Assignment Requirements

Group assignment

- Do your lab’s safety training.

- Characterize the laser cutter (focus, power, speed, rate, kerf, joint clearance, types).

- Document group work and reflect what you learned.

Individual assignment

- Design and document a parametric construction kit (consider kerf).

- Cut something on the vinyl cutter.

- Include original design files and hero shots.

Group assignment

Group assignment

Progress Status

This is for reporting progress (not for visitors to click).

Group page link + notes added.

Missing final photos and conclusions.

Upload .zip with source files.

Assignment Requirements

Learning outcomes

- Demonstrate and describe parametric 2D modelling processes.

- Identify and explain processes involved in using the laser cutter

- Develop, evaluate and construct a parametric construction kit

- Identify and explain processes involved in using the vinyl cutter

Have you answered these questions?

- Linked to the group assignment page✅

- Reflected on your individual page what you learned of your labs safety training✅.

- Explained how you created your parametric design.✅.

- Documented how you made your press-fit construction kit✅.

- Documented how you made something with the vinyl cutter✅.

- Included your original design files✅.

- Included hero shots of your results✅.

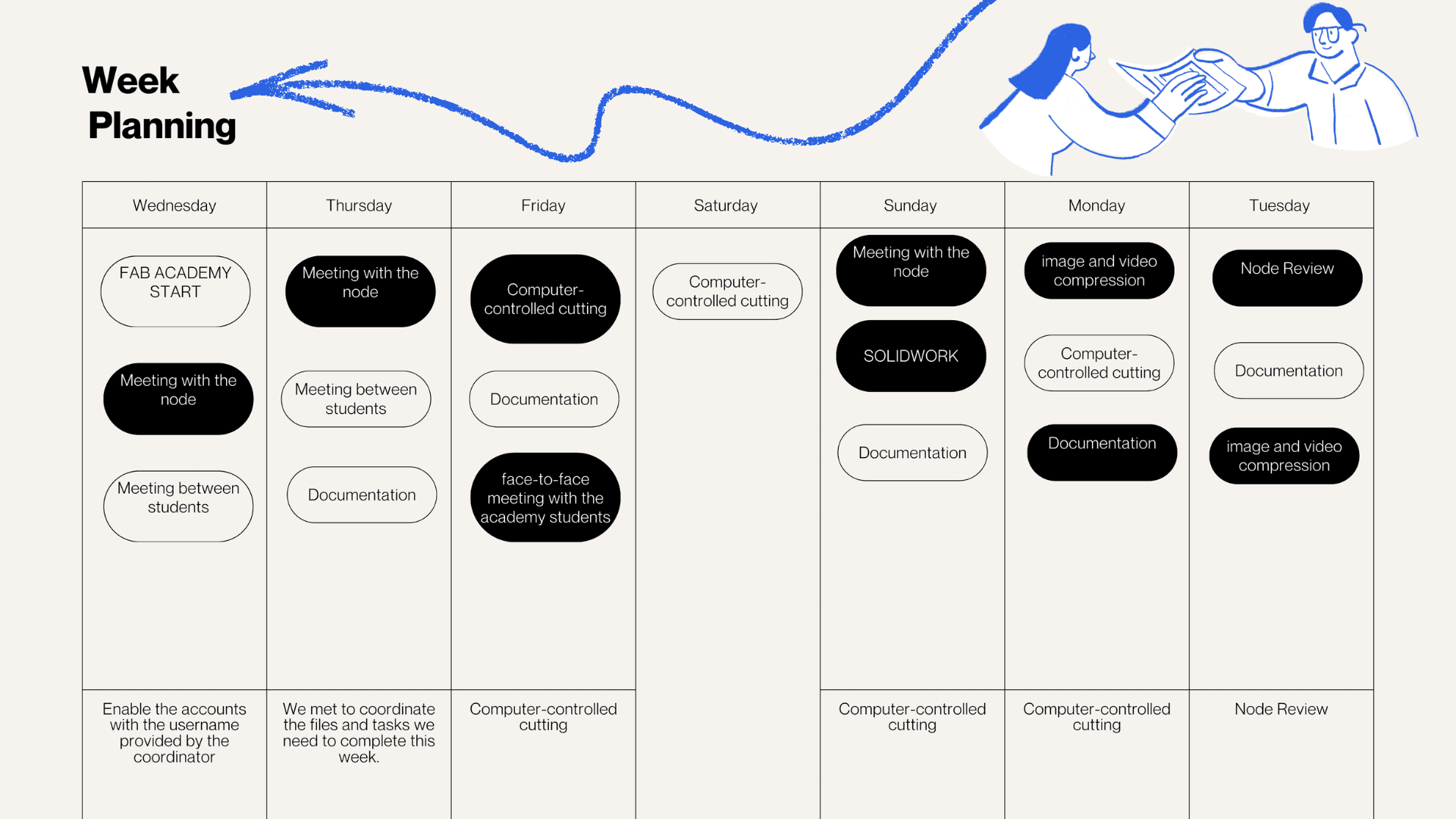

Weekly planning

During the Computer-Controlled Cutting week, group and individual activities were carried out. The group task involved laboratory safety training and characterizing the laser cutter, considering aspects such as focus, power, speed, cut type, joint clearance, and the materials it can process. All work was documented on the group website, and each participant individually wrote a reflection on the lessons learned. In the individual tasks, each participant designed, laser-cut, and documented a parametric construction kit, taking into account the characteristics of laser cutting, and also performed a cut using a vinyl cutter.

group work

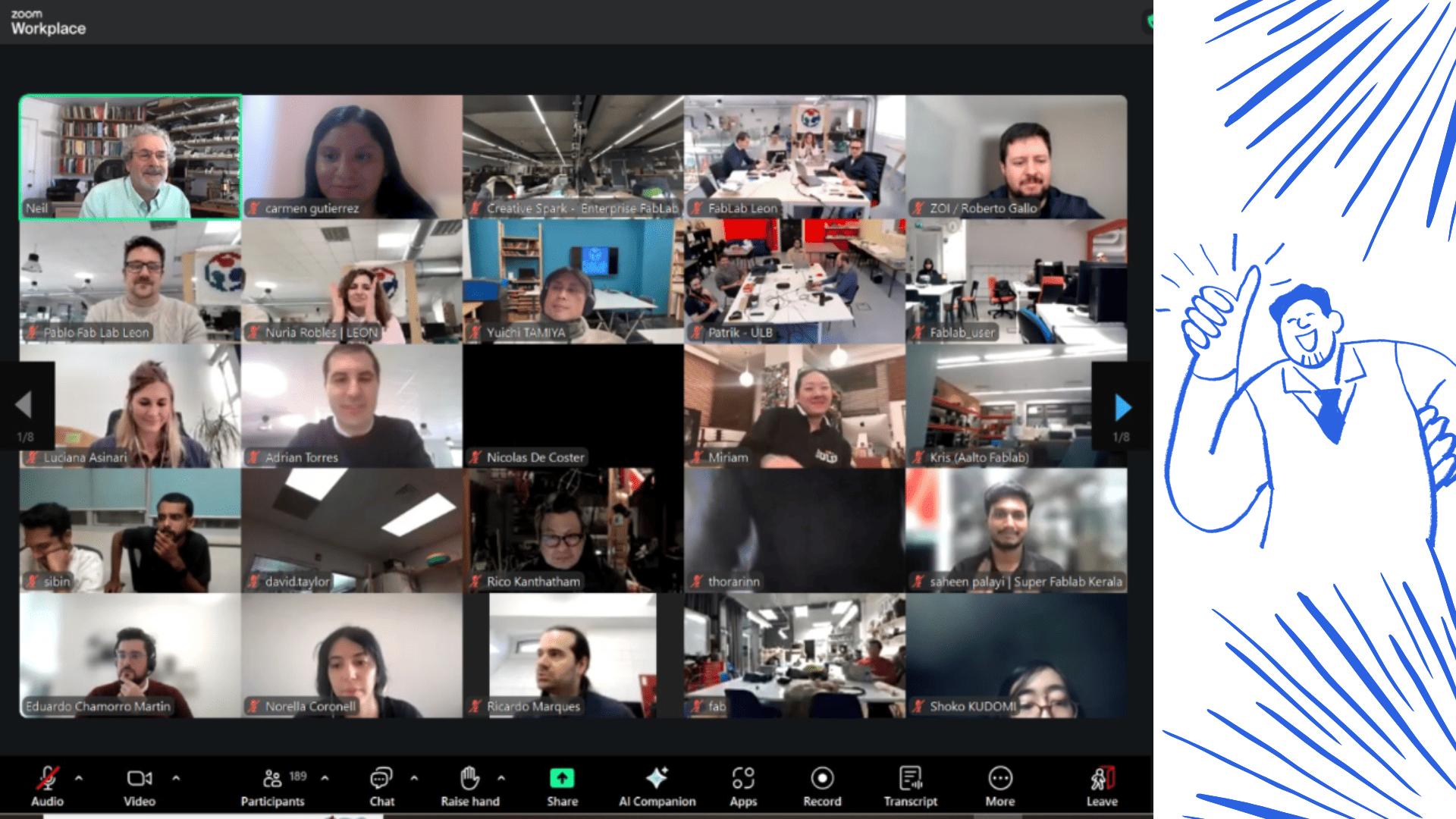

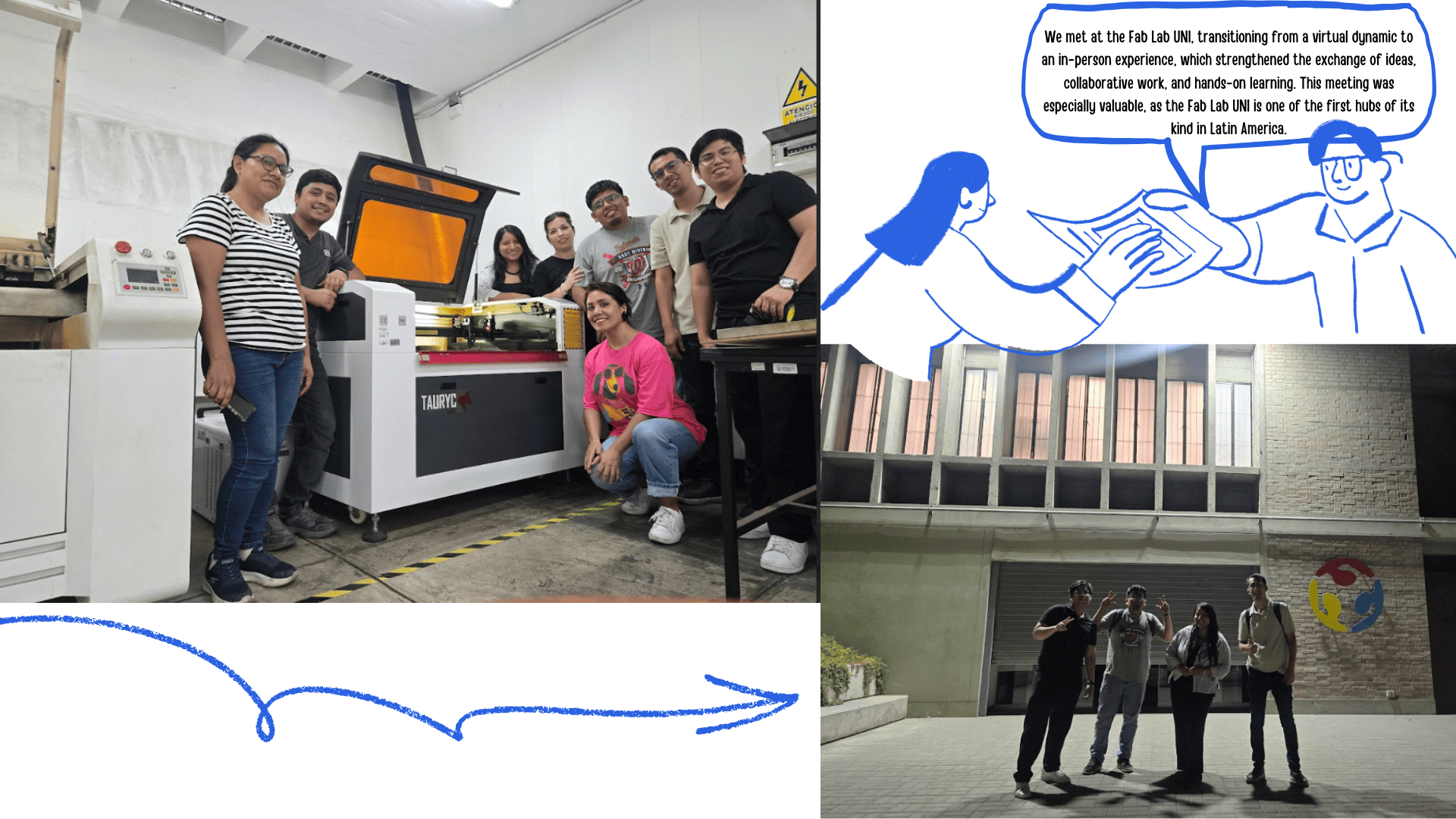

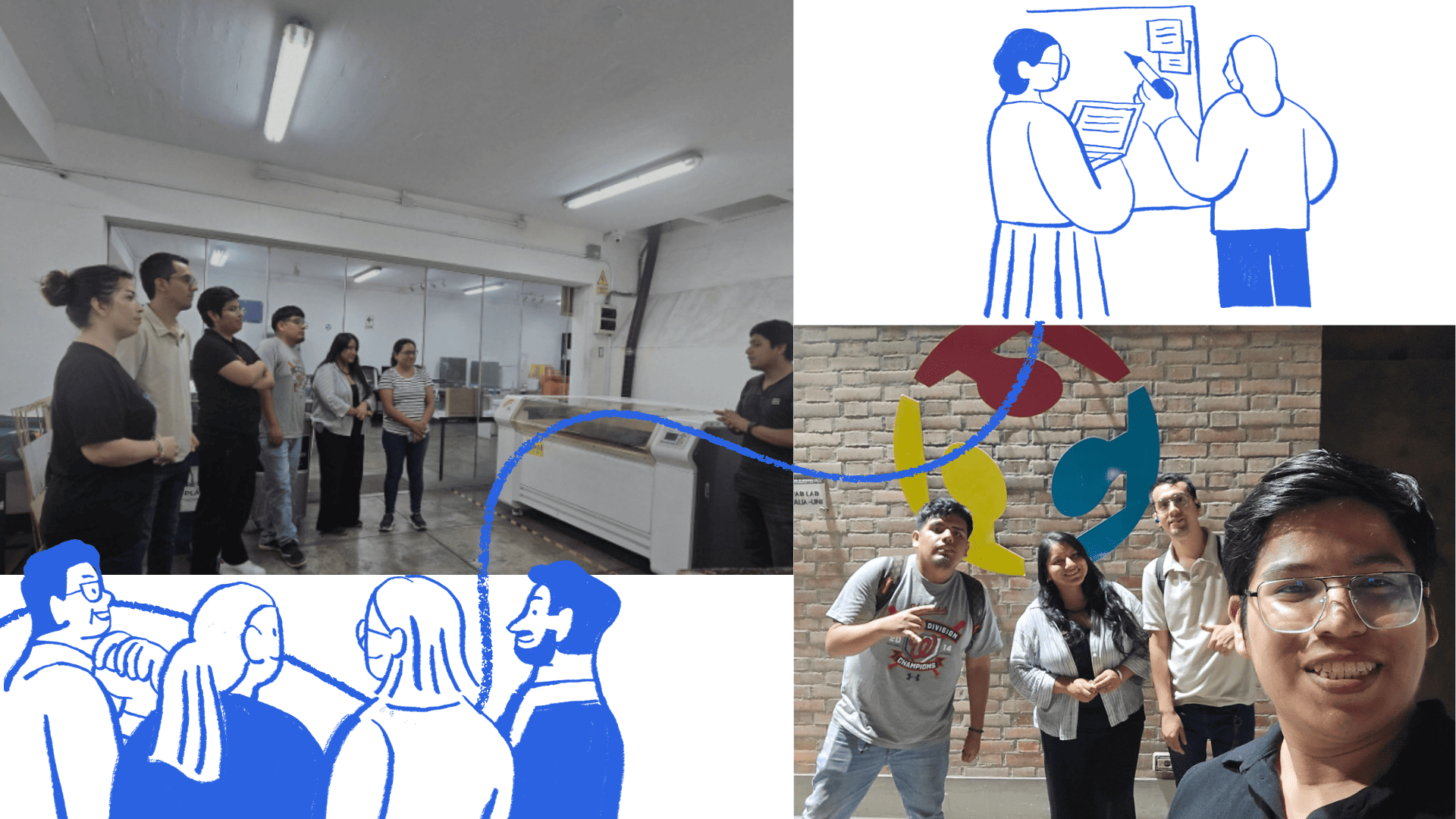

We are the FABLAB Peru node and have a presence in various regions of the country, including Lima, Junín, and Loreto. For this group project, we first held a virtual group meeting to coordinate ideas, objectives, and tasks. Subsequently, we had the opportunity to meet in person at the FABLAB UNI laboratory, a key space within the network of nodes, as it was the first Fab Lab in South America. This laboratory was established between 2010 and 2011 and inaugurated during the FAB7 World Congress, an event that also saw the launch of the Fab City project. The in-person meeting allowed us to finalize our plan, learn about and evaluate various materials, their uses, and the necessary files for fabrication. On this occasion, we were all able to meet to develop the group task, strengthen our bonds, get to know each other better, and share the projects that each node is working on. We were guided by Evelyn Cuadros as instructor and Grace Schwan as support. The development of Task 3 is presented below.

