Computer-Controlled Cutting

Task:-

Group assignment: lab's safety training, Characterize lasercutter's focus, power, speed, rate, kerf, joint clearance and types.

Documenting my work to the group work page and reflect on my individual page what i learned.

Individual assignments: Design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, Cut something on the vinyl cutter.

Group Assisgnment

For detailed information, refer to group assisgnment page

Personal reflection: Safety Measurements

If you are not aware of what might go wrong, how to handle it if it happens,

and how to avoid putting yourself in such situations in the first place, you may put yourself at risk.

Machines in the lab are expensive and powerful, so for both our safety and machines, we must be aware of

and responsible for following proper safety measures.

In case anything catches fire (laser cutting), do not open the lid immediately.

Either press the emergency switch or pause the machine's job first.

Always keep the exhaust ON while operating the machine.

The most important rule is to never leave the machine unattended while it is running.

Make sure the materials being used are suitable for the particular machine. For example, in laser cutting,

we should not cut PVC or ABS, as they release hazardous gases.

Practice using proper PPE (Personal Protective Equipment) such as mask, gloves, and goggles as part of general safety measures.

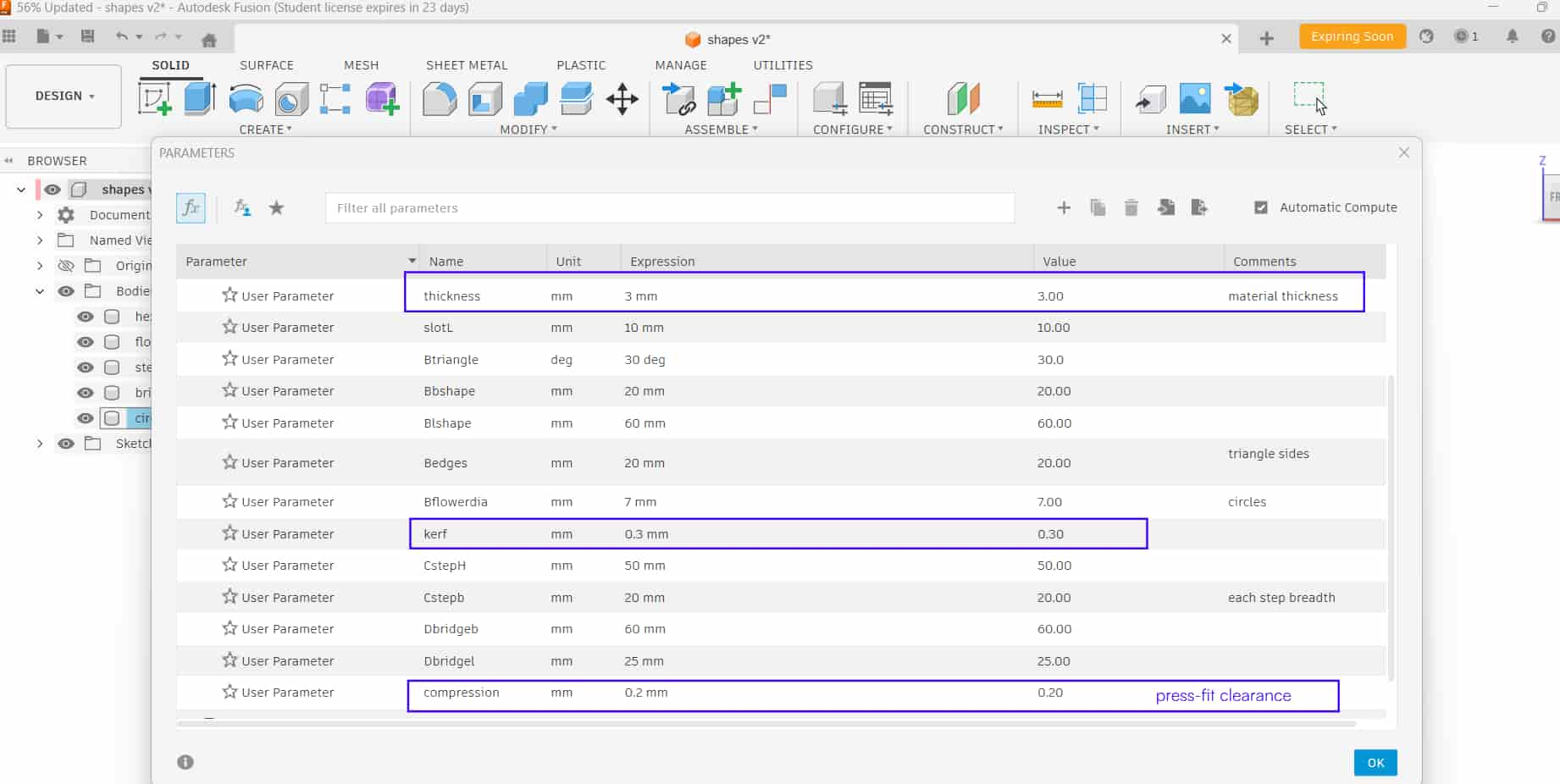

As it is a group assignment, our instructor made us all try designing a parametric test jig sketch in Fusion 360 individually, so that we can understand how to adjust slot dimensions parametrically and test different fitting tolerances. As the result of test we found value of kerf, press fit, material thickness.

Kerf

refers to the amount of material that is removed by the laser beam during the Laser cutting process.

Kerf values we got from test are :

Carboard: 0.3mm

Wood:mm

Acrylic:mm

Press fit

For getting tight-fit joints, we need to know the compression or press-fit tolerance of the materials.

By adjusting the slot width based on the compression value, we can achieve joints that fit tightly.

Press-fit clearance: 0.2mm

Individual Assignments

Computer Controlled Cutting - using machines that follows x and y coordinates to cut or engrave materials.

Before starting with CAM, i think we need to be clear with what is the difference between fabrication and Manufacturing, it was pretty confusing for me.

From my understanding:

Fabrication: the process of making something by joining things / parts together,

prototyping and making almost anything. This includes cutting , bending , welding them to create a finished product,

in small batches. Making parts or prototypes that meets the design.

Manufacturing: it could be in large scale, mass production, converting raw materials to finished goods for customers.

it is highly standardised so that each batch of the products turns out to be same.

Material use is optimised for cost and waste reduction.

Digital fabrication- is the process of desiging things using digital softwares then producing them using computer- controlled machine.

Machines like 3d printers, lasercutter, cnc machines, vinyl cutter.

The basic workflow- designing on computer >> send the file to a machine >> machine makes the tangible object out of it automatically.

CAM - Computer Aided Manufacturing - it is a software process of converting cad designs into machine instructions(toolpath / g-code).

Basically it is like translator who translate the design language into machine language, so that machine can understand:

- Where to move

- How deep to cut

- What power, speed

- Machining sequence

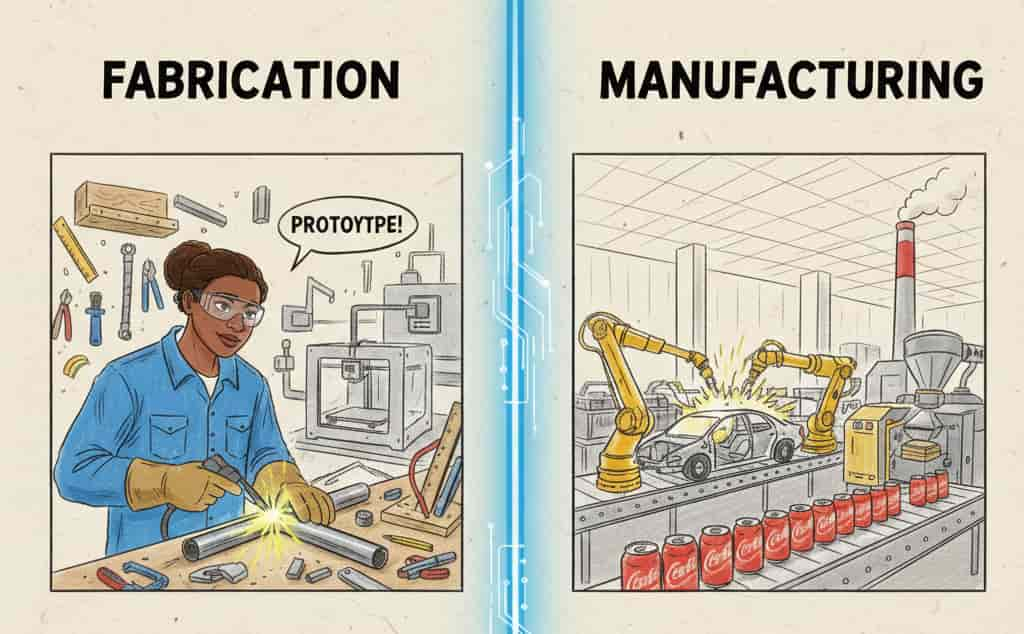

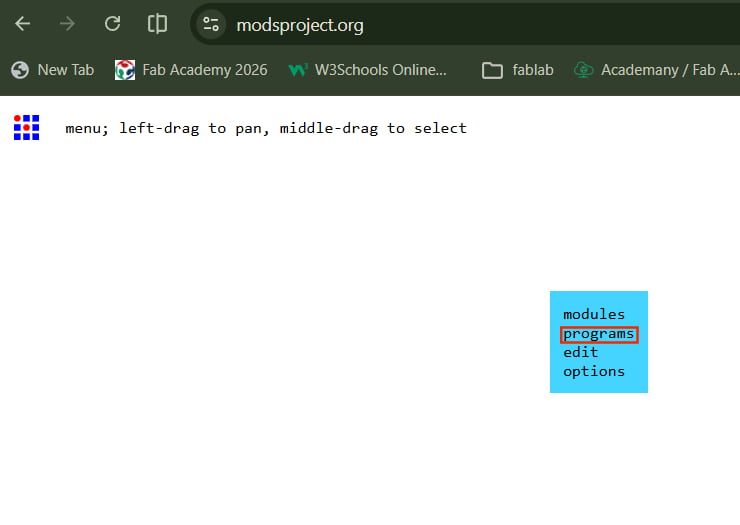

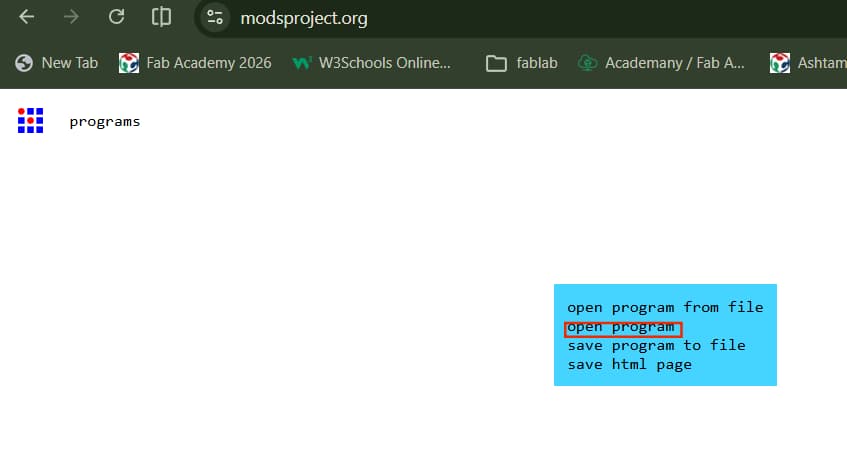

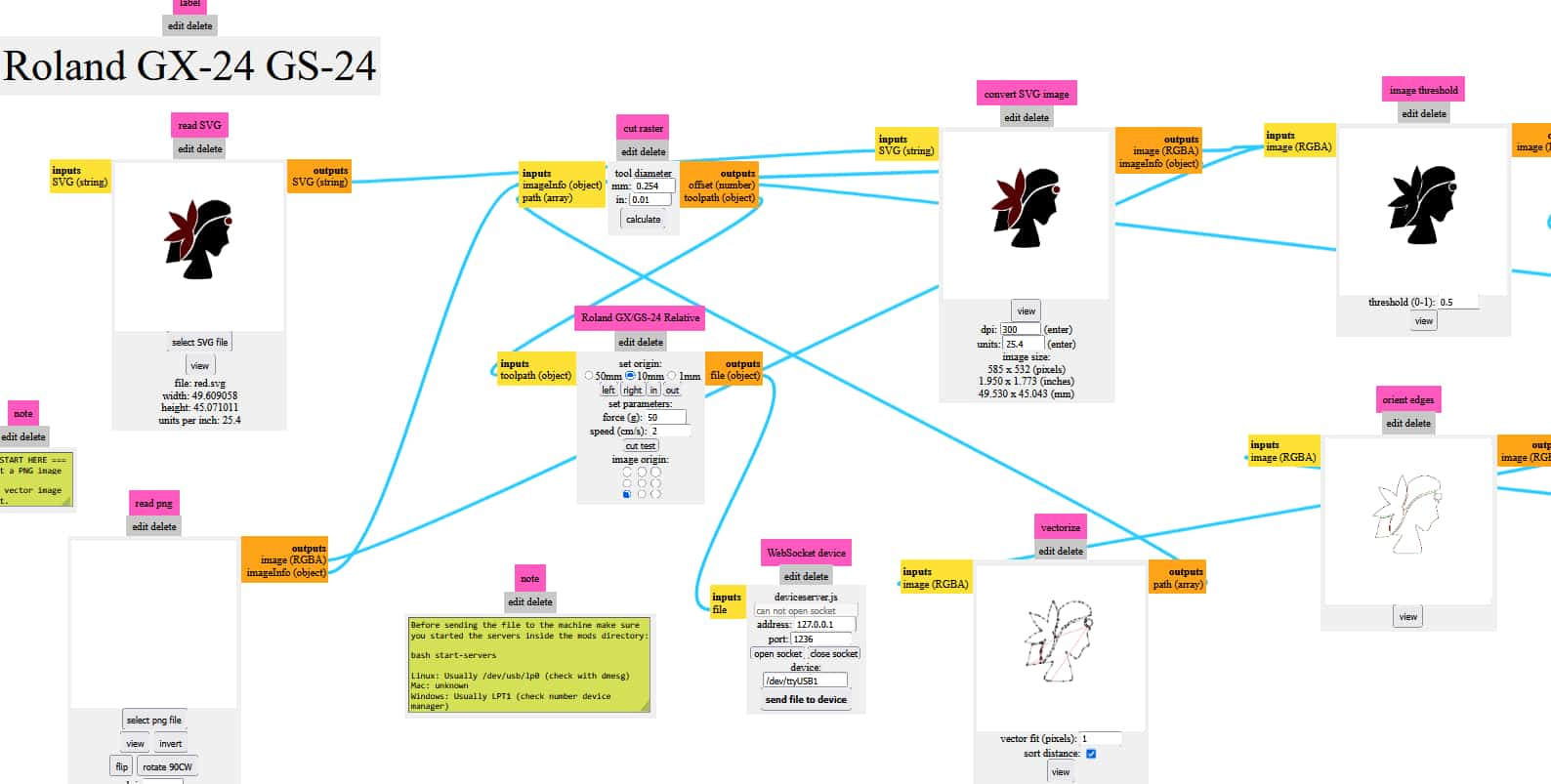

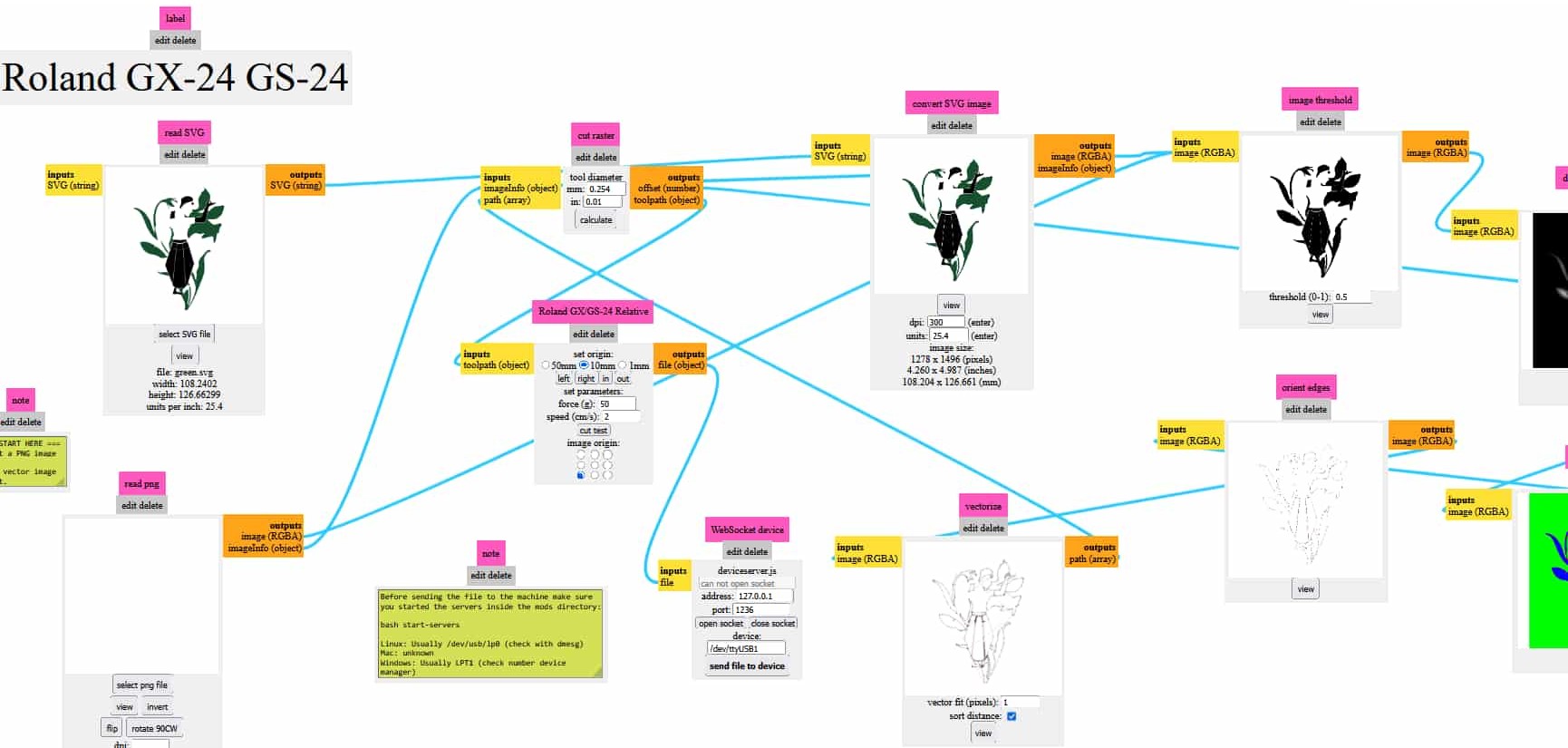

Mods Project

Here in fablab, we basically use ModsProject to send files to machine, which is browser based CAM open-source platform where you can connect fabrication machines and send file to machine.As its name mods, it is modular tool space where small functional blocks / modules connects together to create manufacturing workflow, like an ecosystem for digital fabrication machine. It is developed at MIT's center for bits and atoms by Prof. Neil Gershenfeld.

Workflow: import design files in svg then convert them into paths, sends machine instructions directly to machines (like vinyl cutter) using “send file to device.”.

Cut something on Vinyl Cutter.

What is vinyl cutter?

A computer-controlled cutting machine that uses a small blade to cut designs into a sheet of vinyl. The cutter is guided by a design that is created on a computer and sent to the machine.

The excess vinyl is then removed by tweezers, blades, leaving behind the desired design. For applying the design to a surface can be done using heat press or adhesive.

