Week 03.Computer Controlled Cutting

This week is all about digital fabrication through 2D cutting, with a focus on vinyl cutting and laser cutting as tools for turning parametric designs into physical objects. We will explore how CAD and CAM workflows translate designs into cuts, learn how different machines, materials, and settings affect results, and dig into concepts like kerf, joint clearance, and press-fit construction. We will get hands-on experience making stickers on the vinyl cutter and designing a parametric laser-cut construction kit, while also working as a group to characterize our lab’s laser cutter and review safety. By the end of the week, we will have tangible, customizable results that reflect experimentation, iteration, and design intent.

Group Assignment

The group assignment can be found on this link.

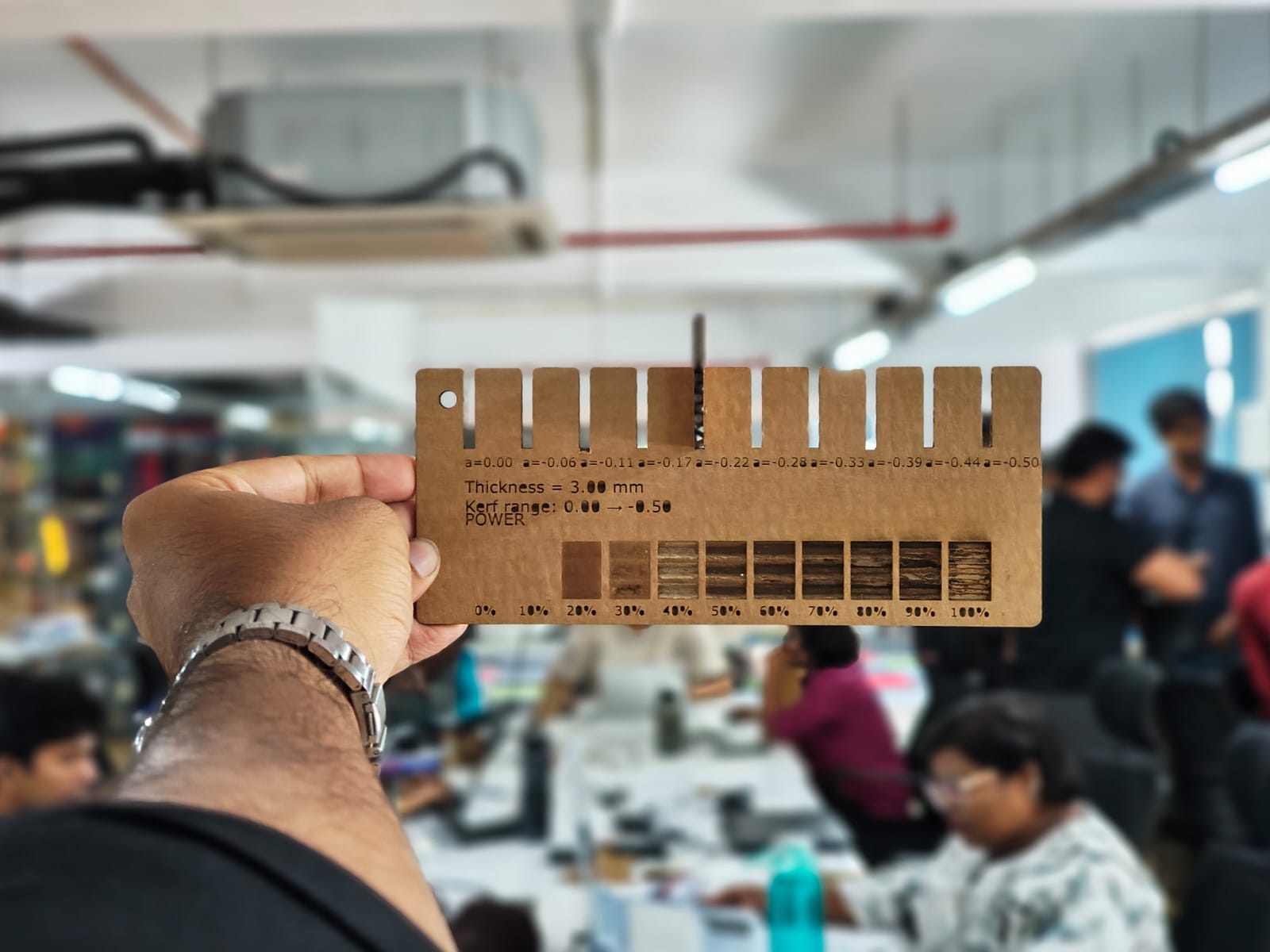

As a part of our group assignment we were given a safety training for operating the laser cutting machine. We found out the kerf values of different materials for a tight press fit.

Safety Training

Strict safety measures were followed during operation:

A detailed version can be found on the Group Assignment link.

Cardboard

As a part of our group assignment we were given a safety training for operating the laser cutting machine. We found out the kerf values of different materials for a tight press fit.

Individual Assignment

Vinyl Cutting

Making Stickers using Vinyl Cutter

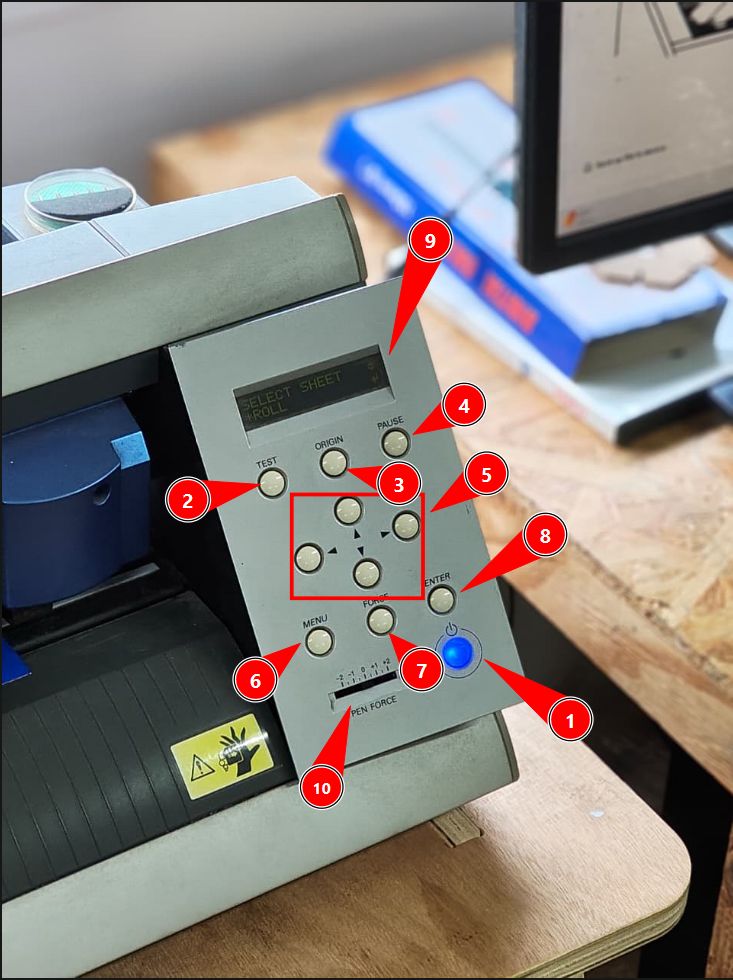

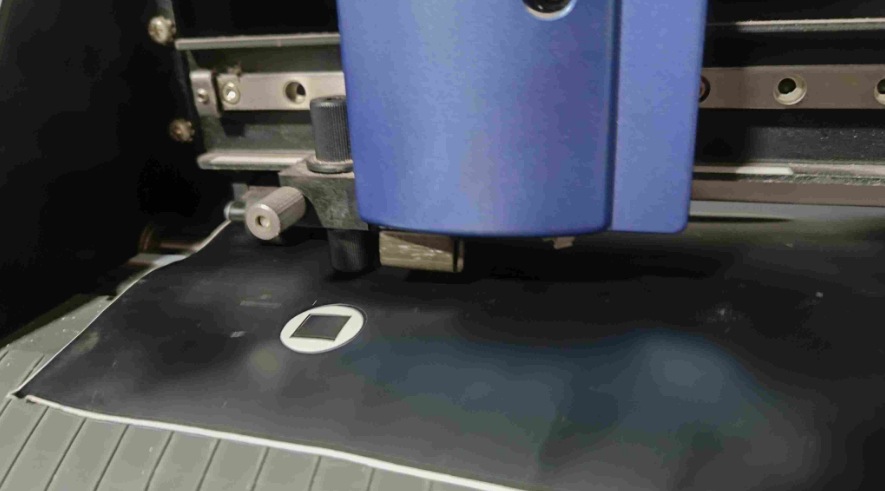

The next part of our assignment was to create stickers using vinyl sheets. For this task, we used the Roland GX-24 vinyl cutter available in our lab. This machine is designed for accurate cutting of thin materials such as adhesive vinyl, heat transfer vinyl, and stencil sheets.

We can select the material feed type such as roll, sheet, or piece. From the control panel, we can also set the origin point, and adjust the cutting force and cutting speed based on the material.