collection of materials

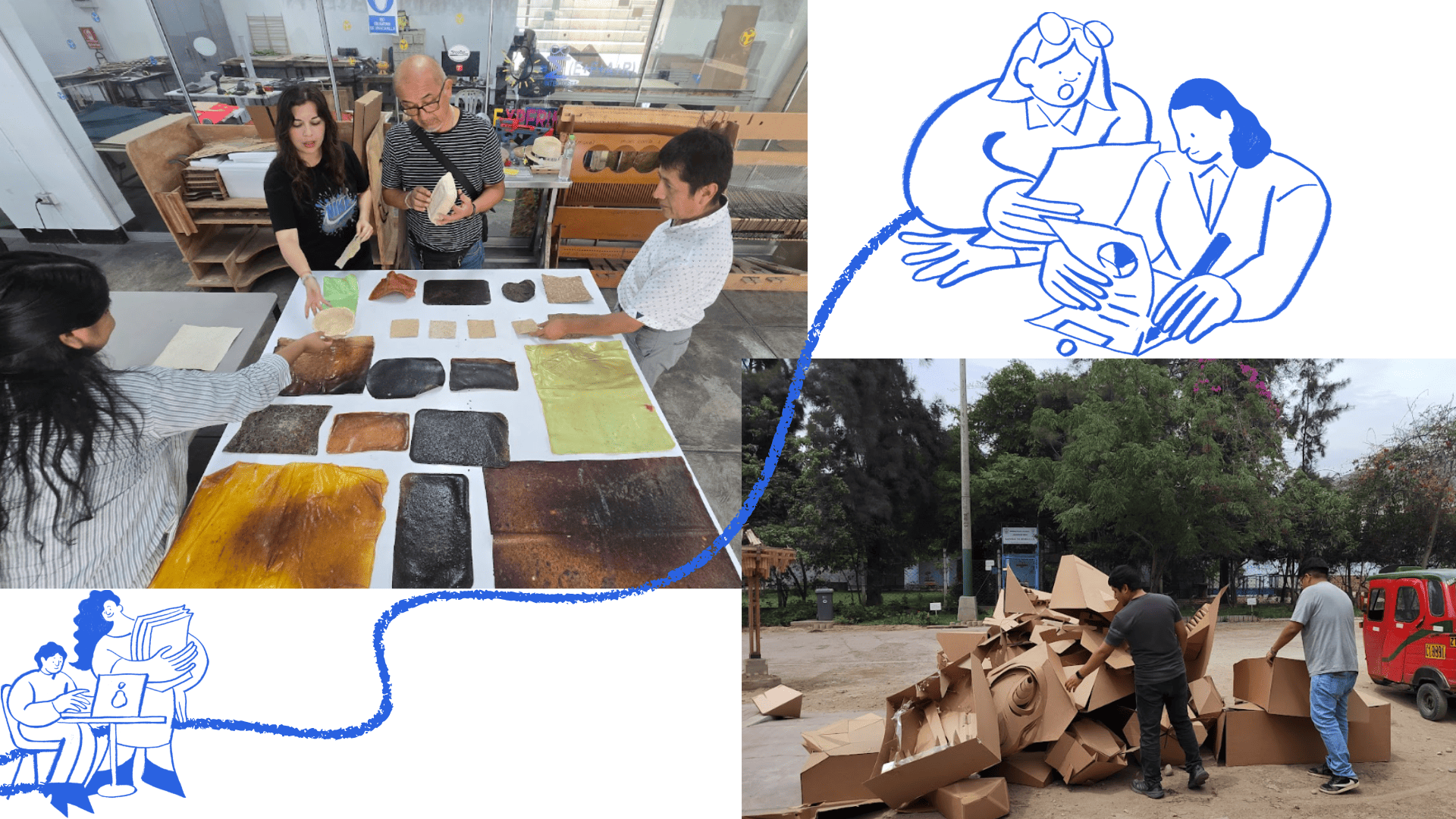

Regarding materials, a group call discussed the different types of materials available at each node, highlighting the importance of collecting and using recycled materials for project development. Special emphasis was placed on utilizing reusable resources as part of a sustainable practice within the Fab Lab network. The materials used at the Satipo node were also reviewed, where biomaterials such as bio-paper and bio-polymers are being developed and are currently being experimented with and applied in various projects. These materials were presented and shared with the group as a reference for future fabrication proposals. During the visit to the UNI Fab Lab, we also had the opportunity to present our ongoing projects and received guidance from the lab director, with whom we shared our progress and approaches. Furthermore, being located within the Faculty of Architecture, the lab allowed us to identify and recycle readily available materials such as cardboard, acrylic, and MDF, which were reused for prototype development and digital fabrication exercises.

laboratory safety training

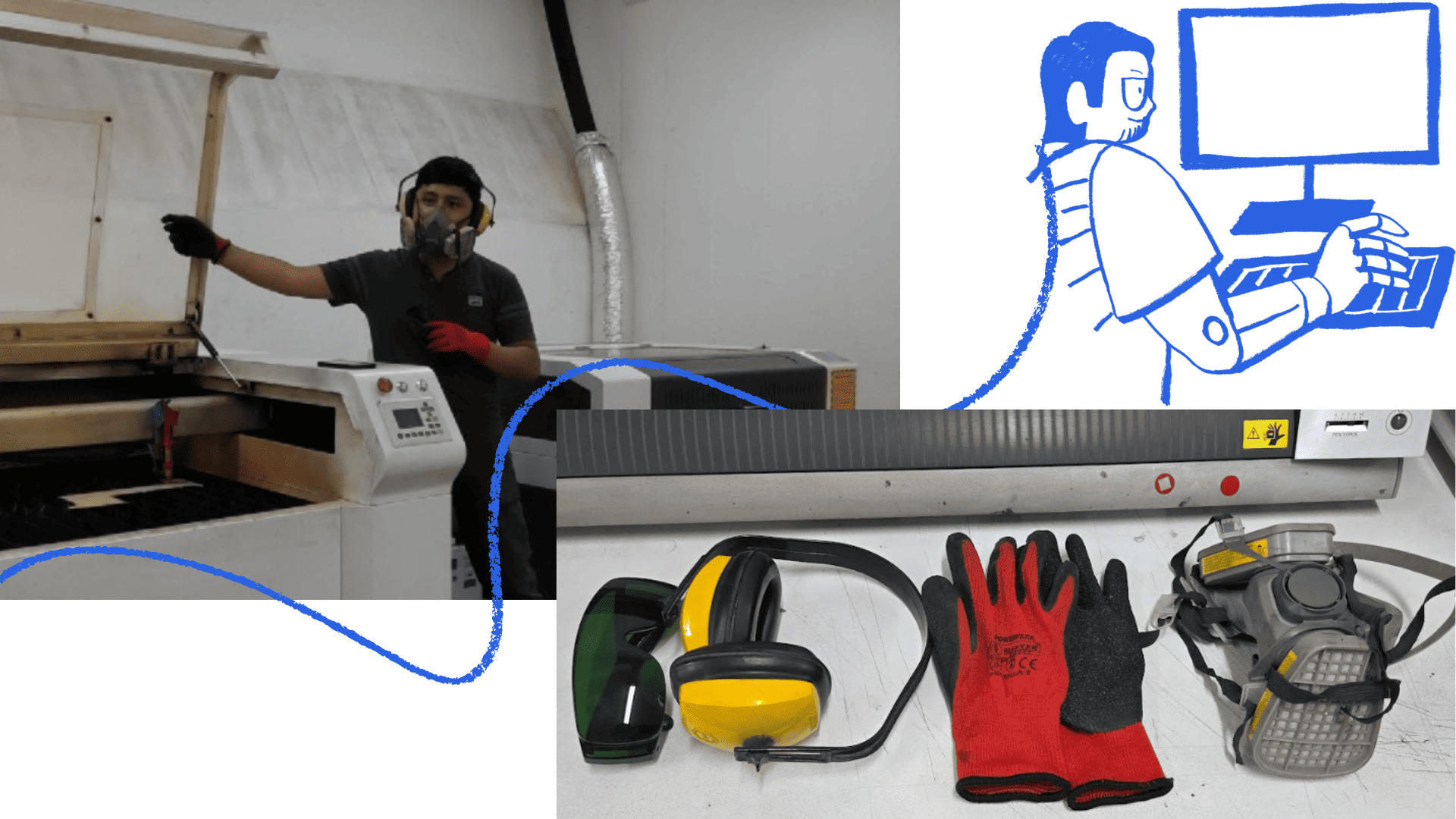

We received safety training at the UNI FabLab, led by instructor Jheferson Lados Villegas. During the training, he explained the importance of personal safety and the correct use of the necessary safety equipment for operating the laser machine, such as protective glasses, gloves, a mask, and ear protection. The training emphasized that these items are essential for preventing accidents and protecting the user's health from risks such as laser radiation, noise, and particle emissions.

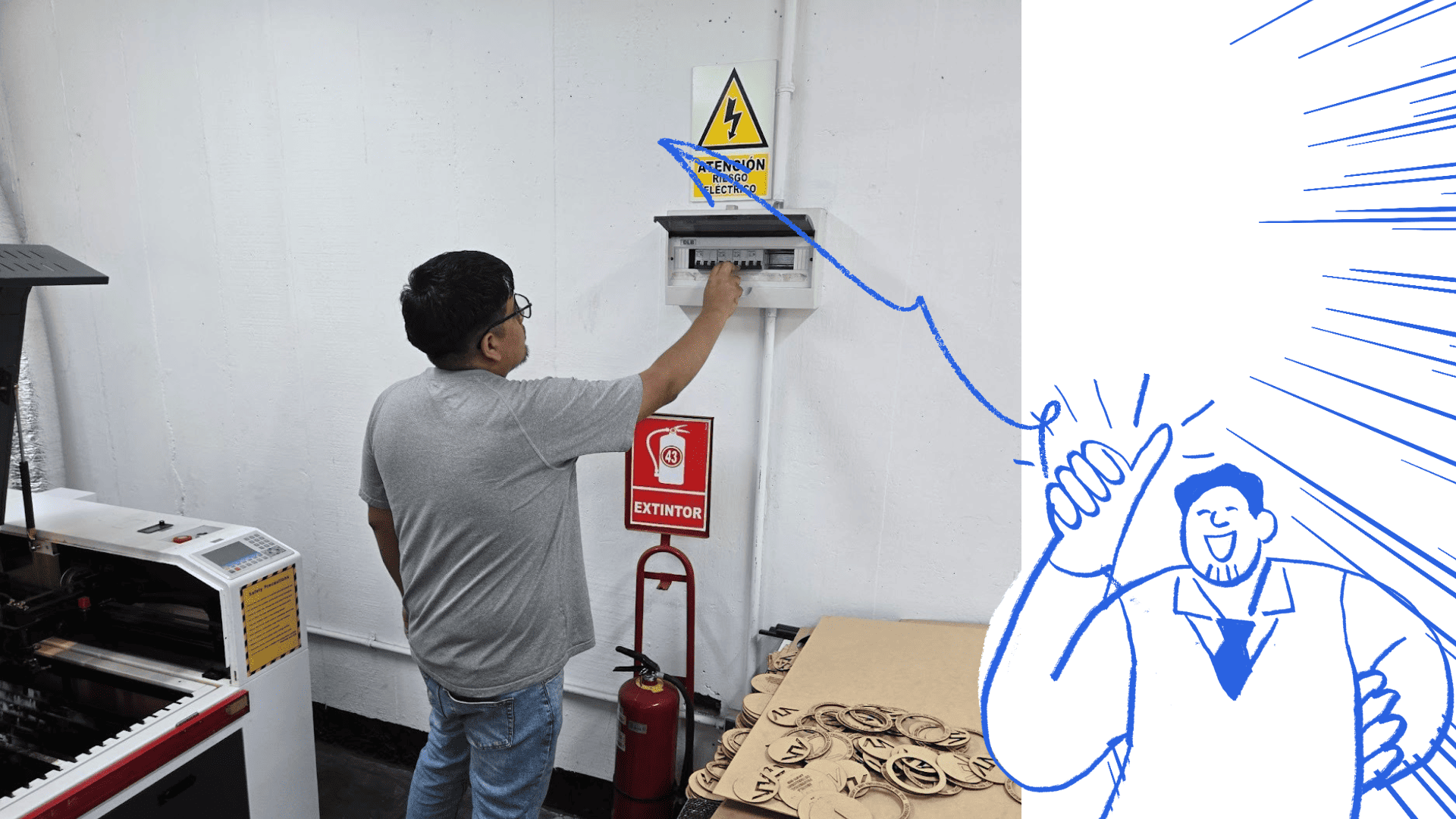

A tour of the laboratory was also conducted to identify the signage, noting the electrical panels, including a main panel and a separate panel for each laser machine. The work area was also explained, emphasizing that it must be respected to ensure safe operation and prevent unauthorized personnel from entering the area while the machines are running..

