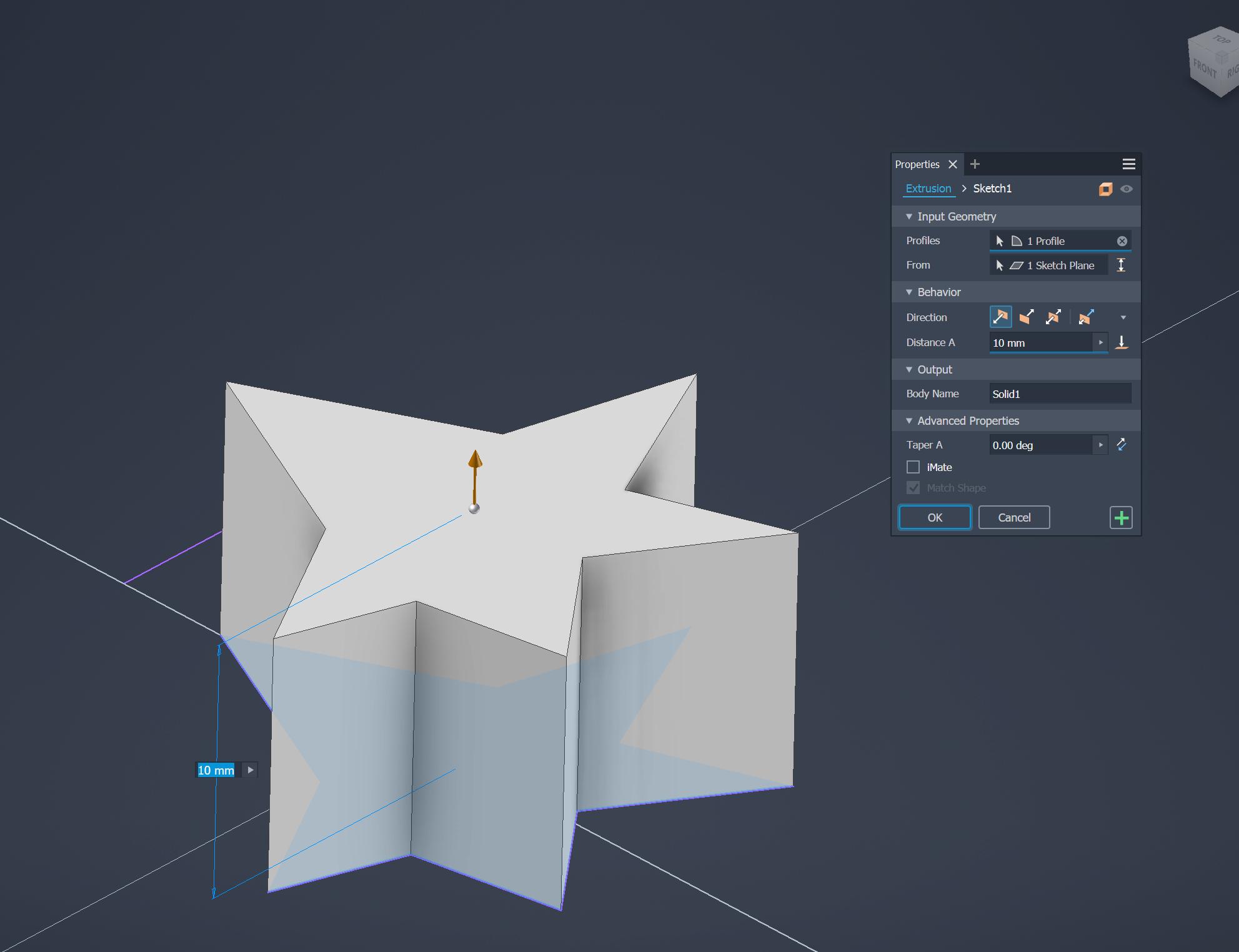

When selecting this option, the software automatically chooses the closed profile created in the sketch, in this case the circle, which defines the shape that will be wrapped around the axis. For example, if a star-shaped profile had been selected, the coil would follow that shape as it is wrapped, resulting in a star-shaped helical form.