Vinyl Cutter Control Panel Settings

Roland CAMM-1 Servo machine settings

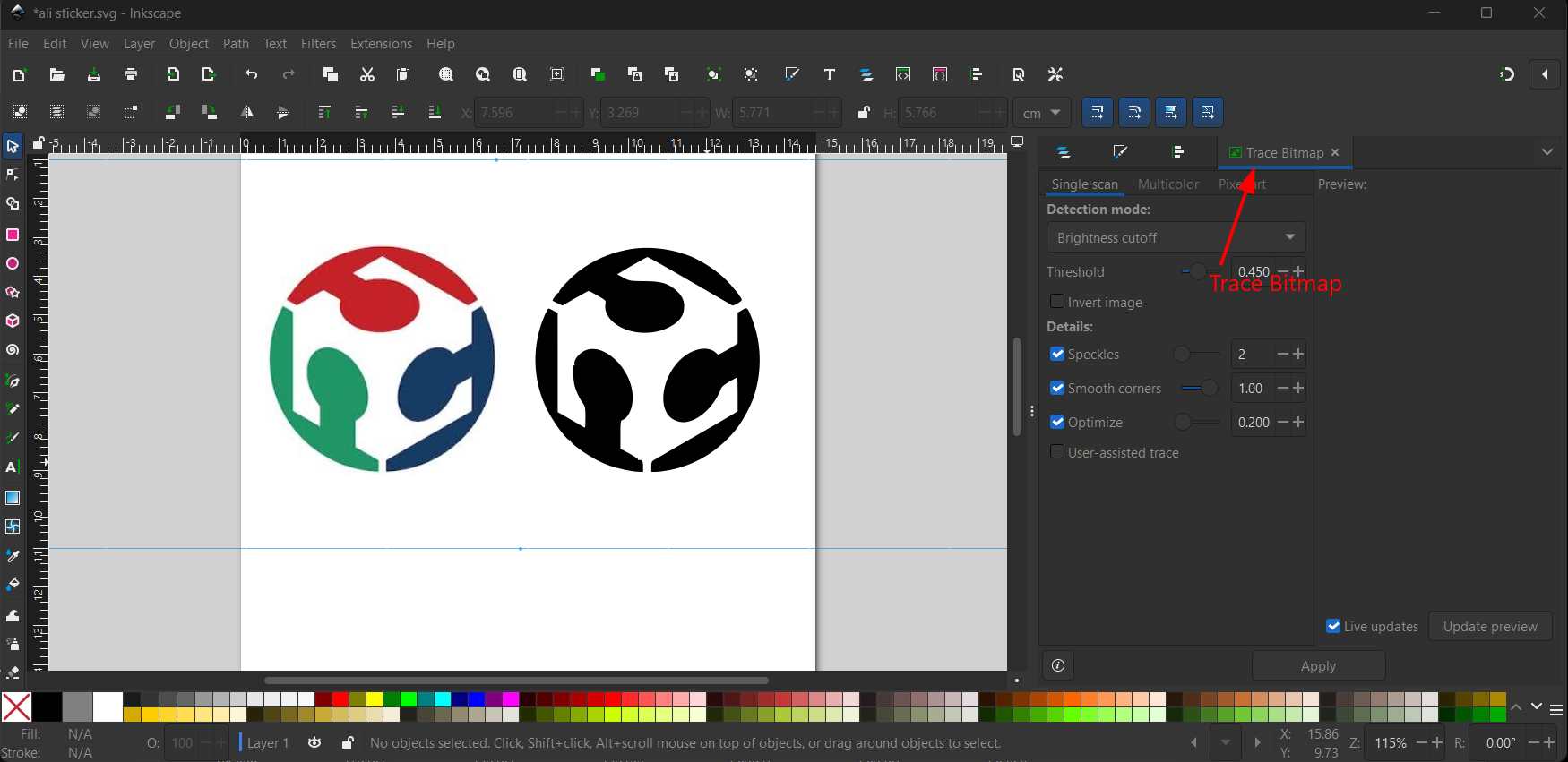

Before using the machine, we first needed to prepare the sticker graphics. For this assignment, I selected the Fab Academy logo as my design. I created the logo in three different colors, so we could cut and make the stickers in different color variations.

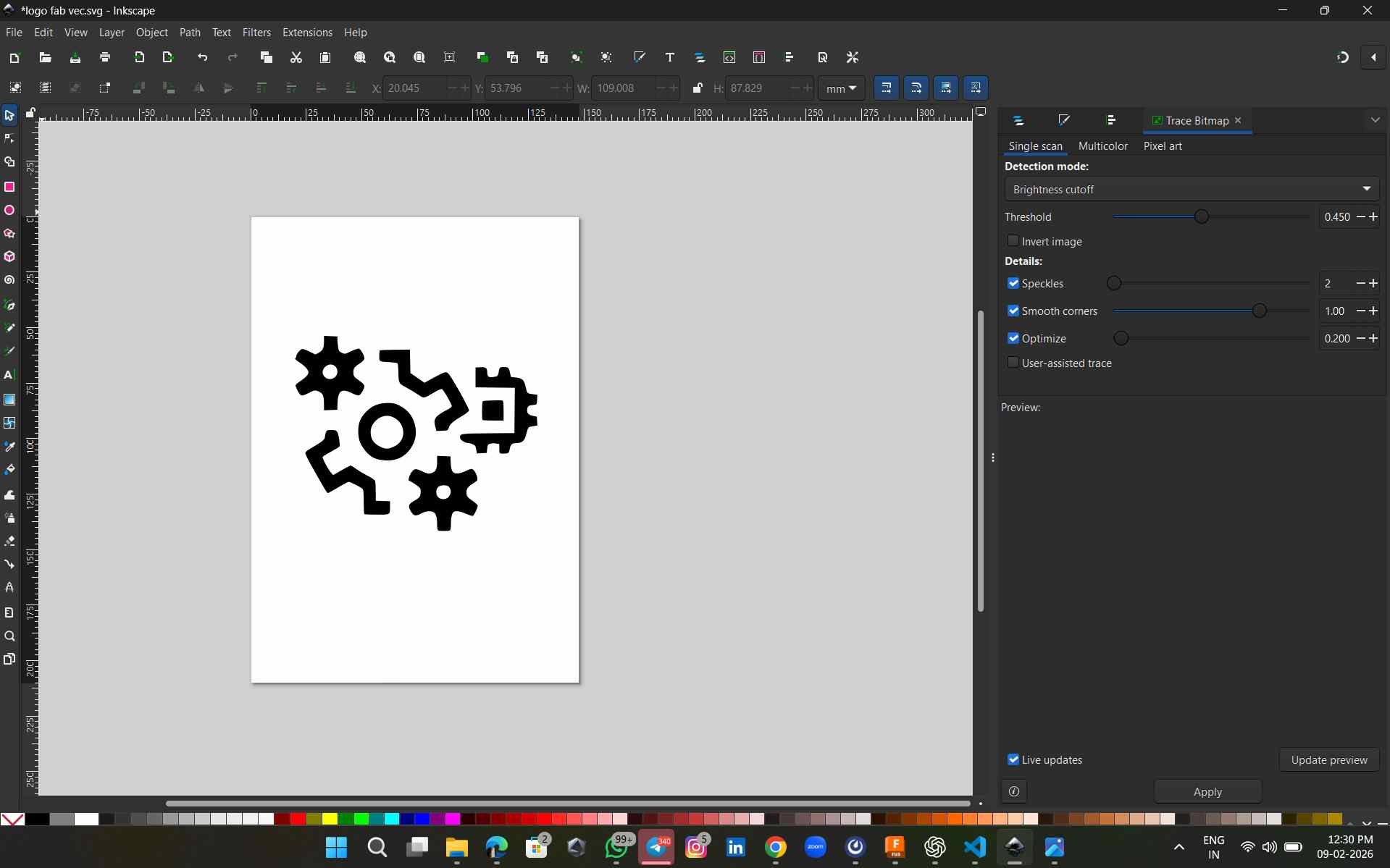

After that, I imported the image into Inkscape and used Trace Bitmap to convert the Raster into a vector file. (This conversion process is explained in my Week 02 assignment.)