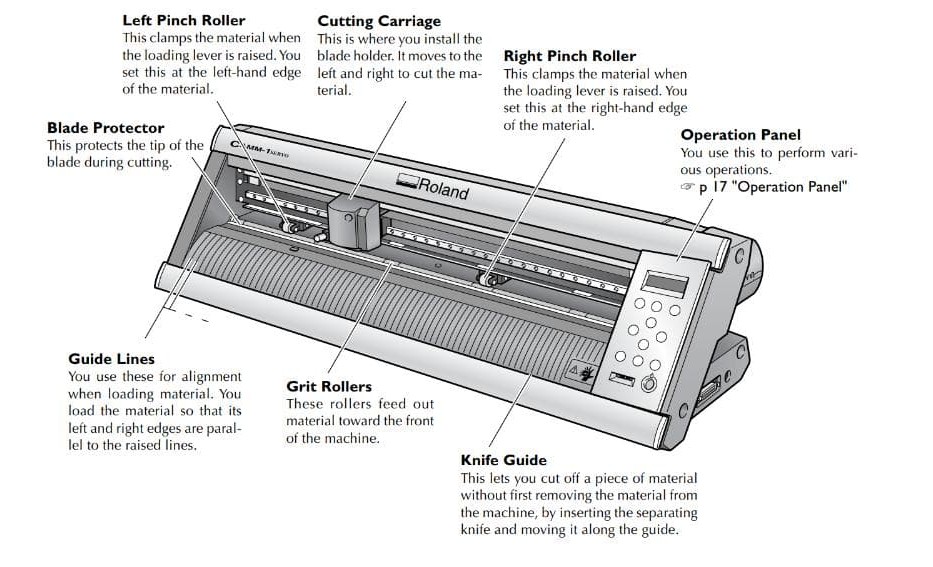

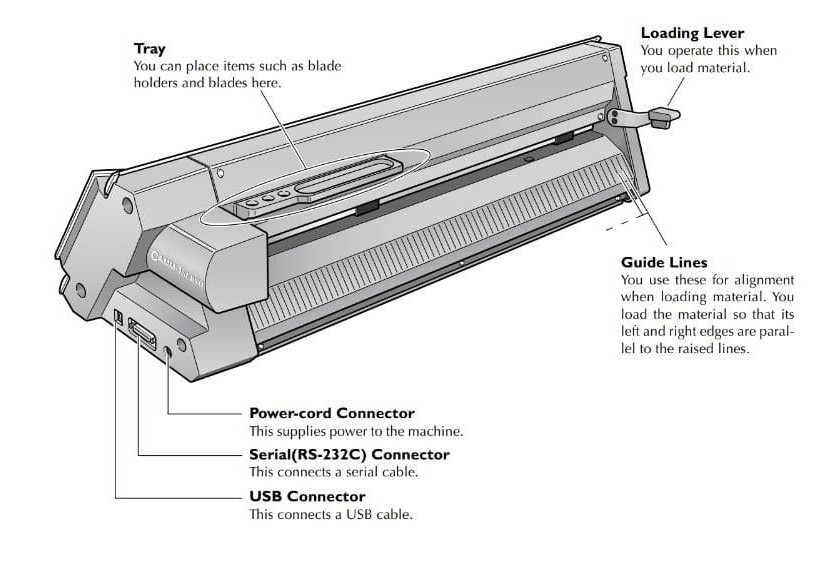

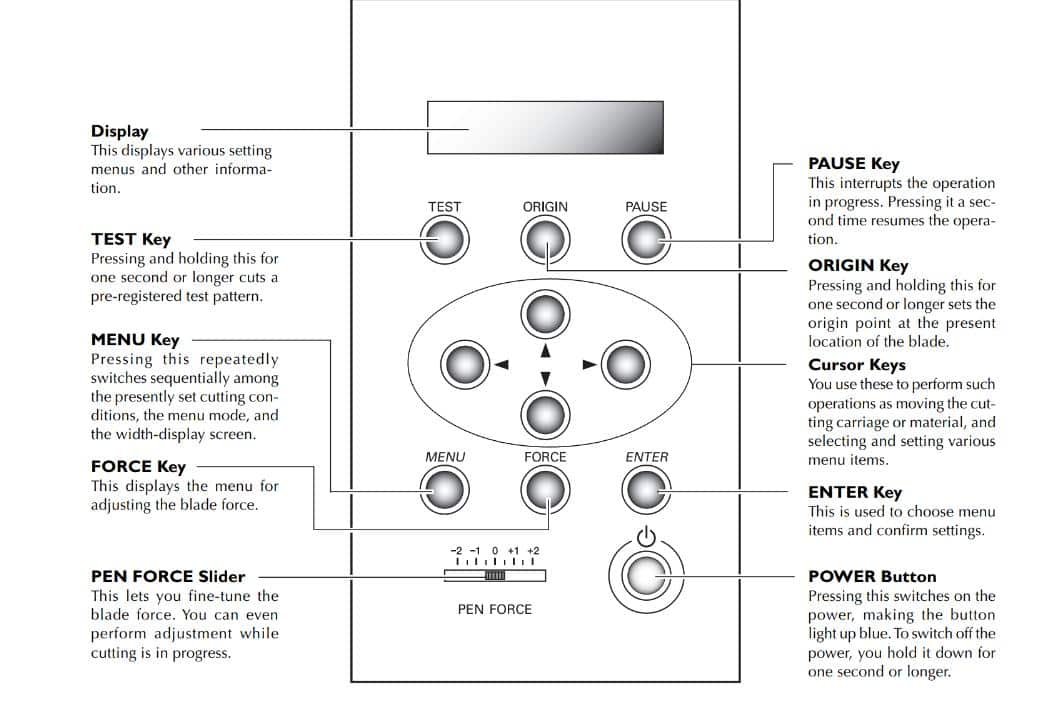

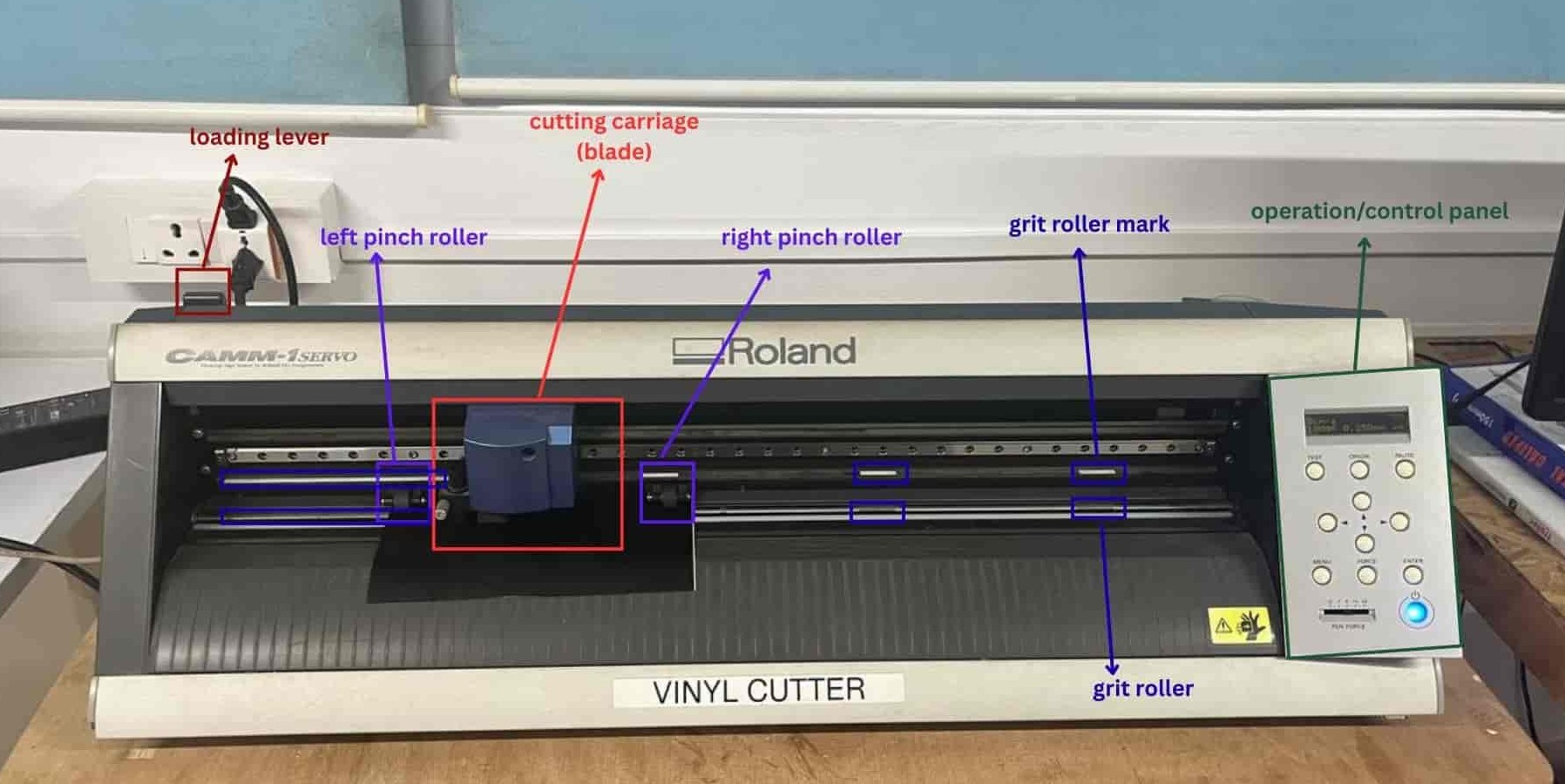

Roland gx-24

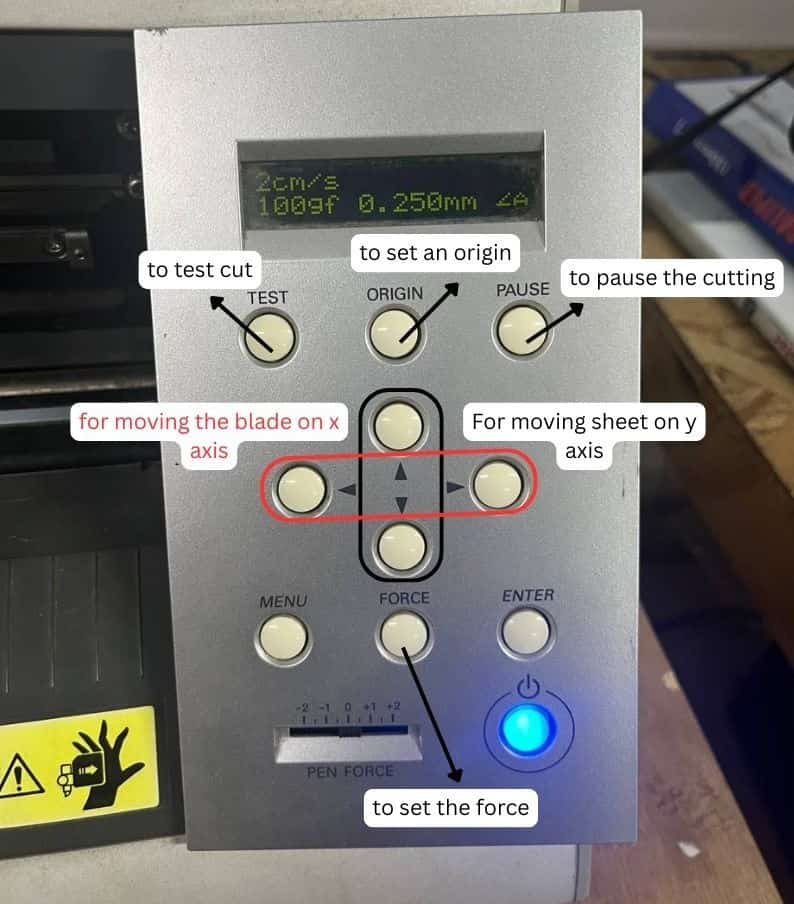

In our fablab, we have roland gs-24; as it is pretty old the control button needs extra force while pressing,

sometimes for enter button - either long press it or press short, depends on its mood.

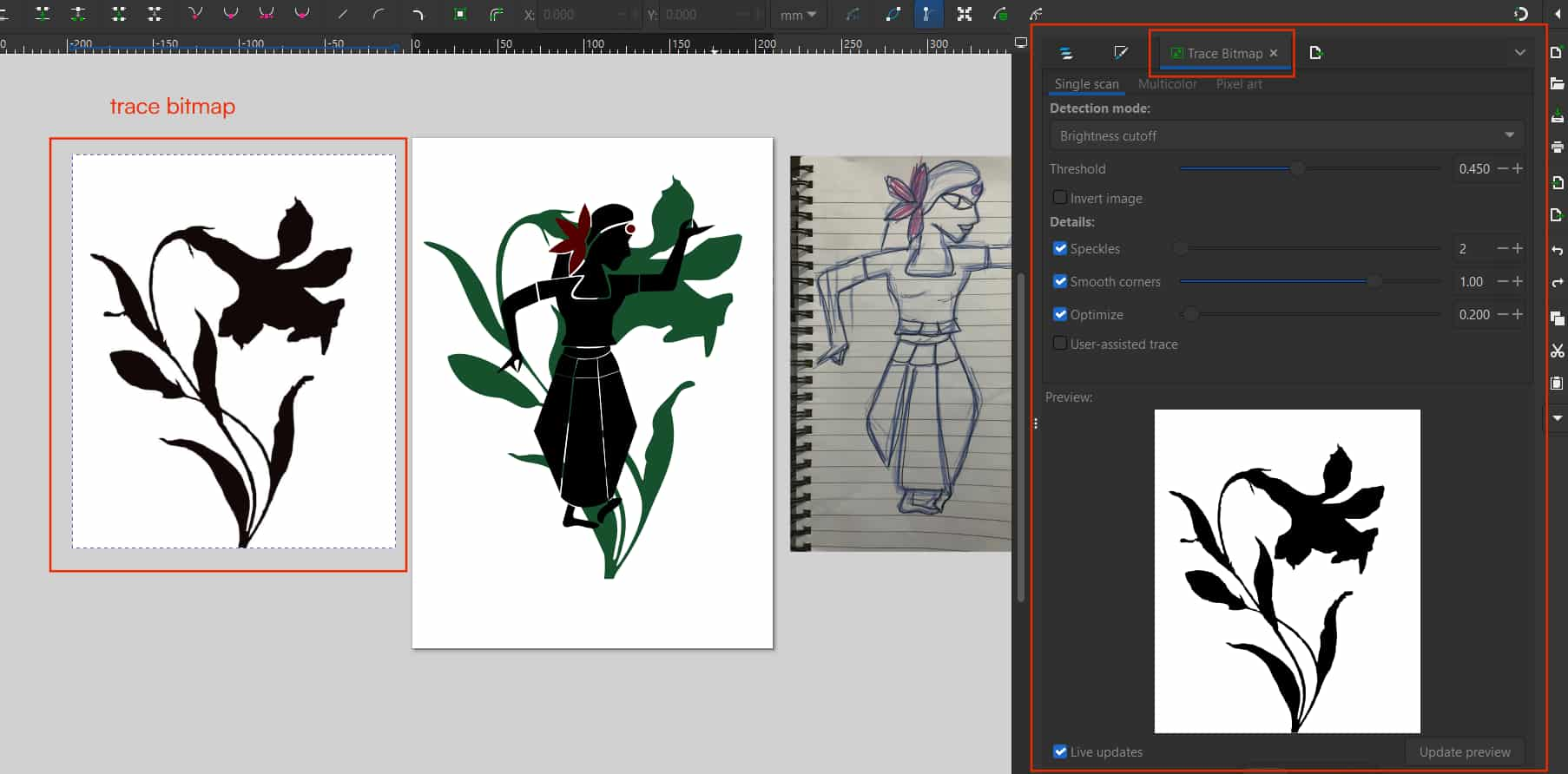

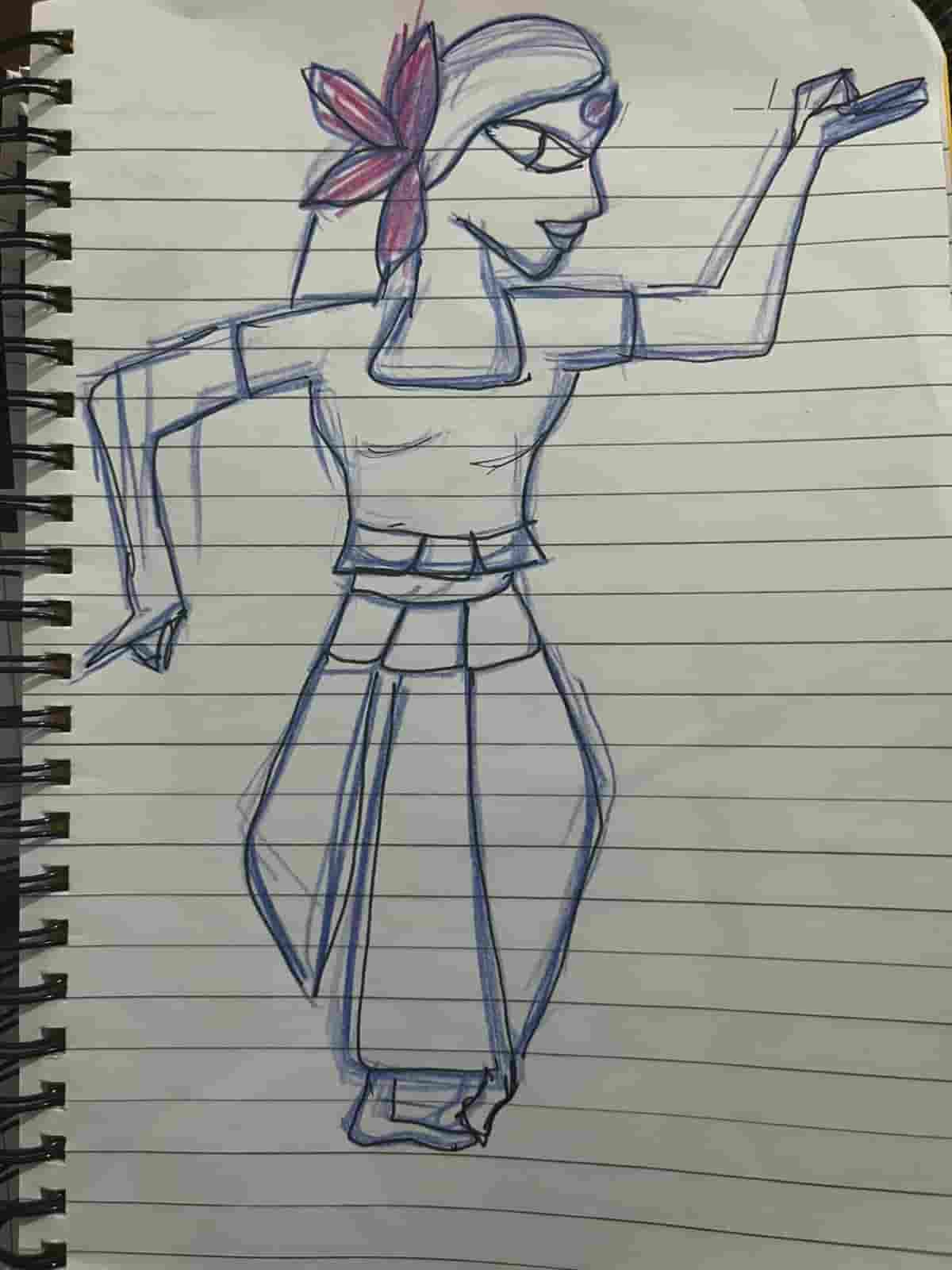

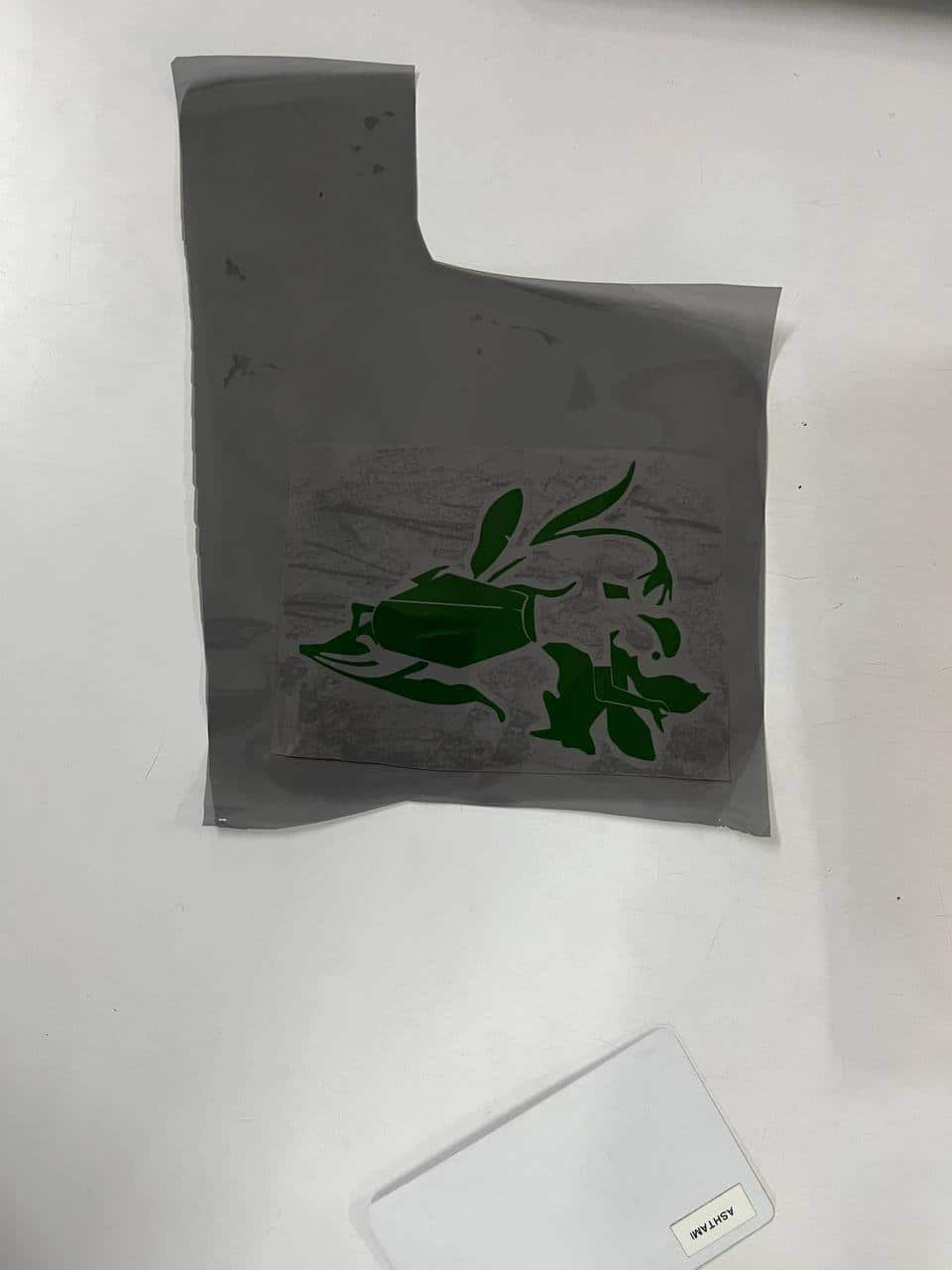

Inkscape: Designing Sticker

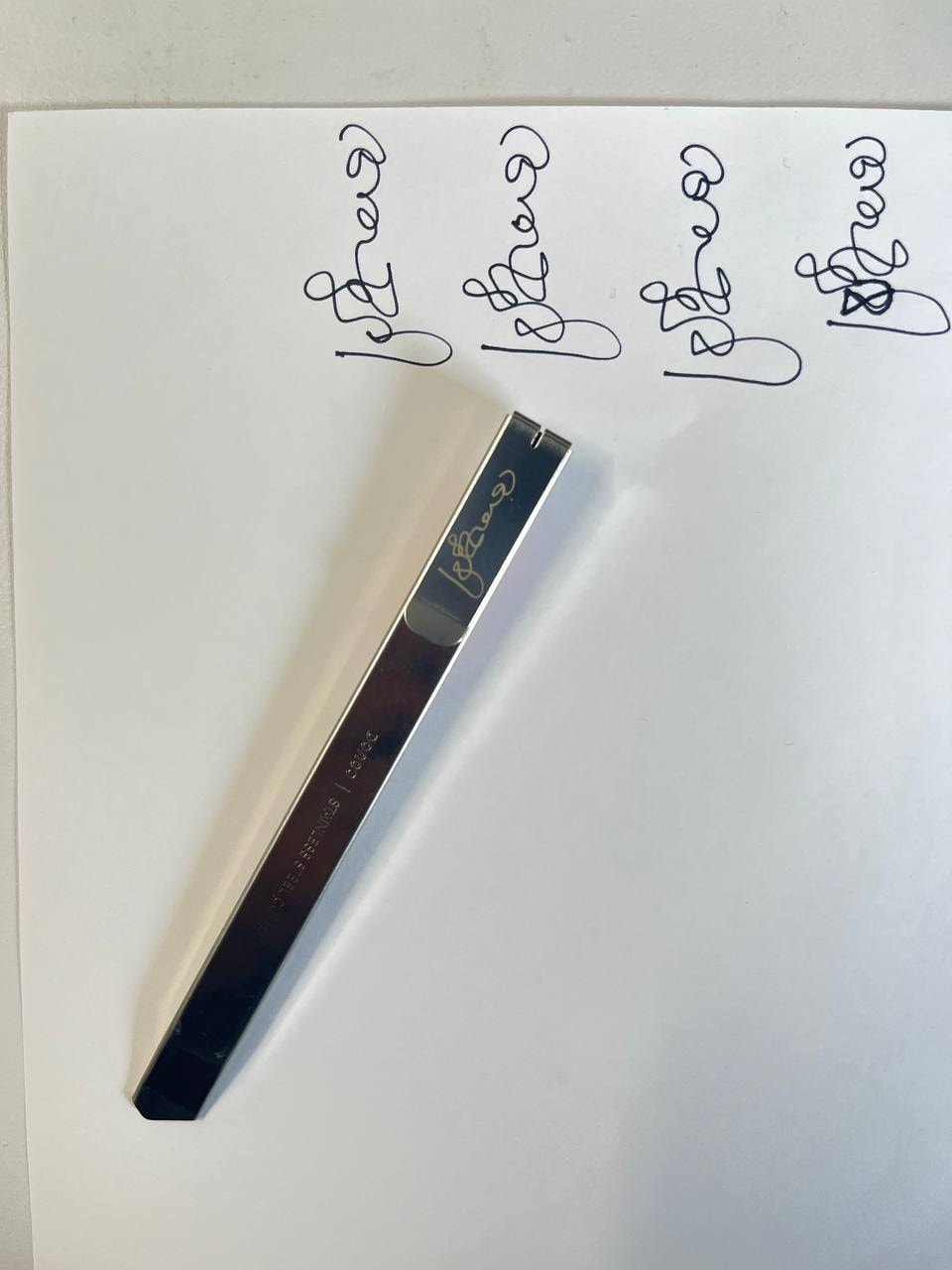

I started by designing the sticker in Inkscape. First, I sketched an Indian classical dancer on my notebook and then imported that sketch into Inkscape.