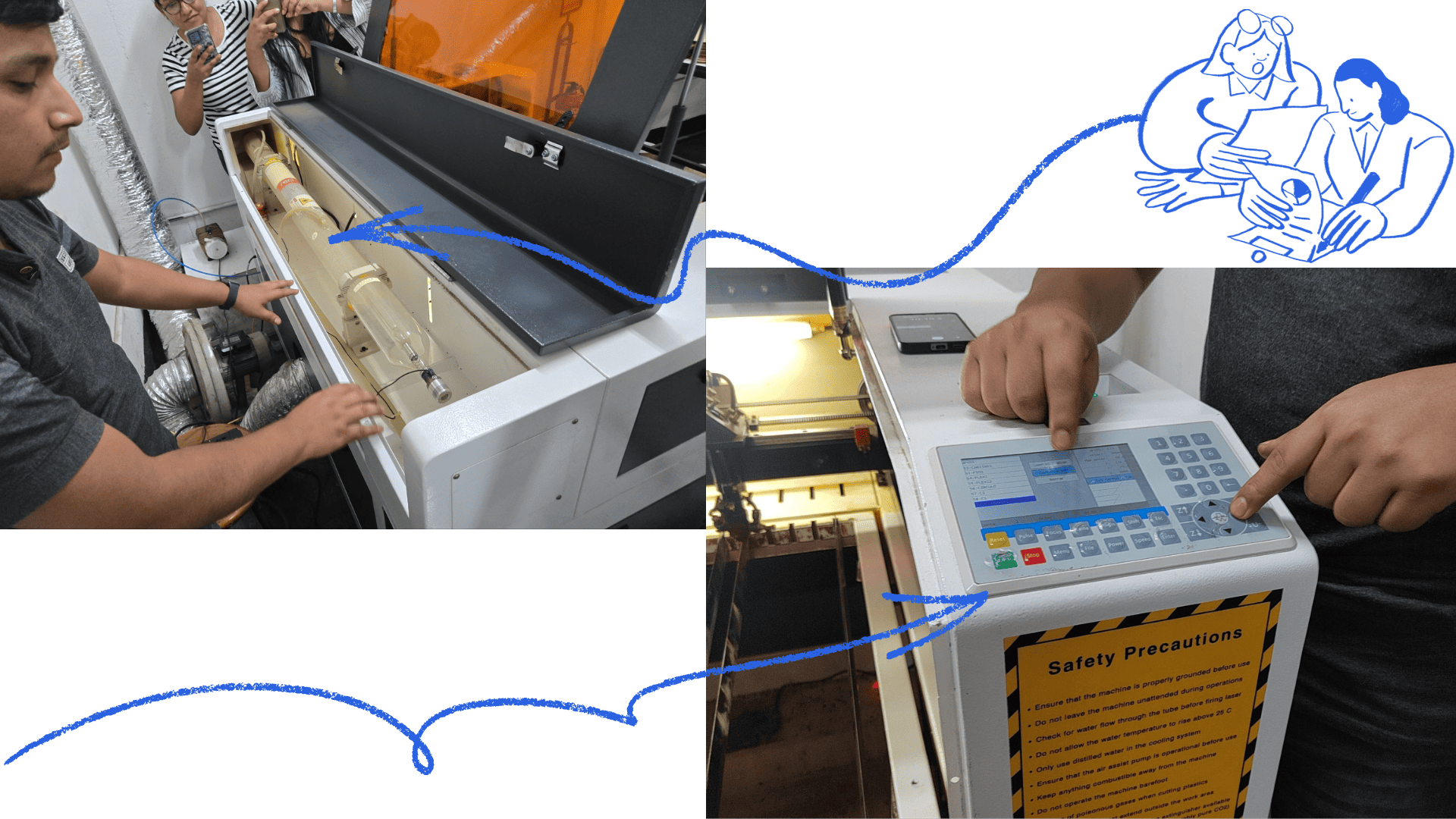

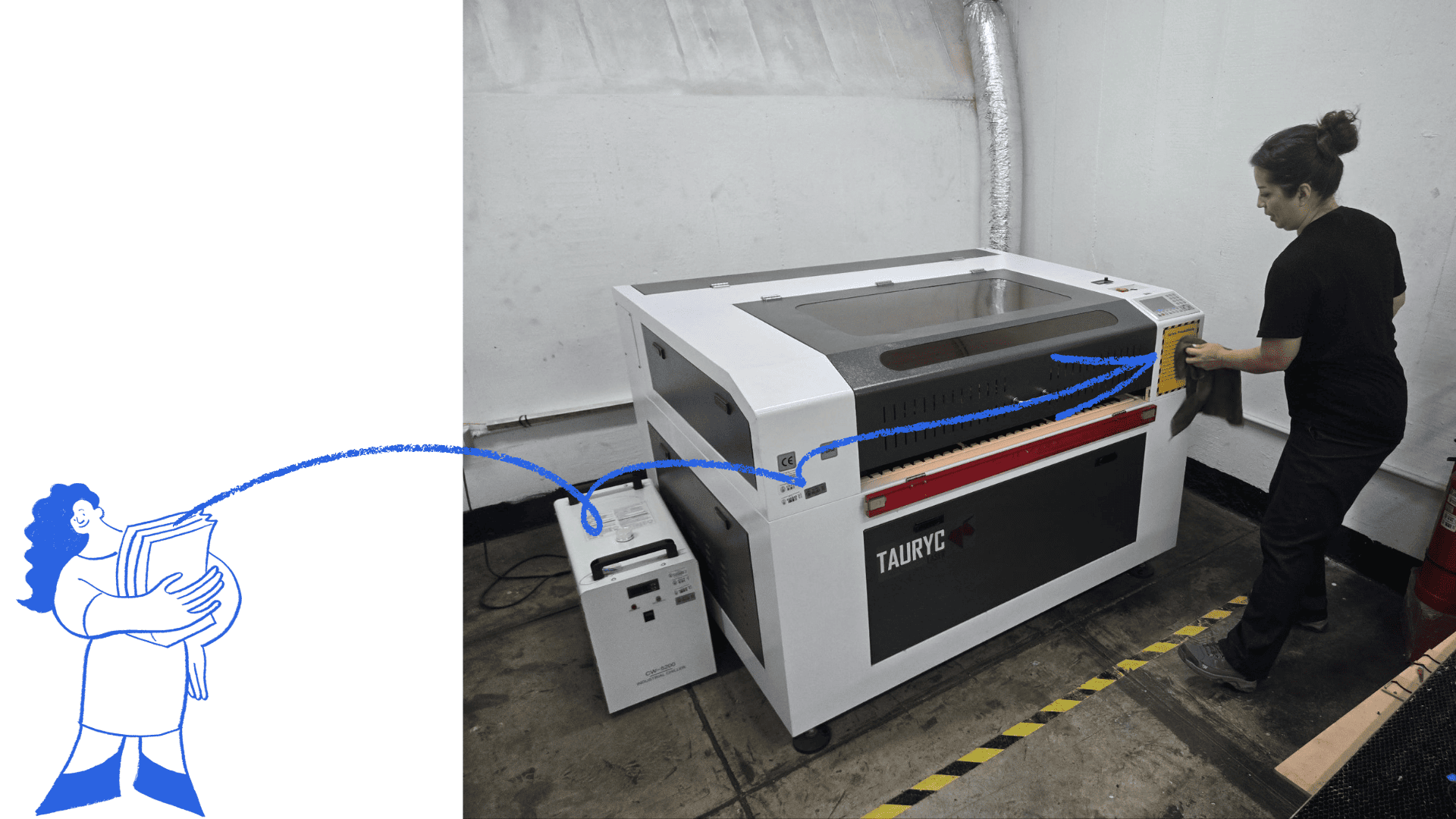

Regarding the laser machines, the series available in the laboratory was presented, detailing their uses and power levels according to the type of material being processed. It was explained that there are differences between the machines: one operates with a closed hood, which provides greater safety for the user by isolating the laser beam, while the other operates with an open hood, requiring greater caution and the mandatory use of protective eyewear..

The main parts of a laser cutting machine were also described, including the laser tube, focusing mirrors and lenses, cutting head, worktable, fume extraction system, control panel, and power supply. Each of these components plays an essential role in the proper functioning and precision of the cut.

Finally, recommendations were provided for the proper use of the laser machine, such as checking the material before cutting, correctly adjusting the power and speed, never leaving the machine running unattended, keeping the work area clean and tidy, and always following the instructor's directions. These recommendations ensure safe and efficient use of the machine, reducing risks and extending the equipment's lifespan.

