Project Context: Why a Skateboard?

Living in a city like Puebla, "last-mile" transportation is a constant challenge. Short distances are too long to walk but too congested for a car.

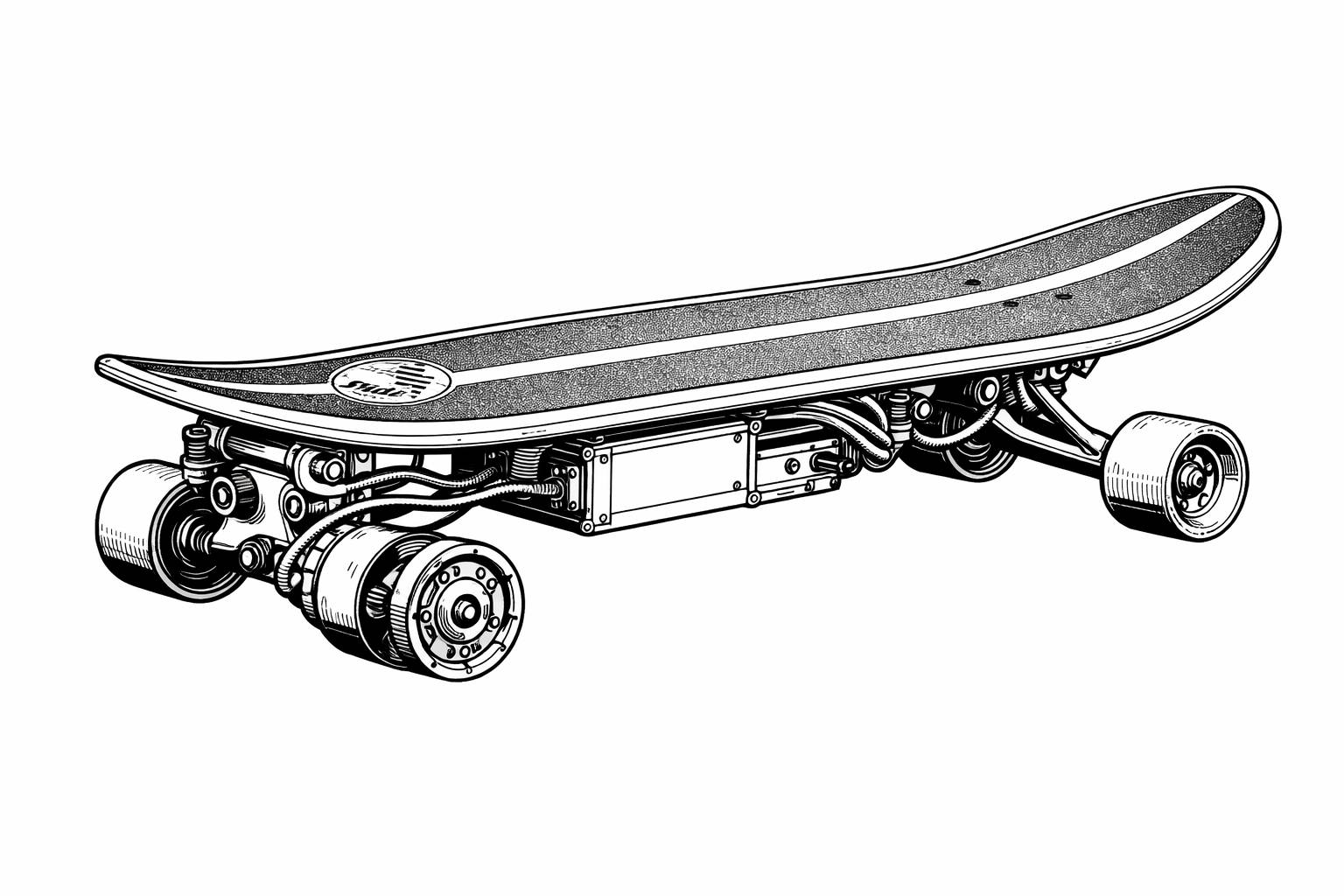

I chose an Electric Skateboard because it combines efficiency, portability, and fun. Unlike a bike, it can be carried into a classroom or office, and unlike a scooter, it requires the rider to develop balance and skill, making the commute an engaging experience rather than a chore.