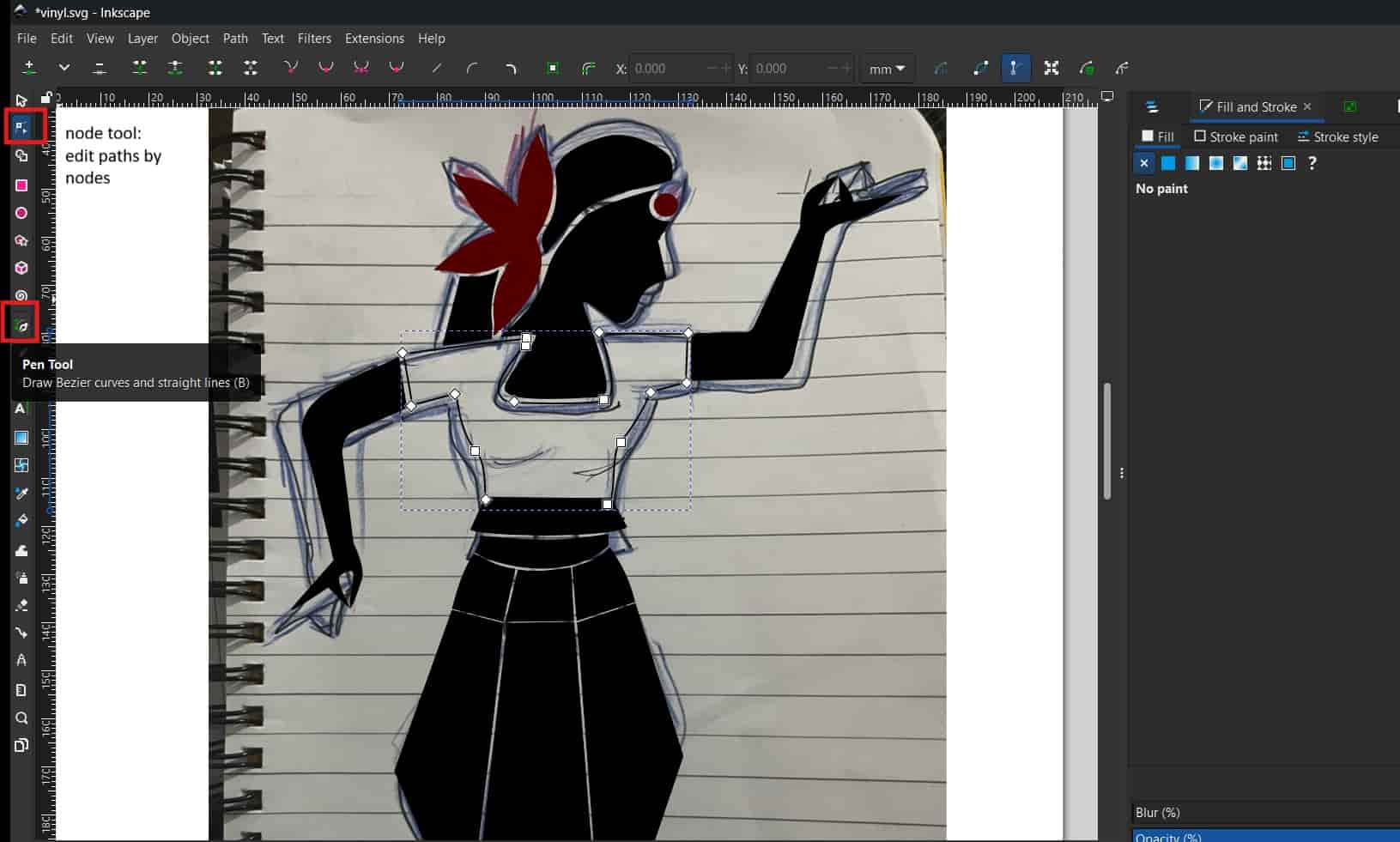

Pen Tool

Using the Pen tool, traced the sketch on the digital canvas

Node Tool

Using the Node tool, adjusted the paths to refine the shapes.

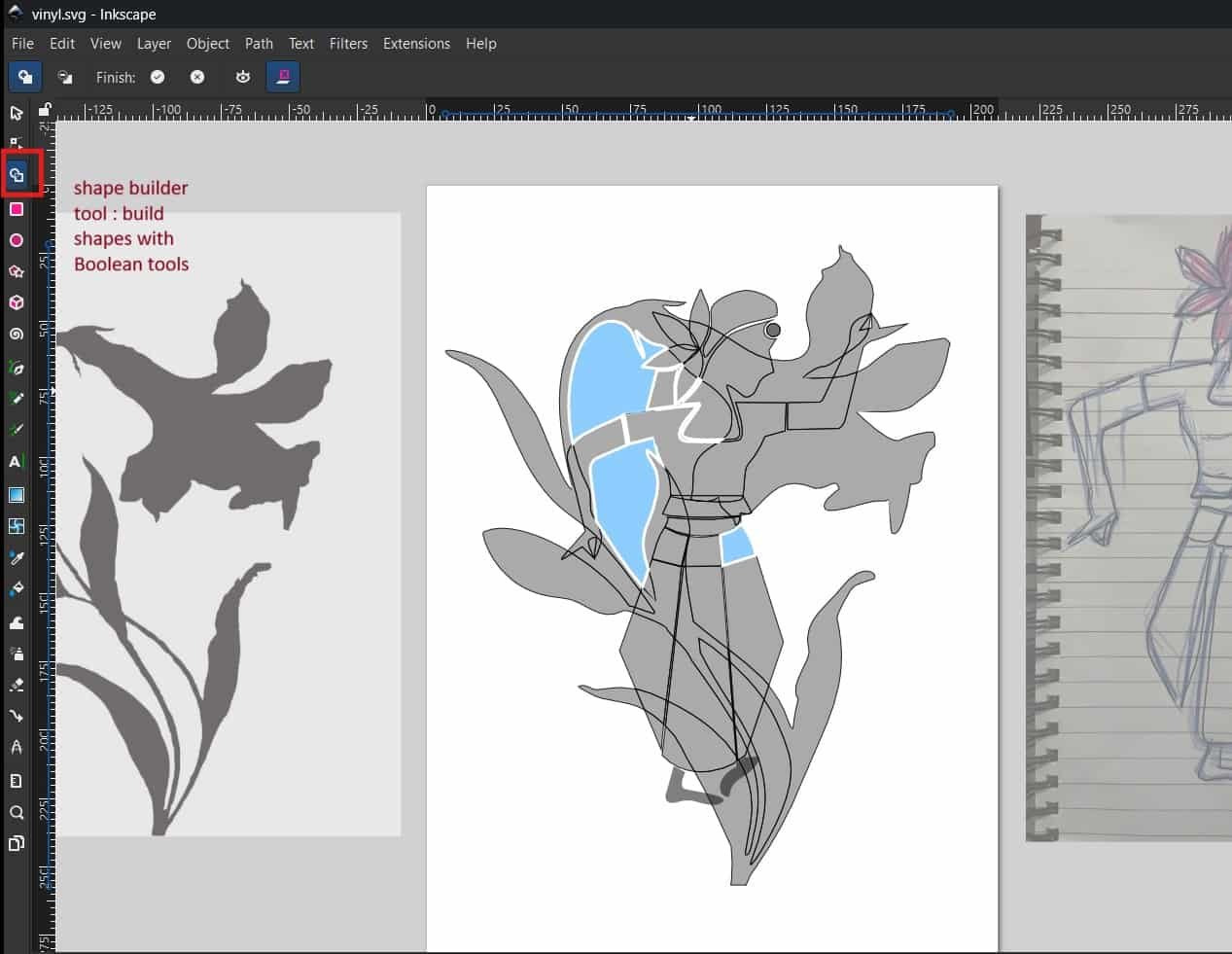

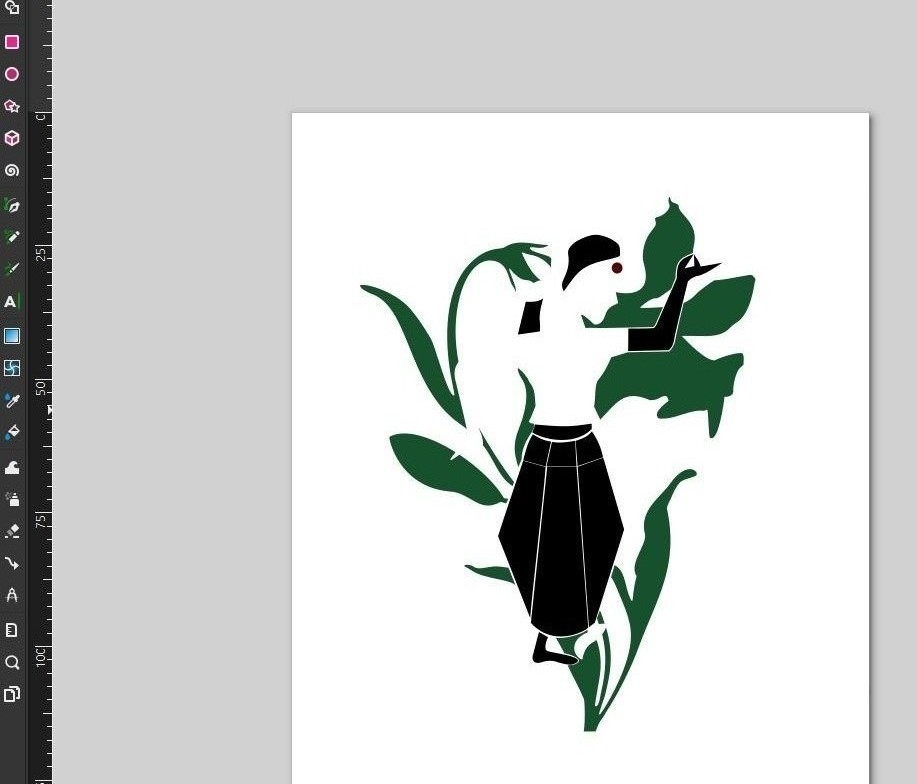

I wanted to add a flower behind the dancer, so I downloaded a flower image from Pinterest and imported it into Inkscape

Trace Bitmap

Using the Trace Bitmap feature, converted the image into a vector graphic.

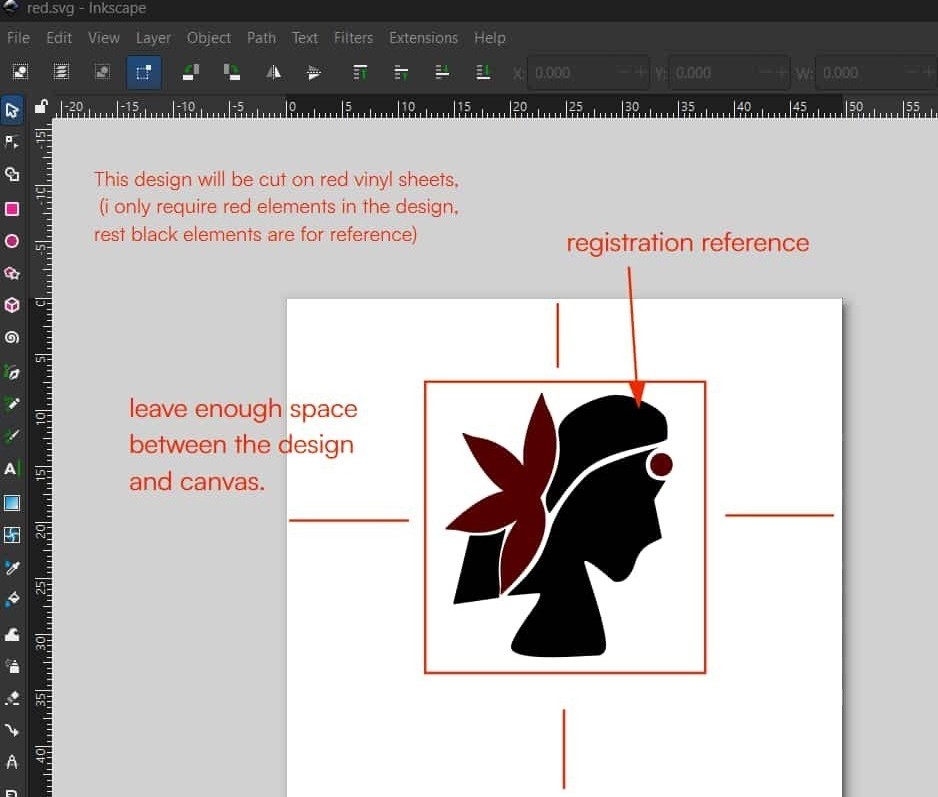

One limitation of vinyl cutters is that they can cut only solid-colored vinyl, so multi-color designs must be cut separately for each color and layered during application. Since my design had two main elements and three colors, I used shape builder operations.

Shape Builder Tool

Build shapes with Boolean tool, i used it (subtract and join/union) to separate the parts for each color.

Each color layer was saved as a separate file and resized to the required dimensions.

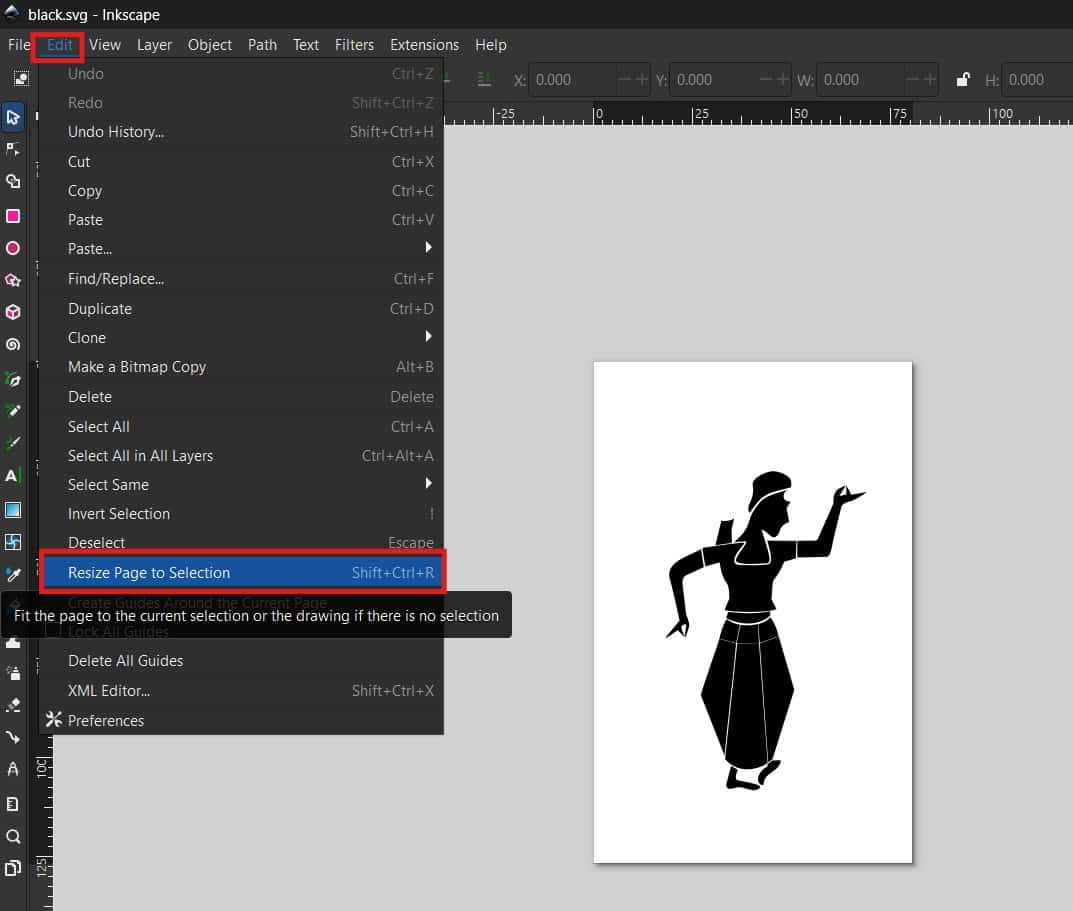

Resize Page to SelectionI resized the canvas using Ctrl + Shift + R to fit the page to the design, ensuring proper cutting without misalignment.

I also left some margin around the design, because if the design is too close to the edge, unwanted gaps may appear while generating the cutting paths. Registration reference were left in each file for accurate alignment while layering the colors. Finally, I saved the files in SVG format for cutting.

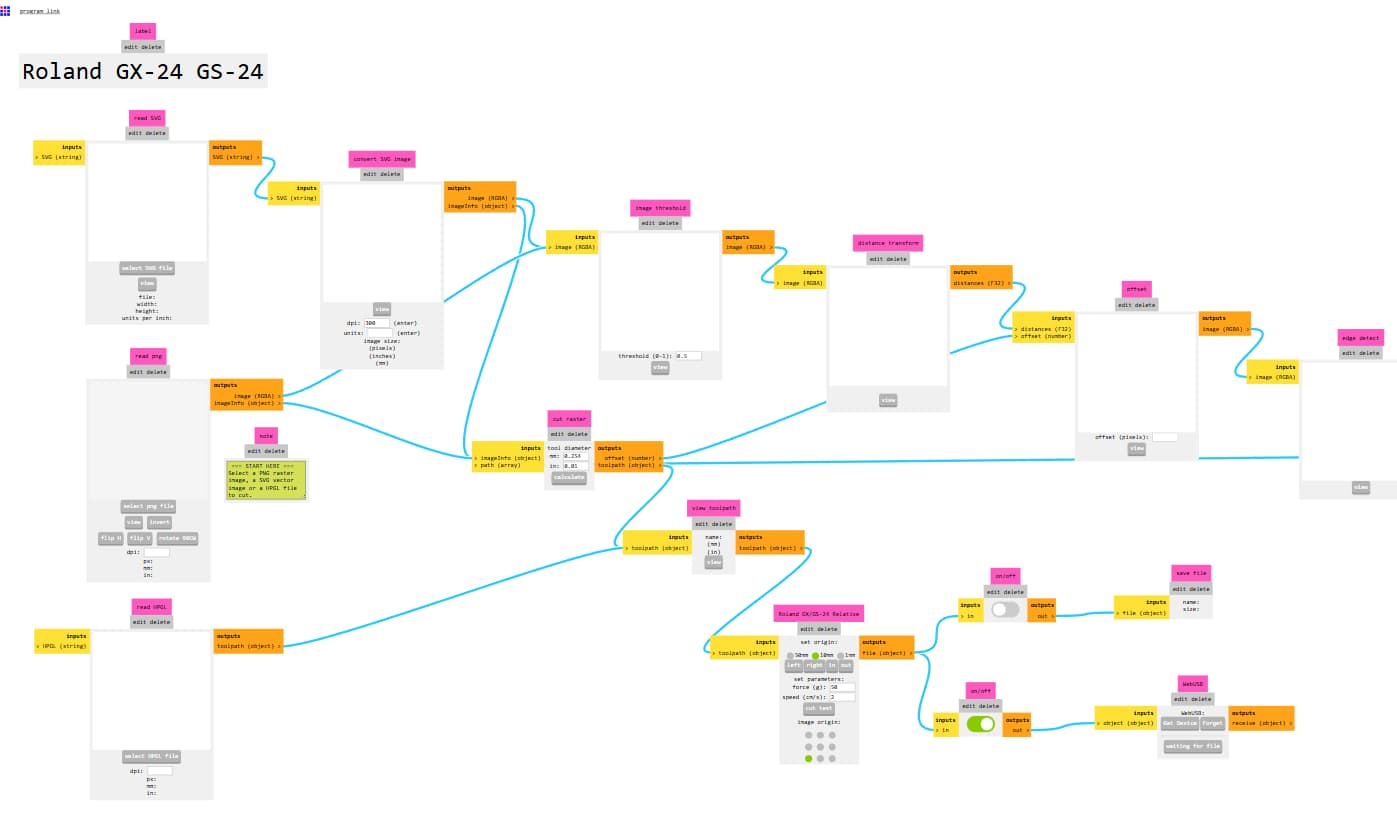

Mods Project: Toolpath Calculation

Open modsproject and upload the svg file in it; for that use option

“select svg file”>> then press calculate which calculates toolpath>> can check the path using “view”>>”send file to device”

.jpg)

Vinyl Cutter Workflow

I'll start with the mistakes I made, so you can be careful and avoid them. I did not pull the loading lever down while inserting the vinyl, and I tried adjusting the left and right pinch rollers from the front.

How to use Roland gx-24

Loading Vinyl

Pull the lever down while loading the vinyl rolls.

Move the blade holder to the right end using cursor key for avoiding interference.

Adjust the pinch rollers from the back side and place them on the grit roller markings

and pull the lever up to lock.

Setting Position

Use the cursor keys (Up & Down- y coordinate) to adjust the vinyl position and press Enter.

Use the cursor keys (Left & Right - side keys - x coordinate) to position the blade and press Set Origin.

Now machine is ready to cut.

After Cutting

Move the sheet forward using cursor keys, cut the vinyl with a blade or scissors, and pull the lever down before unloading.