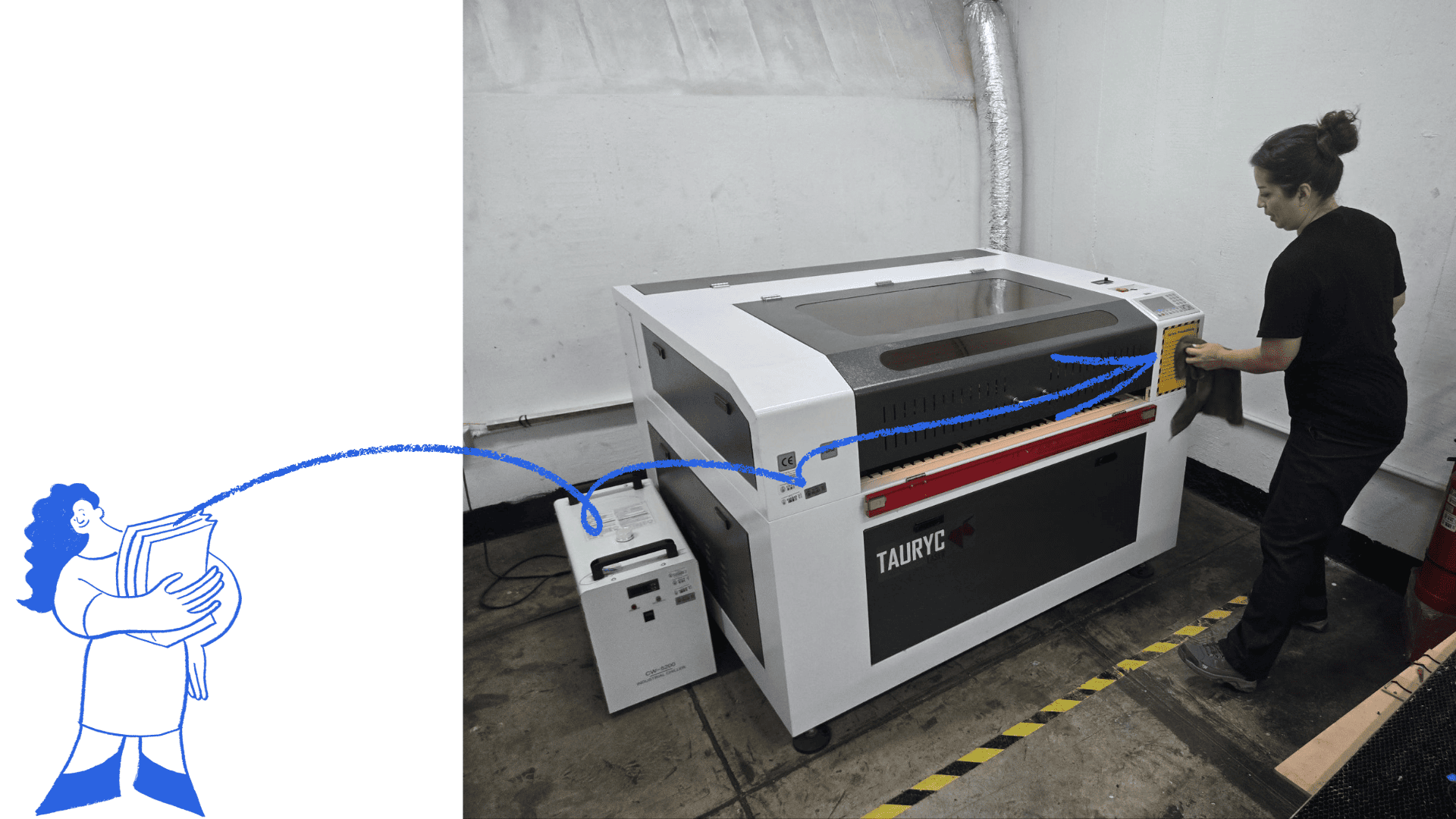

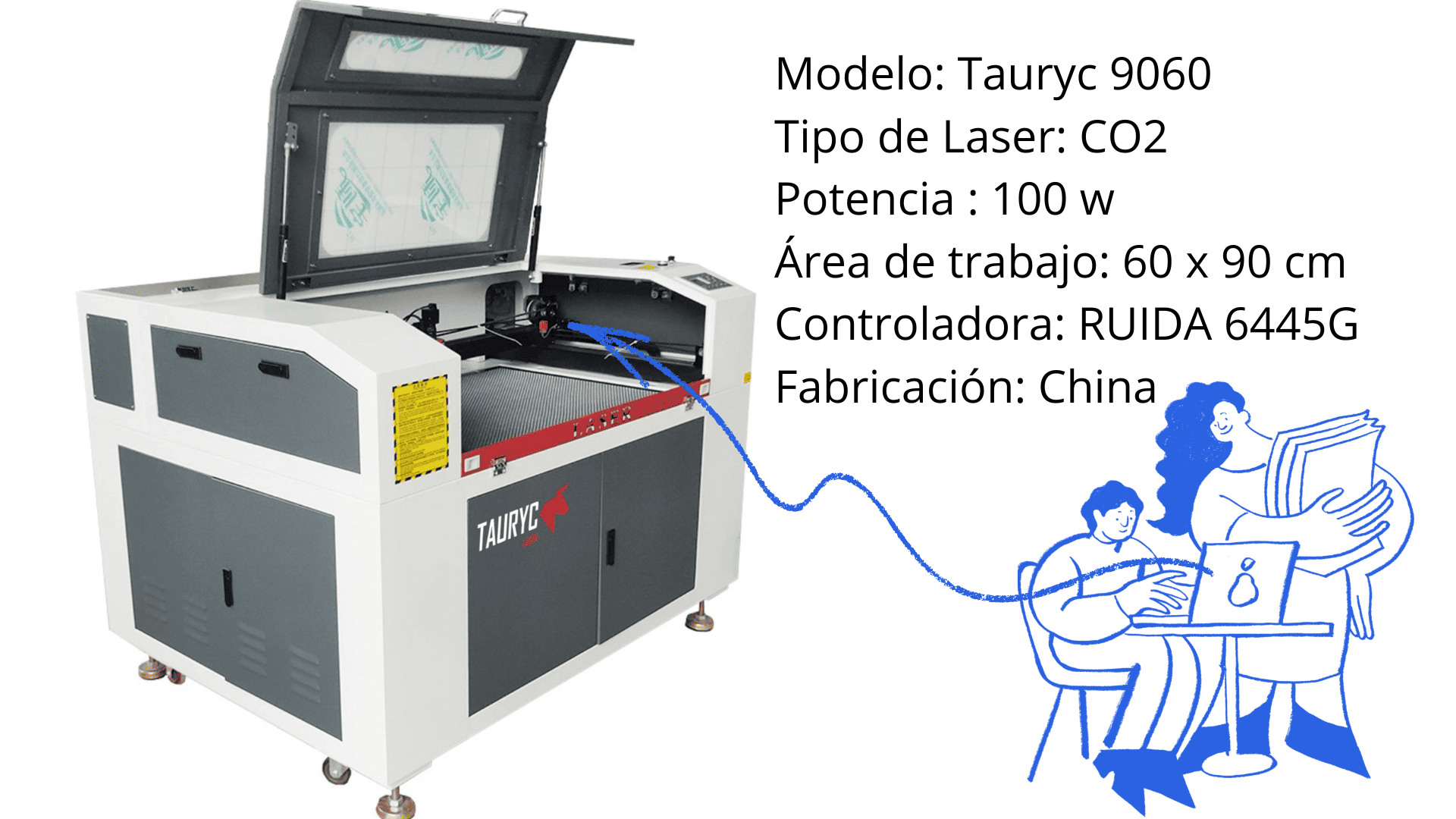

Features of the Laser Cutting Machine

Calibration Tests

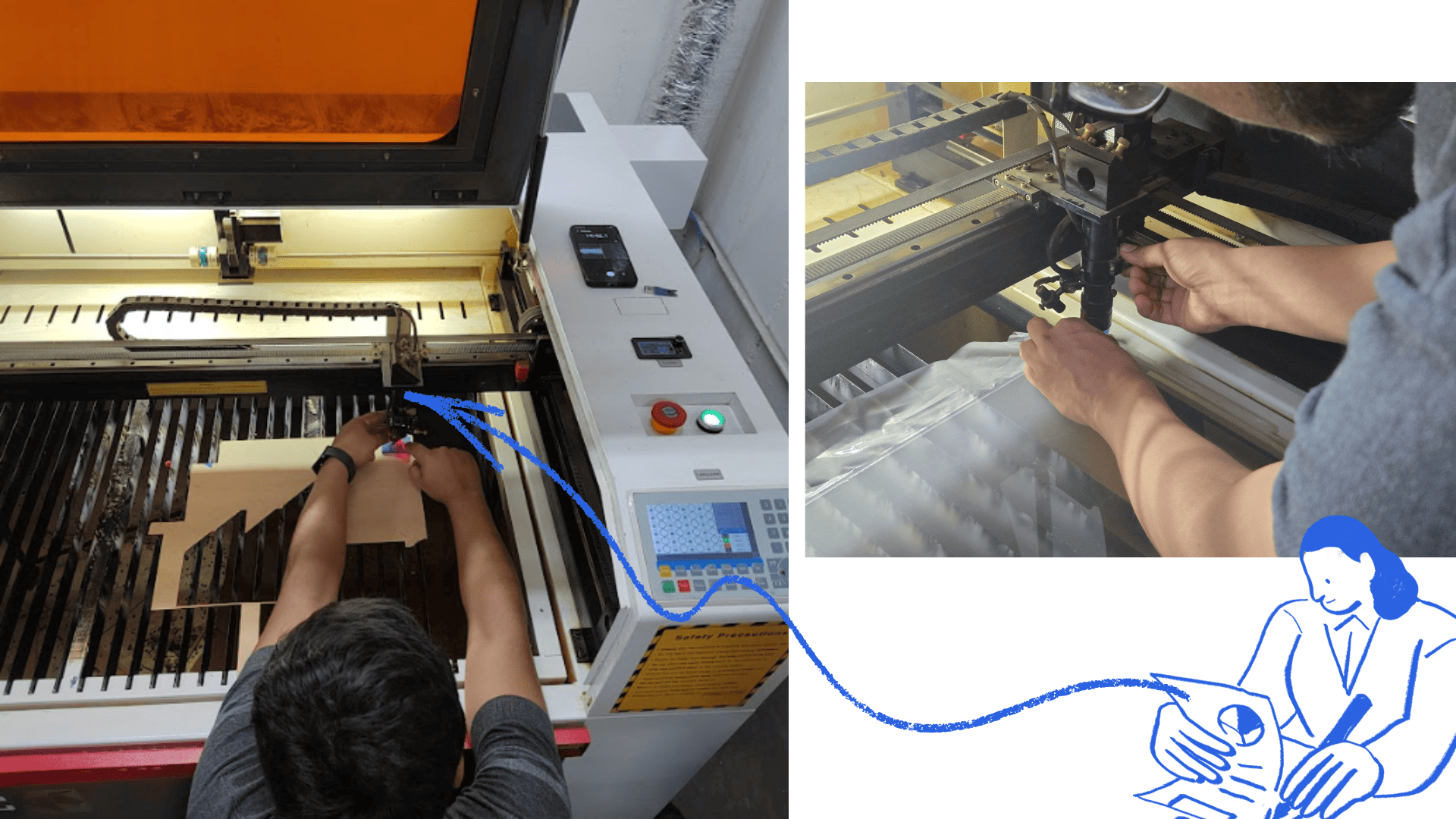

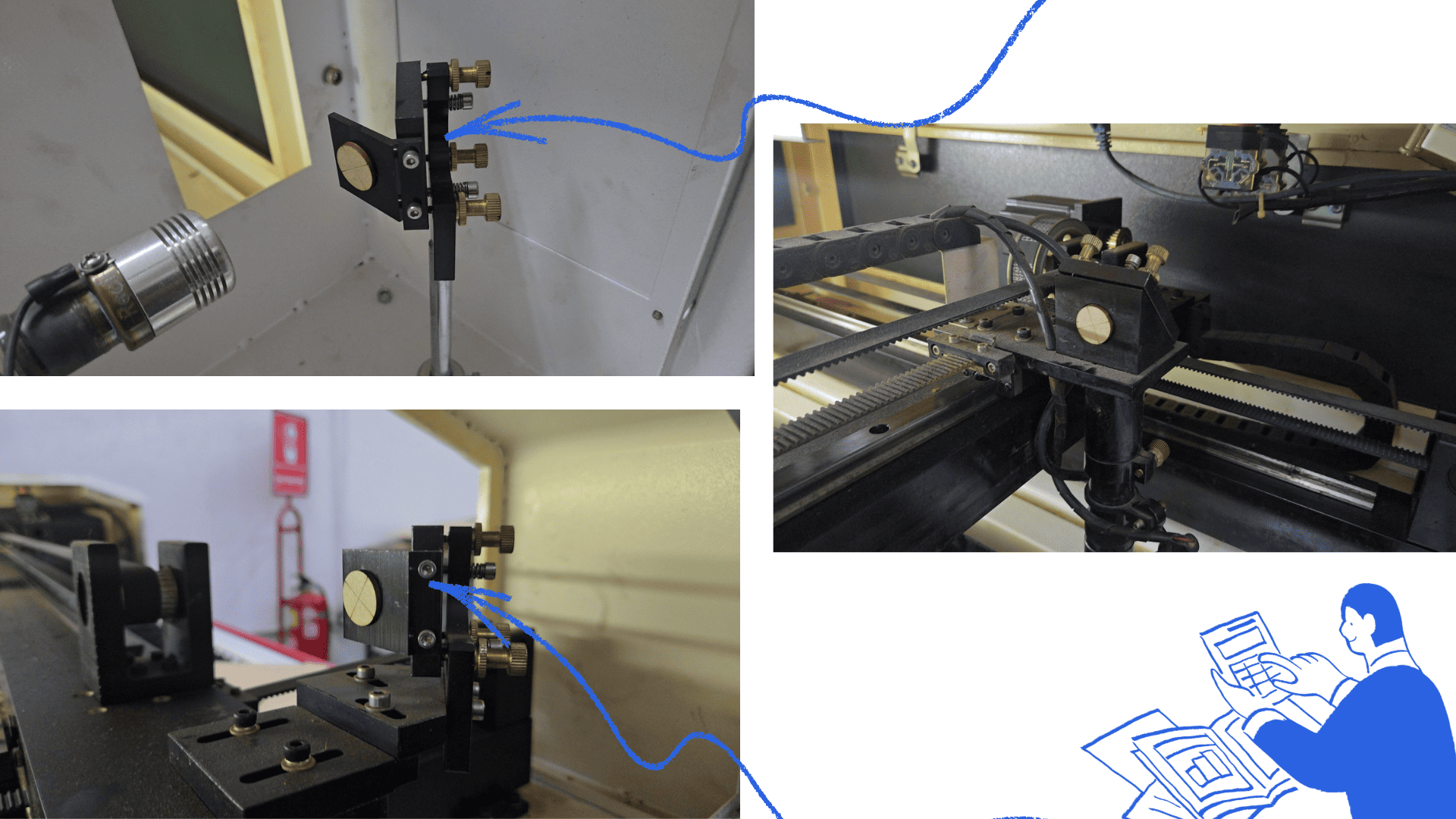

Calibrating a laser cutting machine is a fundamental process to ensure accuracy, quality, and safety during use. First, it is essential to ensure that the worktable is przperly leveled, adjusting the table height or the laser to achieve optimal focus on the workpiece.

Next, the mirrors are checked and adjusted. It is important to verify that the mirrors are clean and properly aligned, as any misalignment affects the laser beam's path. A laser pointer or marker can be used for this procedure, ensuring that the beam is correctly reflected from each mirror to the cutting head.

Next, the cutting head is aligned, ensuring it is perpendicular to the work surface. Any misalignment must be corrected to prevent irregular cuts or loss of precision during the manufacturing process.