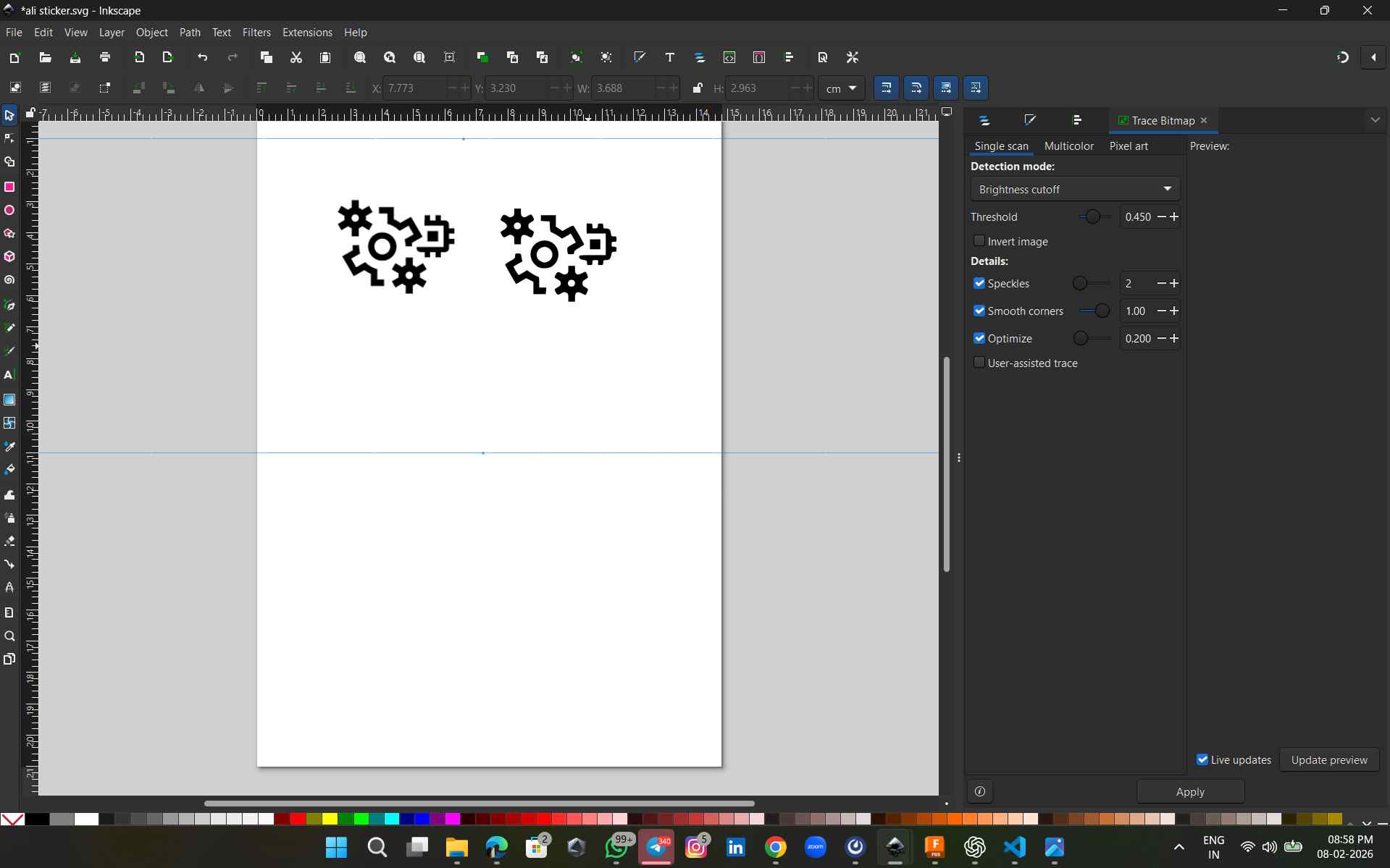

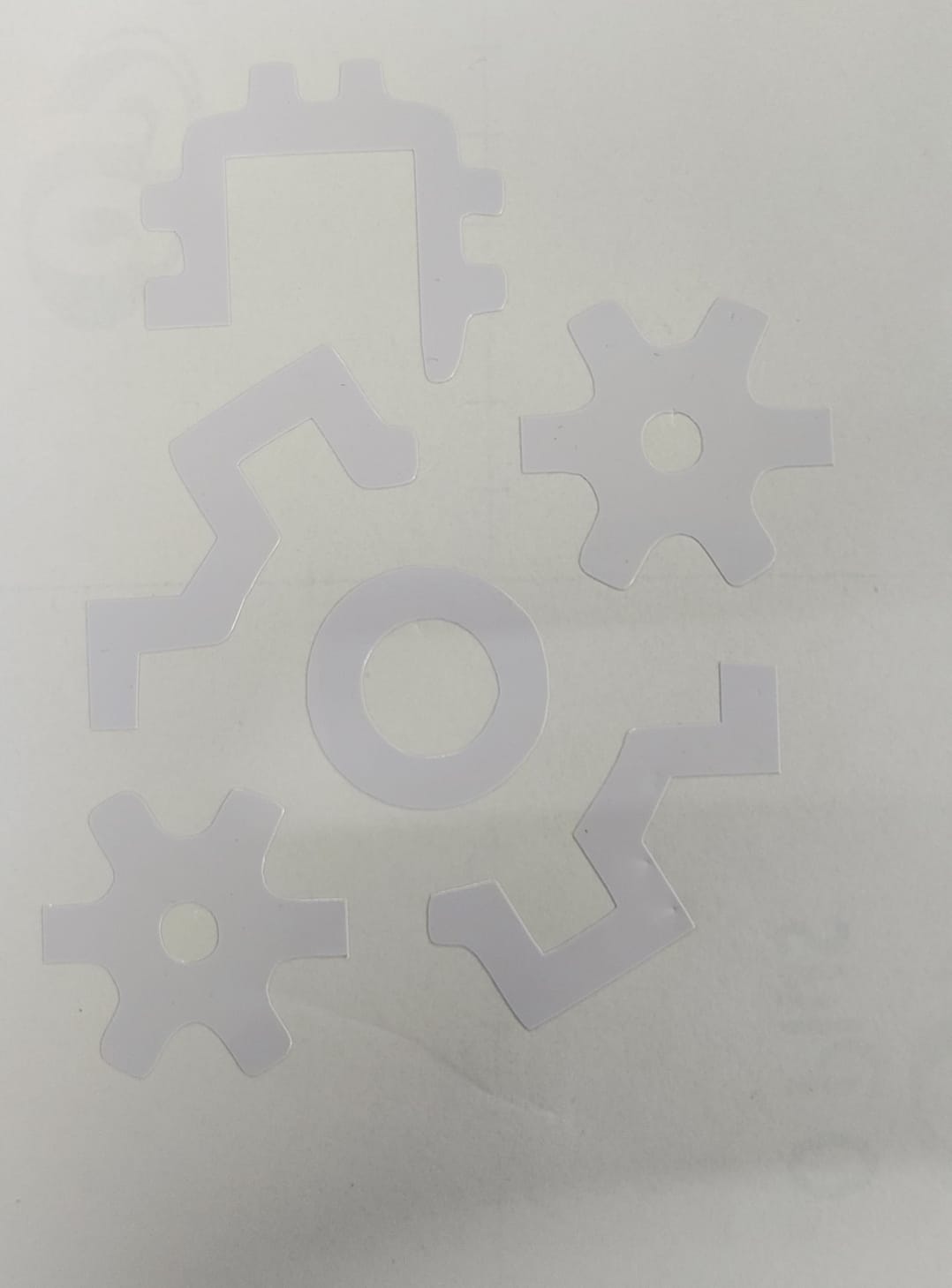

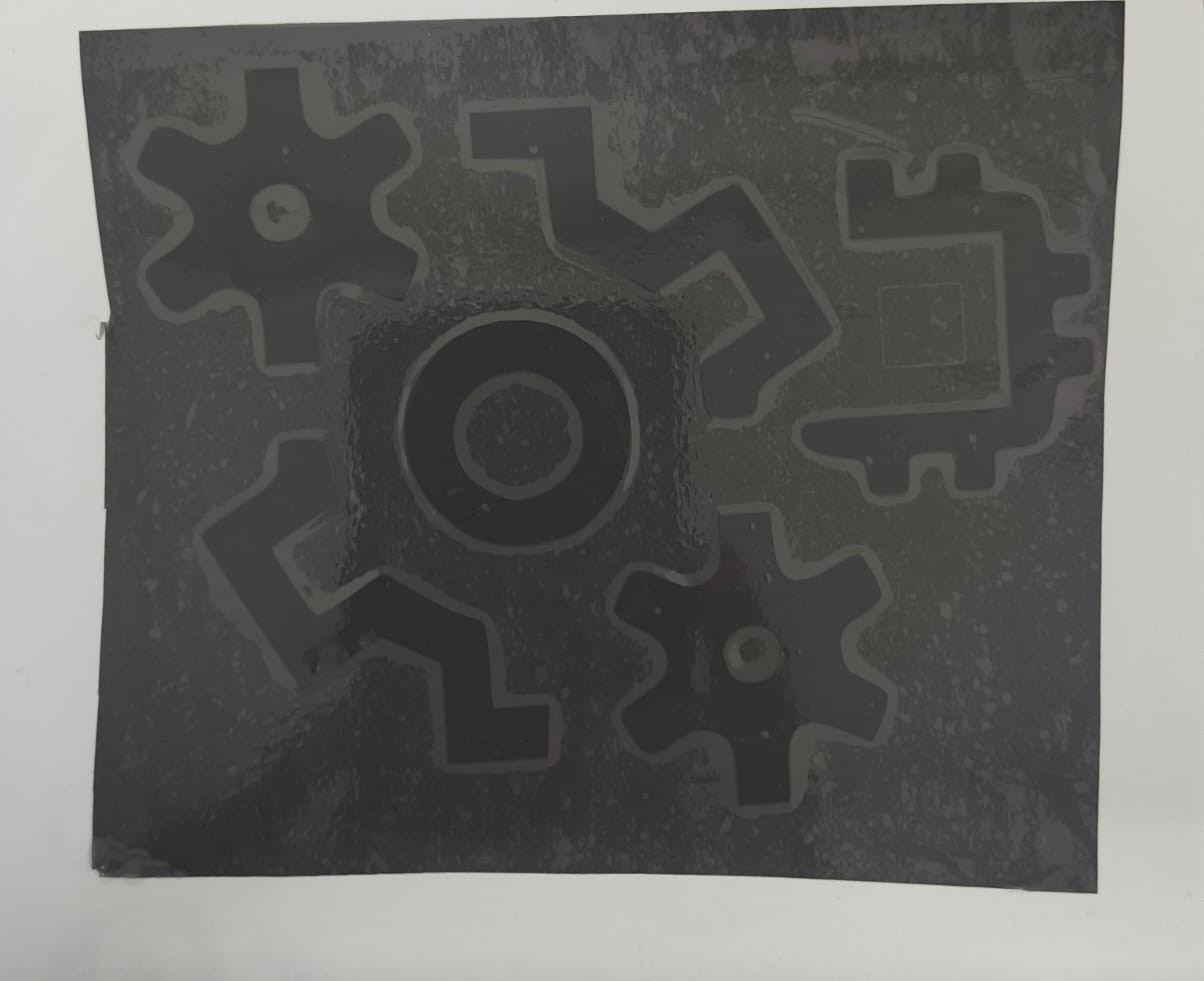

I made a second sticker design based on a mechanical shaft and gear graphic sourced from Google, and prepared it for vinyl cutting.

To make sure the design edges were not cut off, I added an offset stroke of about 2–3 mm around the traced image. After that, I resized the canvas (Ctrl + Shift + R). Then I removed the stroke since it was only needed for spacing. Finally, I selected the full design and saved it as an SVG file.

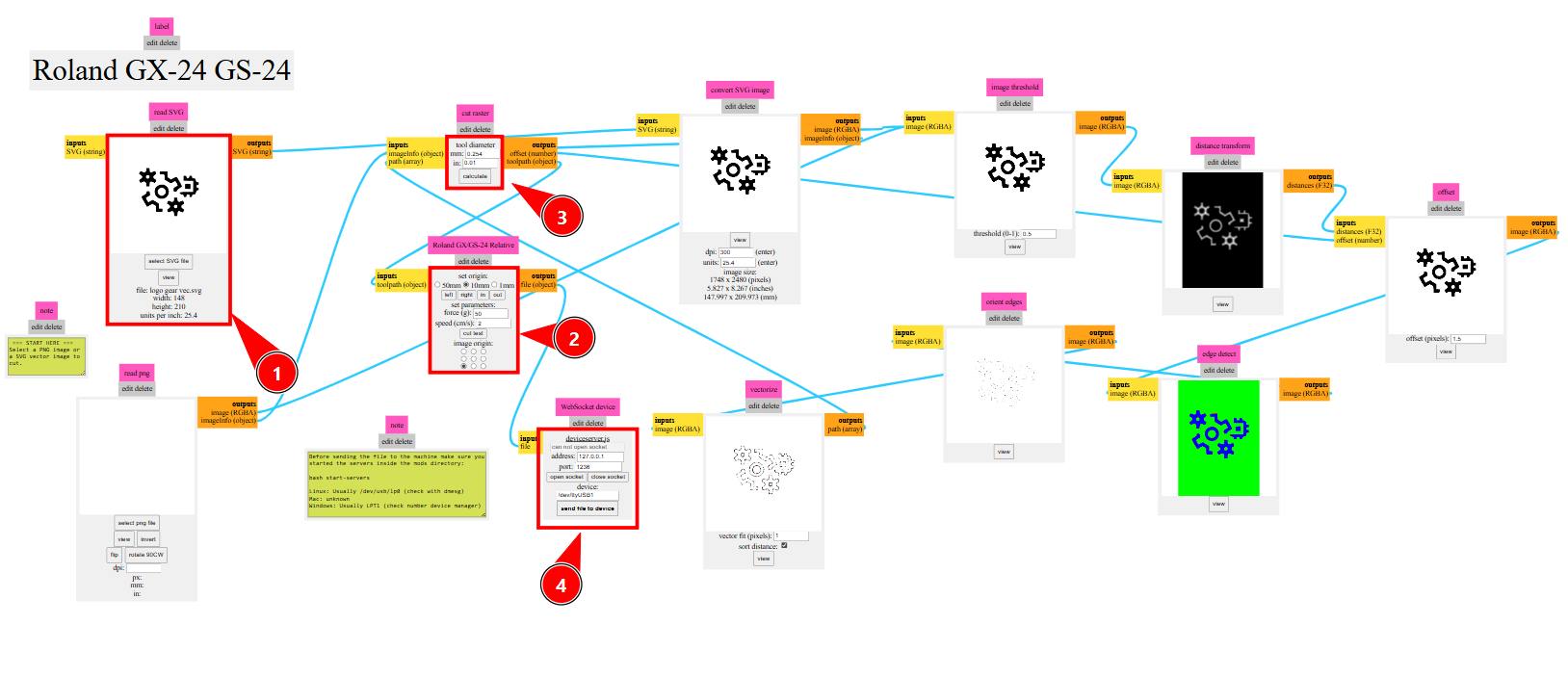

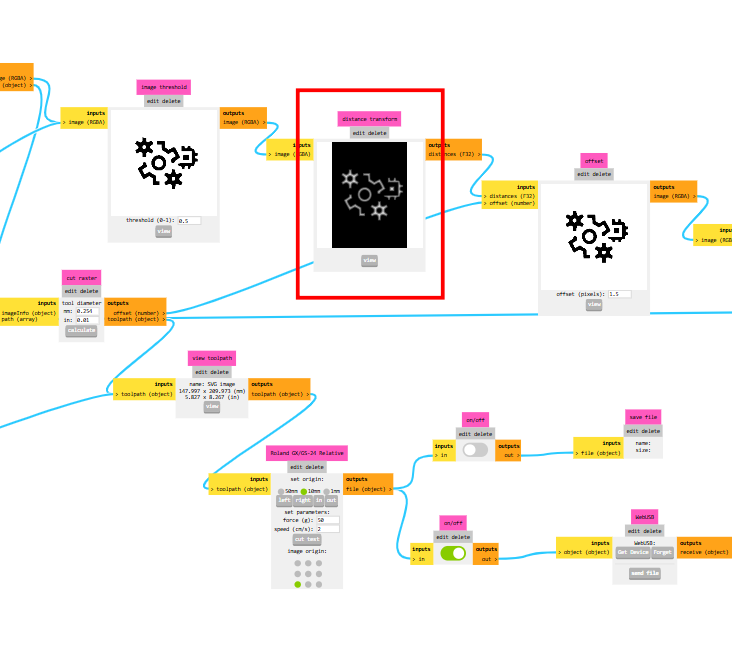

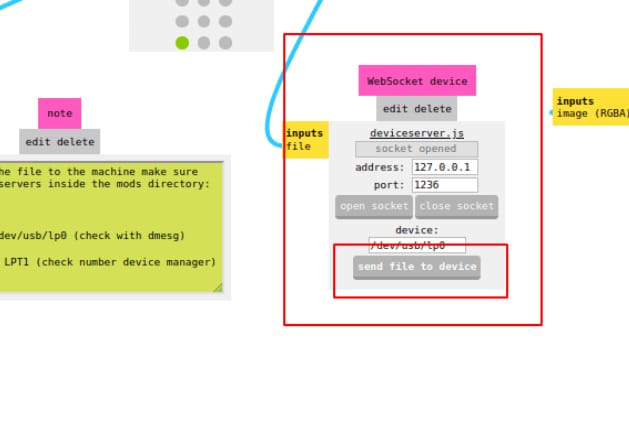

Next, we opened the MODS software and imported the SVG file we prepared. MODS is an open-source, browser-based tool developed by MIT that converts design files such as SVG, PNG, and DXF into machine-readable formats. It allows us to customize toolpaths, set cutting parameters, and send commands directly to machines like vinyl cutters, laser cutters, and CNC machines. After importing the design, we set the required cutting parameters in MODS before sending the file to the vinyl cutter