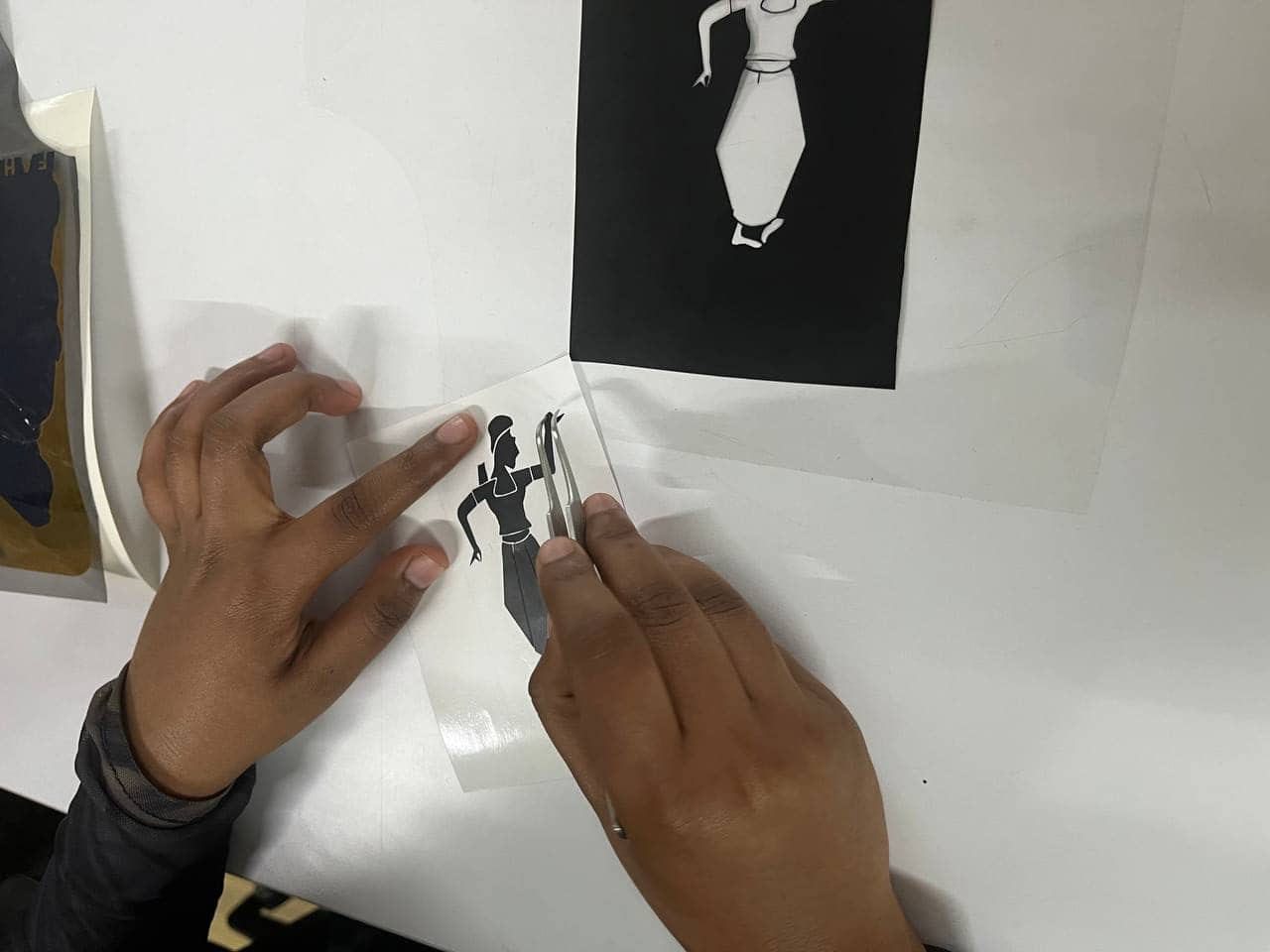

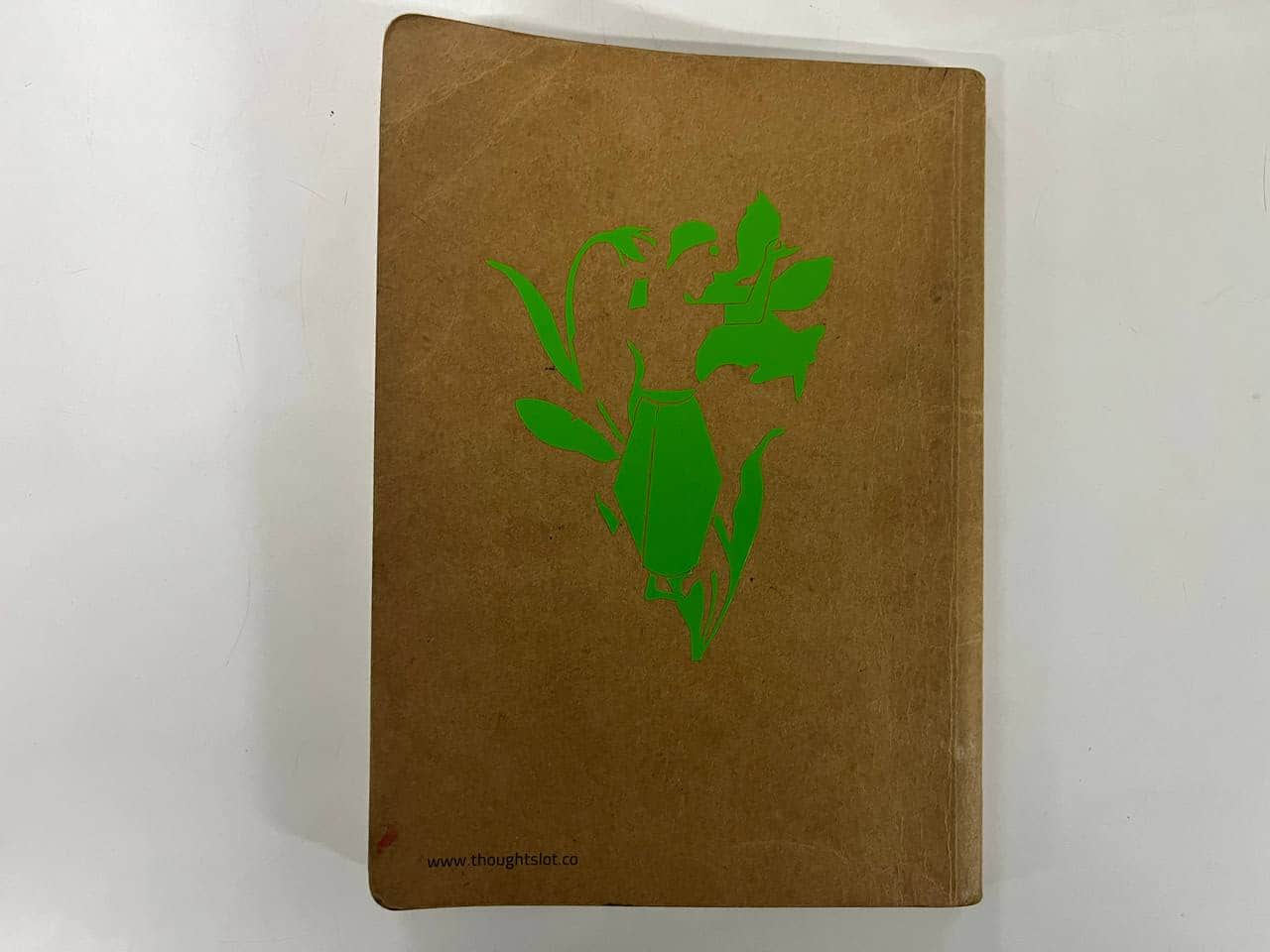

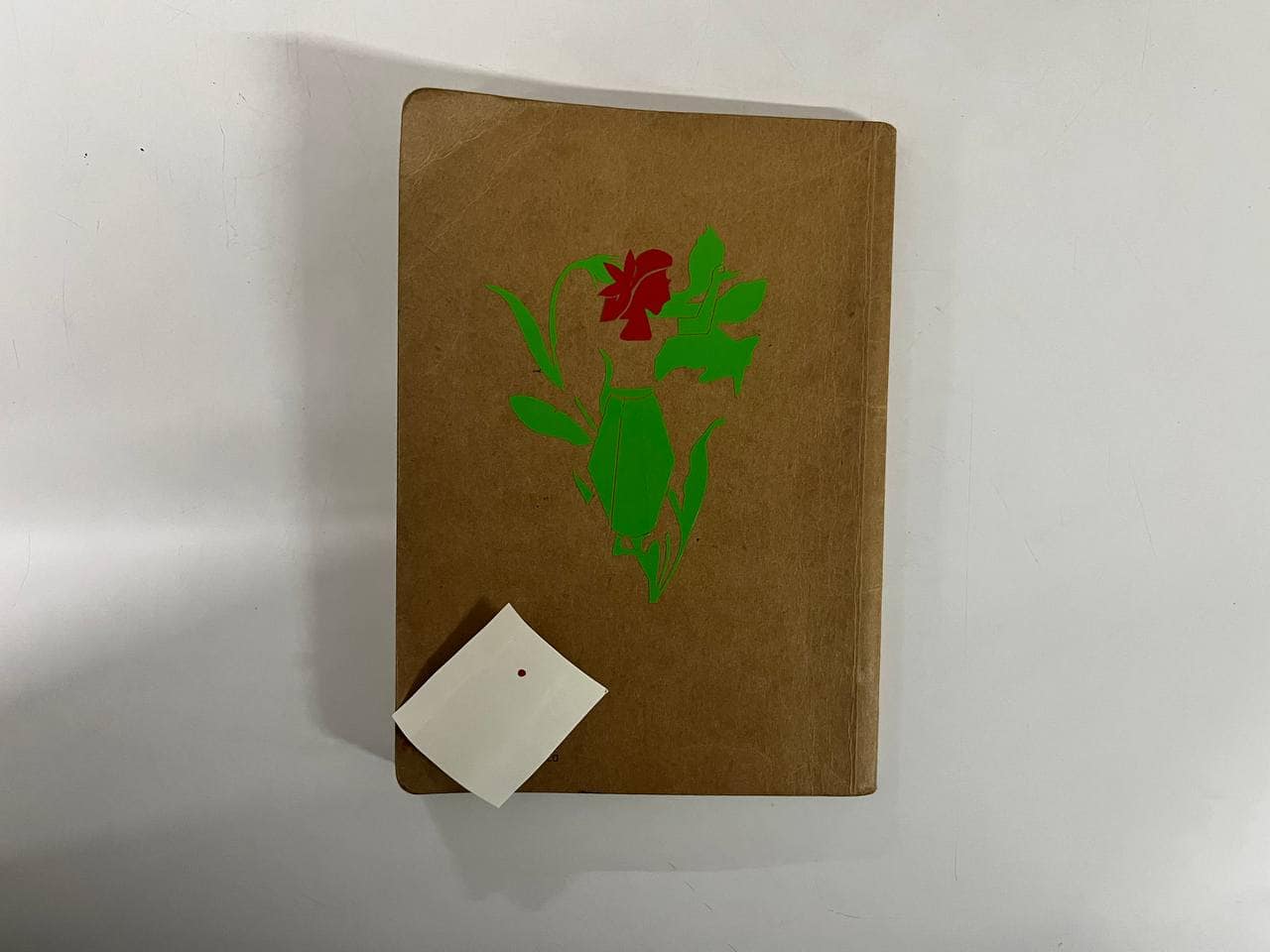

Final Sticker Assembly

For my sticker, I used three vinyl colors: red, green, and black.

After cutting, I removed the unwanted vinyl using tweezers and a blade.

Then I used a transfer (adhesive) sheet to lift and apply the design layer by layer—first green, then red, and finally black.

I reused the transfer sheet for each layer and pasted the final sticker on the backside of my sketchbook.

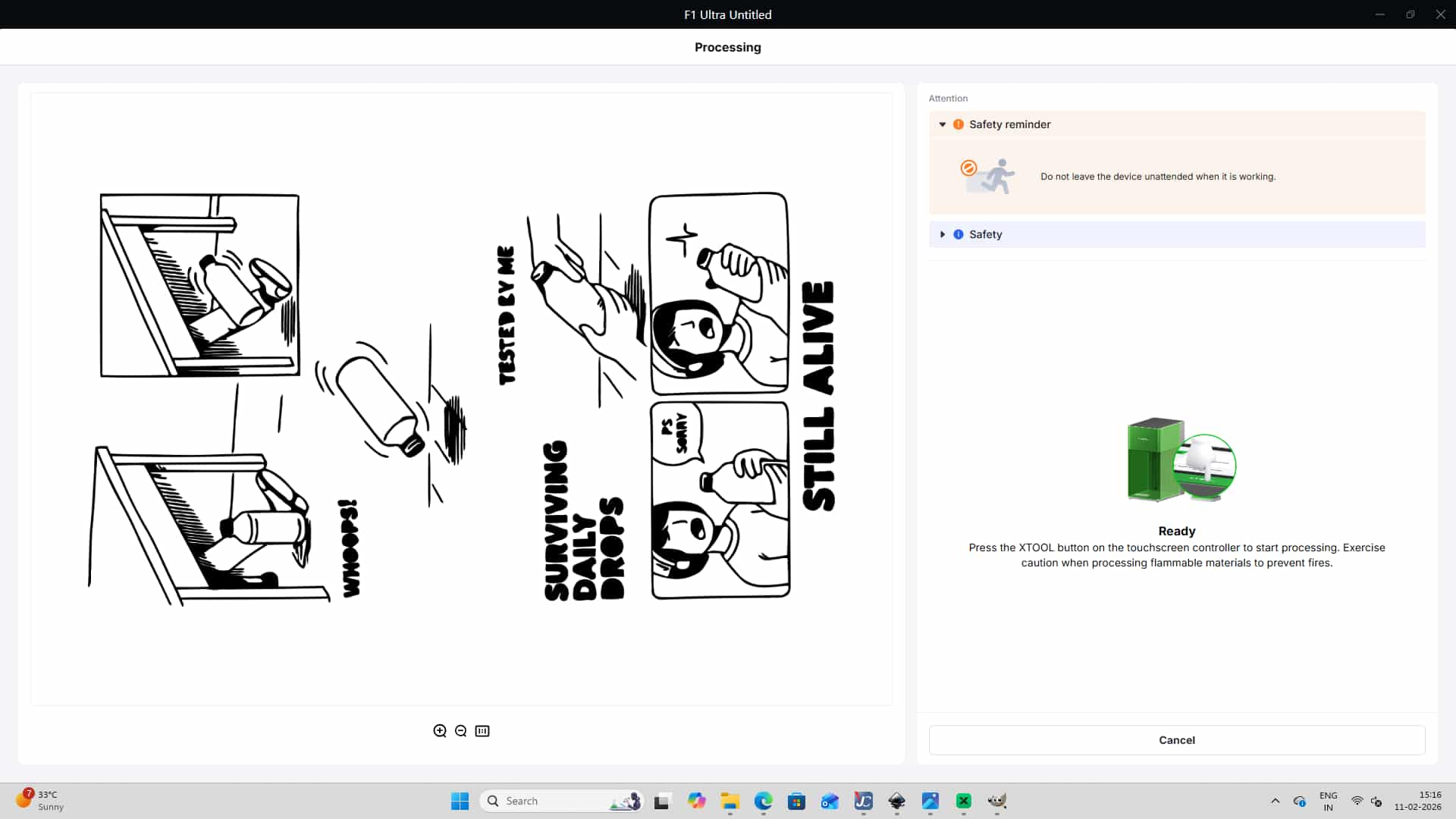

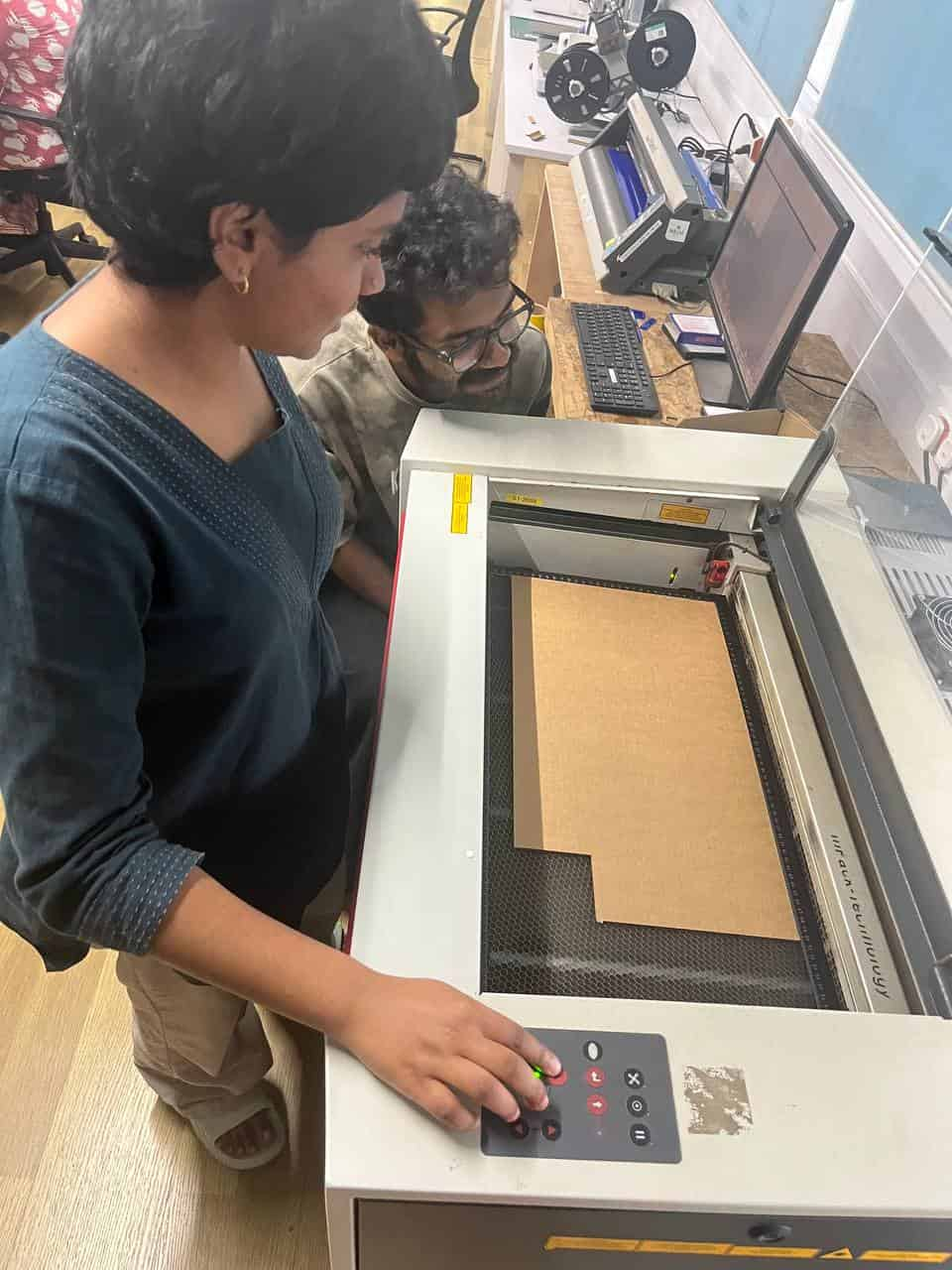

Laser Cutting - Trotrec Speedy 100

What is laser cutting?

Trotec Speedy 100

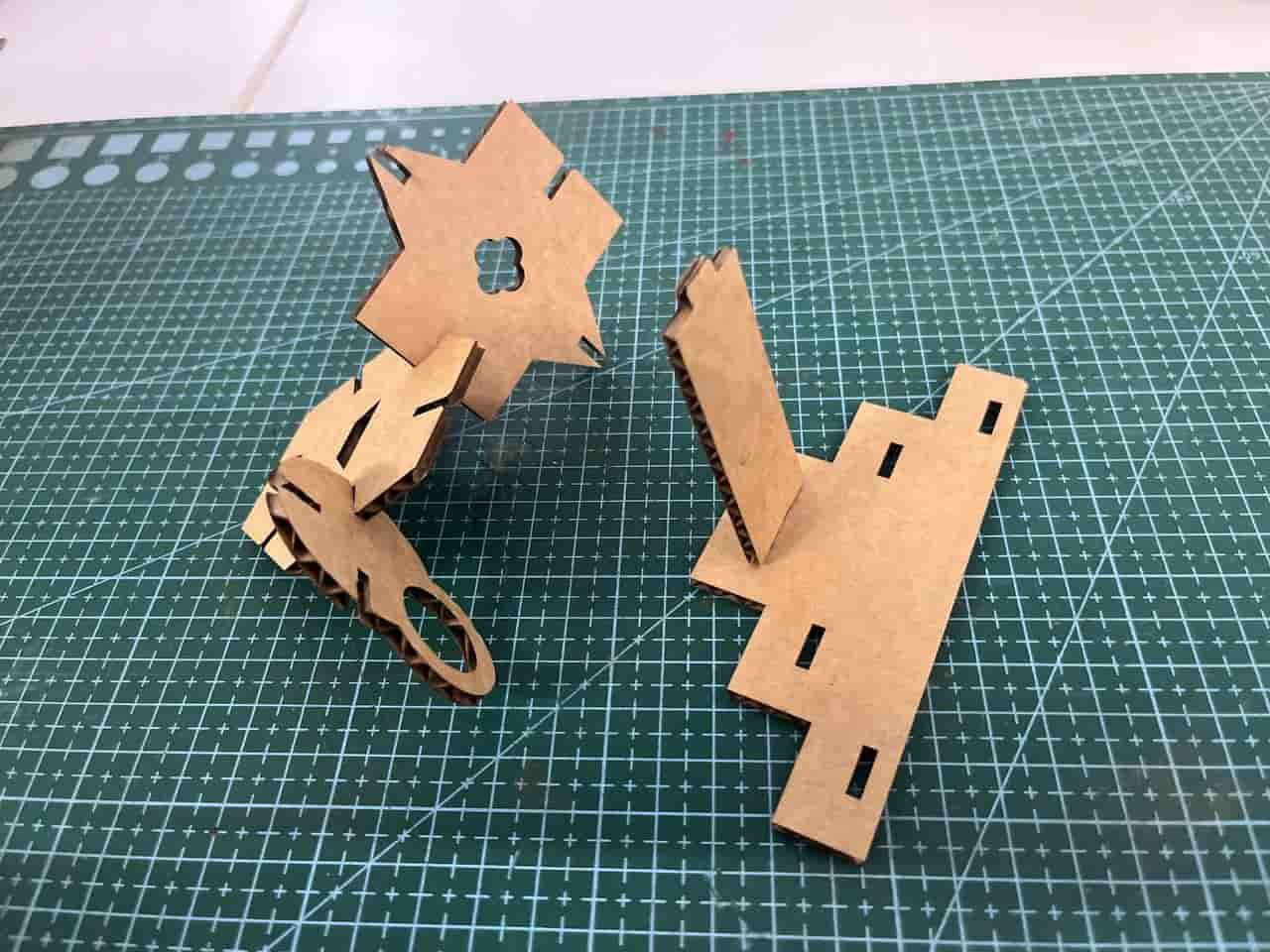

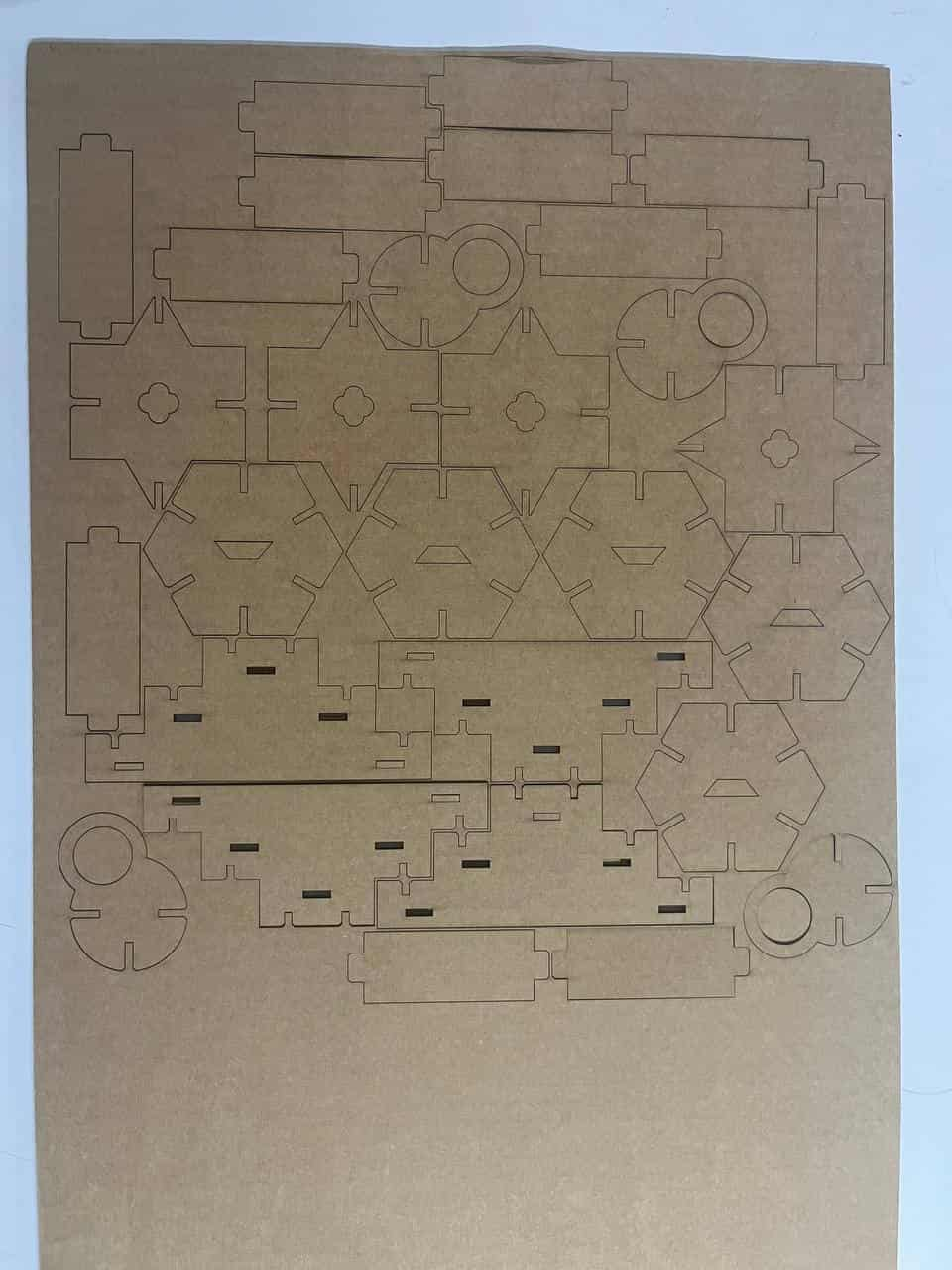

Making Parametric Construction Kit

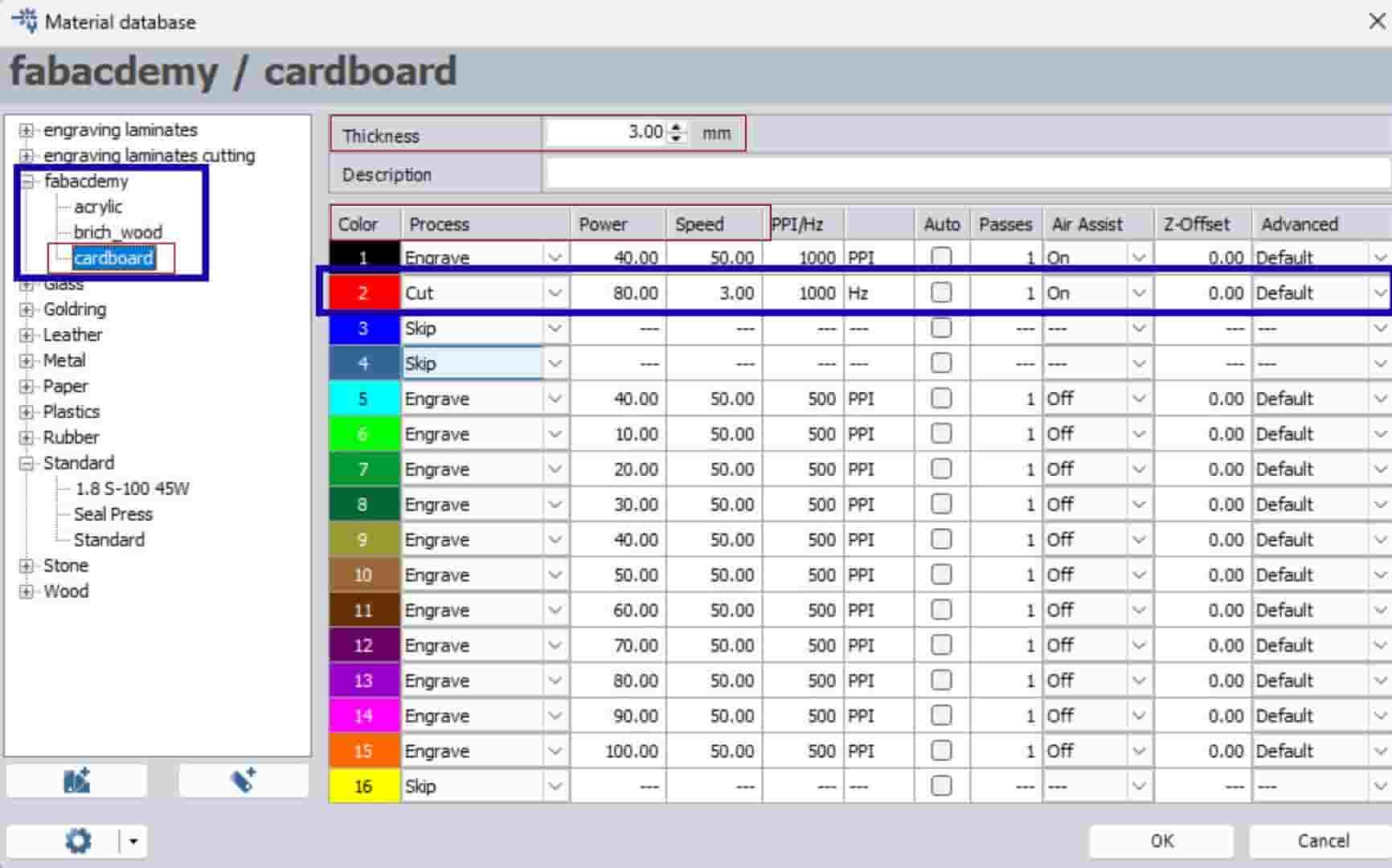

we had to design a parametric construction kit using cardboard as the cutting material.