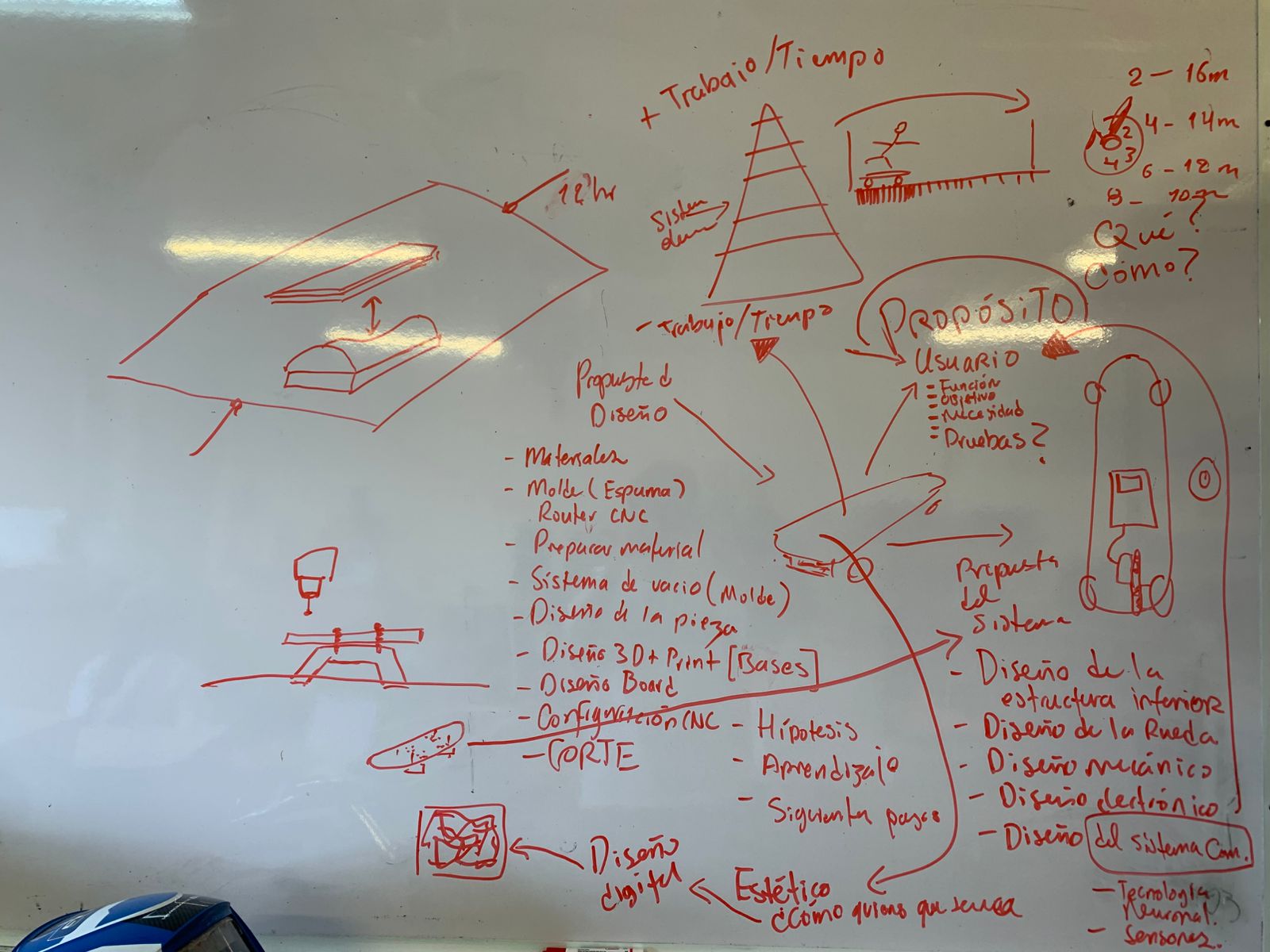

[ CLEAN COPY: WHITEBOARD DELIBERATION ]

The Decision Process

Choosing the final project was not immediate. I had to weigh two main ideas based on Fab Academy's "making almost anything" philosophy:

Remote Controlled Car

Fun to build, but limited practical use. It felt more like a toy than a tool for personal growth or social impact.