Here are the steps to use MODS

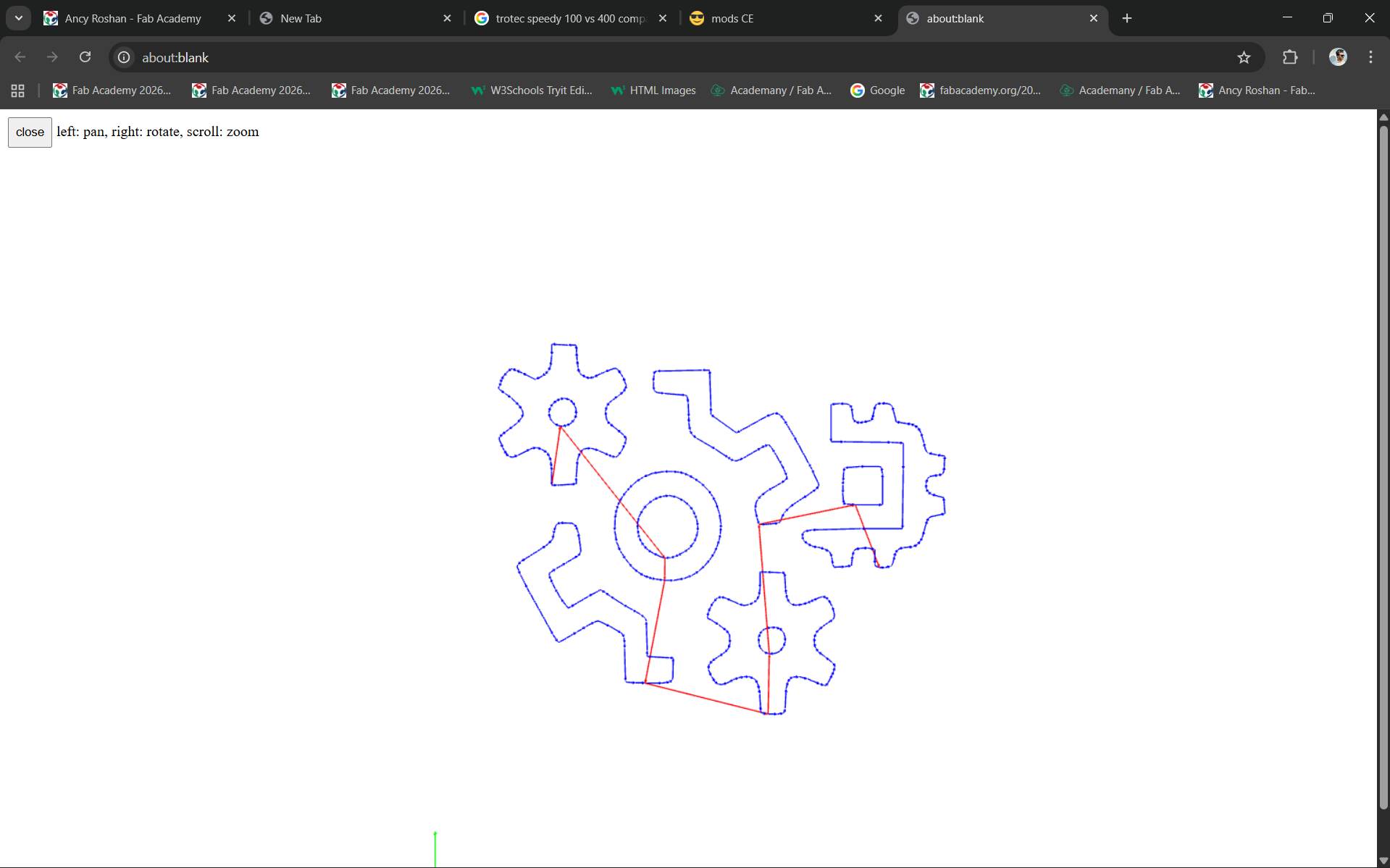

If we Click the view button in 'vectorize module' after calculation that will show the vinyl cutter tool path in New Tab

The other modules shows offset and how much detail we can get and etc...

We needed to set the machine origin based on the vinyl roll position. After setting the origin, I made a few test cuts to check and adjust the cutting depth.

Cutting Parameters

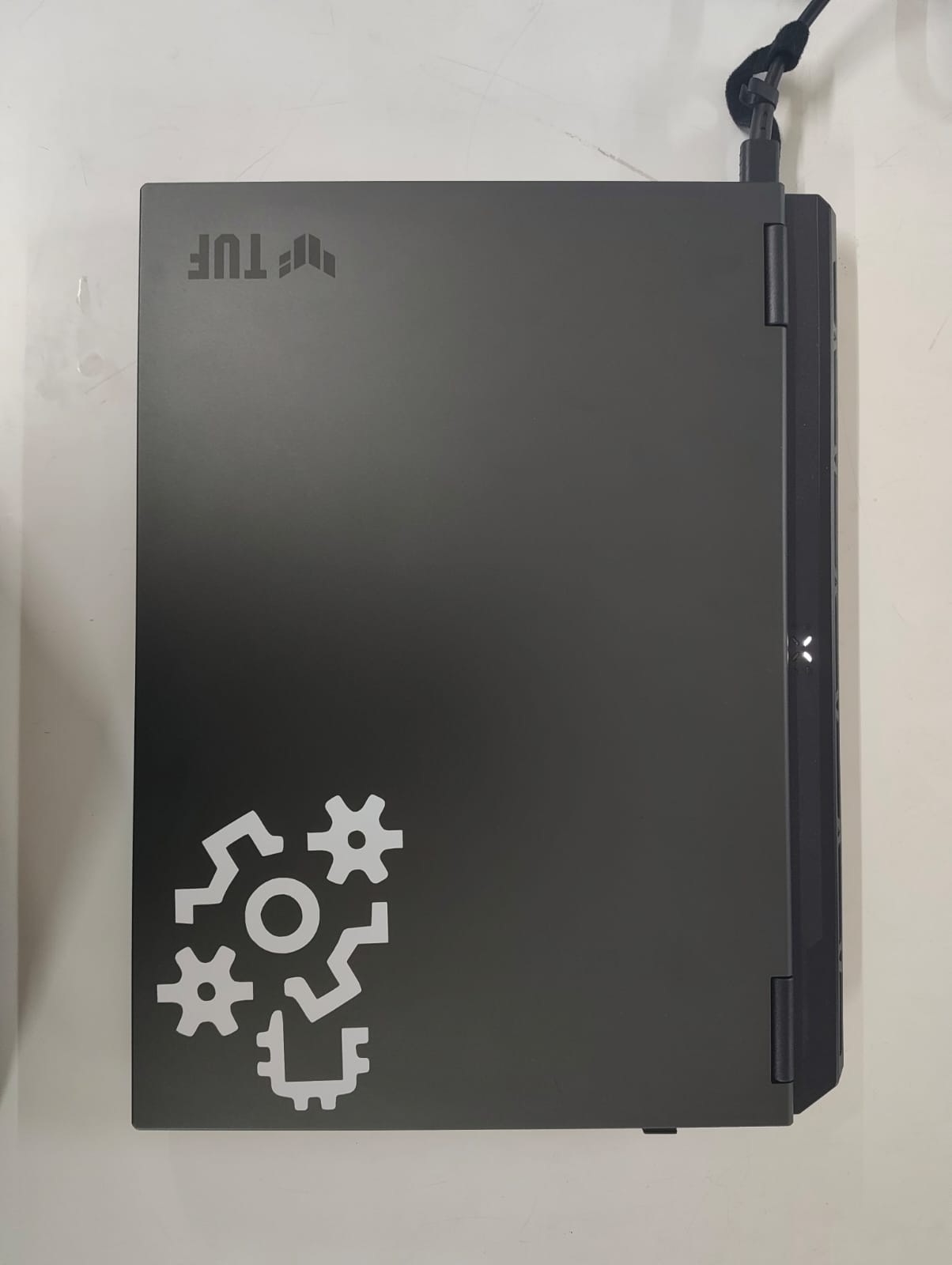

I decided to apply the first sticker on my lap top . First, I removed the unwanted vinyl parts (weeding). Then, I took a piece of transfer paper, peeled off the backing, and carefully placed it on top of the vinyl sticker

Then, I placed the vinyl along with the transfer paper onto my laptop. After positioning it properly, I slowly peeled off the transfer paper while ensuring the vinyl stayed on the surface smoothly without creating any air bubbles.

I would like to create more sticker designs in the future, because I really enjoyed this process and found it fun.

Making a parametric construction kit.