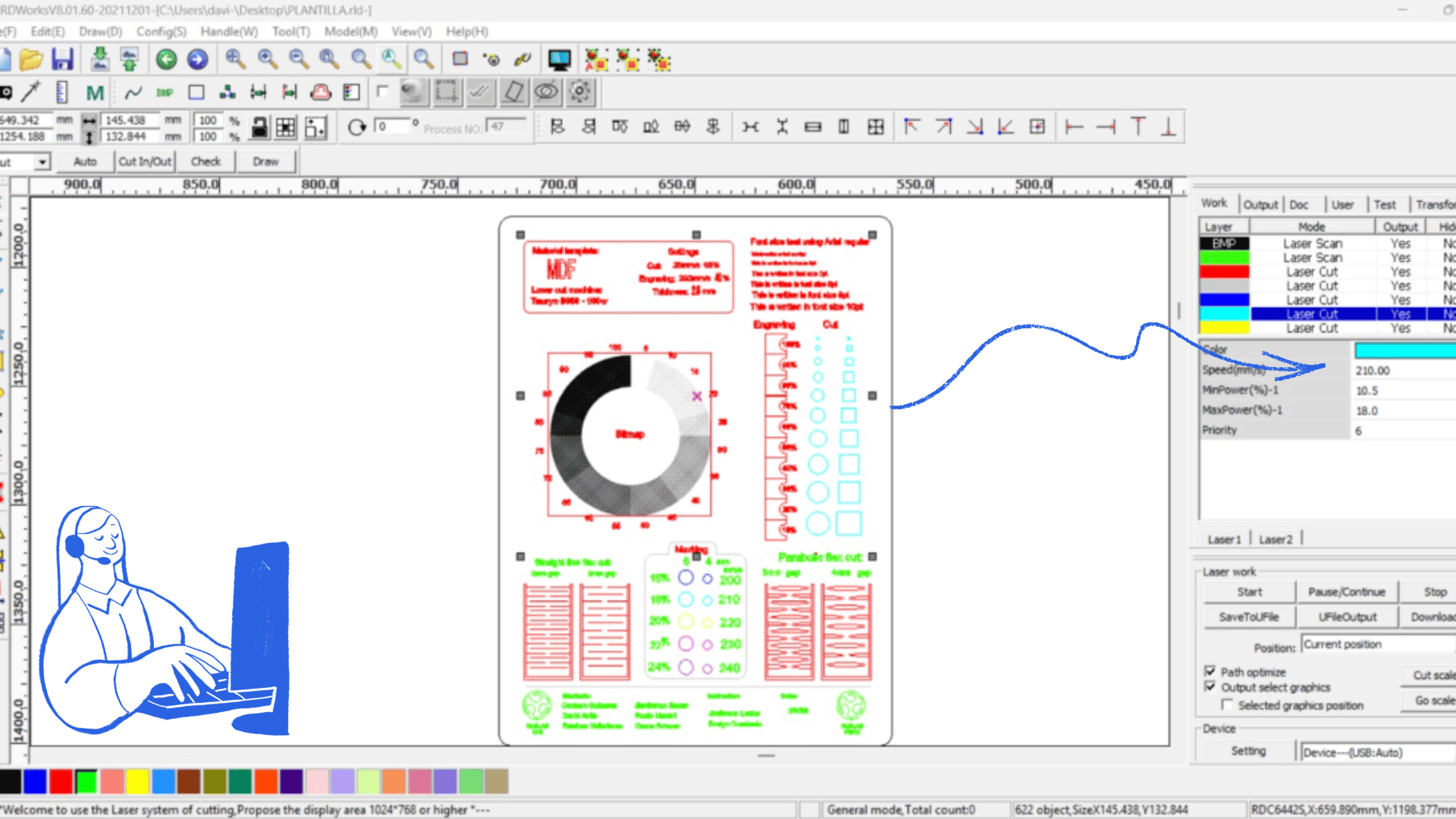

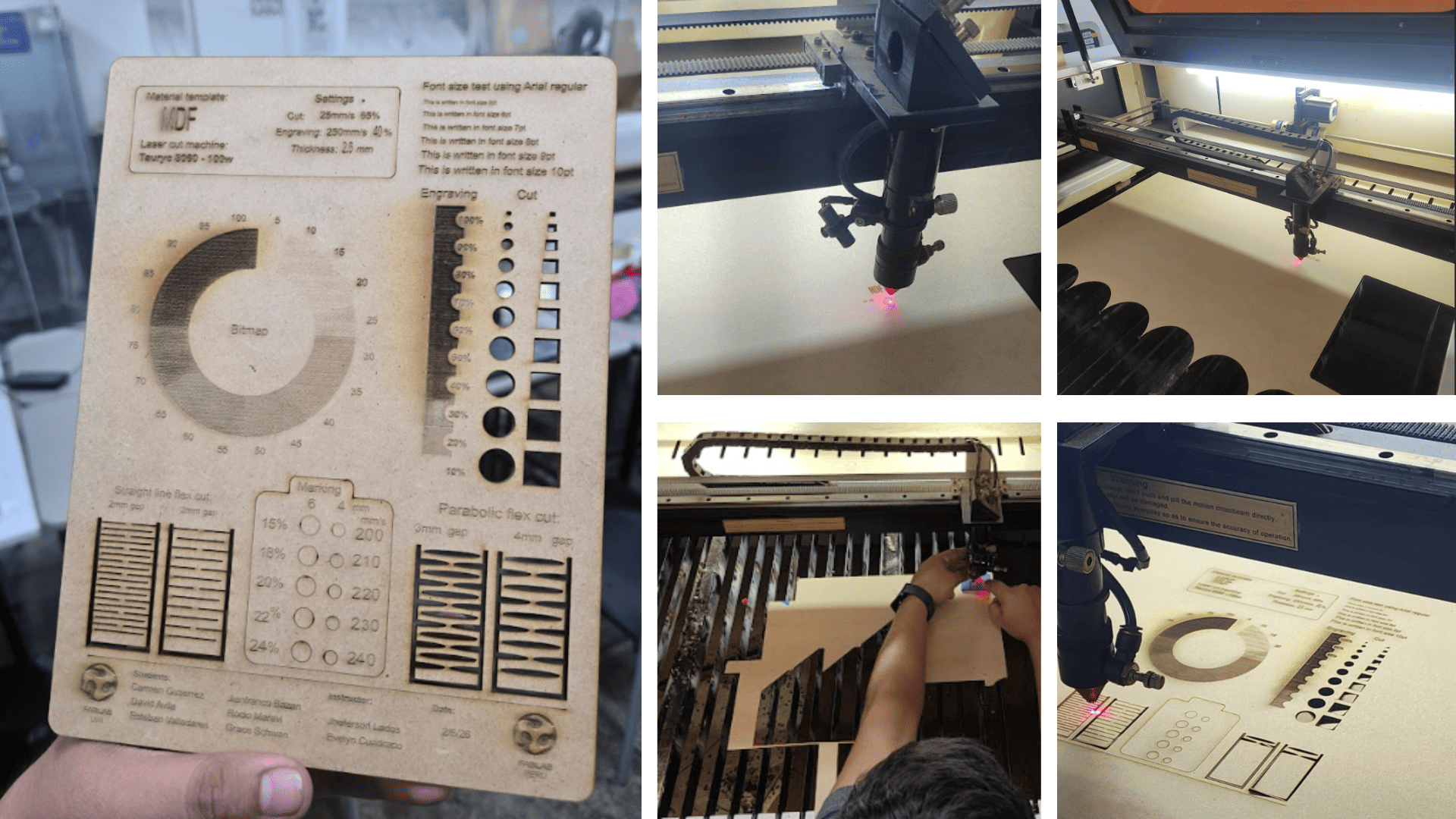

Parameter-MDF 2.6 Tests

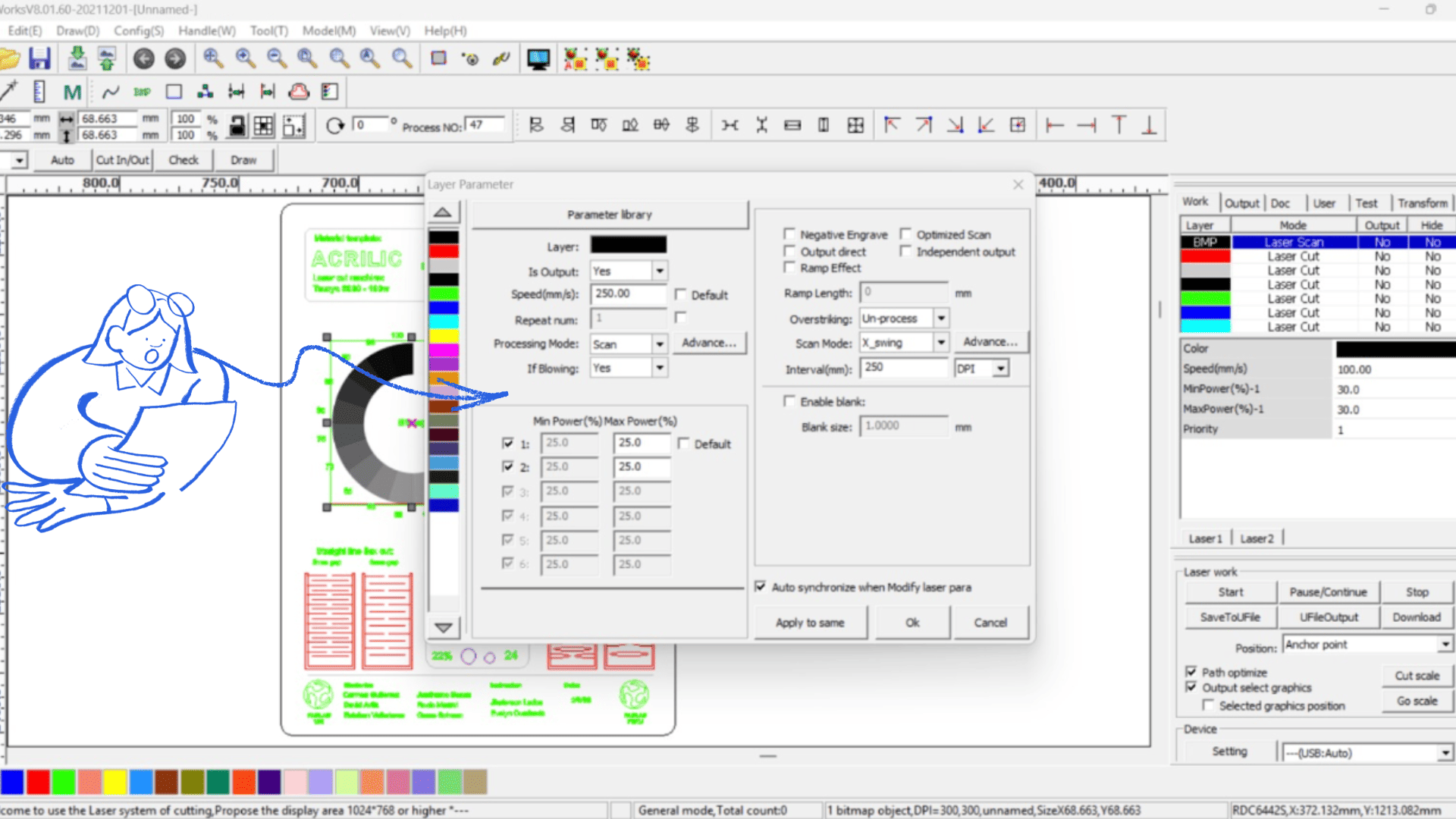

We edited our laser cutting and engraving test template, first using Corel Draw to optimize it and add our letterhead. The template includes laser cutting, marking, and engraving operations, in raster or bitmap format.

Luego exportamos la plantilla al programa controlador láser RDworks, para lo cual editaremos primero nuestra paleta de grises en bitmap para hacerle prueba en grabado.

- The bitmap engraving had to be configured as a dot grid because sending it as is didn't produce a grayscale image.

- The power tower in the engraving doesn't appear as stepped due to the burnt finish.

- The minimum sizes in the cut display well in basic shapes.

- The letter sizes display well.

- The quick laser marking test shows optimal results in its shapes.

- The flexible pattern tests in the 3mm space show more flexibility with this material.

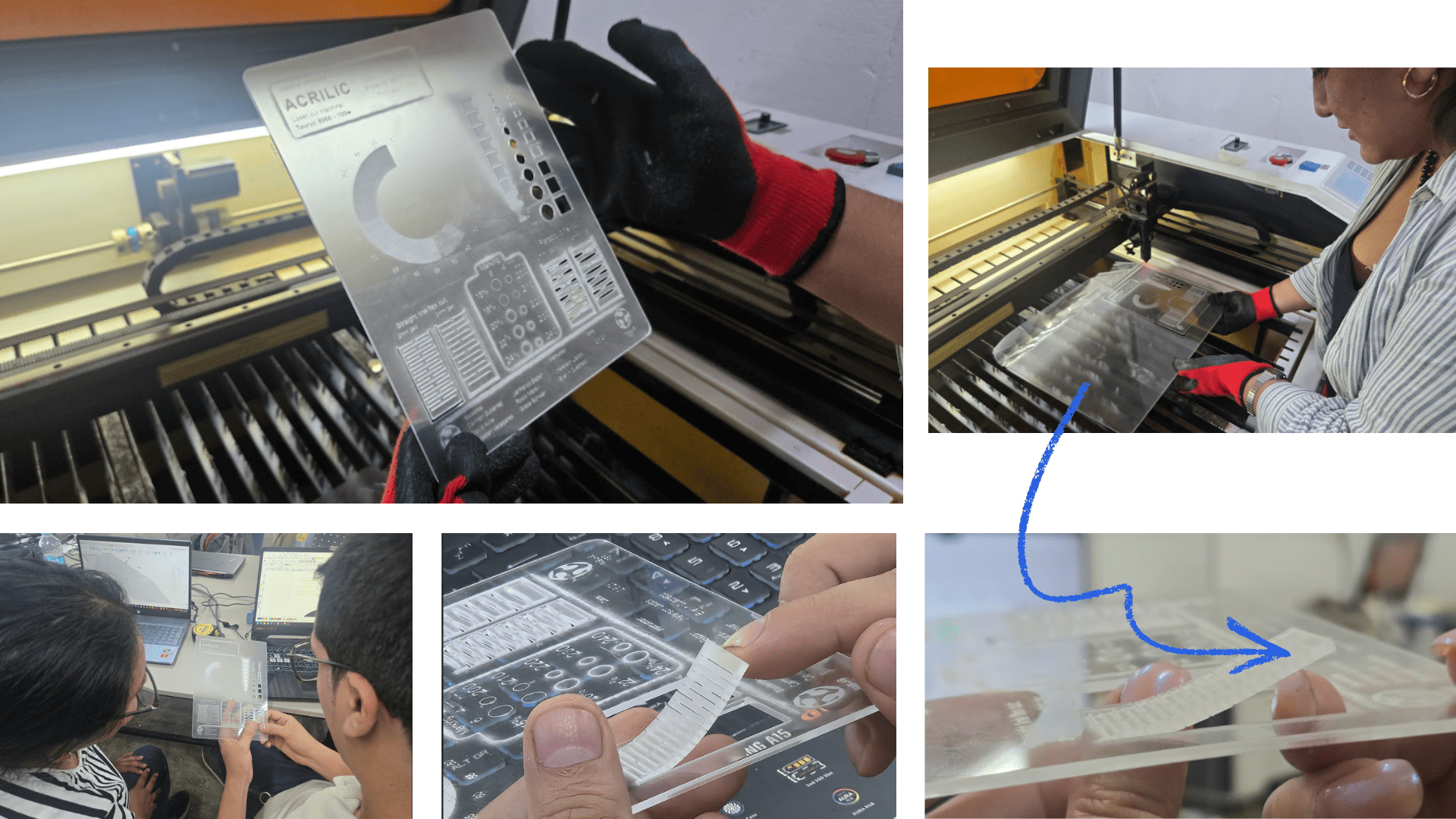

Parameter Tests - Acrylic 2mm

A laser cutting and engraving test was performed on acrylic. During the process, different power and speed settings were evaluated to achieve a clean and precise finish. The cut resulted in polished edges characteristic of acrylic processed with a CO₂ laser, while the engraving showed a uniform matte finish.

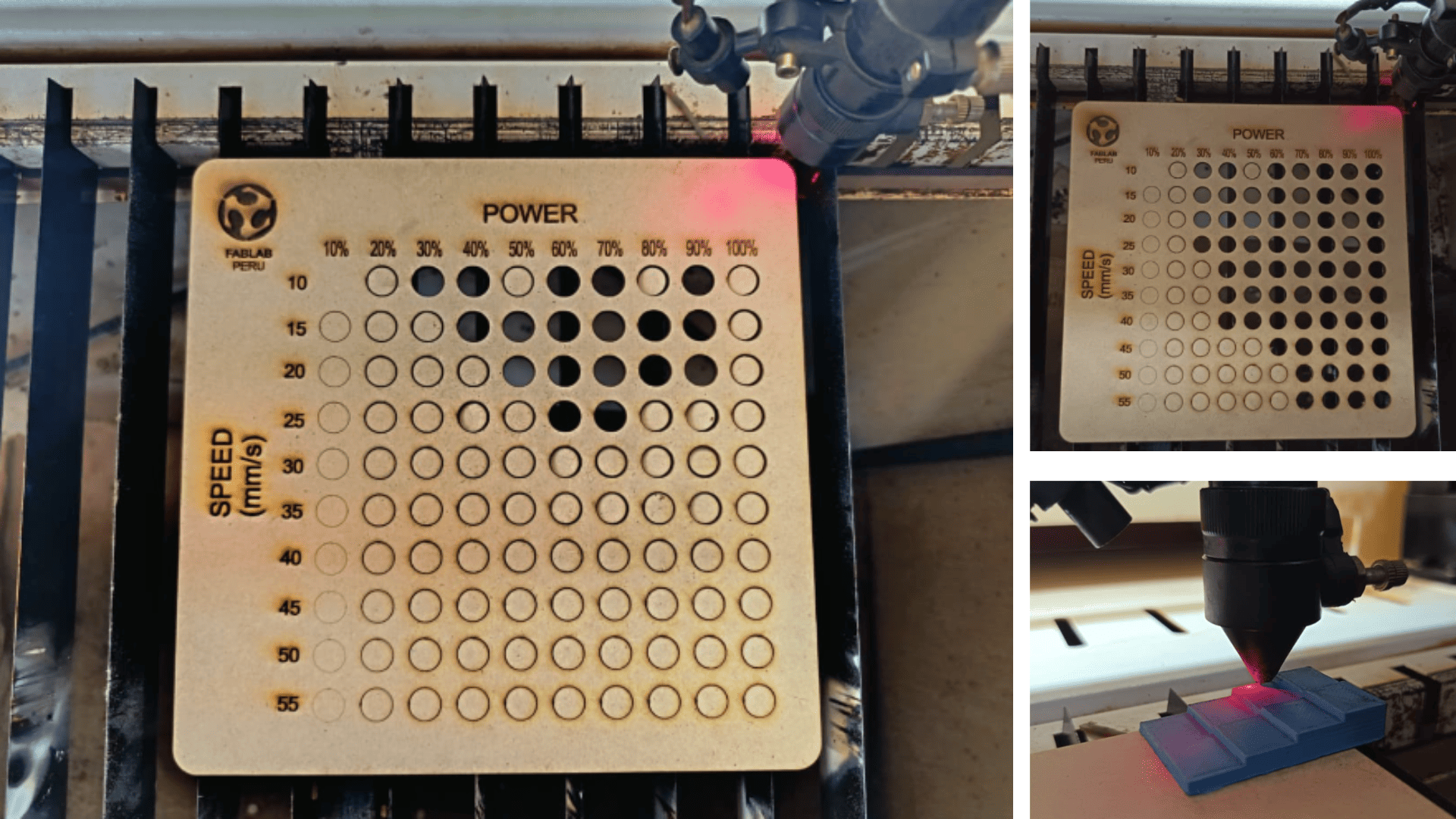

Minimum and maximum speed and power test

Se realizó una prueba de valores mínimos y máximos de velocidad y potencia en la cortadora láser con el fin de identificar los parámetros óptimos de corte y grabado. Se evaluaron diferentes combinaciones para observar el comportamiento del material frente a variaciones extremas. En los valores mínimos, el corte fue incompleto y el grabado presentó baja intensidad. En los valores máximos, se logró un corte más rápido, pero con riesgo de quemado o derretimiento en los bordes. Esta prueba permitió establecer un rango adecuado de configuración para obtener mejores resultados según el tipo y espesor del material.

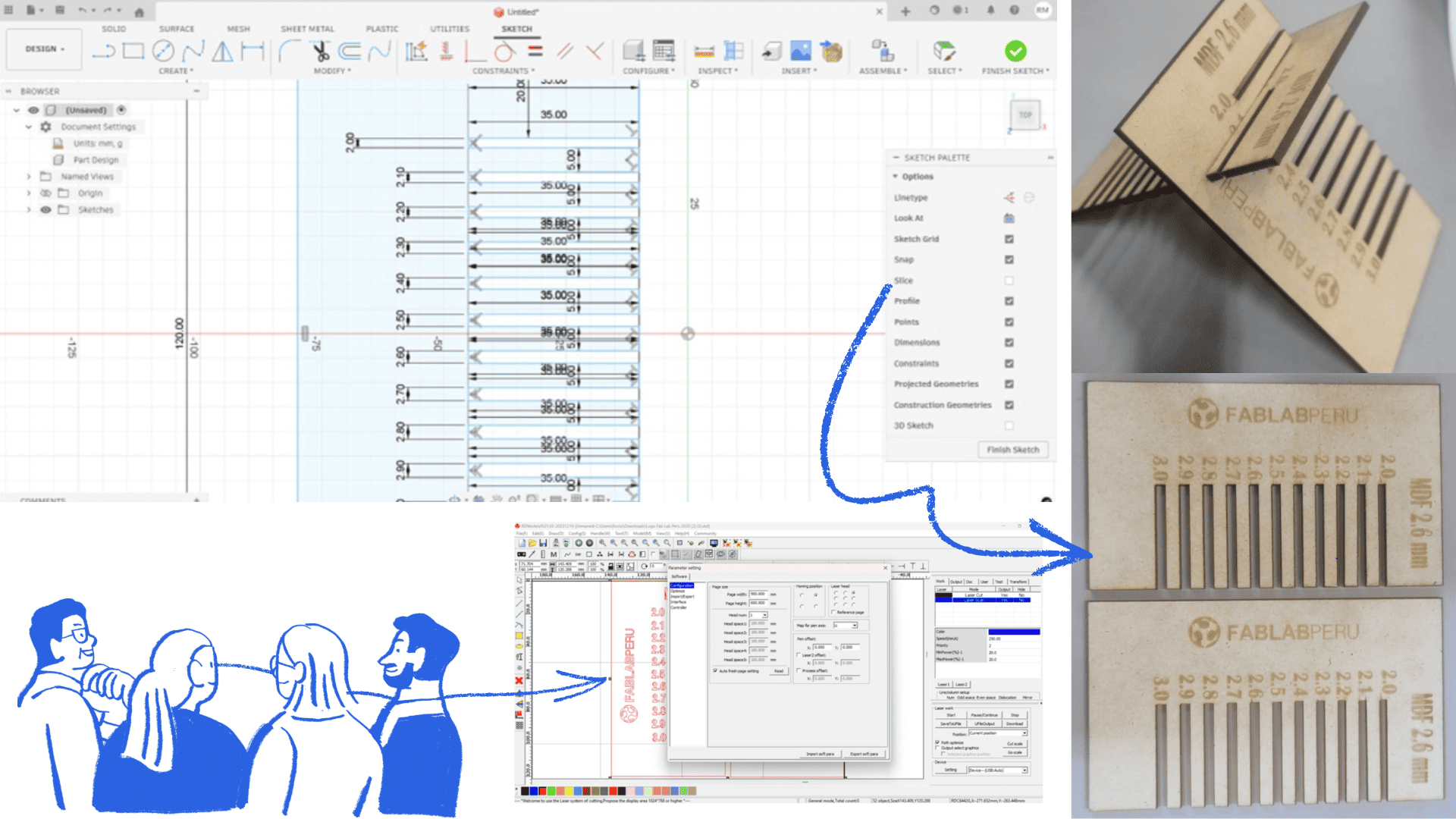

Se realizó una prueba de kerf con el objetivo de medir el espesor real que el láser elimina durante el proceso de corte. Para ello, se diseñó una pieza con múltiples ranuras de diferentes medidas y se evaluó el ajuste entre piezas macho y hembra. Los resultados permitieron calcular la pérdida de material producida por el haz láser y ajustar las dimensiones del diseño digital para lograr un ensamble preciso. Esta prueba es fundamental para proyectos de corte paramétrico y kits de construcción, ya que garantiza un correcto encaje entre las piezas.