The kit was created with different joints so that the parts can be assembled without glue and can be rearranged to build different structures.

Why parameters?

The design was made parametric so dimensions like material thickness, kerf, and press-fit clearance can be changed easily by updating parameter

values instead of editing each sketch individually or redrawing them.

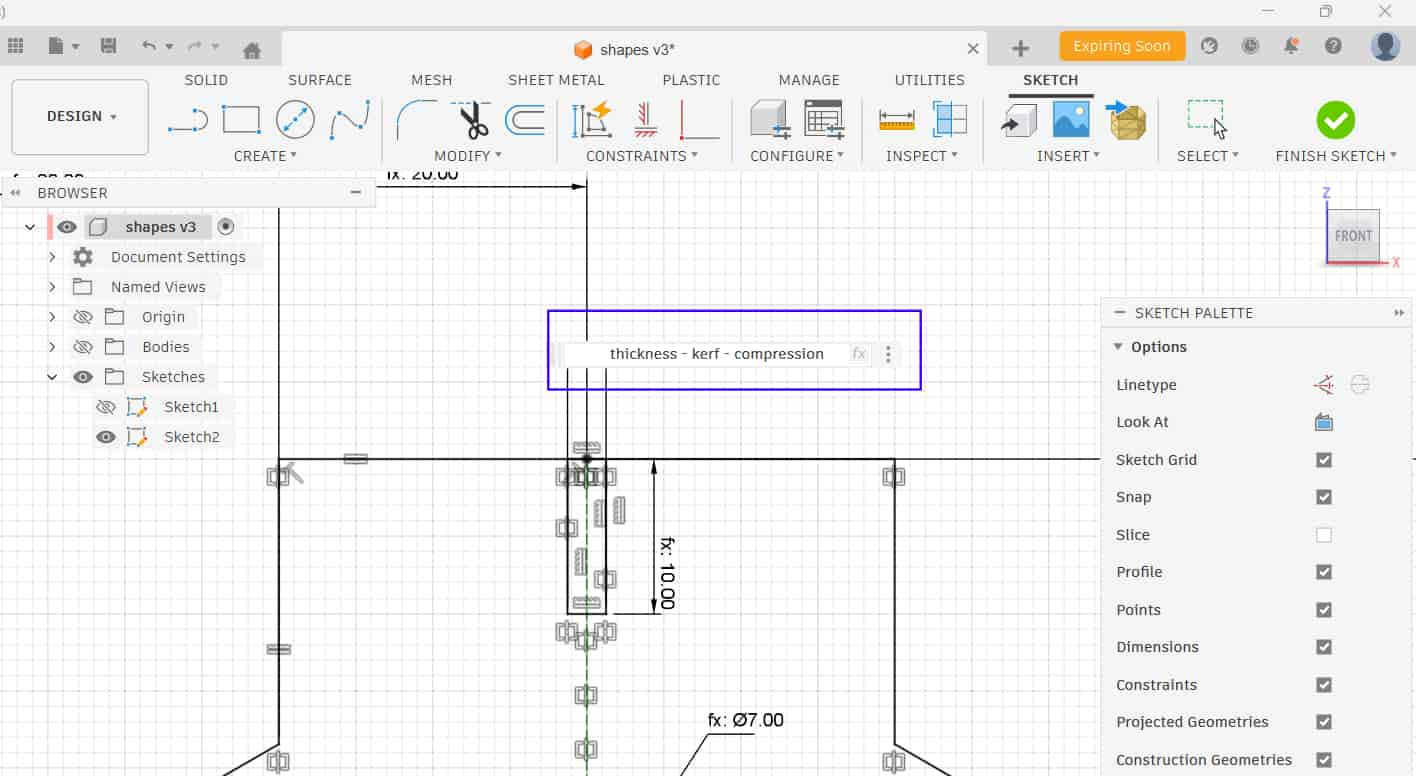

In Fusion 360, I used Create Sketch to construct the shapes and defined the sketch using parametric dimensions. Tools such as polygon, line, rectangle, circle, offset, and mirror were used, along with constraints, to fully define the sketch.

Kerf

0.3mm

Compression

0.2mm - Press fit clearance

Thickness

3mm - Material thickness

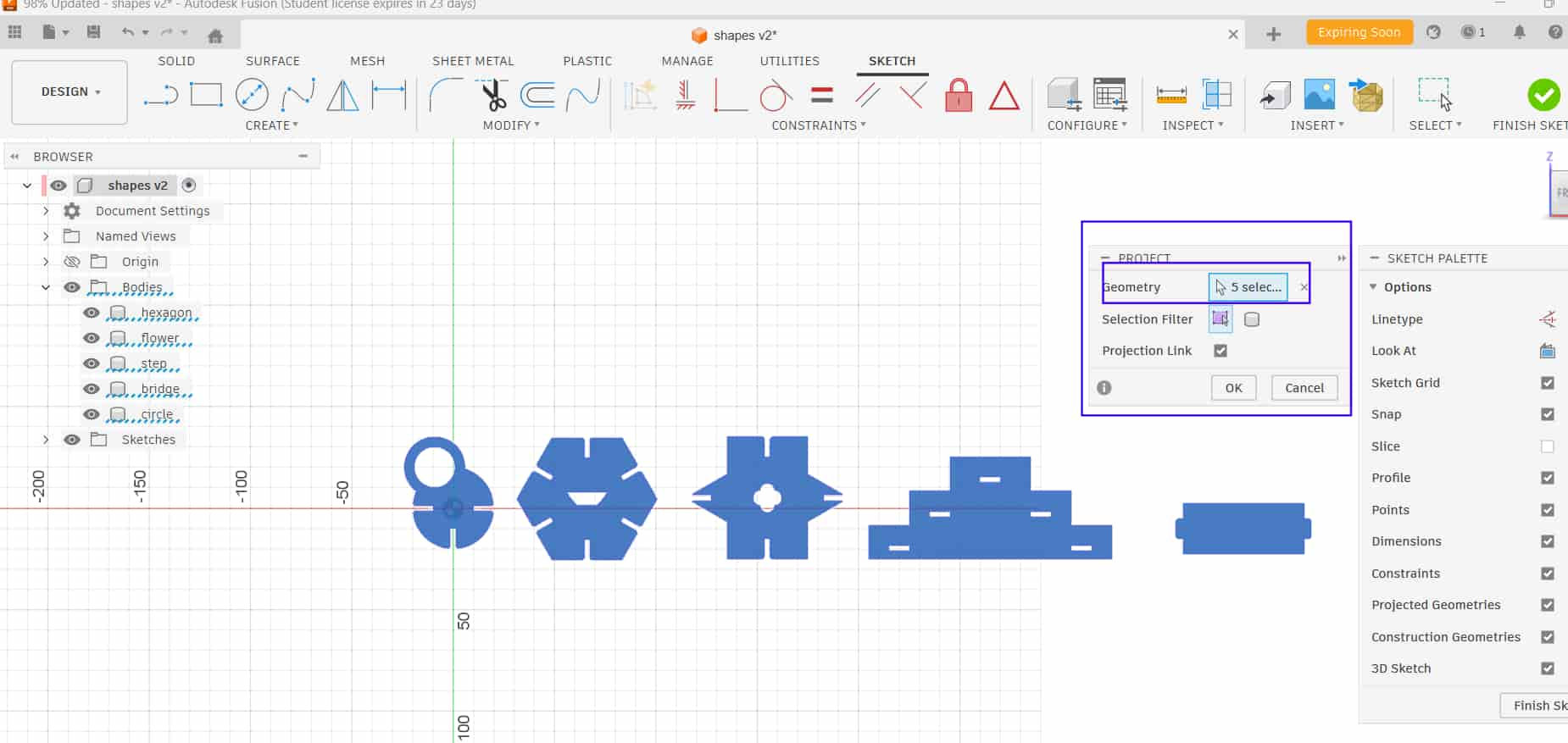

I sketched each component one by one and extruded them. A chamfer was applied to the edges of the slots to make insertion easier. In a new sketch, I used:

Project tool

Press "P"/ you find it in "create"to project the sketch onto the plane. Afterward, save it as DXF.

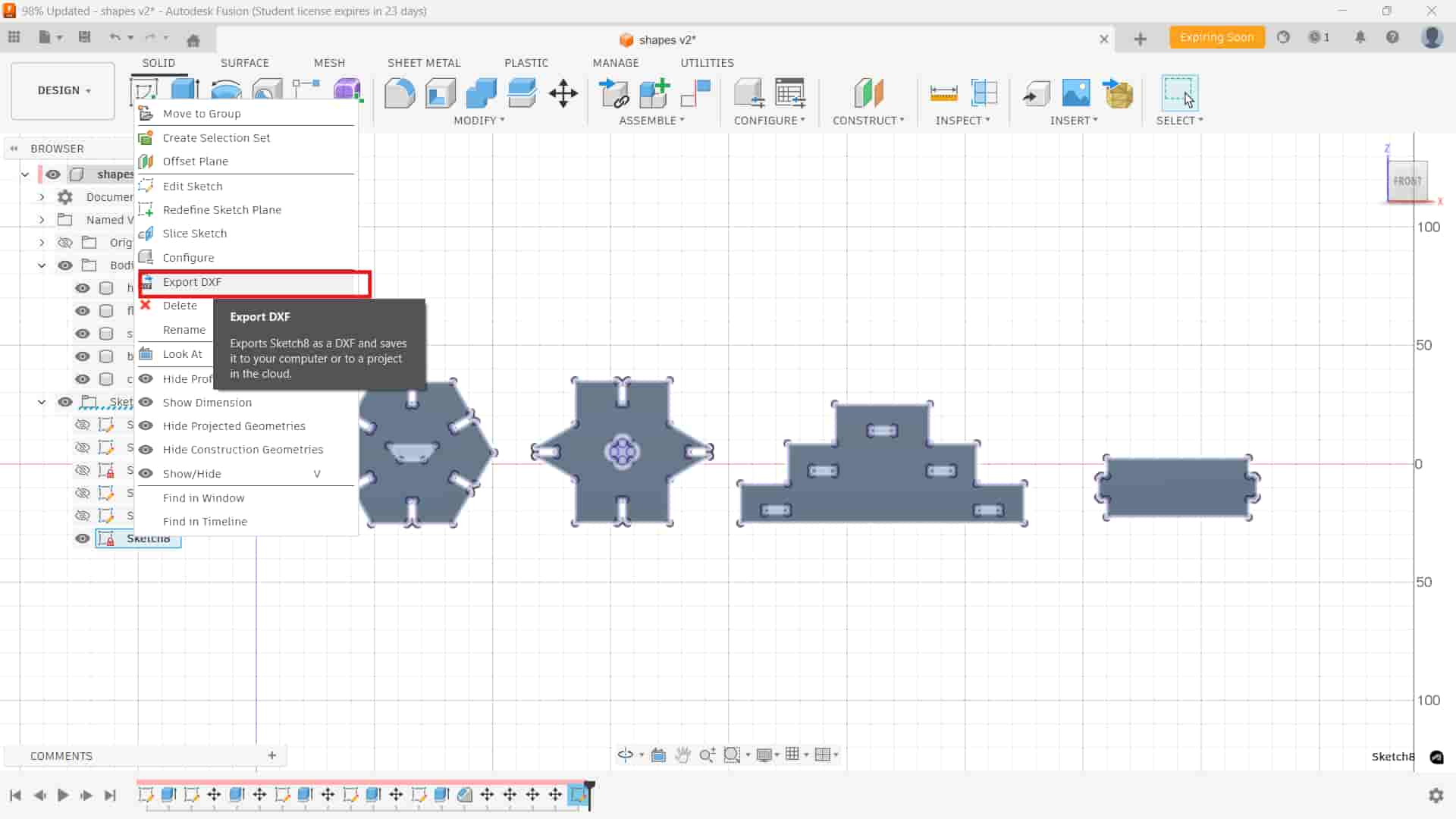

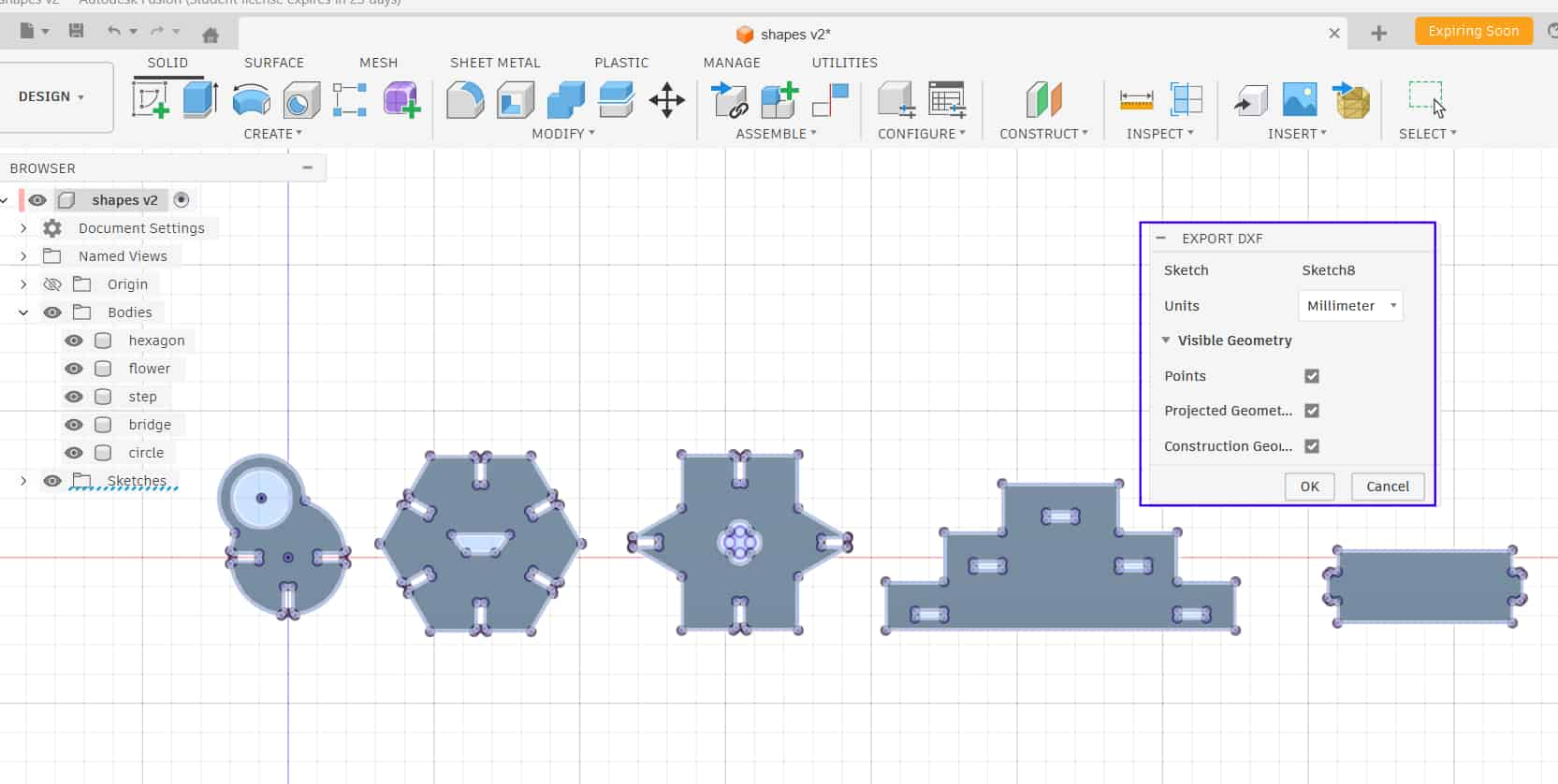

Export DXF

Right-clicked on the projected sketch and exported it as a DXF file, which exports the 2D sketch for cutting.