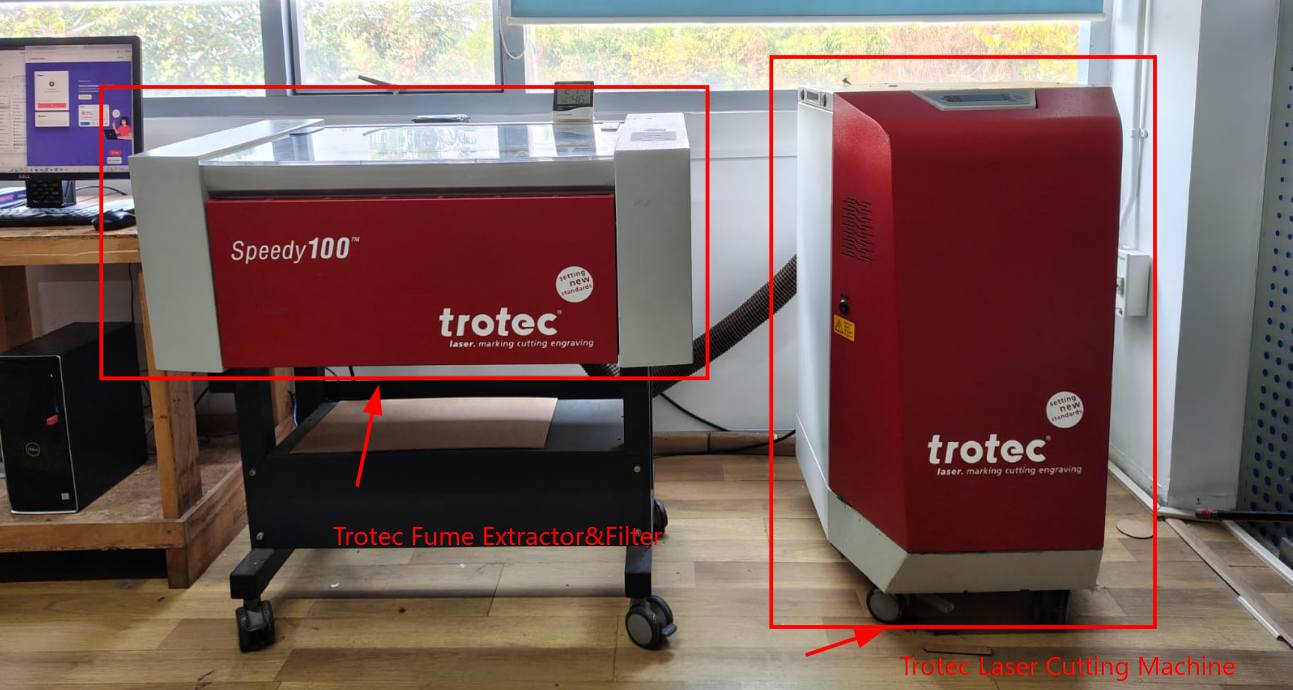

Trotec Speedy 100

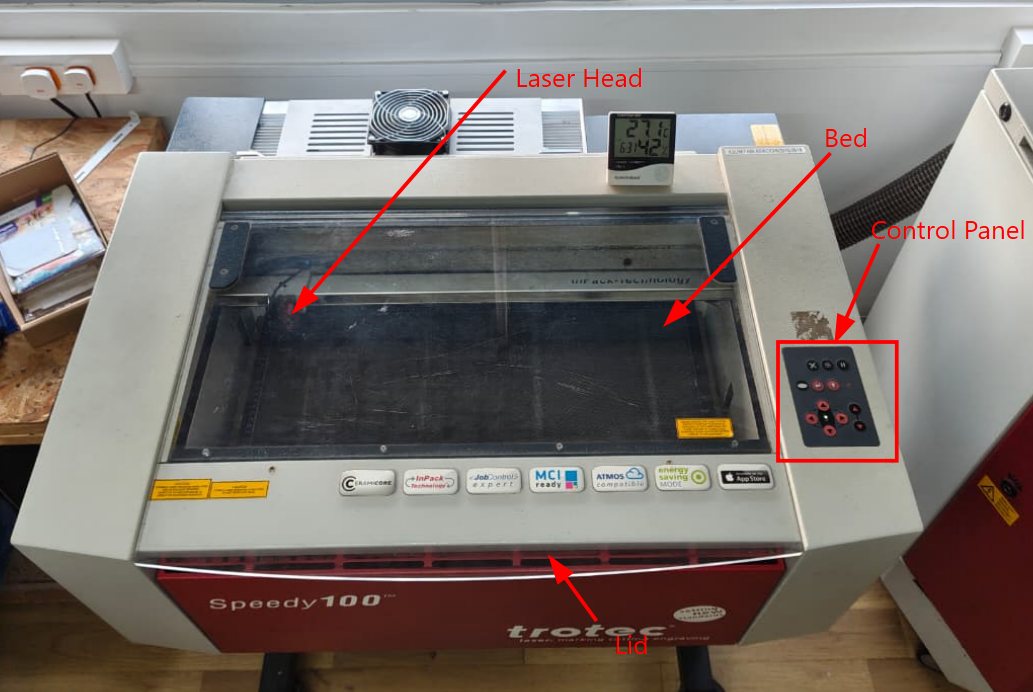

The Trotec Speedy 100 Flexx is a high-performance machine used for both laser cutting and laser engraving. It belongs to Trotec’s Speedy series, which is well known for its quality and reliability.

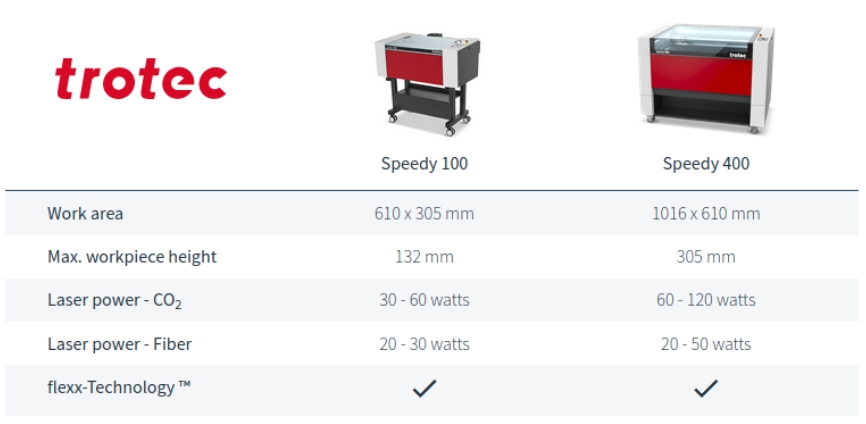

Trotec Speedy 100 vs Speedy 400

The Speedy 400 machine at the Super FabLab is significantly more powerful than the Speedy 100 and also features a larger work area, as shown above.

The “Flexx” feature means the machine combines both a CO₂ laser and a fiber laser in one system. This allows it to process a wide range of materials using a single machine.

To cut materials of different thicknesses, the laser head and the workpiece must be kept at the correct focus distance. This tool is used to set the focus distance on the Speedy 100 laser machine. We must adjust the focus manually each time we use a different material thickness.

This is the control panel used to move the laser head and select the work area. It also includes other controls such as the fan control, pause button, and Z-axis bed leveling options.

To cut materials of different thicknesses, the laser head and the workpiece must be kept at the correct focus distance. This tool is used to set the focus distance on the Speedy 100 laser machine. We must adjust the focus manually each time we use a different material thickness.