The FabLab UNI provided us with a suitable and well-equipped space to carry out our group work safely and in an organized manner, which was essential for the successful completion of the planned activities. Having access to this laboratory allowed us to work with the necessary machines, materials, and tools, strengthening hands-on learning and collaborative work among the different groups. Furthermore, the importance of respecting the shared space was emphasized, so at the end of the activities, we left the laboratory clean and tidy, following the established FabLab UNI rules. Maintaining the work area in good condition not only ensures the safety of users but also contributes to the proper functioning of the laboratory and the care of the equipment for future use.

Individual tasks

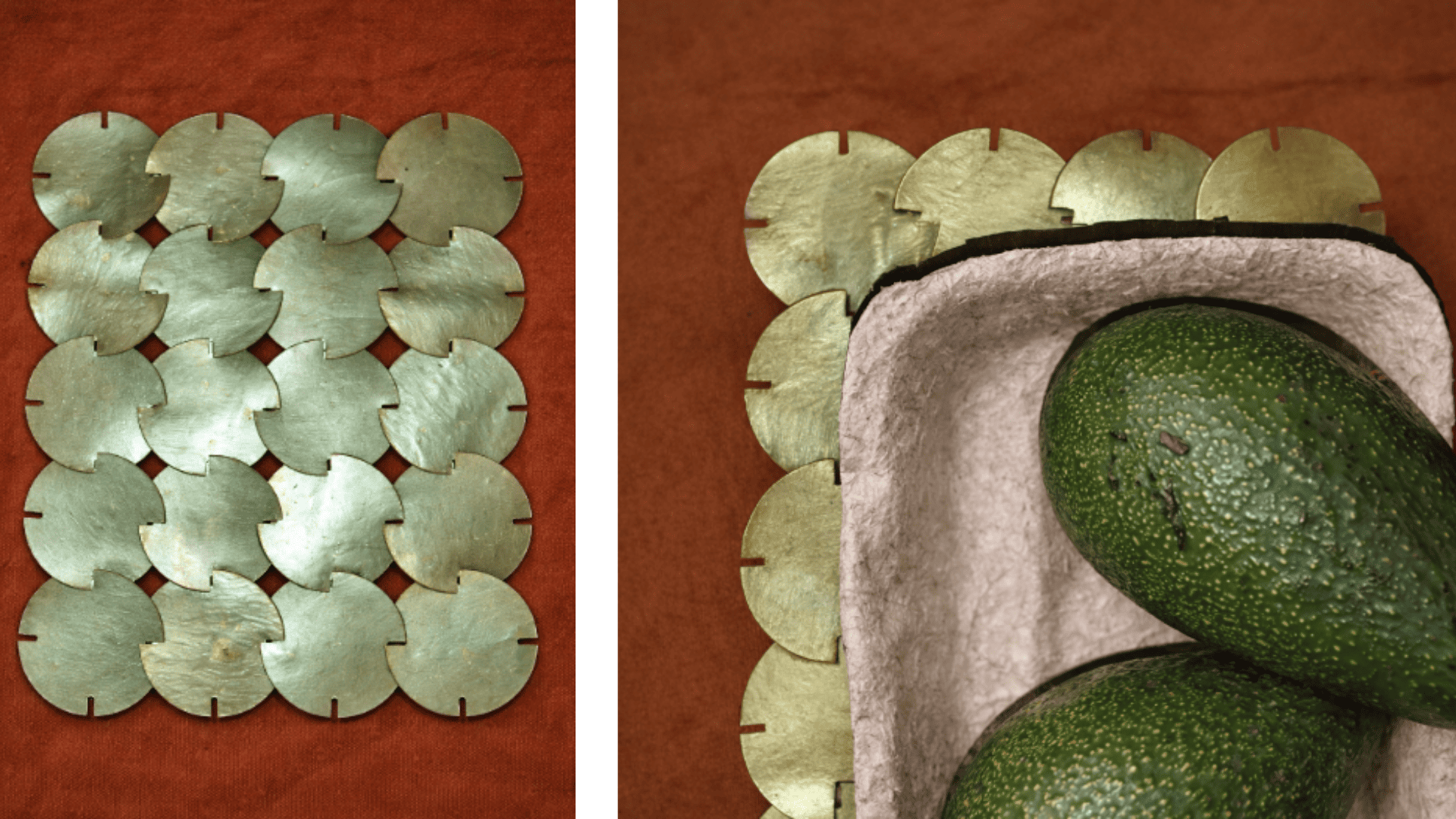

Parametric construction kit

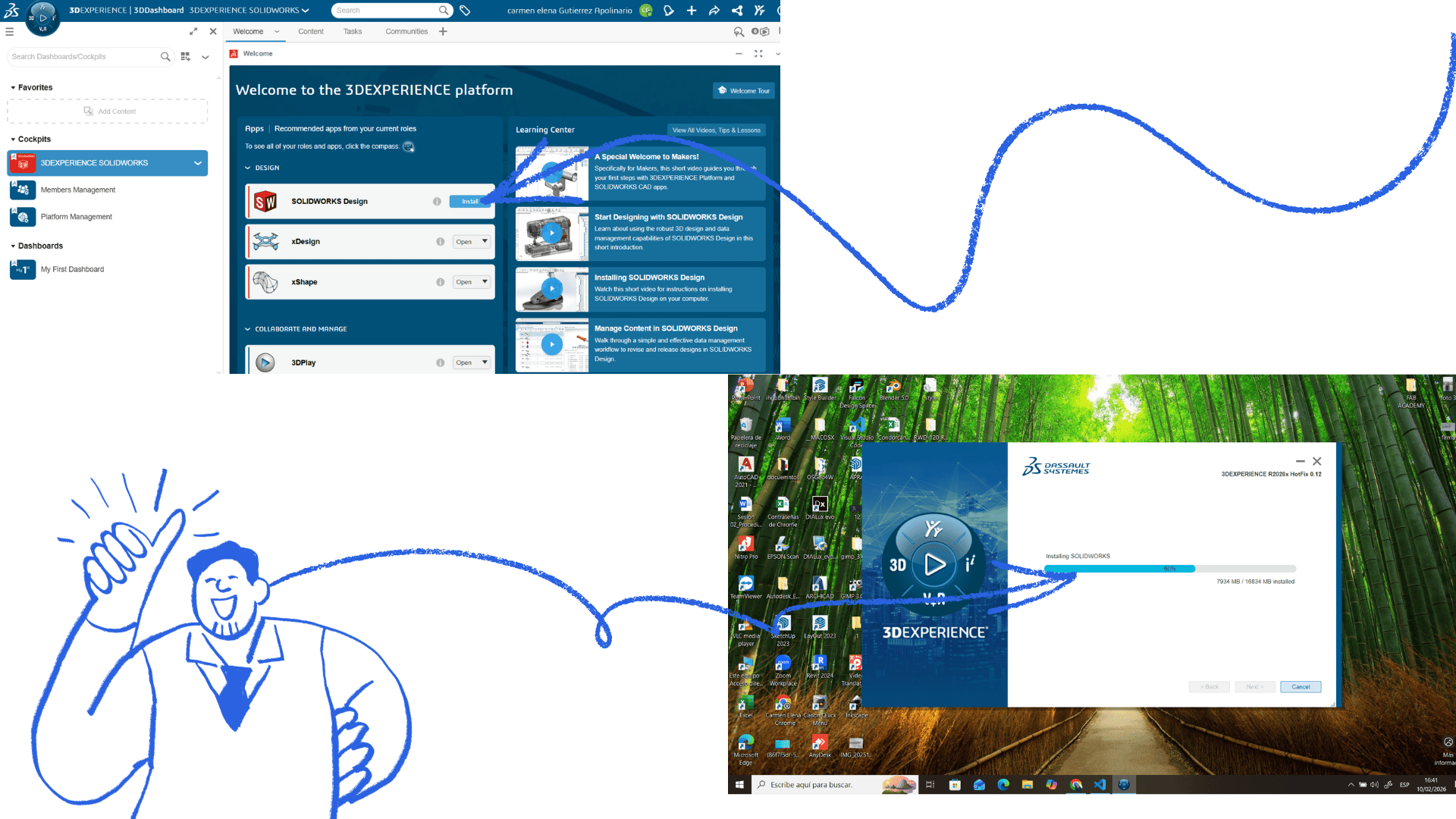

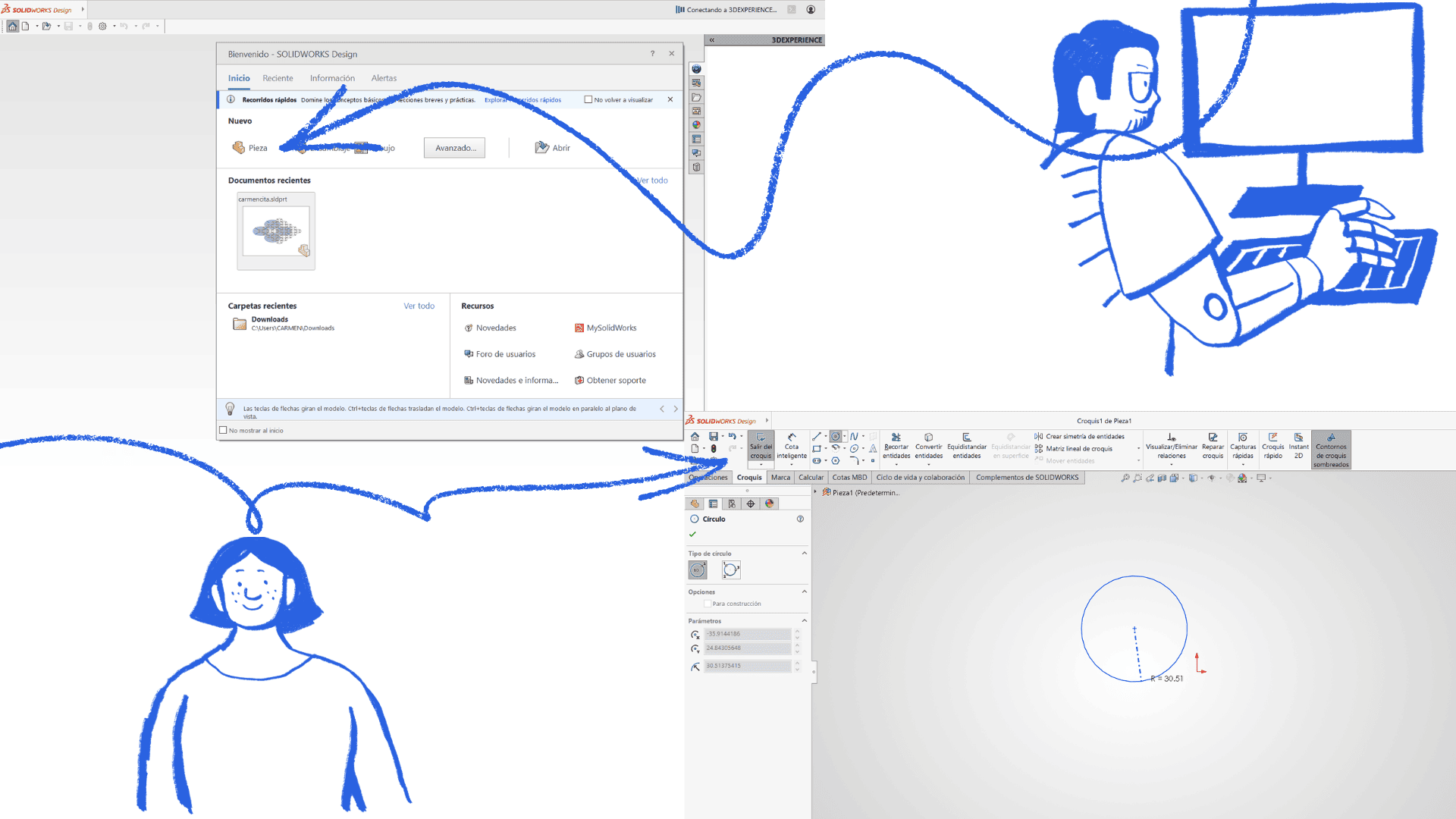

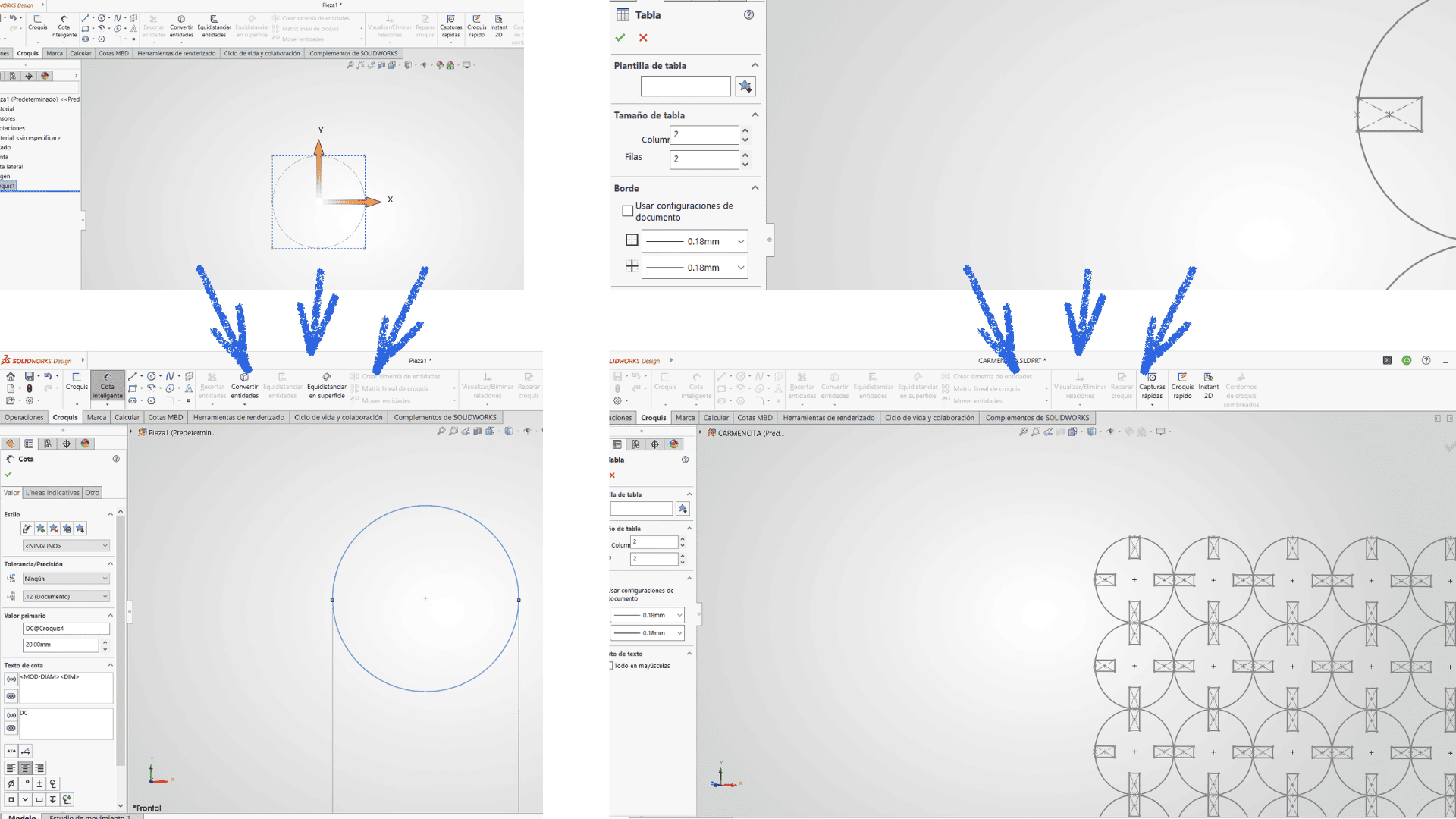

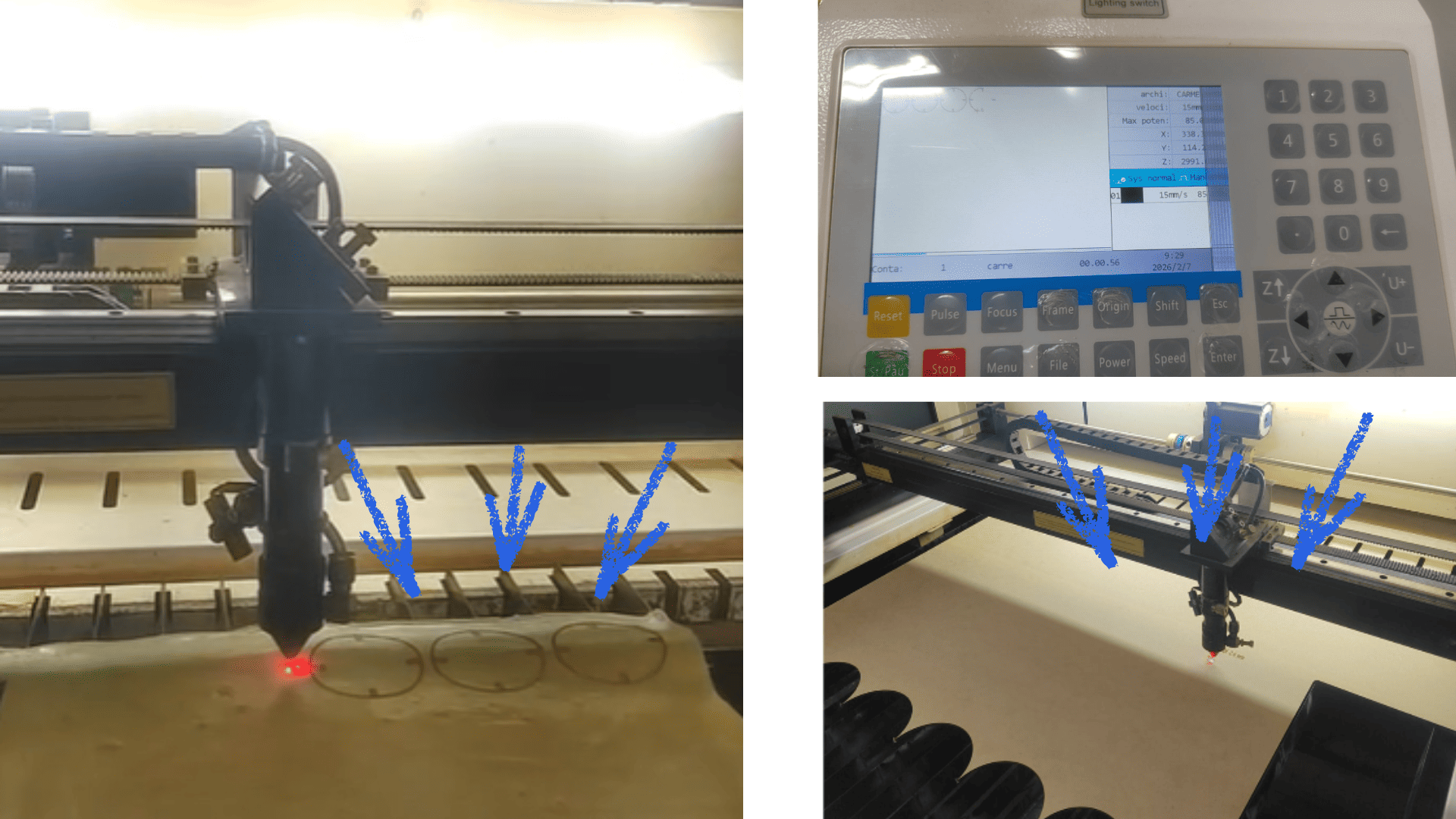

I downloaded and installed the SolidWorks software and then began the design process, starting with a basic shape—in this case, a circle. The intention was to experiment with the geometry and play with the form, establishing specific parameters and measurements from the outset. To do this, I took into account the actual thickness of the materials to be used: 2 mm MDF and 2.01 mm biopolymer. It was necessary to apply constraints and geometric relationships to ensure that the object had the correct proportions and maintained dimensional consistency. I also used the equations and values option in the toolbar to add the kerf to the joints in the base module. Subsequently, I performed the dimensioning, considering this reference, subtracting the kerf measurement from the joints to guarantee a proper fit between the pieces. Once the parameterization process was complete, I configured an array pattern to generate multiple copies along the X and Y axes. Finally, the file was exported in a format compatible with laser cutting and processed in RDWorks for manufacturing.