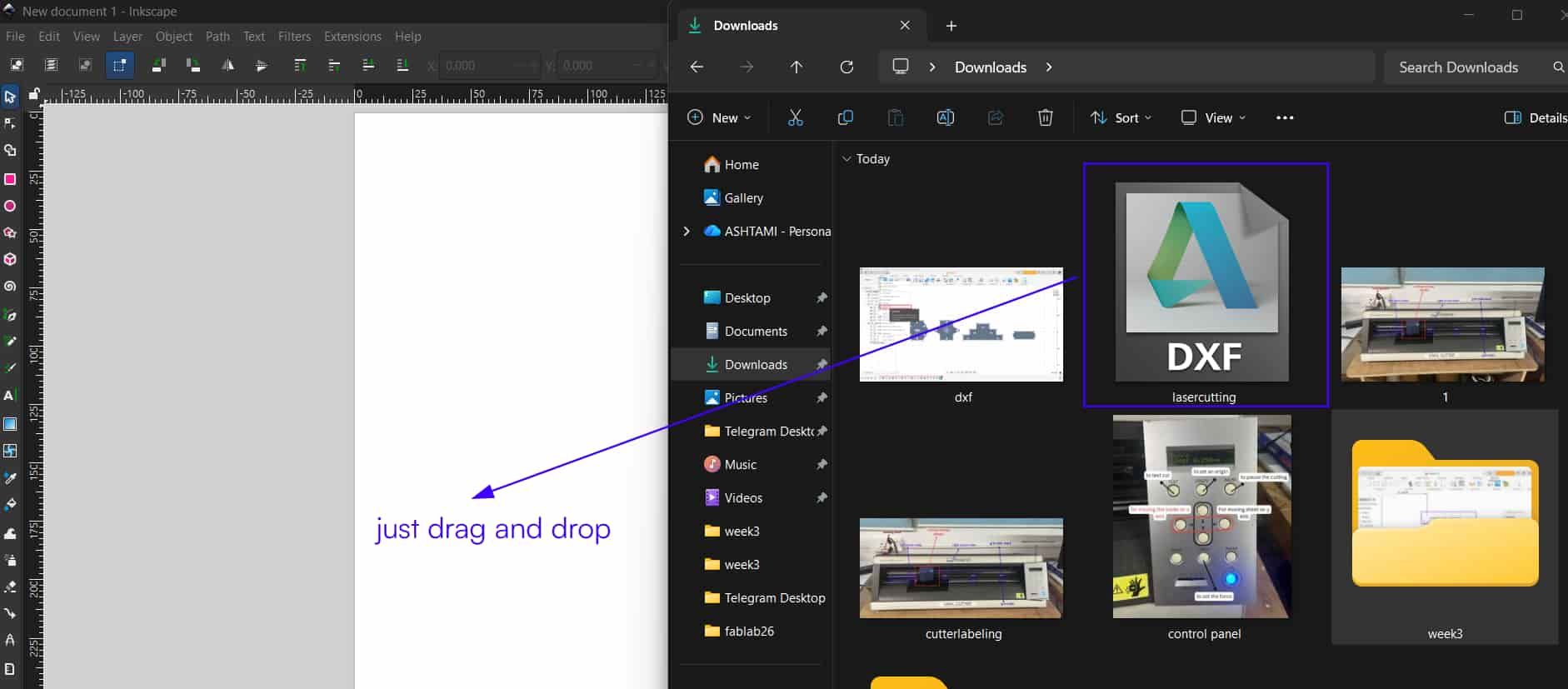

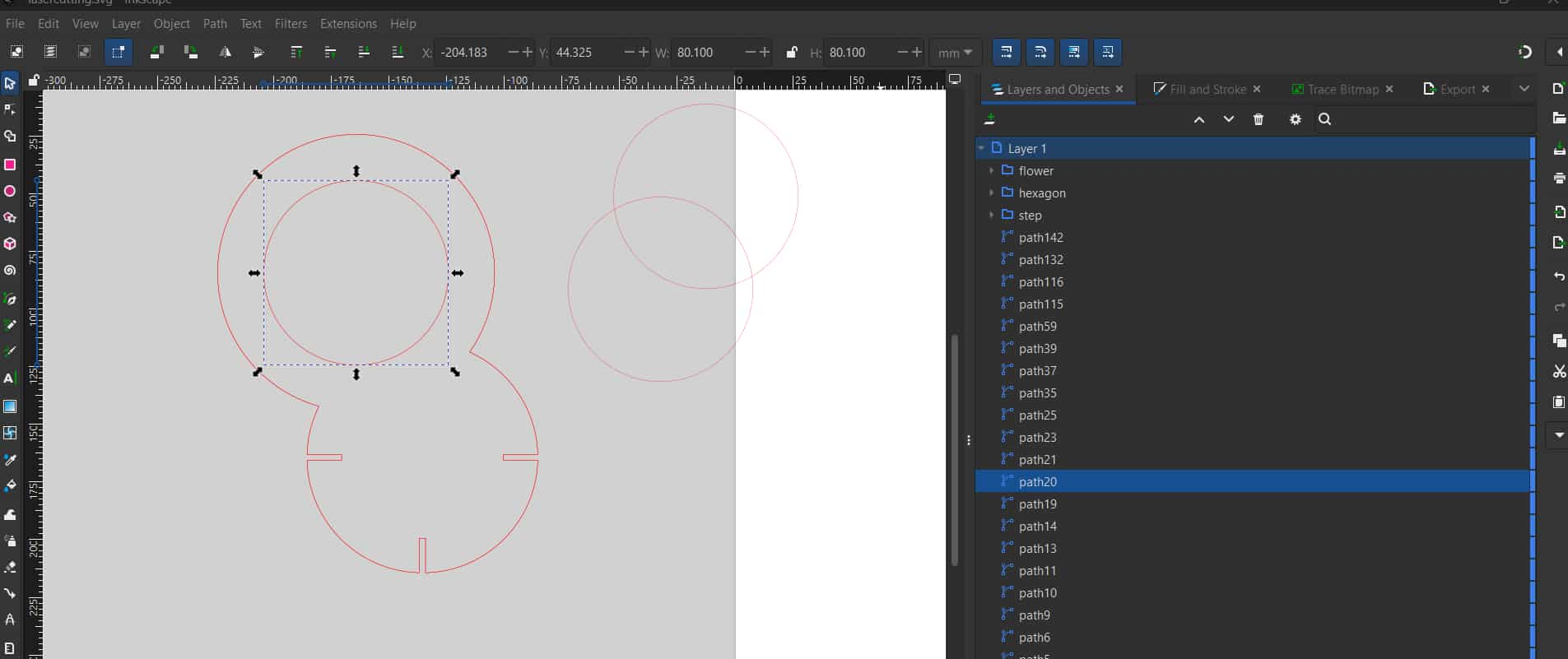

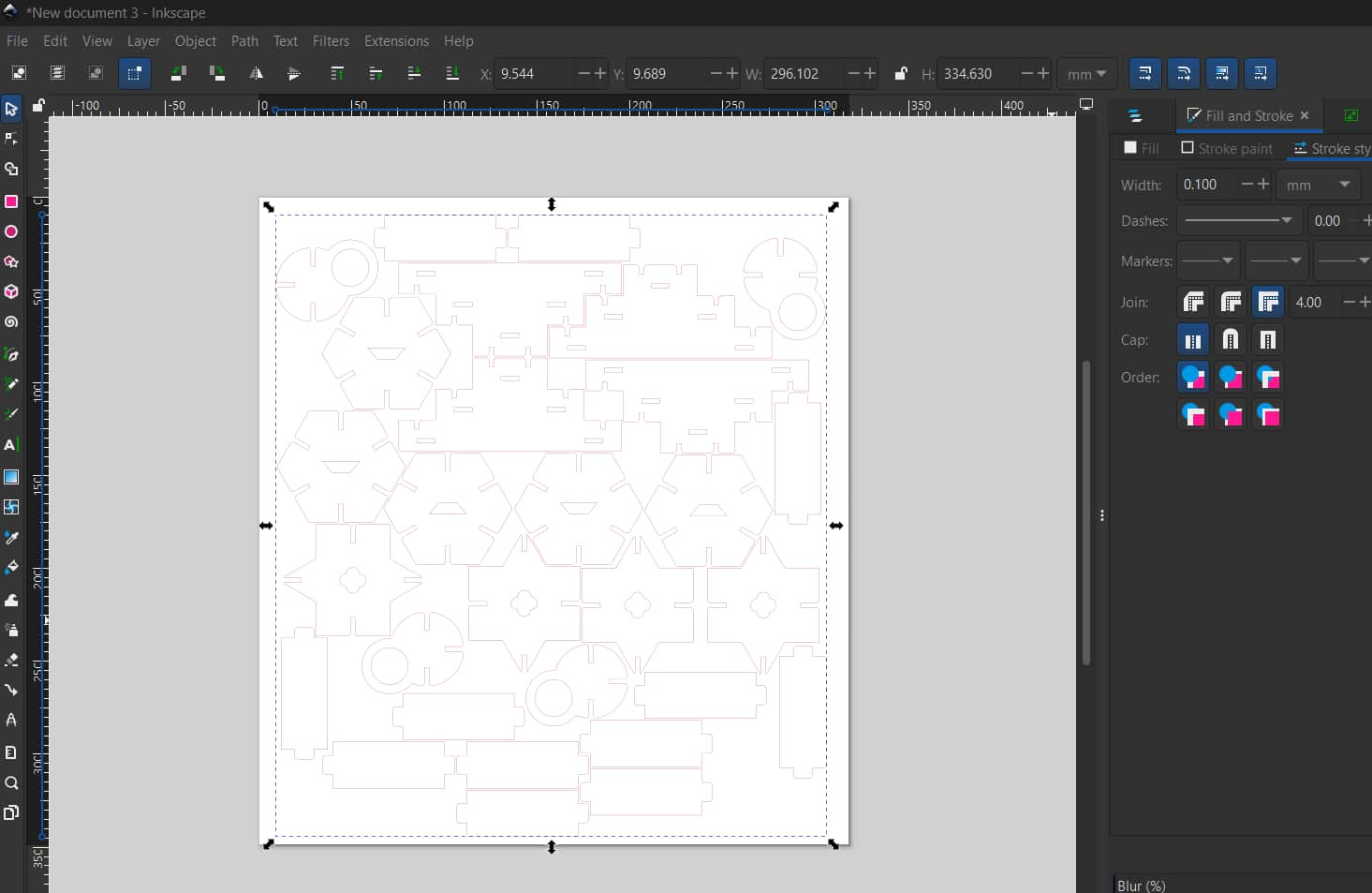

Importing to Inkscape and Editing

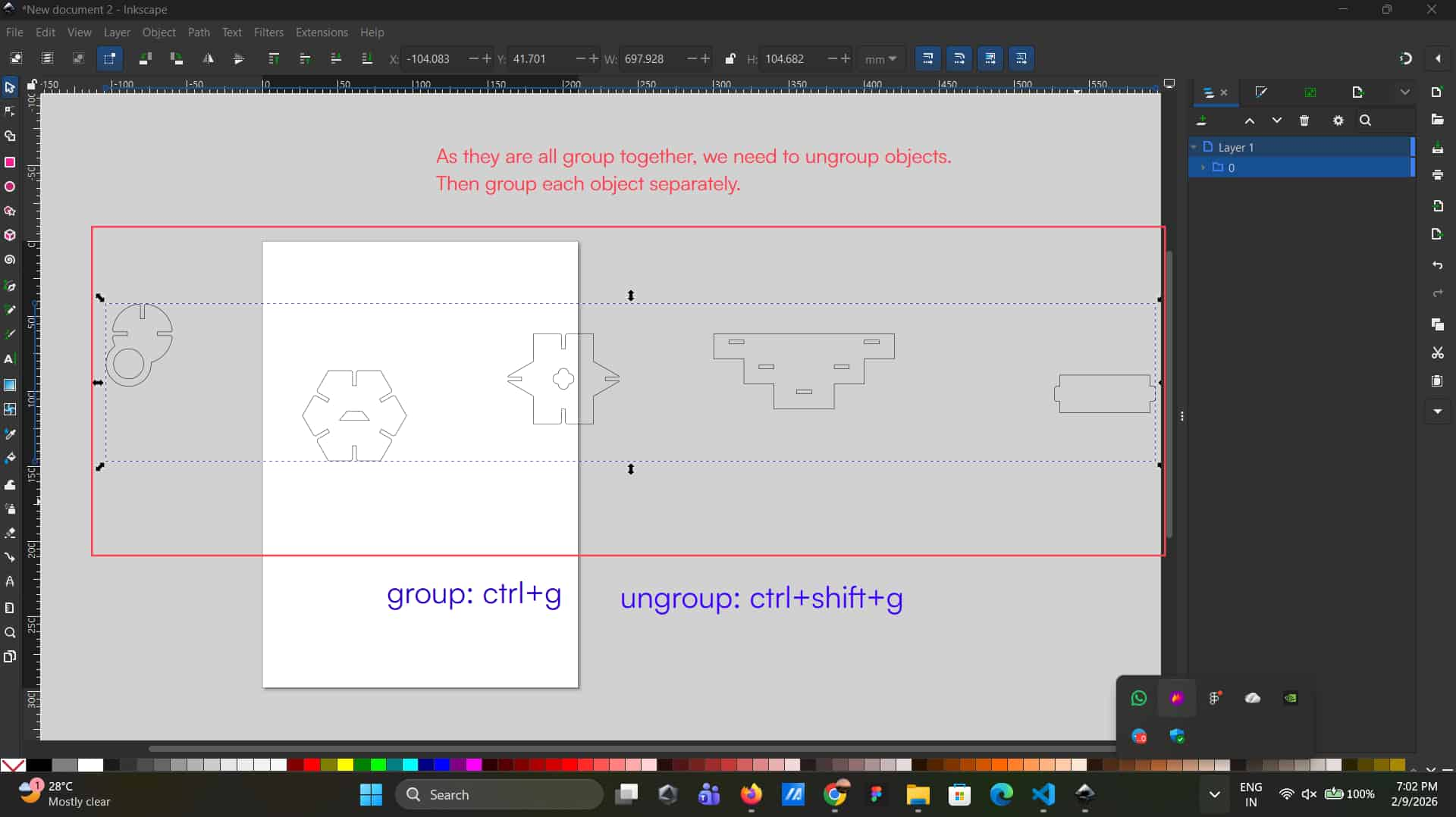

Open the DXF file in Inkscape by dragging and dropping it into the workspace. Then ungroup the elements and group each object individually as needed.

Ungroup

As they are all grouped together, need to ungroup the elements. To ungroup: ctrl+shift+g

Group

For grouping elements, select the specific elements, then ctrl+g

The mistakes (try not to do these, be carefully)I made was: that some sketch paths were duplicated multiple times

(either during DXF export from Fusion 360 or while editing in Inkscape).

Because some paths were duplicated, the machine continued cutting along the same path

multiple times, which caused the laser to pass repeatedly over the same area and resulted in small sparks.

Therefore, it is important to check and remove any duplicate or overlapping paths in Inkscape before sending the file for cutting.

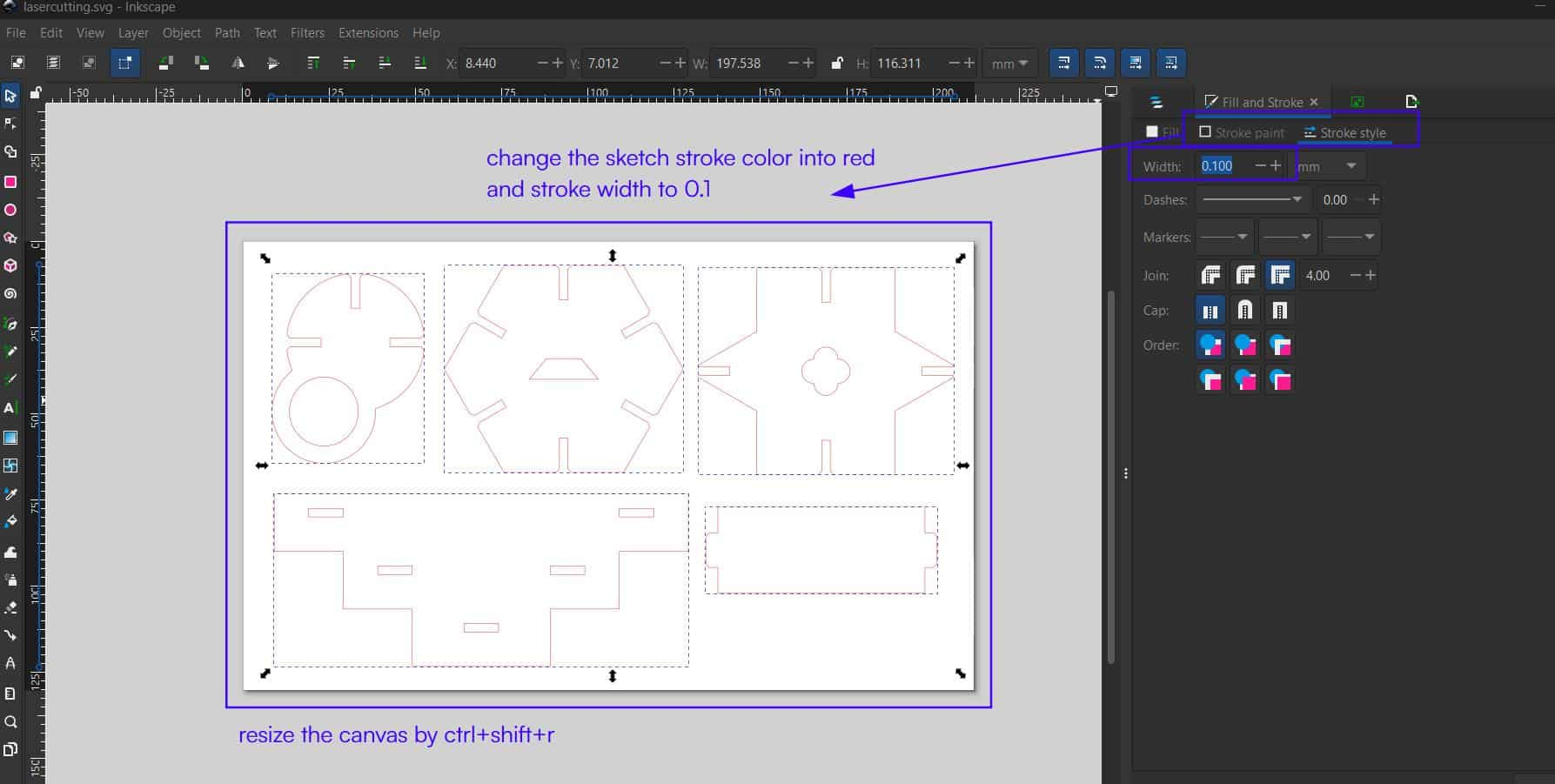

After grouping the objects,

Stroke Paint

change the stroke color to red and set the stroke width to 0.1 mm, as in the machine's (Trotec laser cutter) material database settings where red color is set for cutting.

Finally resize the canvas (ctrl+shift+r) and save as SVG file.

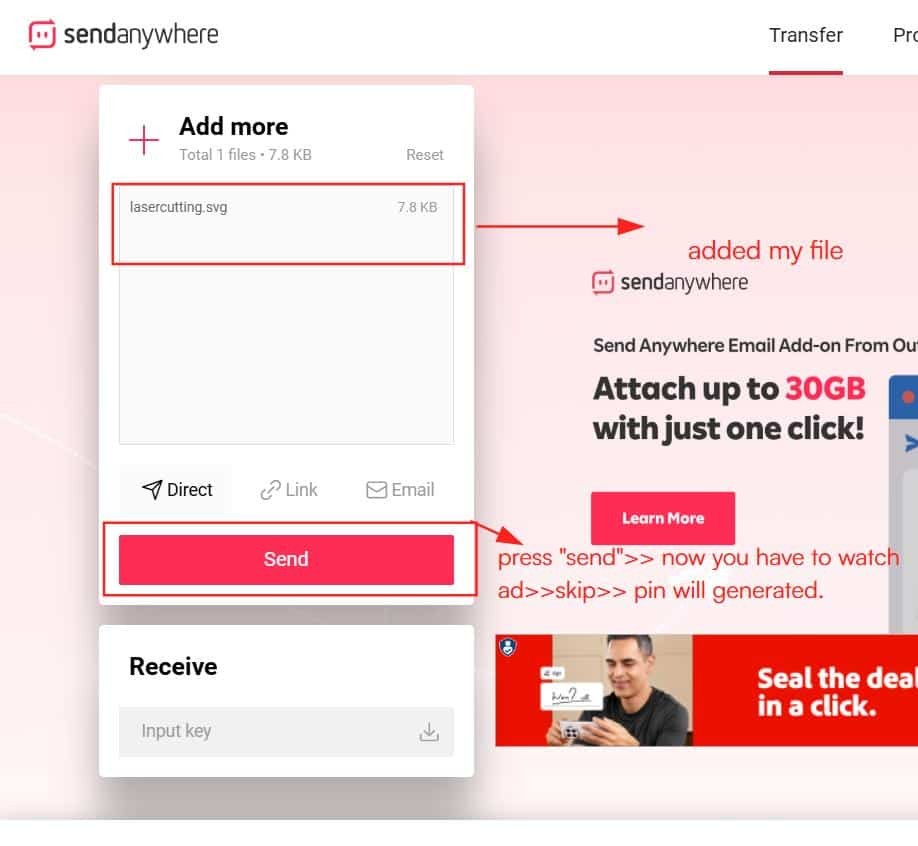

Send Anywhere and Sending to Printer

Why we sending file to fablab pc?

Sender's system

To send the file to the Fab Lab system connected to the Trotec machine, we used Send Anywhere.

First, upload the SVG file >>click Send, which generates a PIN code.

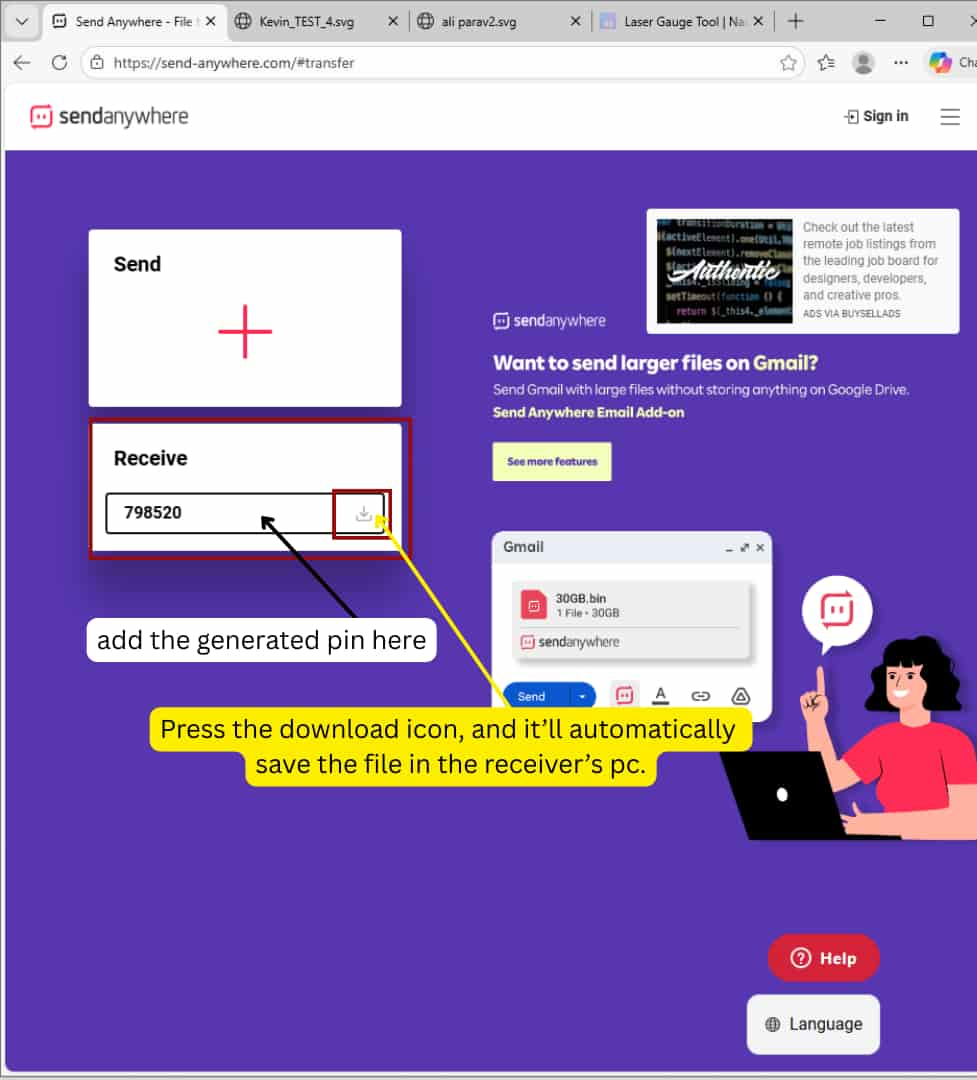

Receiver's system

Then, on the receiving computer, enter the same PIN code to receive and download the file.

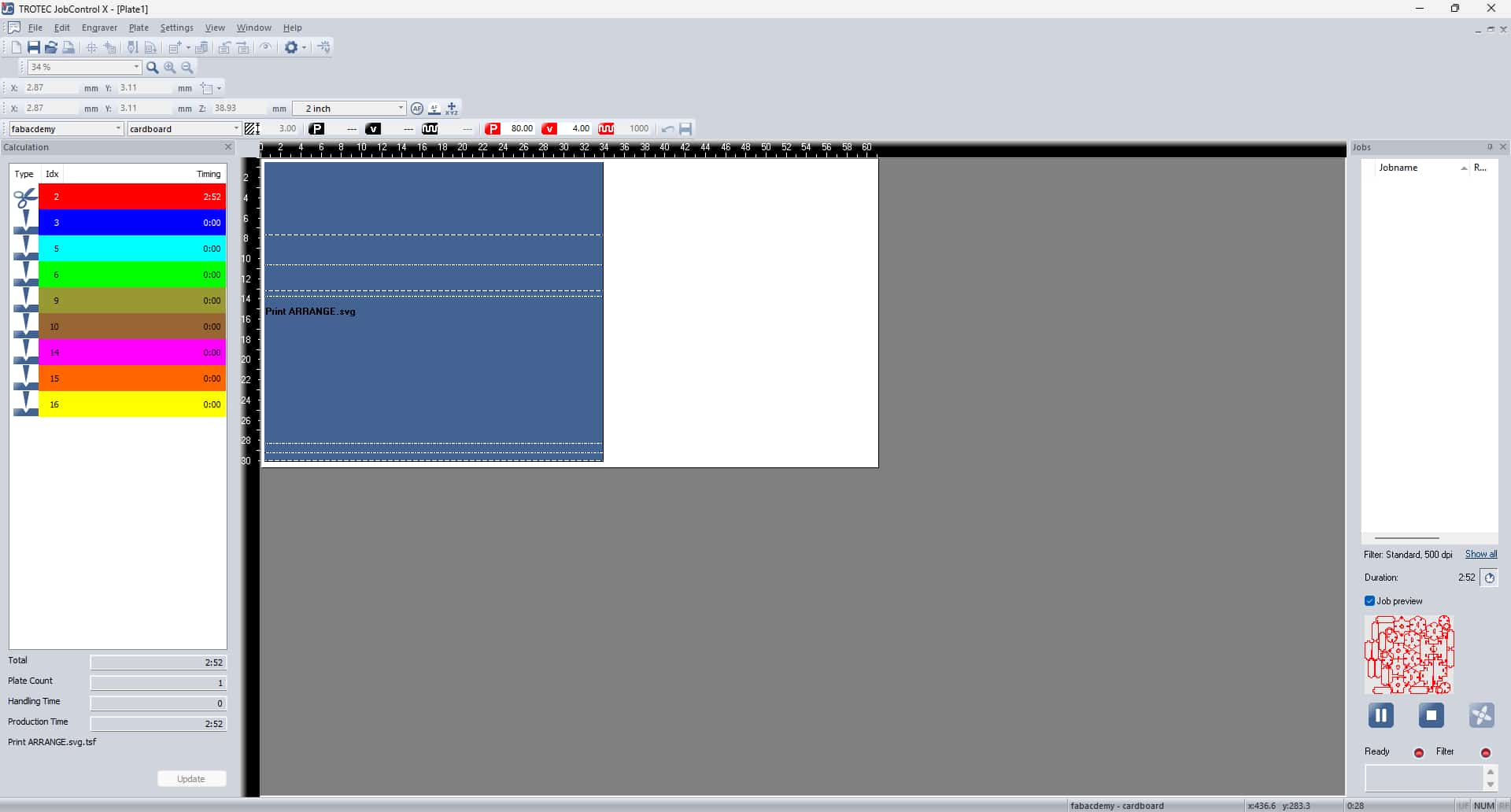

Inkscape >> Send file to printer

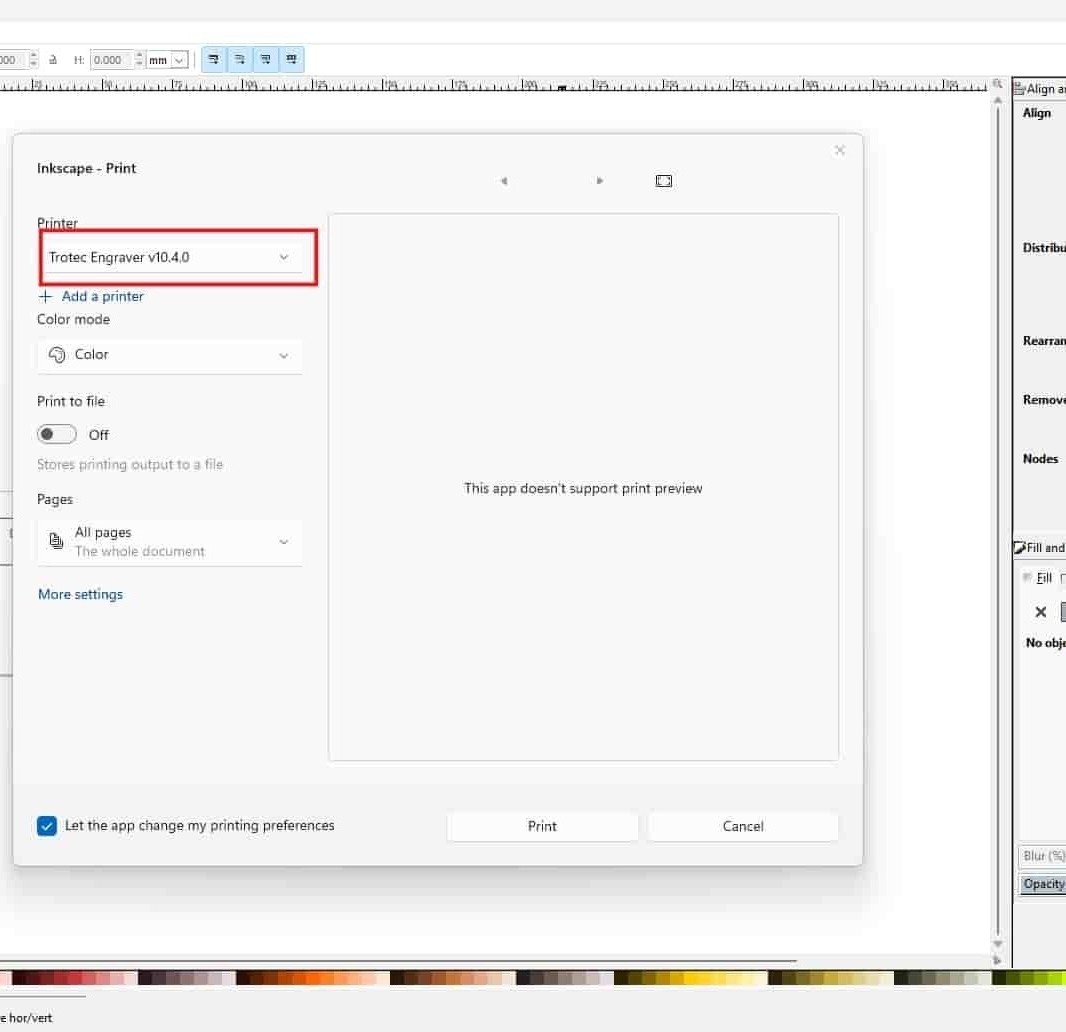

Open the file in Inkscape on the Fab Lab PC and press Ctrl + P to print. Select the Trotec Engraver, which opens the file in Trotec JobControl software.