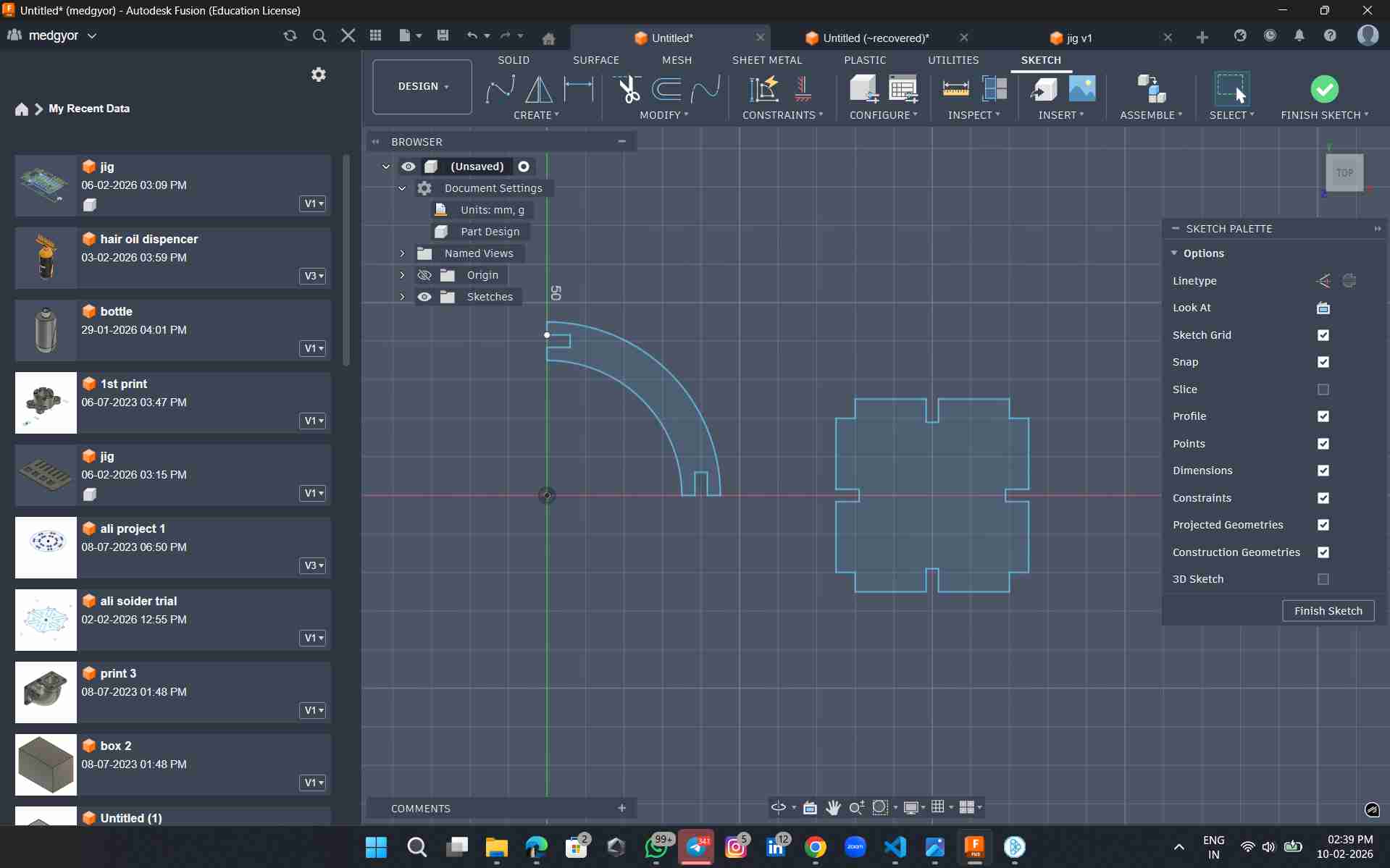

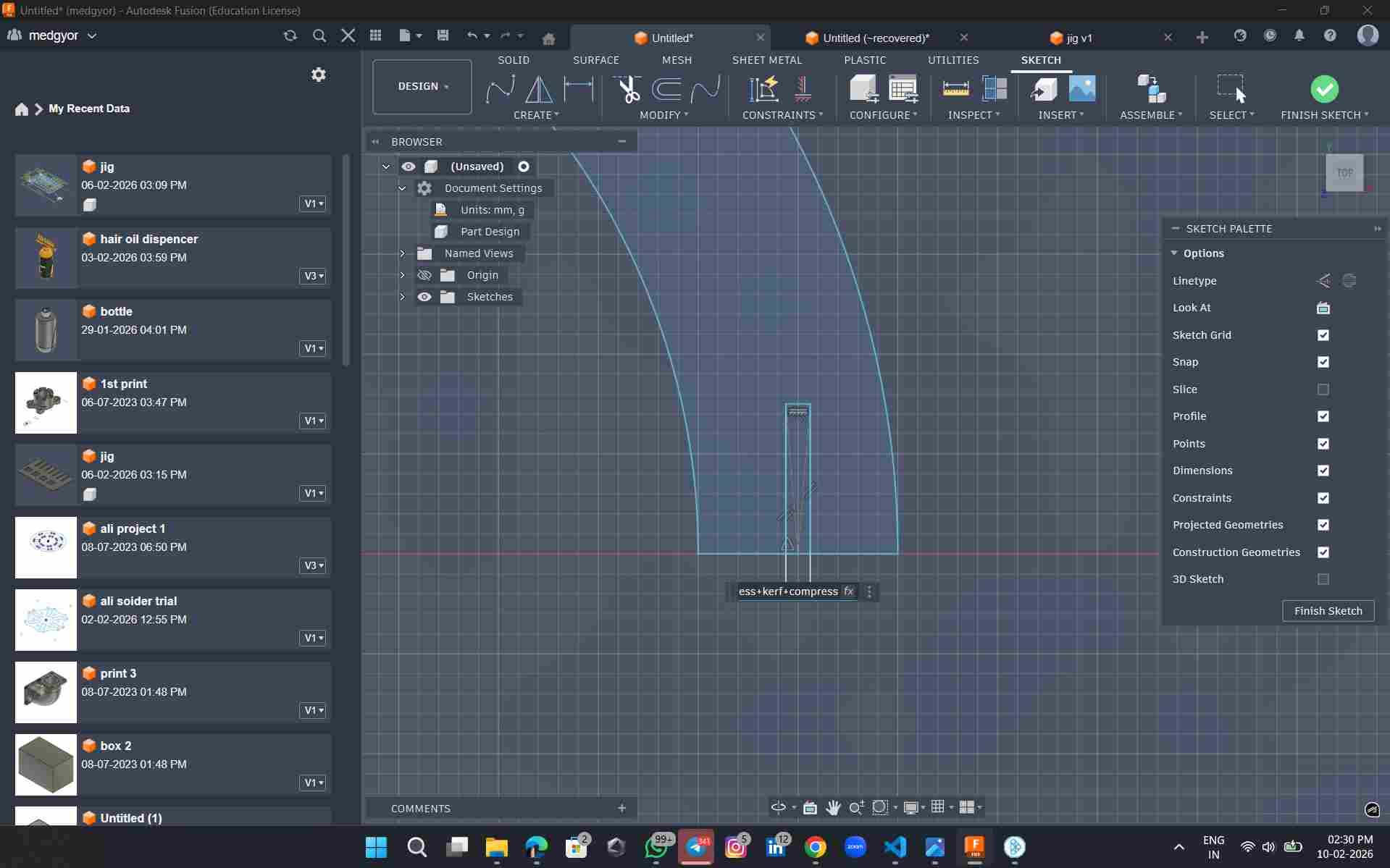

Parametric design

We had to design a shape that could be repeated and joined in different ways. I used Fusion 360 and created the model using the Modify → Change Parameters tool. This method is useful because the dimensions can be changed easily by updating the parameter values, instead of editing the sketch manually. It is a powerful feature and can be used in many different design applications.

So, if you change one value, the whole model updates automatically

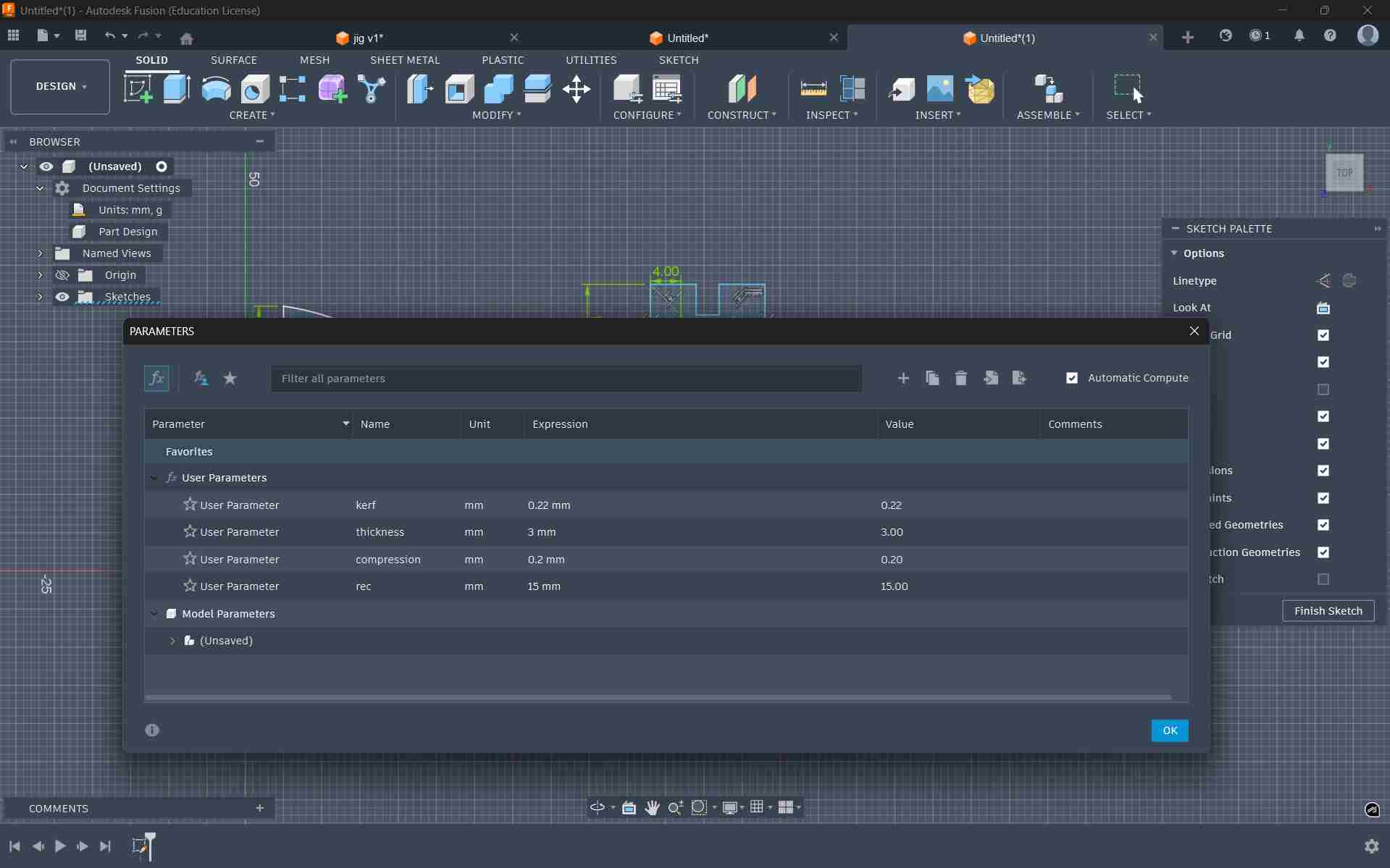

parameters

I began by setting the parameters first. Go to modify and at the bottom of the drop down you can see change parameters.When you click on it you will be taken to a dialogue box where the user can set the parameters. I set the values for the thickness of the material, kerf value of the materials and compression .I then took these parameters to make equations to set the width of the slot.

You can type in the parameter that was set previously into the dimensions . The software will automatically resize the dimension to fit the parametric values

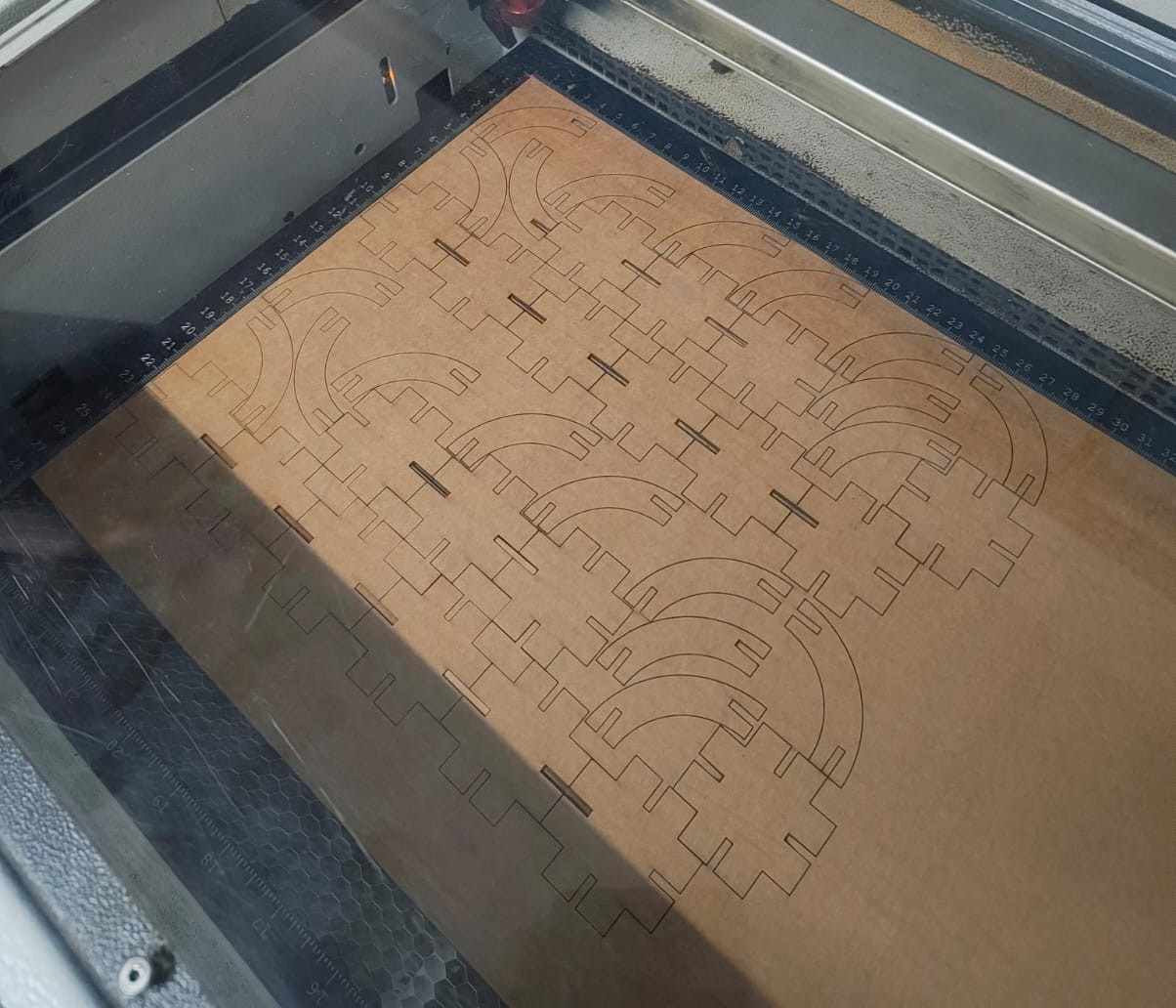

Operating the laser machine

Click Ready to give the print .The laser will start the cutting process.

Click Ready to give the print .The laser will start the cutting process.