>

>

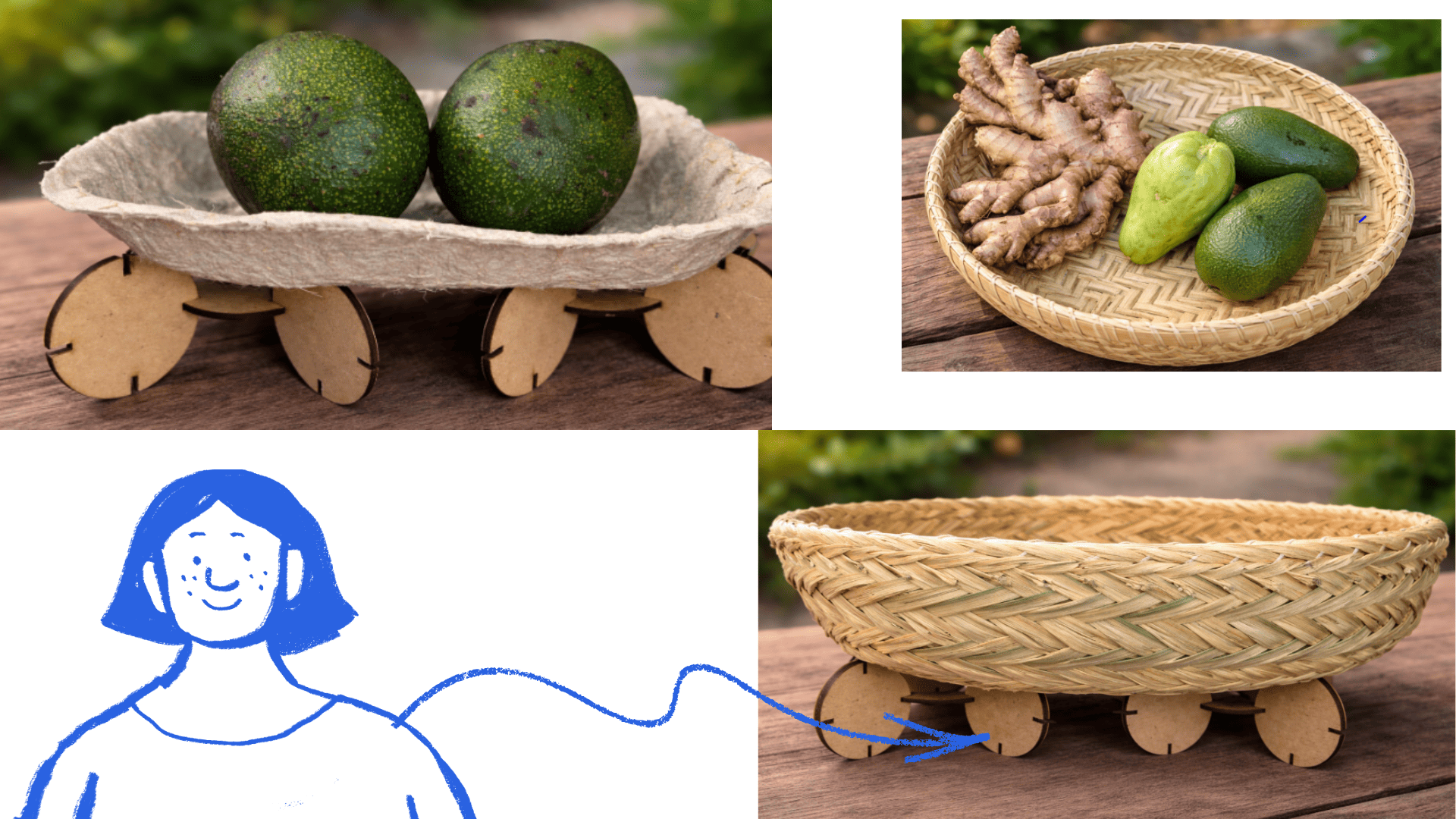

creations with the parametric kit

In this project, I had the opportunity to explore various materials: one commercial, like MDF, and another developed in the biomaterials workshops, specifically a biopolymer. In the creation of these biomaterials, we incorporated natural pigments from local communities, such as annatto, turmeric, and coffee grounds. This allowed us not only to experiment with physical properties but also to integrate local identity and knowledge into the process. This week, we conducted a workshop for teachers from Pangoa and Satipo, in the native community of Cheni. This experience was very meaningful, as the training was geared toward participants from across the Pangoa River basin. In this workshop, I shared the work developed in week 3, especially the biomaterial creation process and the parametric cuts made with the biopolymer. The teachers quickly associated the parametric pieces with pedagogical applications. They proposed using them as a teaching resource for addition and subtraction, by adding or removing circles that fit together without adhesives, thanks to the interlocking system. The same thing happened with the pieces made of MDF. It was very interesting to observe how they began to generate different shapes and configurations from the same basic module. The most valuable aspect was understanding, from a different perspective, the potential of these designs. In addition to their educational use, they identified that they could function as supports for baskets made in the community, creating bases for plates or display structures. This experience demonstrated how parametric design and biomaterials can interact with pedagogy and local production, expanding their application possibilities.