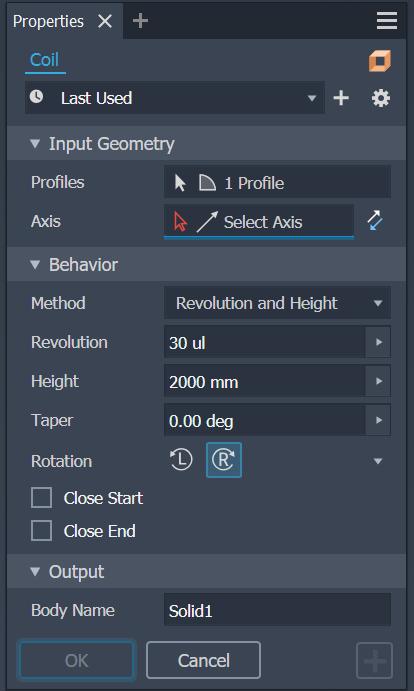

In the Axis section, you must select the line created above the circle. In some cases, it may be necessary to click several times until the axis is correctly selected. When the cursor changes to a cross, it indicates that the line can now be selected and used as the axis.

The axis is the central line around which the coil is wrapped. It acts as a guide line that the profile rotates around. The axis is not a limit or a maximum range; it simply defines the direction and position of the coil. The entire coil follows this axis, whether it is vertical, horizontal, or inclined.

Within the Properties panel, the size and shape of the coil can be defined. In the Behavior section, there are four available methods, where two values are specified so that the software can calculate the third (height, revolutions, or pitch).

In Revolution and Height, the number of turns and the total height are defined, and the pitch is calculated automatically. In Revolution and Pitch, the number of turns and the distance between them are specified, and the total height is calculated. In Pitch and Height, the pitch and the total height are defined, and the software calculates how many revolutions fit within that space. Finally, the Spiral method creates a flat spiral with no height, which is not used for springs but for planar geometries.

In simple terms, the Height property defines how long the spring is, meaning the total length it occupies. Revolutions indicates how many turns the spring has, which determines how the coils are distributed along that length. Pitch defines the distance between each turn, controlling how close or dense the coils are.

Height:

Revolution:

Pitch:

Finally, I pressed OK to confirm the parameters and generate the final spring. If, after creating the solid, I want to modify the sketch or any of the coil properties, I can simply right-click on the coil feature in the browser. From the available options, I can choose Back to Sketch or Back to Coil.

Back to Sketch returns to the original sketch. This is when I clarify what I left pending in the sketch: the relationship or distance between the circle and the line created determines the diameter of the spring. In other words, if this distance increases, the diameter of the coil also increases.

With a distance of 10 mm between the circle radius and the line:

With a distance of 50 mm between the circle radius and the line:

Finally, Back to Coil returns directly to the Coil properties panel, allowing changes to parameters such as height, revolutions, pitch, direction, or behavior method without modifying the original sketch geometry. This is useful when the general shape is correct, but dimensional adjustments are still required.

The Render function in Autodesk Inventor is used to give the model a realistic appearance by applying materials and visual properties, without changing its geometry. To assign a material to my design, I went to the upper right panel and clicked on the material browser icon (the white circle with small squares). From the available materials, I selected Mild Steel, which assigns metal properties such as appearance, density, and physical behavior to the model.

To achieve a good presentation of the material, it is necessary to choose proper lighting, as it complements the selected material and enhances its appearance. To adjust the lighting, I went to Environment → Inventor Studio and selected a preset lighting environment, such as Soft Light, to improve the visual quality of the model.

Finally, I discovered that by double-clicking or right-clicking on the part name in the browser and selecting iProperties → Physical, it is possible to view the physical properties of the selected material. In this section, parameters such as mass, density, volume, and center of gravity are displayed, based on the material assigned to the model.

Fun fact: Autodesk Inventor files created in older versions can be opened in newer versions, but files created in newer versions cannot be opened in older ones. In this case, I chose to work with Inventor 2024, since this is the version available on the Fab Ulima computers.

First I started my 3D modelling with Fusion 360 due to prior experience and Inventor for its user-friendly interface and strong focus on closed solid modeling, which fits the requirements of my project.

Second, I continued my 3D modeling process using Fusion 360 due to my prior experience with the software, and Autodesk Inventor for its user-friendly interface and strong focus on closed solid modeling, which fits the requirements of my project.

If the files are too heavy to be previewed directly in the repository, I can upload the 3D model to Sketchfab (https://sketchfab.com/) and embed or link it there to allow interactive visualization.

During this week's class, the global instructors emphasized the importance of compressing images and videos, since this assignment includes a large amount of media content.

To handle this, I used two main tools:

These tools allowed me to efficiently compress my images and videos before publishing them on my class page.