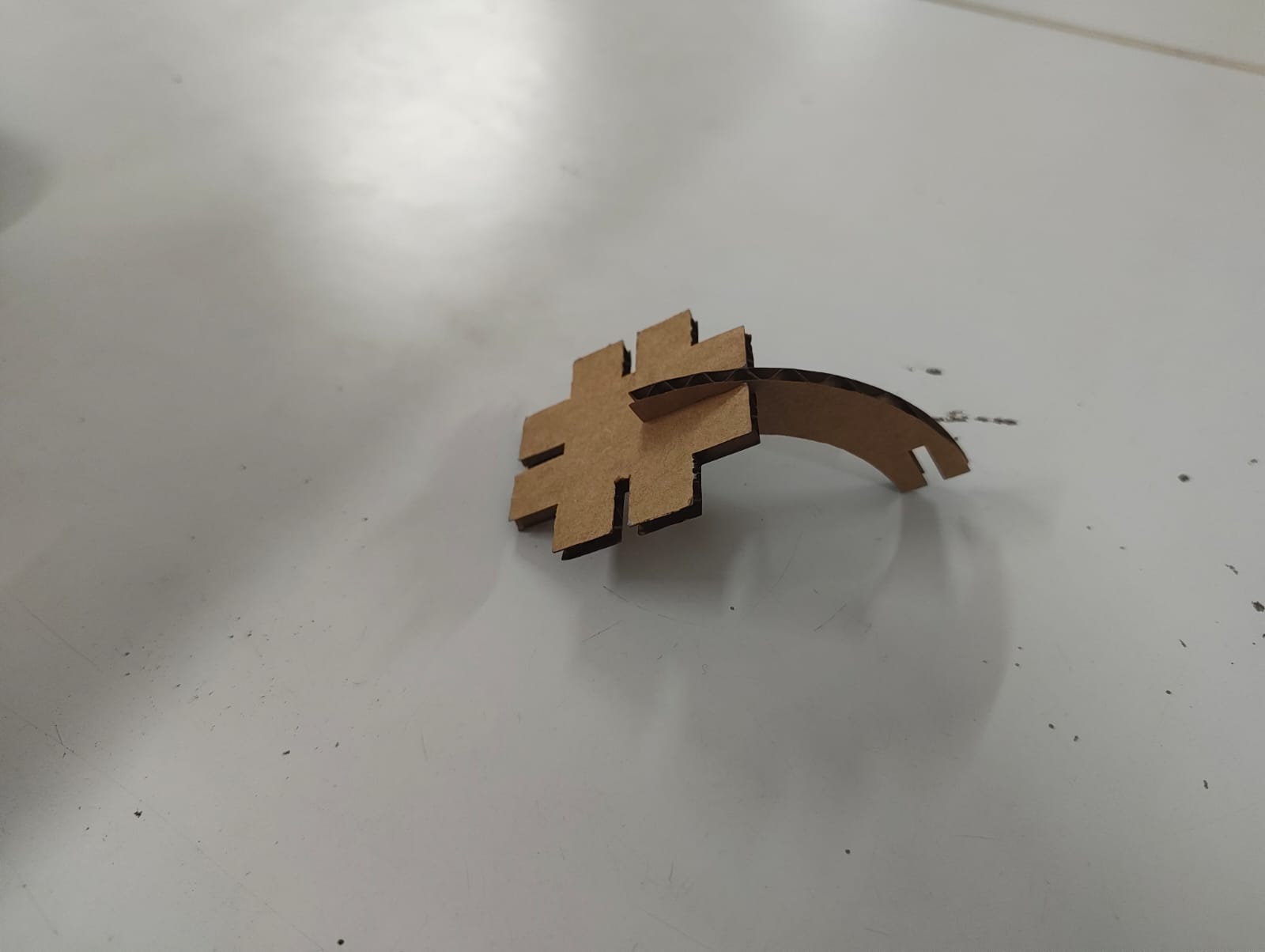

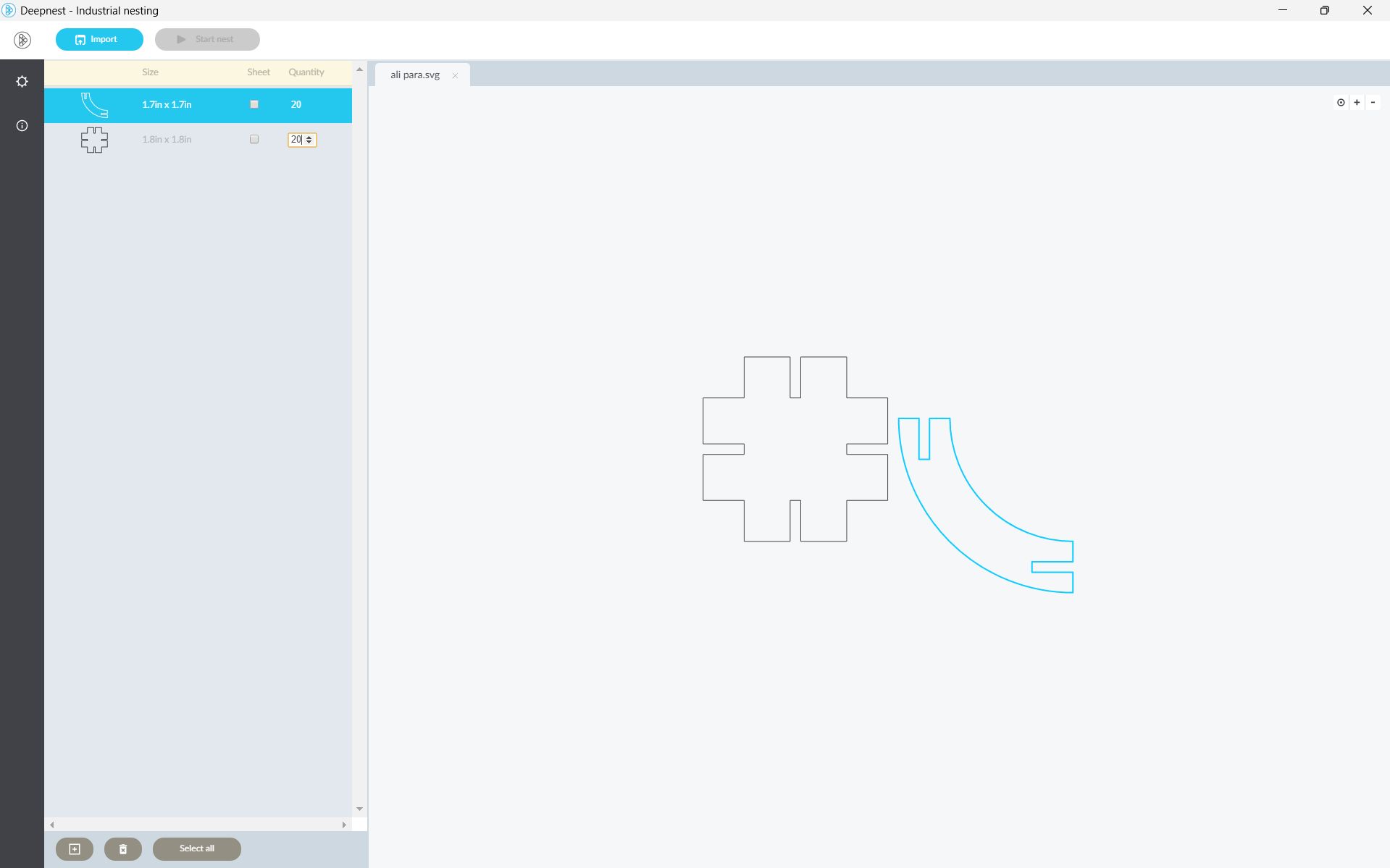

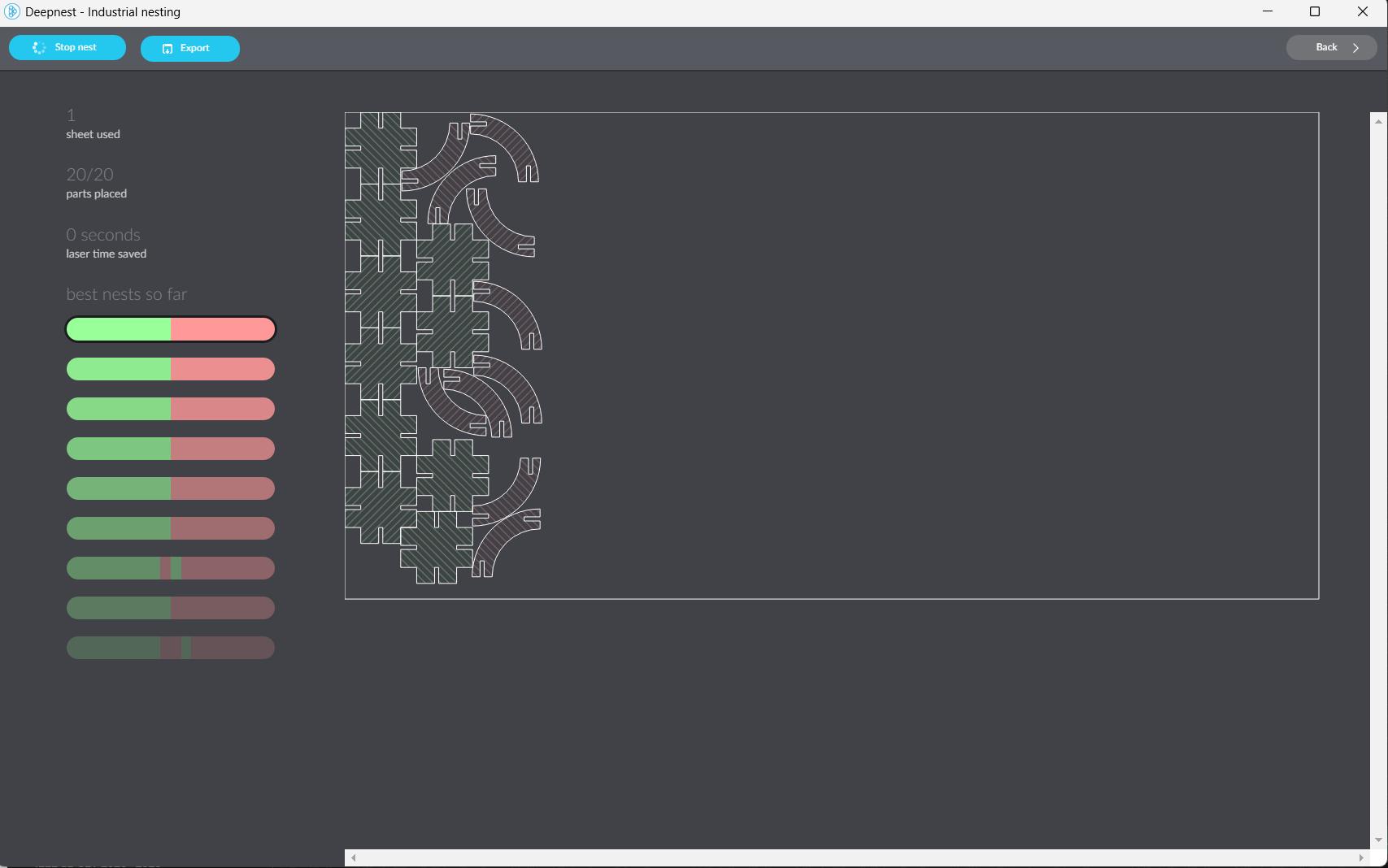

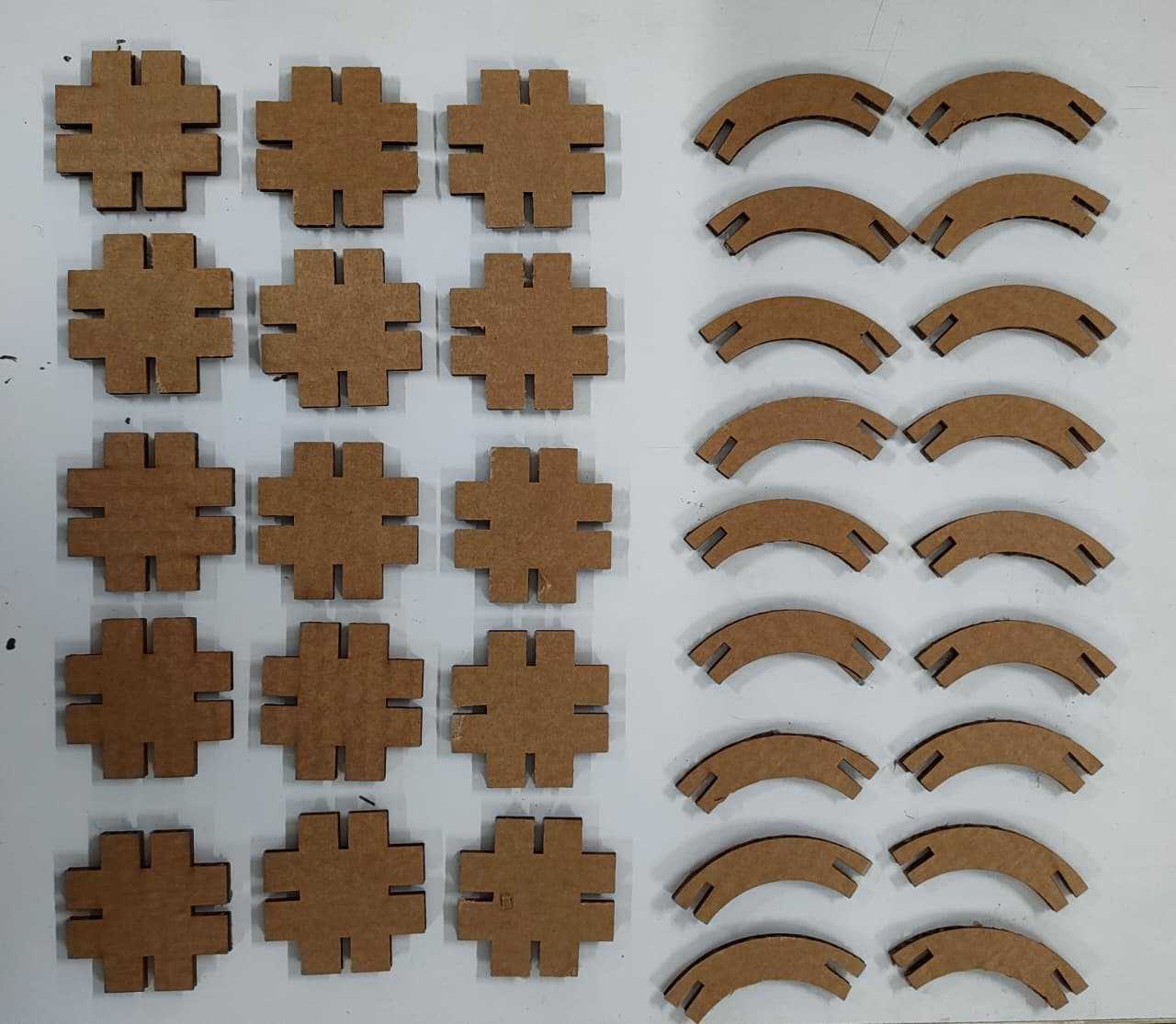

After removing the pieces from the cardboard, I checked the press-fit. The fit was satisfactory, so I used DeepNest to generate multiple copies of the shapes and arrange them efficiently to reduce material waste.

Using rectangular array i made more shapes and then used the 'Arrange' function to make them nested into the size of the cardboard I had.