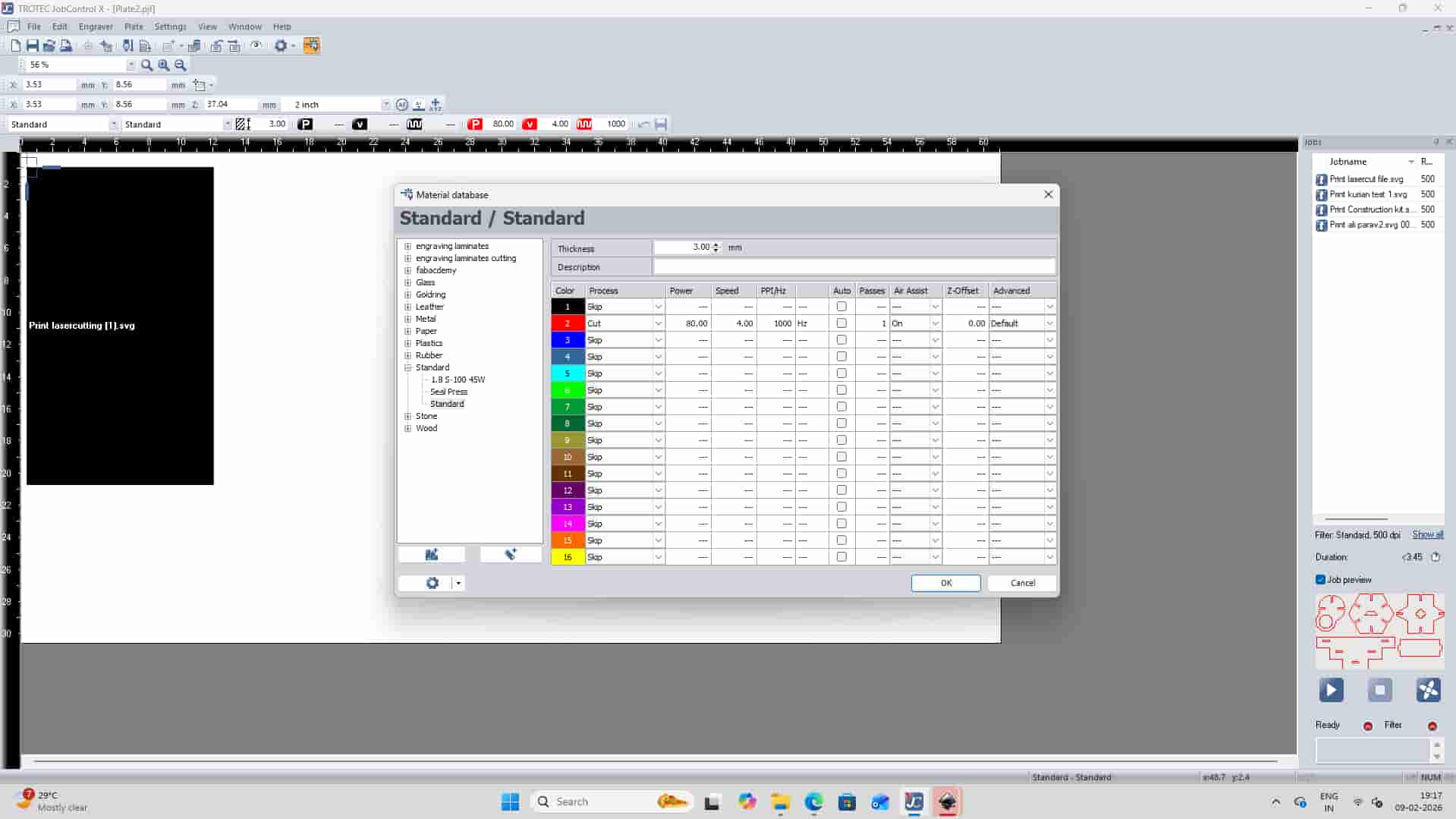

Setting up machine and Trotec JobControl software

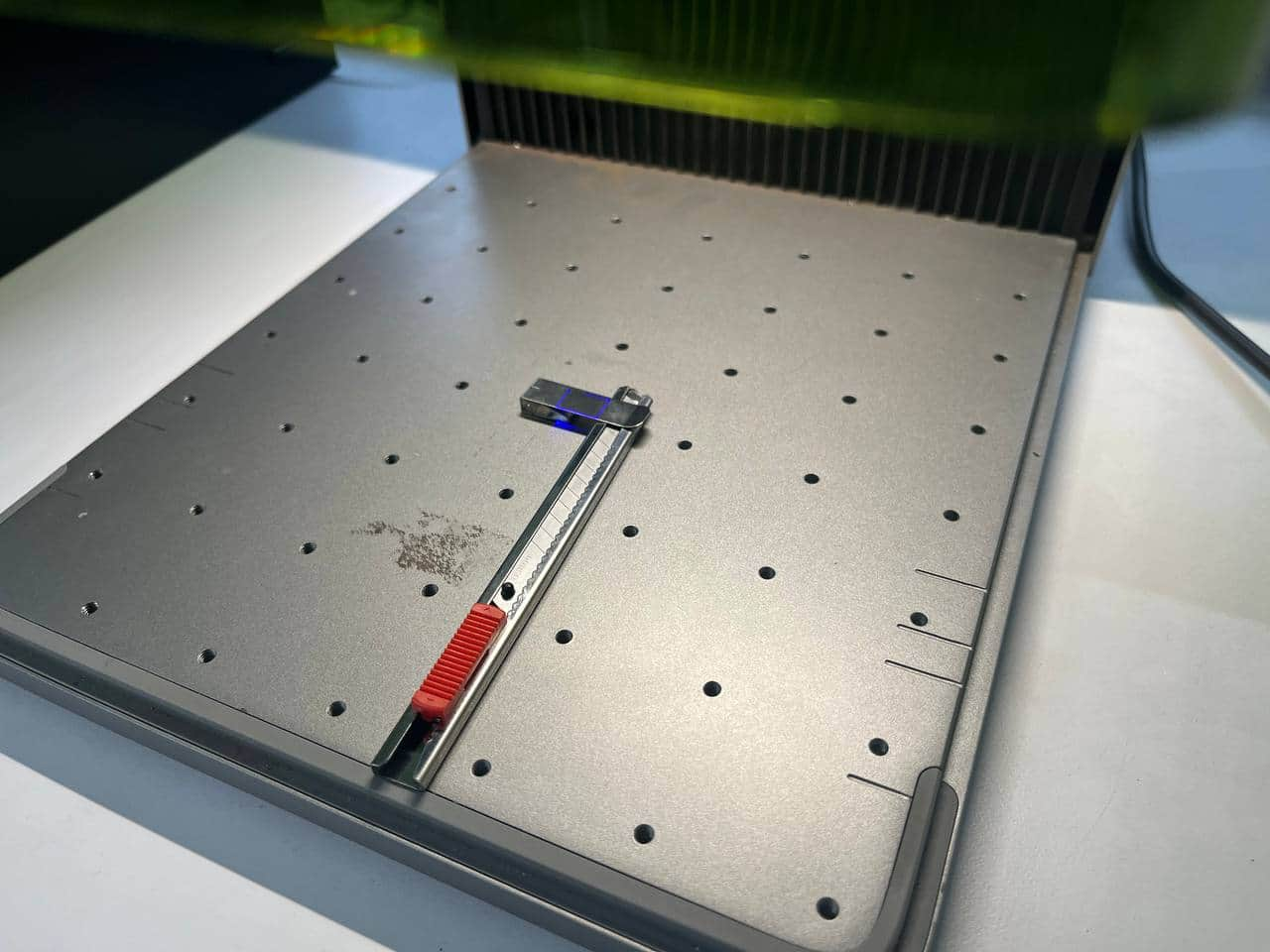

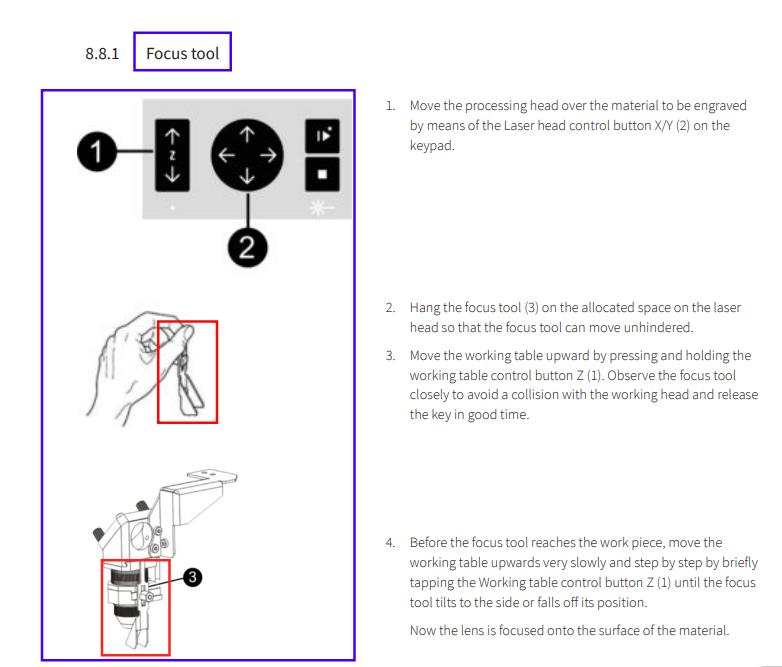

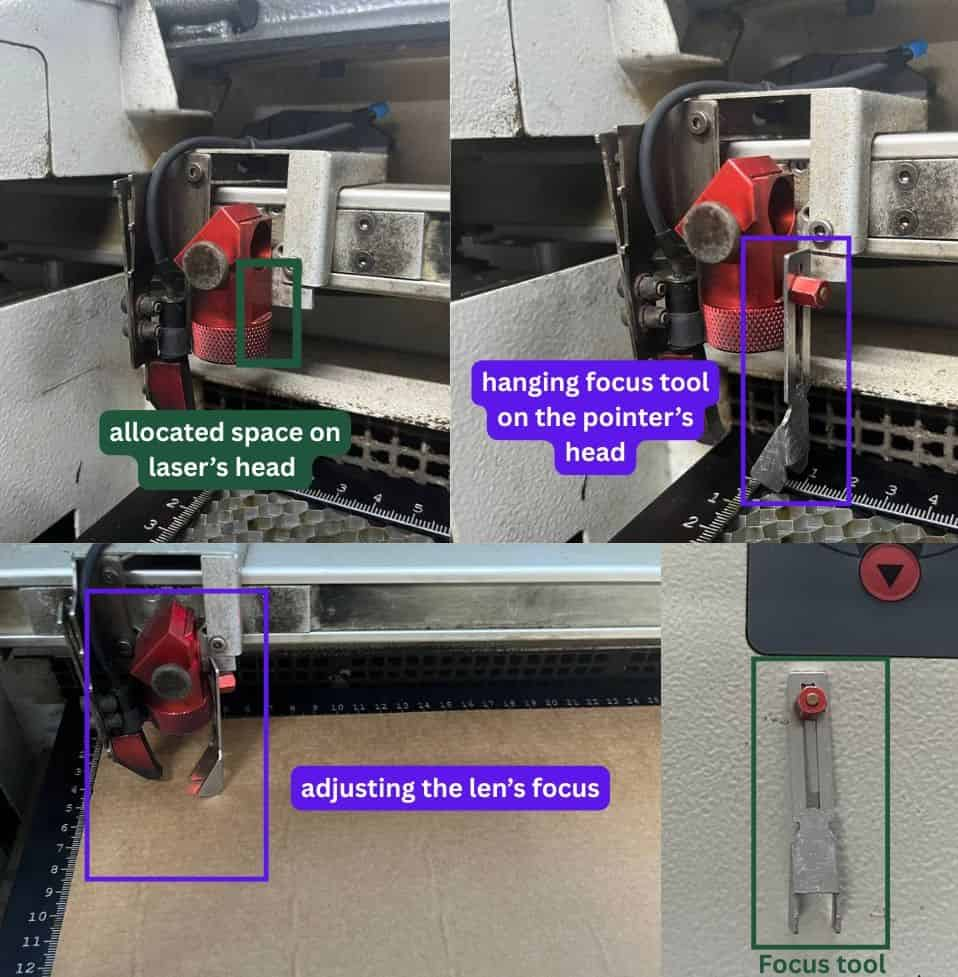

Setting focus

Go to the laser cutter machine. Hang the focus tool in the allocated space on the laser head.

Raise the working table using the Z-axis control until the focus tool just touches the material

surface and tilts or falls, this indicates that the lens is properly focused.

Setting Origin

Move the laser head to the desired starting point on the material using the cursor keys (X and Y coordinates).

The small red laser pointer shows the exact cutting position.

Return to the computer, align the sheet edge with laser pointer in the software. For aligning the laser point you can either drag the cutting piece selection to the pointer or manually go to the machine control panel and adjust them.

Material Database

choose the correct material settings (power, speed, process) from the material database.

Once everything is set, press the Ready/Play button in JobControl to send the job to the laser cutter and start cutting.

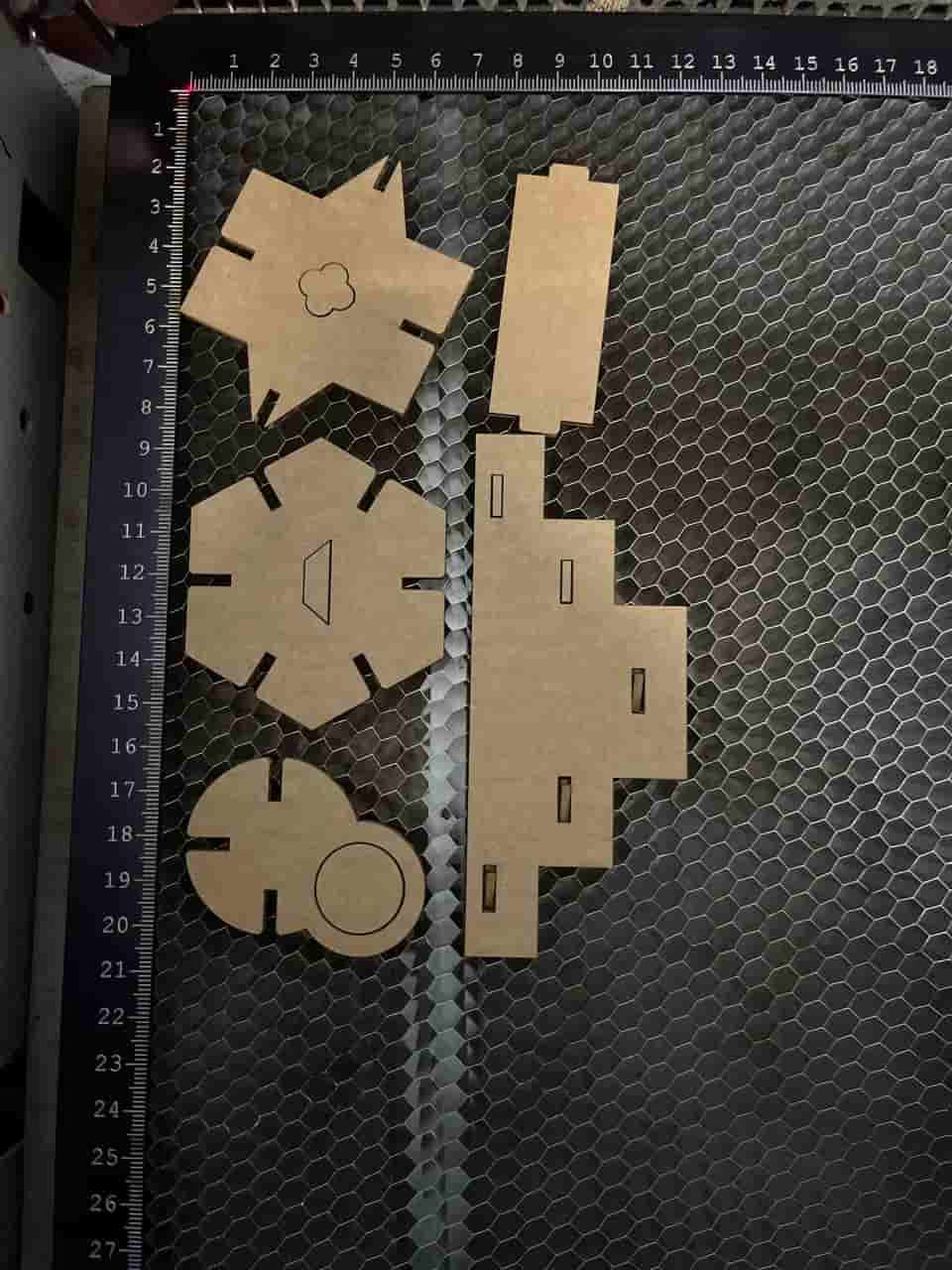

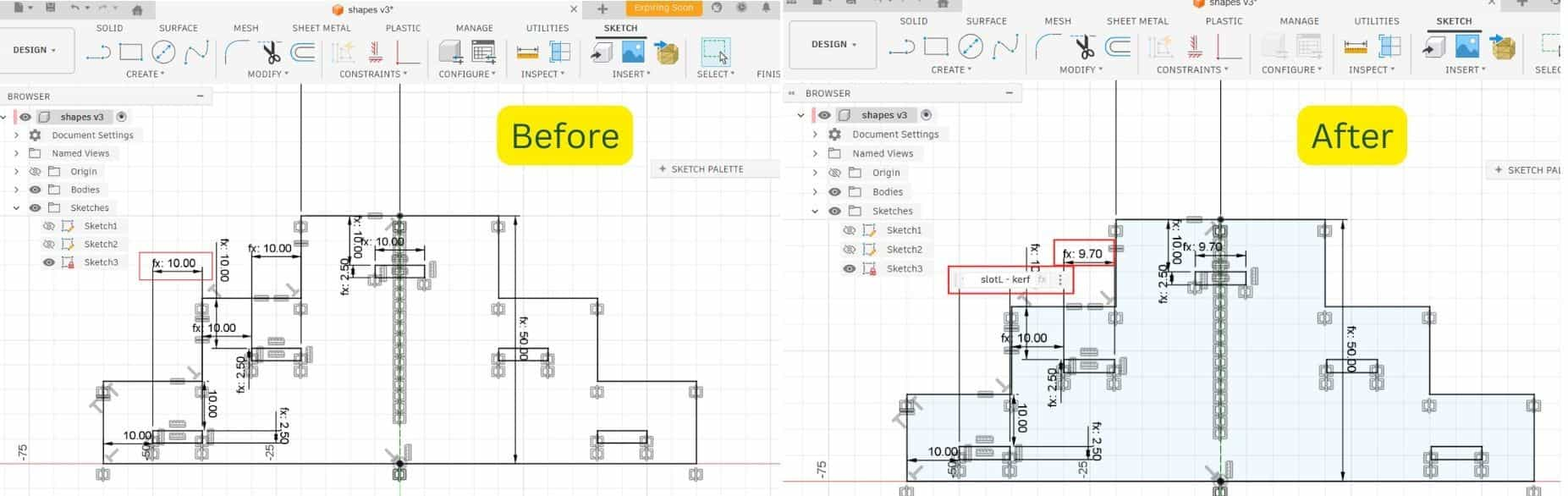

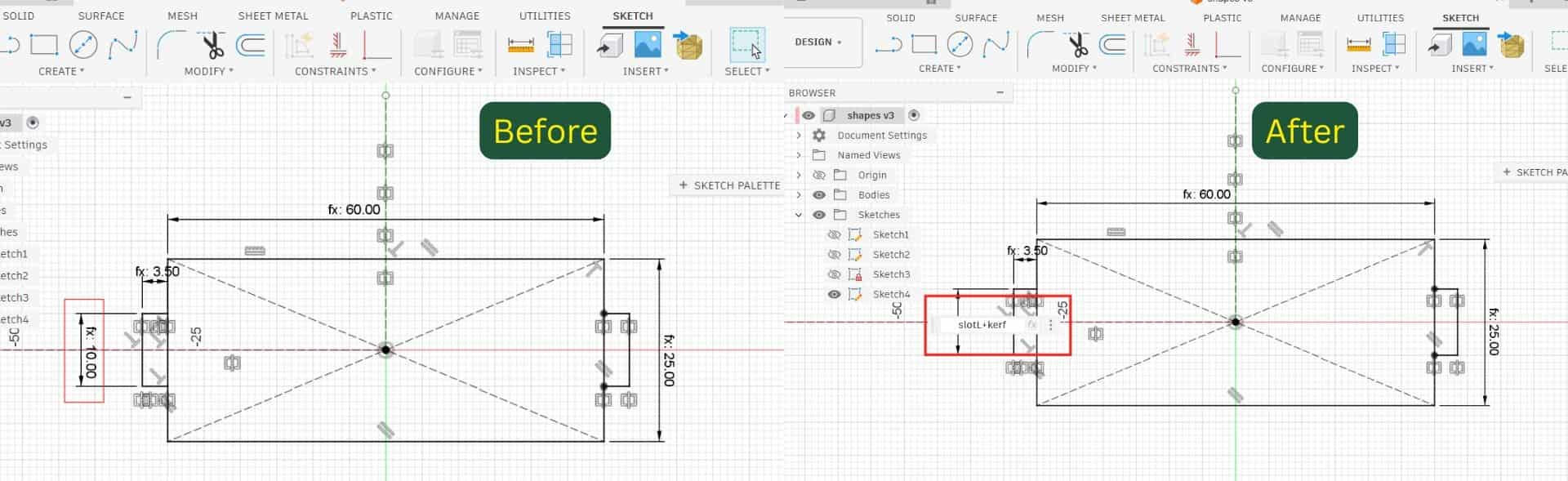

Test Cutting My Kit

First we had to do the test cut for the construction kit to check the fit. Initially I was very eager to directly make the whole kit.