creations with the parametric kit

creations with the parametric kit

creations with the parametric kit

creations with the parametric kit

creations with the parametric kit

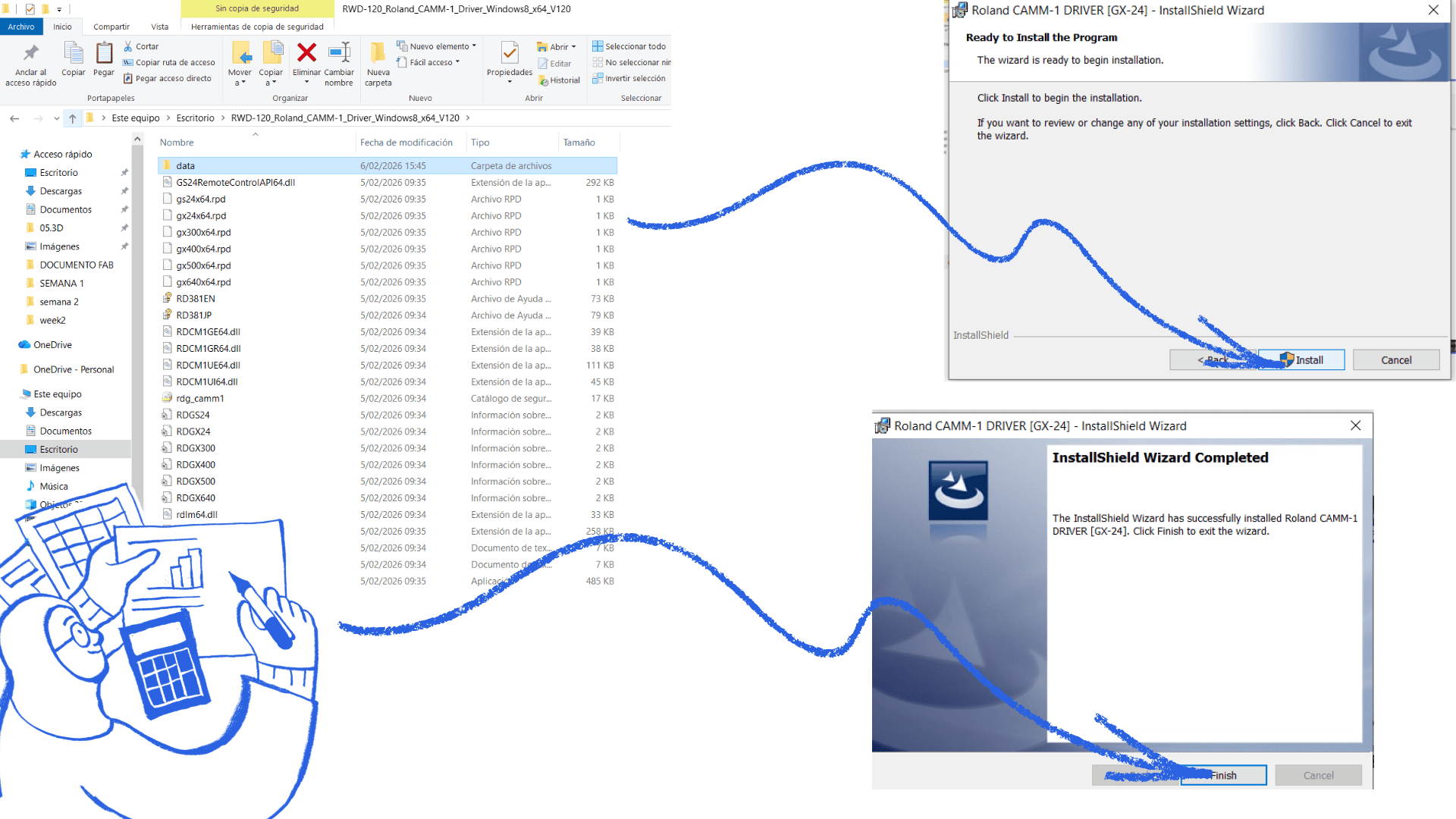

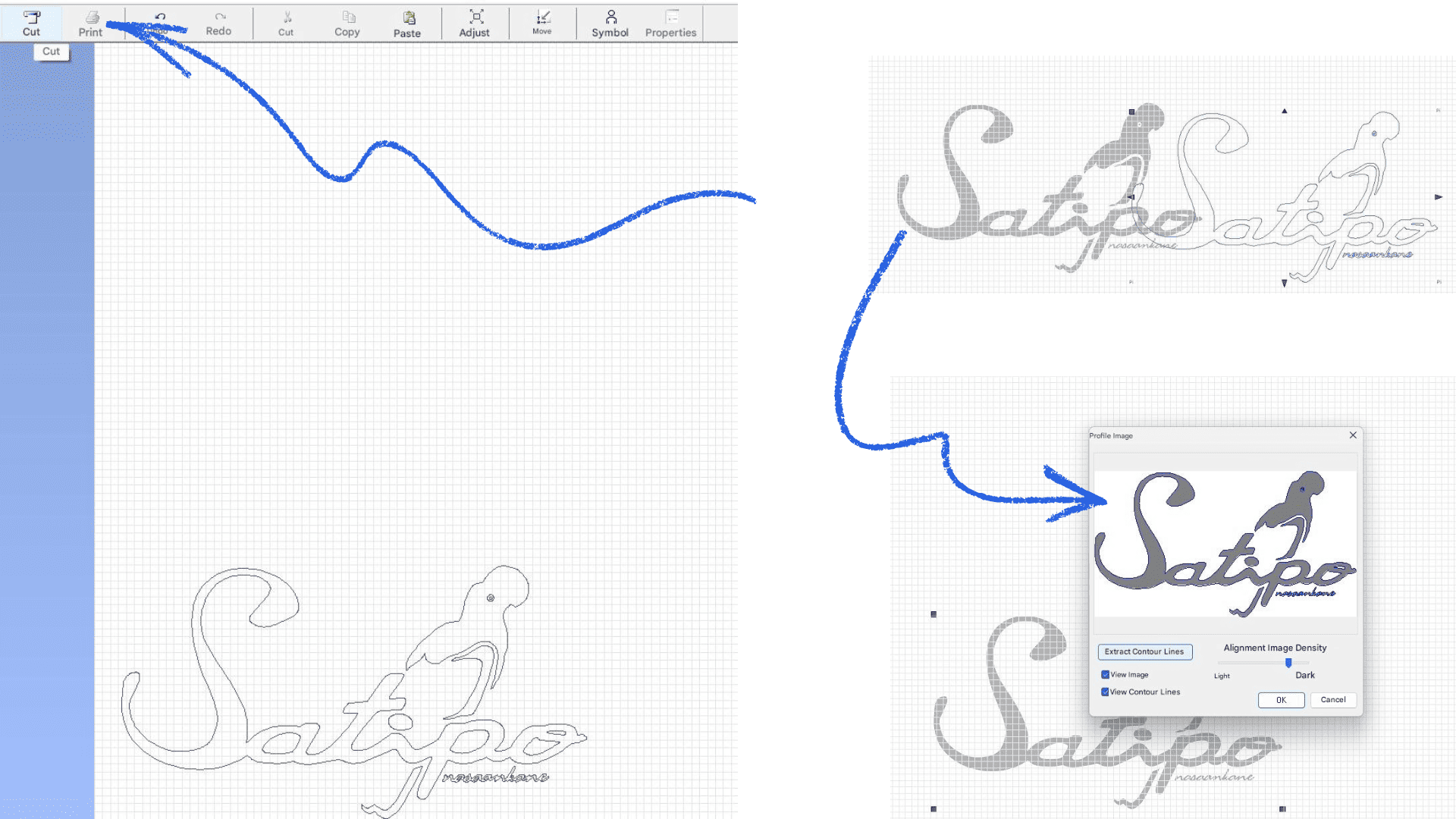

Vinyl cutting

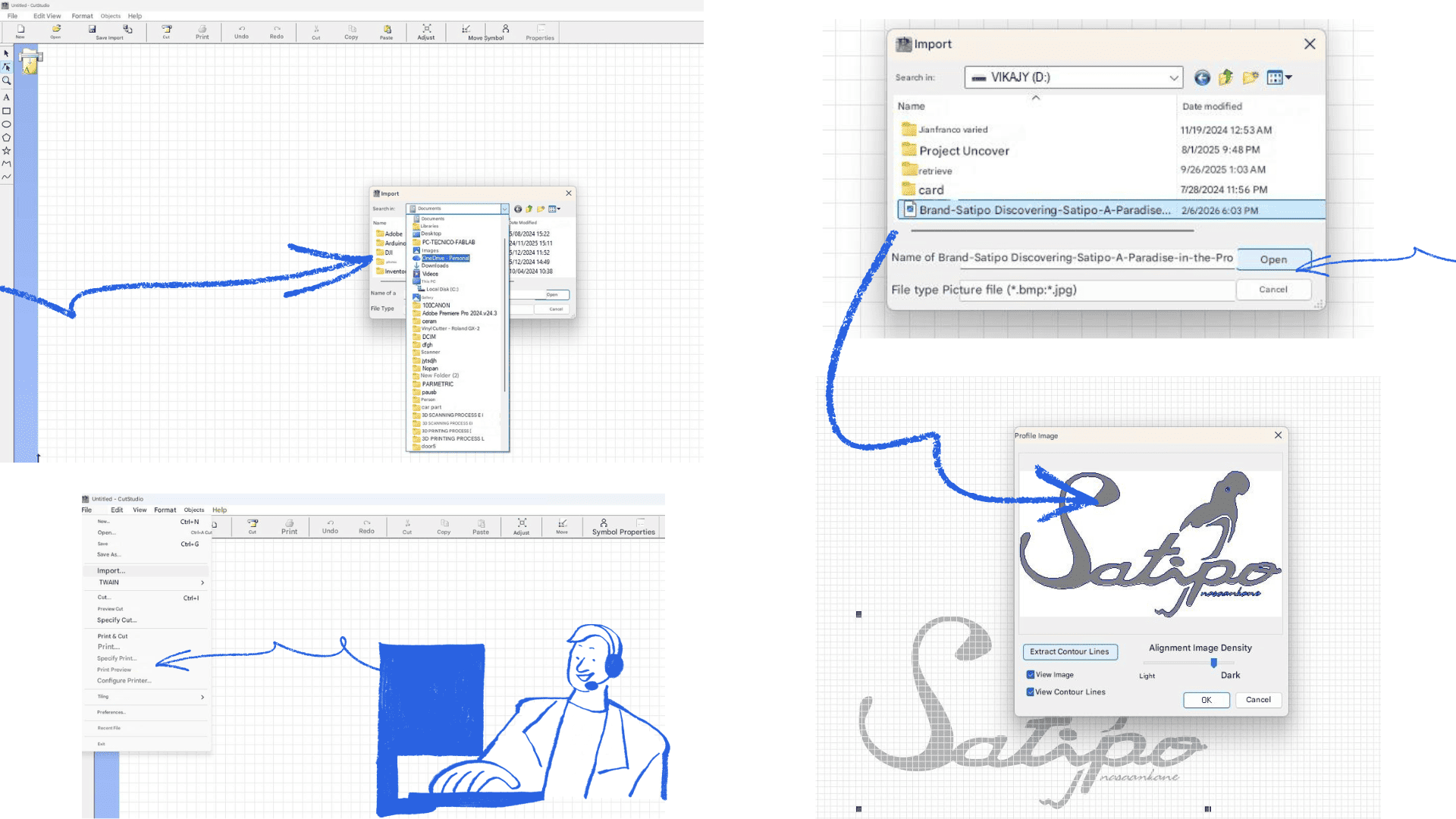

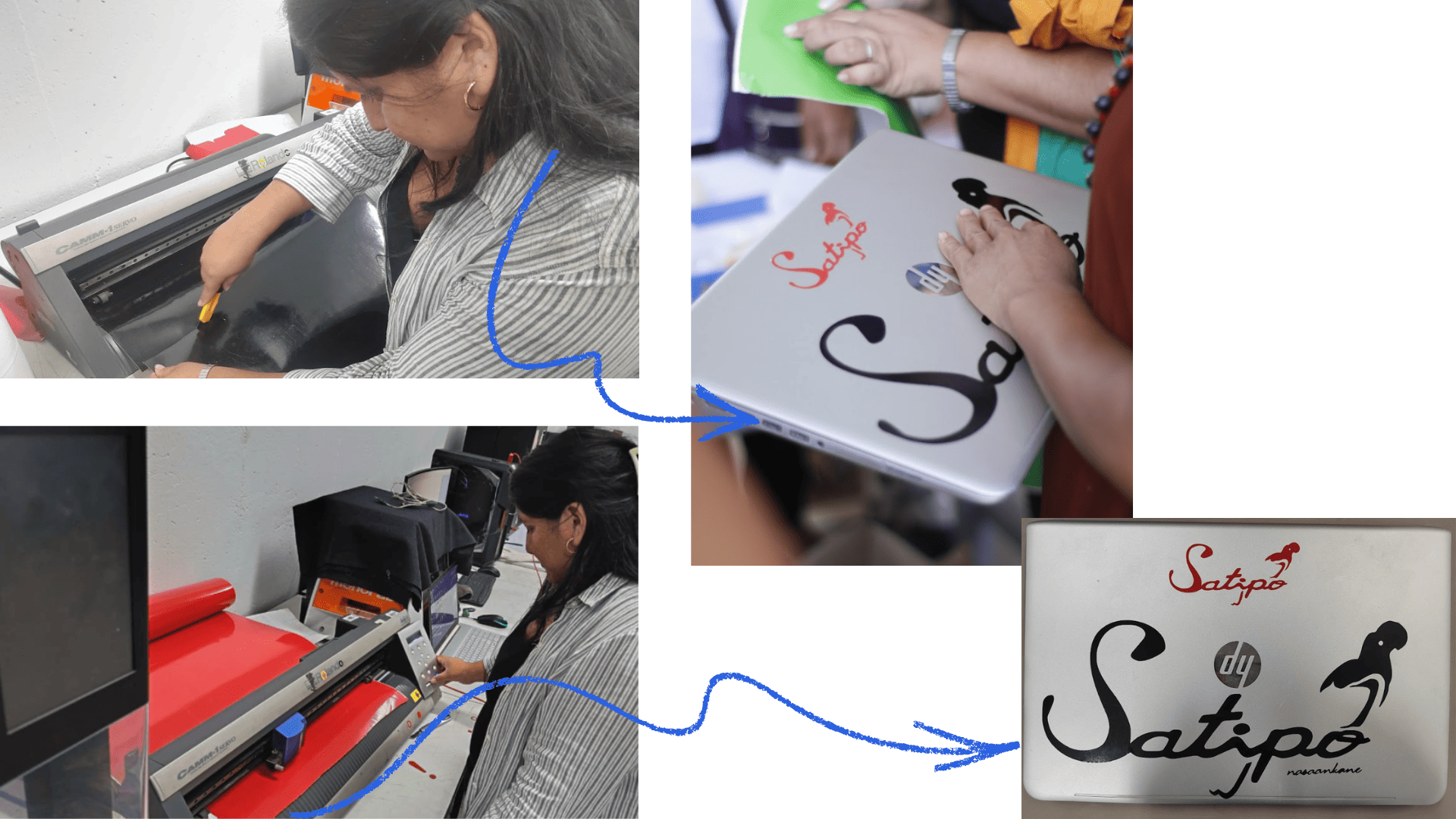

We performed the vinyl cutting using the Roland GX-24 machine at Fab Lab UNI, which accepts materials up to 60 cm wide. Initially, we installed the corresponding software. The lab manager explained how the machine works, its main parameters, and provided recommendations for proper use.

Afterward, we began working with the vinyl cutter. We used a JPG image, which was imported into the program. Using the same software, we performed the vectorization process (rasterization/tracing), which converts the image into cutting lines so it can be sent correctly to the machine. Then, we adjusted the cutting parameters, such as speed and pressure, according to the type of vinyl used.

I decided to work with the Satipo brand logo, conducting tests in different sizes and colors. Once the cut was made, I proceeded with the weeding and transfer process to apply it to my laptop. The result was satisfactory, as the vinyl adhered correctly, without tearing or causing any difficulties during application.

This practice allowed for a better understanding of the workflow from file preparation to final vinyl application, as well as the importance of properly configuring the parameters according to the material.

Vinyl cutting

Vinyl cutting

creations with vinyl

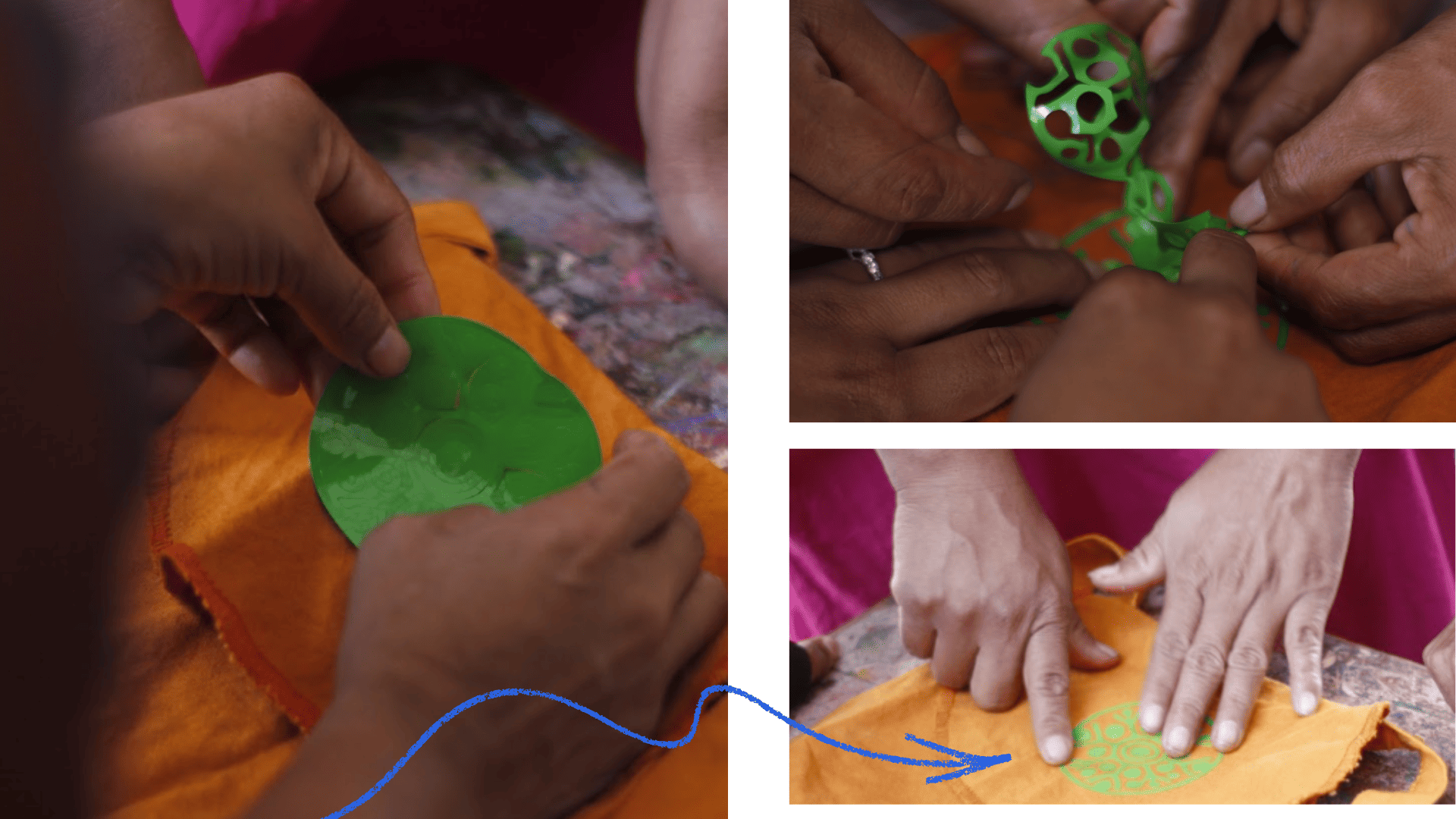

During the activity in the native community of Cheni, I also had the opportunity to share my knowledge of vinyl cutting with the participating teachers. I brought some pre-cut versions of the REGEN logo to demonstrate the process and the application possibilities of this technique.

The teachers applied the vinyl to a bag made of tocuyo, a traditional fabric, dyed with pochotoroki, a natural bark used to dye cusma (a type of tunic). The experience was very enriching, as it allowed us to integrate digital technology with the community's own knowledge and materials.

In this way, it became clear how vinyl cutting can complement artisanal processes, generating new design proposals that respect local cultural identity.

Vinyl cutting

Vinyl cutting

Reflection

2D and 3D design programs play a fundamental role in current creative and technical processes. 2D programs allow you to work on flat surfaces, facilitating the creation of drawings, plans, illustrations, and graphic designs. Their simplicity makes them ideal for initial conceptualization, rapid visual communication, and the development of basic ideas. On the other hand, 3D programs expand these possibilities by allowing you to represent objects with volume, depth, and realism. Thanks to them, it is possible to visualize spaces, products, or structures from different angles, simulate materials, and better understand the spatial relationship of elements. This is especially useful in areas such as architecture, industrial design, and animation. These two types of programs are not mutually exclusive; rather, they complement each other. 2D design is usually the starting point for sketches and diagrams, while 3D design allows you to transform those ideas into more complete and realistic models. Together, the appropriate use of 2D and 3D tools strengthens creativity, improves design accuracy, and optimizes learning and production processes.