“I used Deepnest.io to arrange the design on the cardboard efficiently, which helped reduce material waste and save space.”

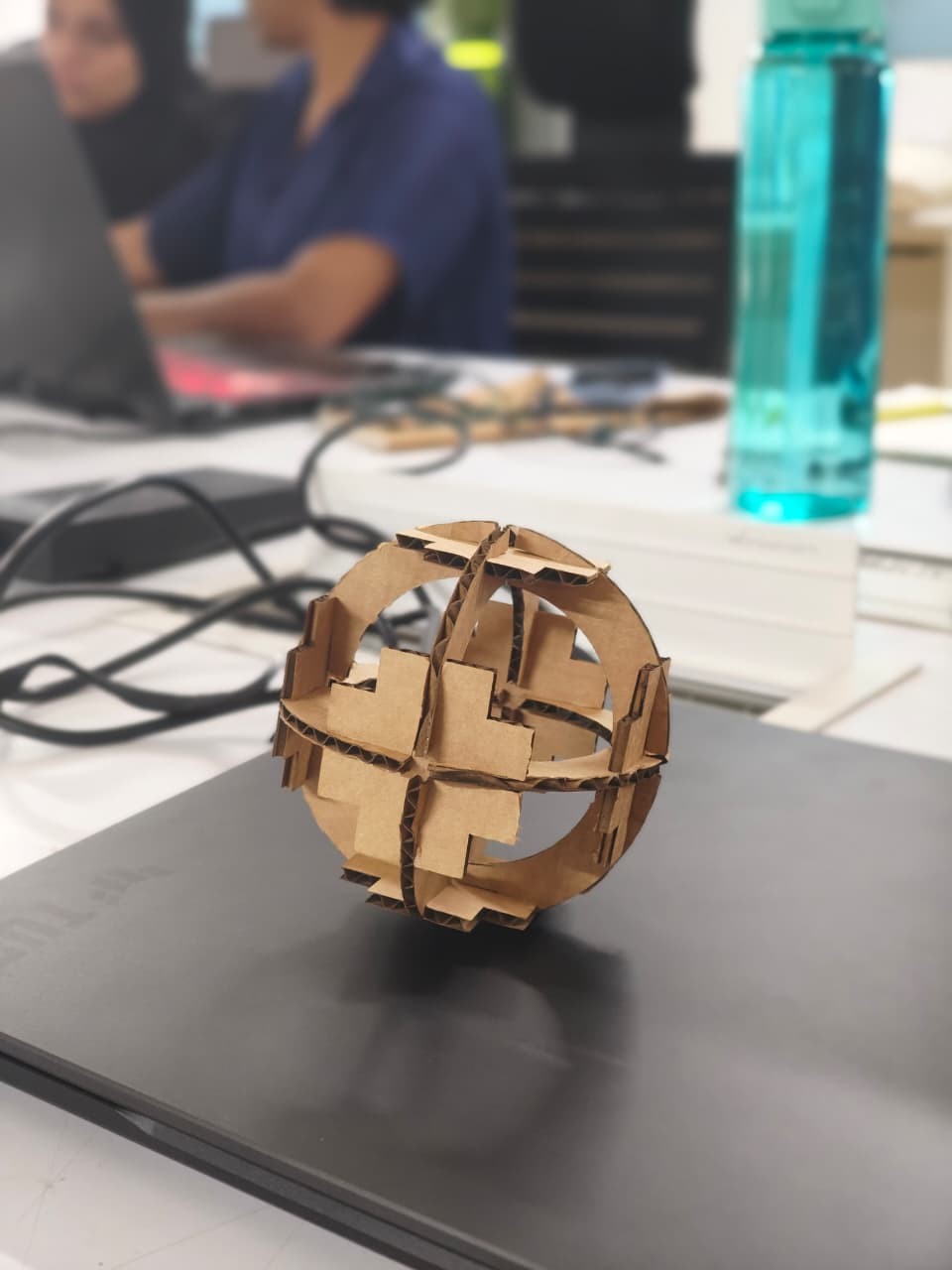

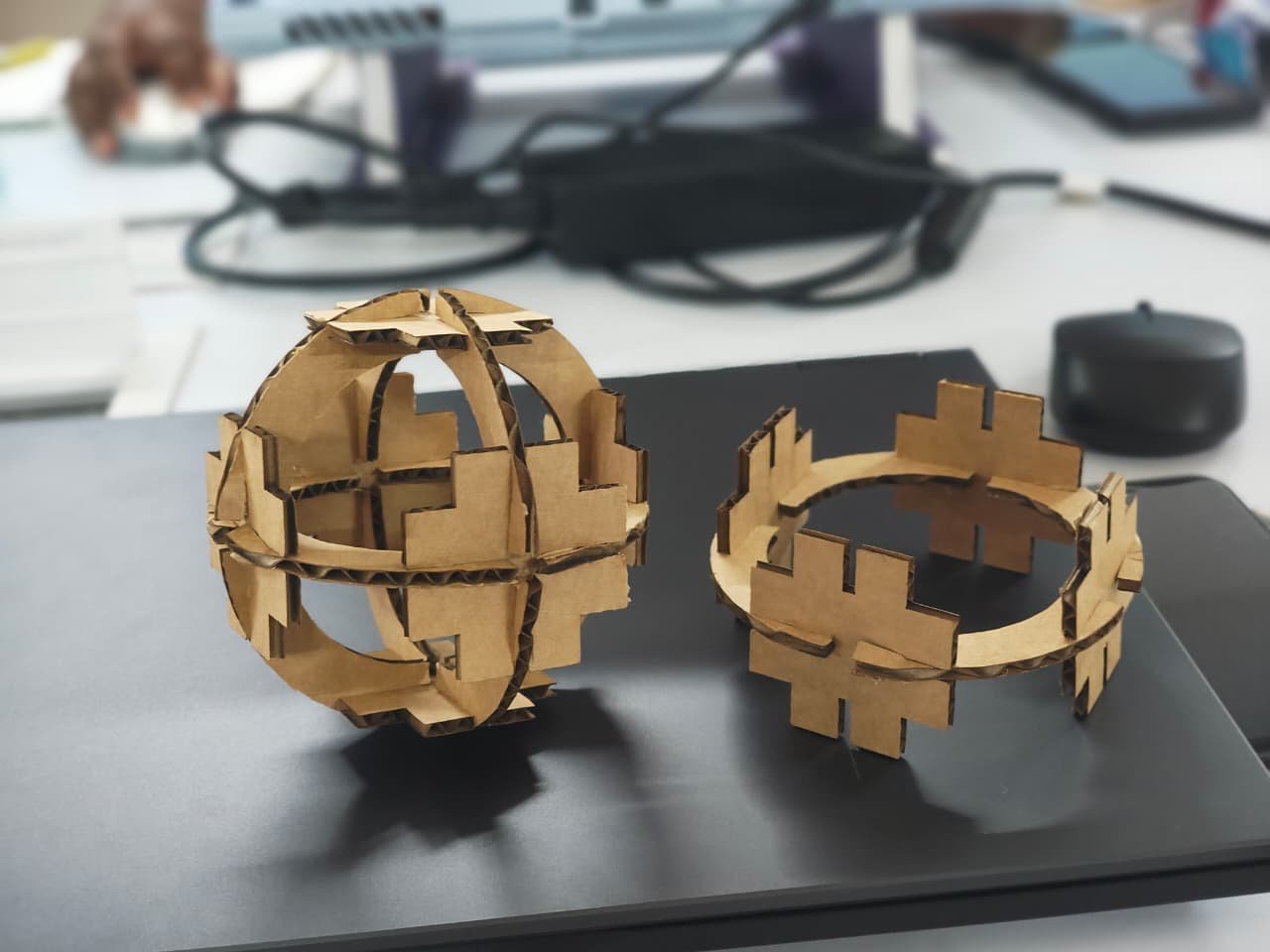

Finally the pieces were cut and i started to create intresting figures with the kit i made.

Hero Shot

Overall, this assignment helped me understand how to operate the machine safely and achieve precise cuts for our designs. I also learned how to use parametric values to create CAD models. I really enjoyed this week of parametric design. I made two models, and they are shown above.