Electric Longboard

Highly interdisciplinary: Requires large-scale CNC (deck), 3D printing (enclosures), Electronics (ESC/Battery management), and Molding (grip/wheels).

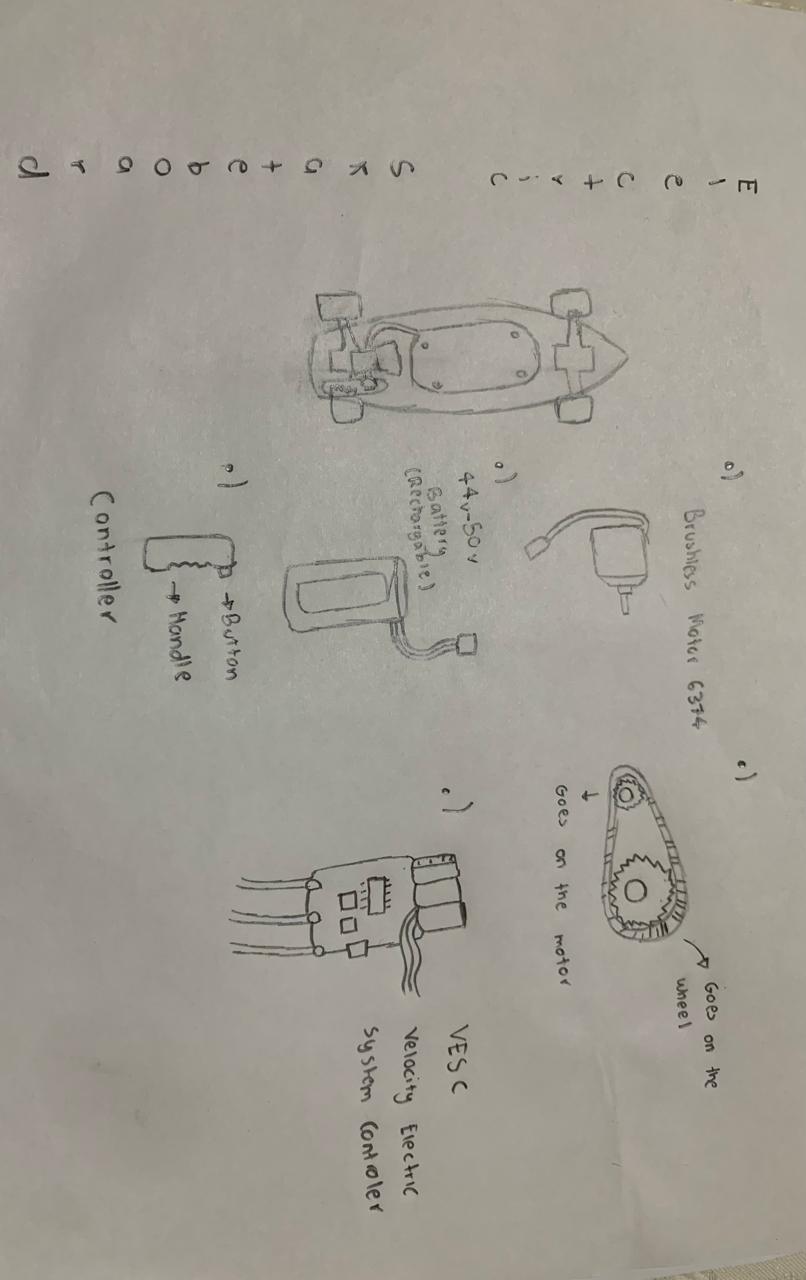

Technical References & Inspiration

Vision & Task Distribution

Instead of just buying parts, my goal is to fabricate as much as possible through the weekly assignments:

Computer Controlled Machining

The Deck: Milling the surfboard-style longboard from high-quality plywood or composite layers.

Embedded Design & Output

The Controller: Designing a custom PCB to handle the wireless signal from the remote and manage motor output.

3D Printing / Molding

Protective Gear: Creating the battery enclosure and motor mounts using carbon-fiber reinforced filaments.