I kept asking Saheen(Instructor) when I could start the final kit, but he suggested doing the test first.

Once I tested it and saw the results, I realized again how important the iterative design process is.

I thought that only needed to consider the kerf while setting the width values. But in the case of a tab - slot joint, kerf must also be considered in the length as well.

Adjusted Value

Since I defined the length parameter as slotL, the slot on the step component became slotL - kerf, and the tab on the strip became slotL + kerf.

After making these corrections, I did the test again, and this time the fit came out much better. This reminded me once again that testing before the final fabrication is very important.

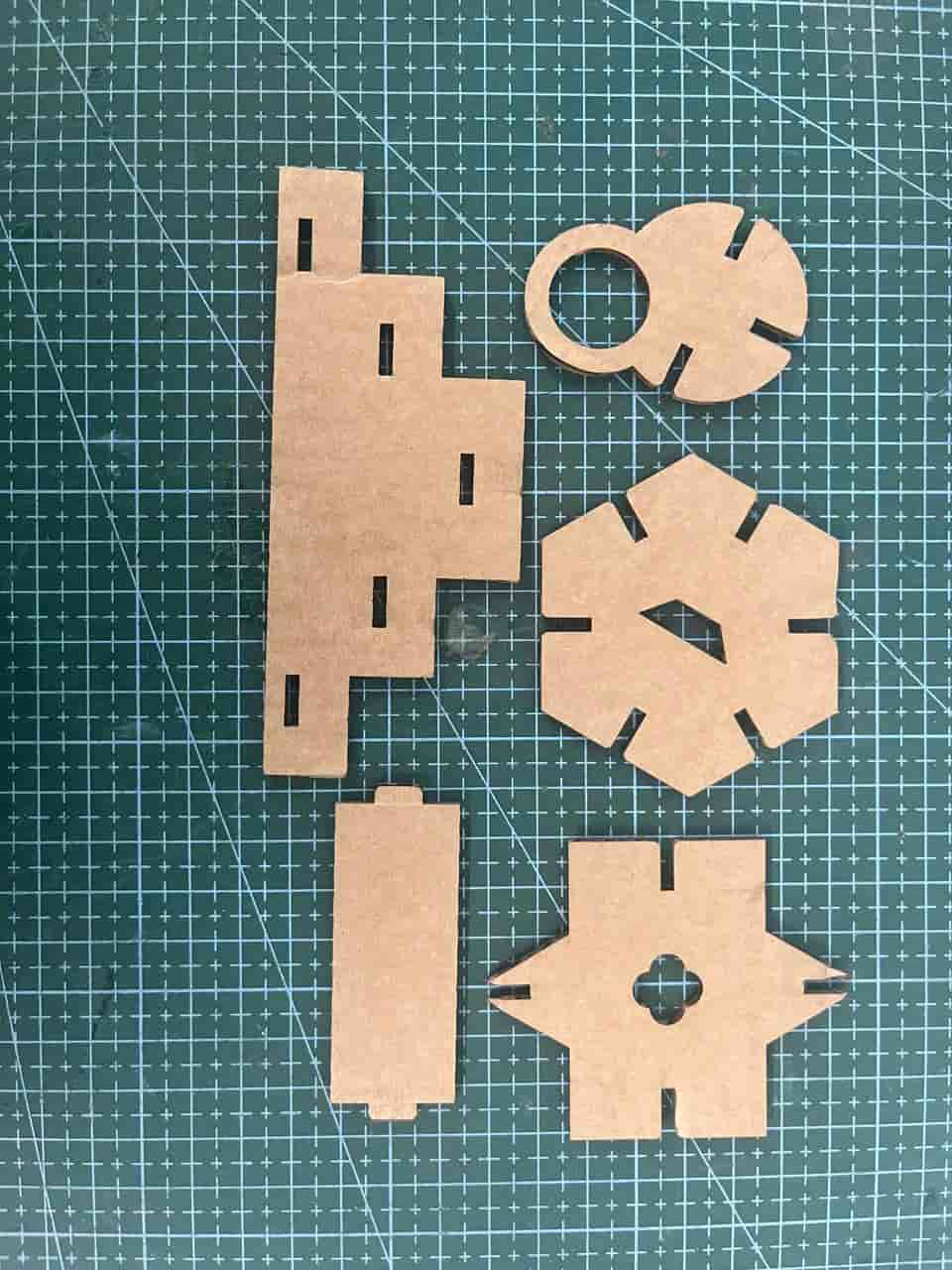

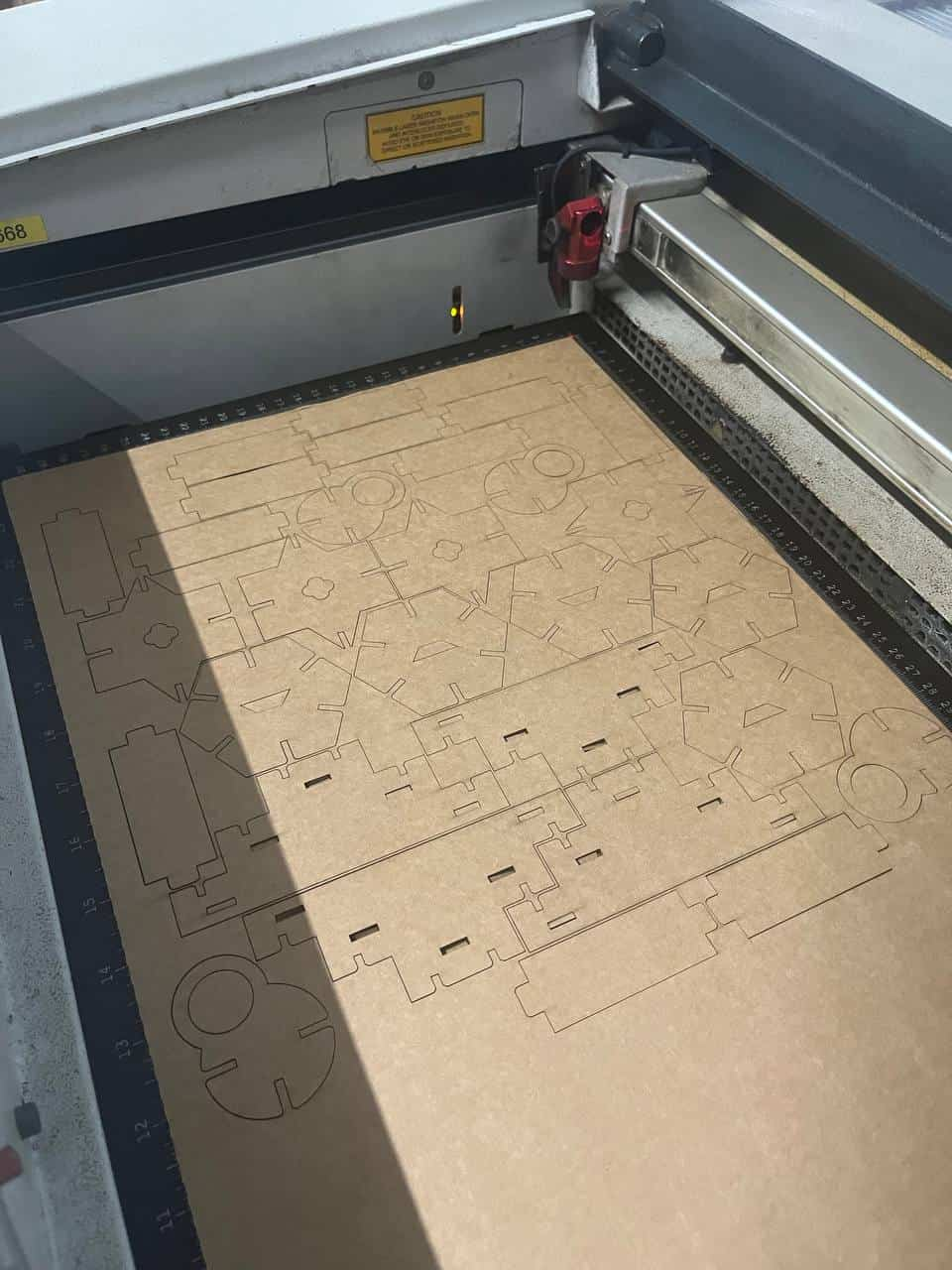

Making the whole kit

First i opened the design in Fusion. All my parts were in bodies, so converted them into components, and then copied and pasted each component as needed. I didn't actually have any fixed requirement for the shapes — they are mostly random, and i wanted to challenge myself to see what all I could construct from them. There is one more thing once you done the minimium requirement of assisgnment, the remaining time you can explore.

[ UPDATES: Fusion has now updated its interface into Parts, Assemble, and Hybrid.

I selected Hybrid because

it allows both part modeling and assembly in the same workspace, similar to the older Fusion version.

Otherwise, if we create in the Parts workspace, they remain bodies, and when inserted into Assemble they convert into components.]

Once I had enough pieces, the next step was arranging them in a better way so that the material waste is minimal.

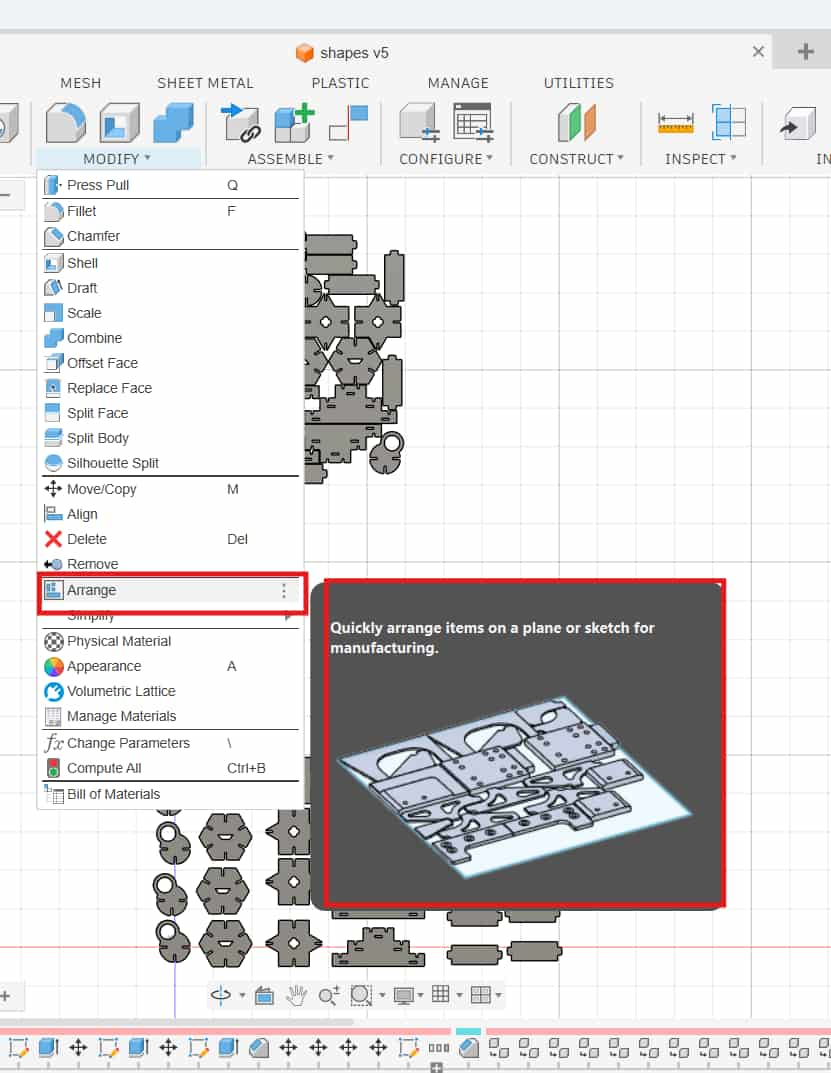

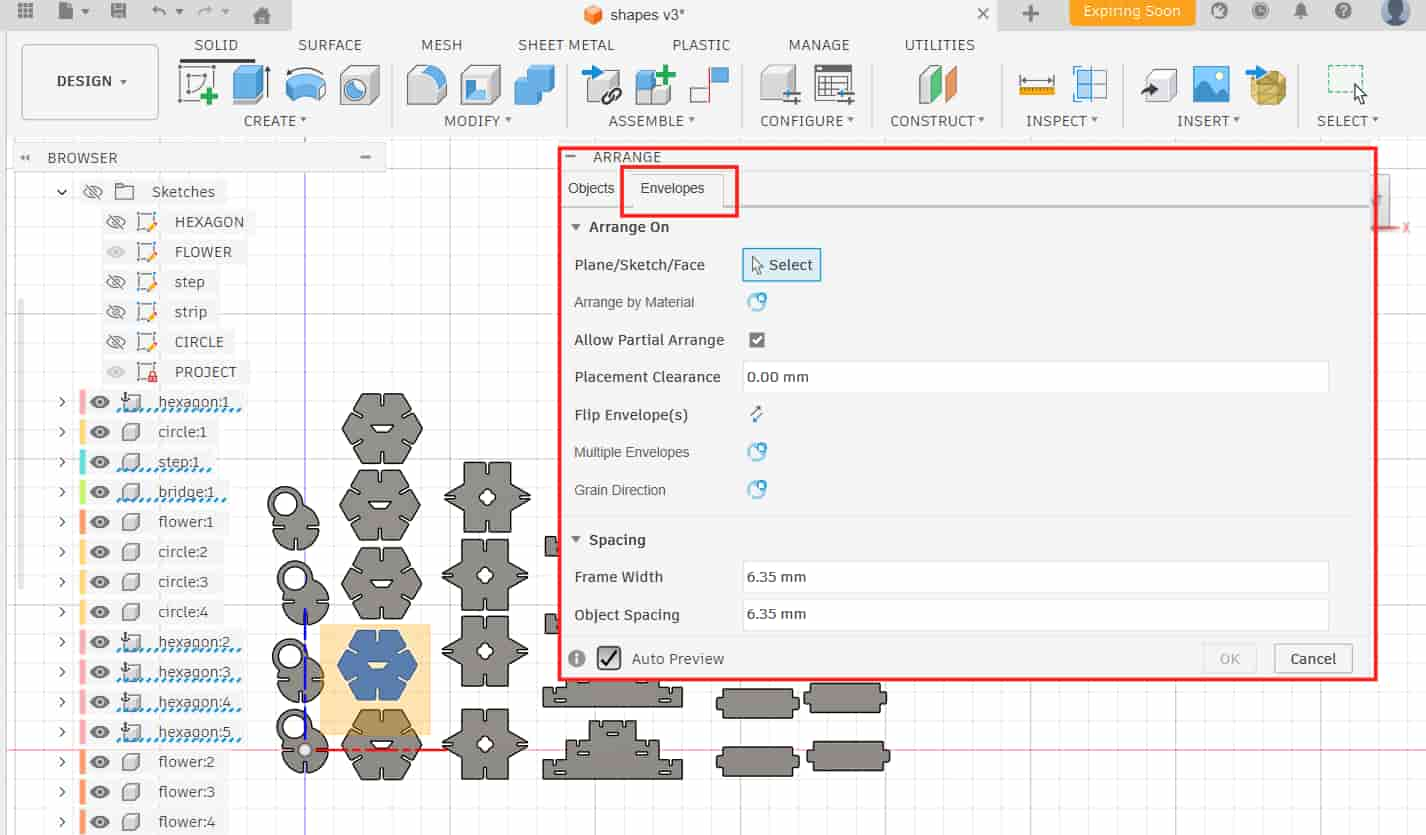

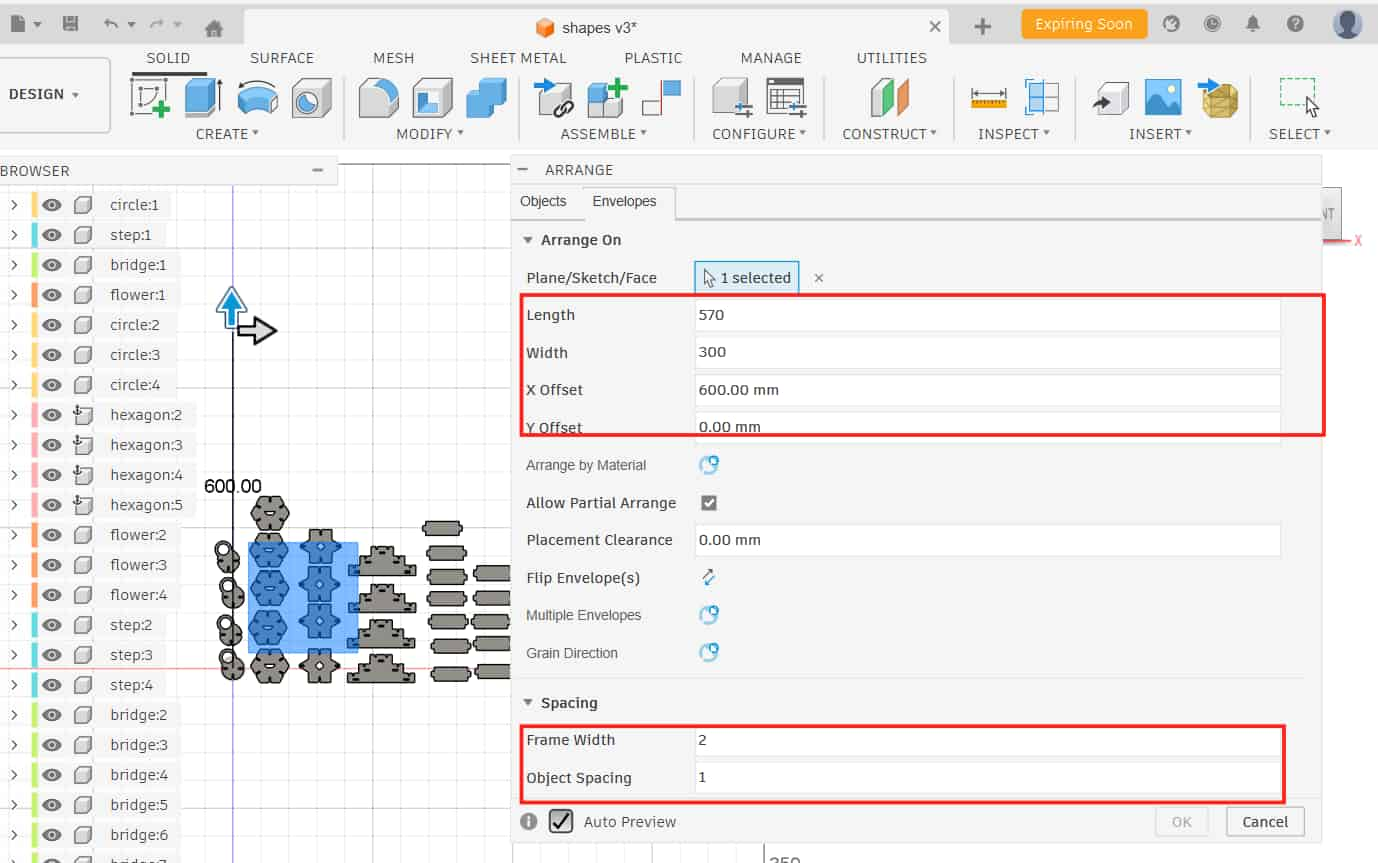

Modify >> Arrange >> Envelopes

Arrange On

I chose Arrange on Plane and selected the Front Plane.

After selecting the plane, the dialog changes and shows the input

fields for length, width, and X-Y offset (offset decides the position of the layout on X and Y axis).

My material size was 570 mm x 300 mm, while the laser cutting working area is 610 mm x 305 mm.

Spacing

In the Spacing section, i have given values to: Frame width (sheet edge margin):2 mm Object spacing (gap between parts): 1 mm.

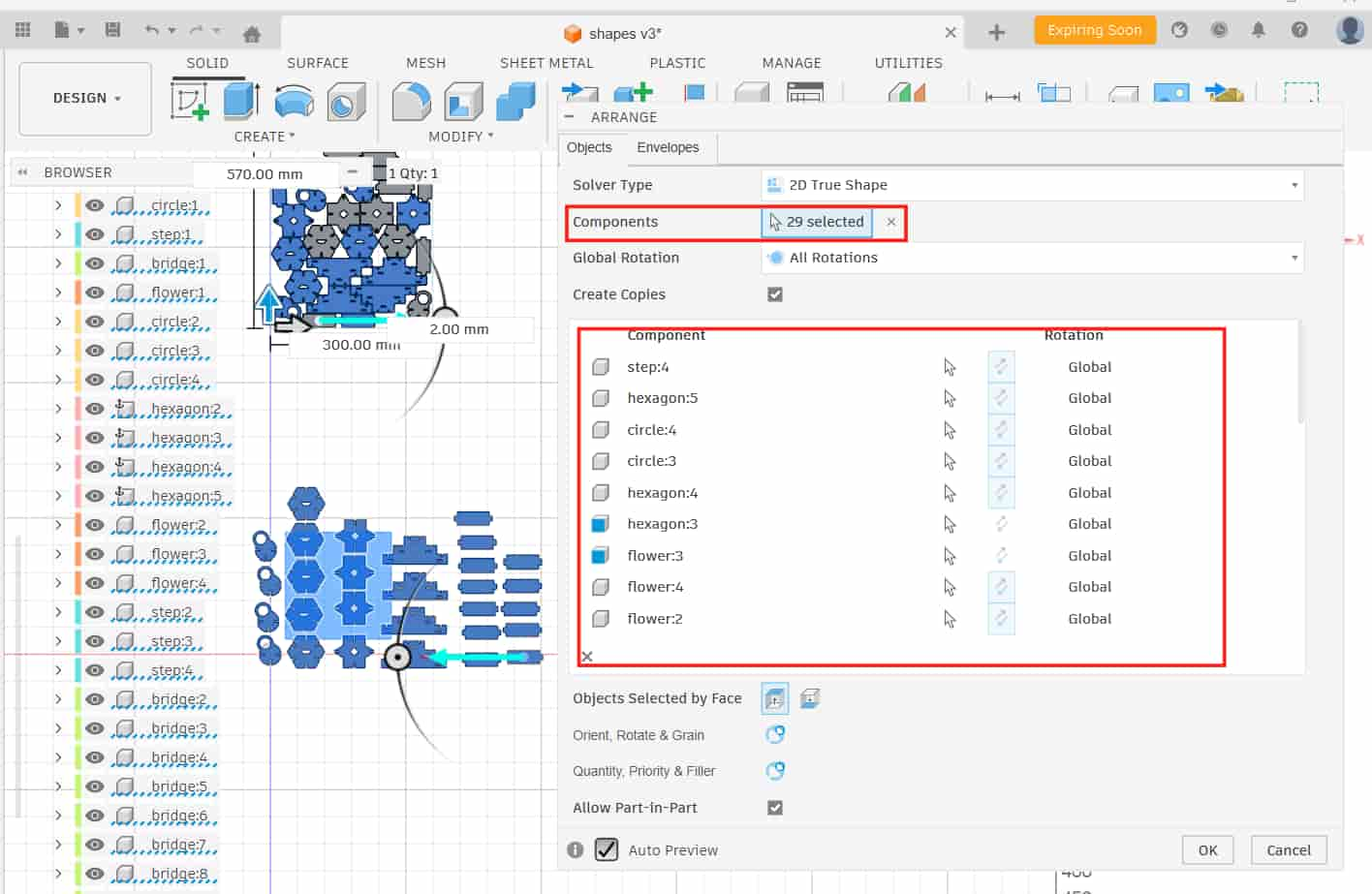

Modify >> Arrange >> Object

Object

I selected all the components that needed to be arranged and clicked OK.

Fusion automatically arranged all the components.

After arranging, I created a new sketch, projected the outlines of the arranged components, and exported the sketch as a DXF.

I opened it in Inkscape, resized if needed, and set the stroke color and stroke width.

Then I followed the same steps as I did for the test cutting and finally cut the whole kit.

Xtool