04. Computer Controlled Cutting¶

- Group assignment

- Do your lab’s safety training

- Characterize your laser cutter’s focus, power, speed, rate, kerf, joint clearance and types.

- Document your work to the group work page and reflect on your individual page what you learned.

- Individual assignments

- Design, lasercut, and document a parametric construction kit, accounting for the laser cutter kerf.

- Cut something on the vinyl cutter.

- Extra credit

- Design for assembly in multiple ways

- Include elements that aren’t flat

- Engrave & cut

Outline¶

Vinyl Cutters¶

Laser Cutters¶

A thermal precision cutting process that uses lenses/mirrors to focuses a high power laser to a ‘spot’ or focal point on the materials surface, allowing for a range of materials to be cut or engraved. This is a subtractive process that requires 2axis of movement. Geometry for cutting = Vectors, Images for engraving = Raster

Types¶

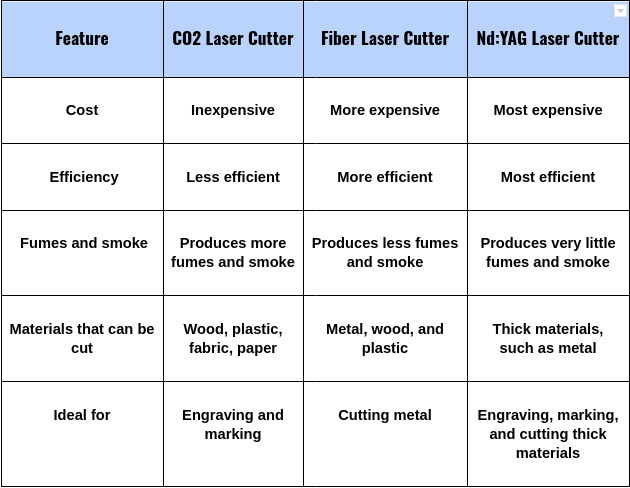

> CO2: Use of a gas mixture (carbon dioxide, nitrogen & helium) as the laser source that is excited with an electrical current, igniting & creates a infrared beam that is focused via mirrors. Versatile with a low barrier to entry, they cut non-metallic materials relatively efficiently & precisely, but do require regular servicing/maintenance

Materials: Paper based, Wood, Plastic, Some fabric, Glass

> Neodymium (Nd/YAG): Uses a crystal to generate the laser it is excited using a lamp or diode, causing it to emit a beam of photons. Incredibly precise & powerful it can cut through thick & metallic materials, but is costly/highly specialised

Materials: Metals, Plastic, Ceramic

> Fibre: A diode injects a low power beam into the fiber which has been 'doped' with rare earth elements, allowing the lasing to be induced & amplified. Precise, efficient & powerful they require minimal maintenance, are widley used in metal fabrication but cost a bit more than CO2 lasers

Materials: Metals. wood, acrylic, or plastics (slower)

<p style="font-size: 11px">

[Laser_types](https://razorlab.online/what-are-the-different-types-of-laser-cutting-machines/)

</p>

¶

Key Terms¶

- Ablation front

- the material surface where the cutting takes place, as the laser / airflow enters the cut some of the lasers energy is absorbed into the abolation front(material) casuing it to heat/melt/vaporize on the laser line

- Kerf

- The width of material removed by a cutting process / loss of material the laser burns away, varies with material type

- Focus

-

- Where the laser beams converge together to form a point of maximum power (focal point) before diverging. This is set by moving the bed hight so the focal point is on the material surface (smaller focal point = less kerf?)

- Cutting head

- Where beams are focused through a lense & down onto the material surface as a thin concentrated beam. focal length = distance between focusing lense & focal point

- PPI

- Firing rate of laser as it moves (pulses per inch)

- Power

- The amount of energy delivered by the laser beam. A higher powerful laser can cut quicker & thicker. A lower powerful laser can cut details & be built in passes

- Speed

- Rate at which laser moves, variable with power. meters per minuet m/min or inchers per minuet ipm

- Frequency

- Number of laser pulses emitted per second, Hz

- Rate

- Speed at which the material is cut, directly related to speed of laser

- Joint clearance

- J

- Joint types

- J

Class¶

Fusion Parametric Design¶

User parameters: Using the ‘+’ to name & define a dimension, when applying dimensions in the sketch window use the name to apply/link Model parameters: The existing dimensions within the model, can be renamed for easier linking when dimensioning

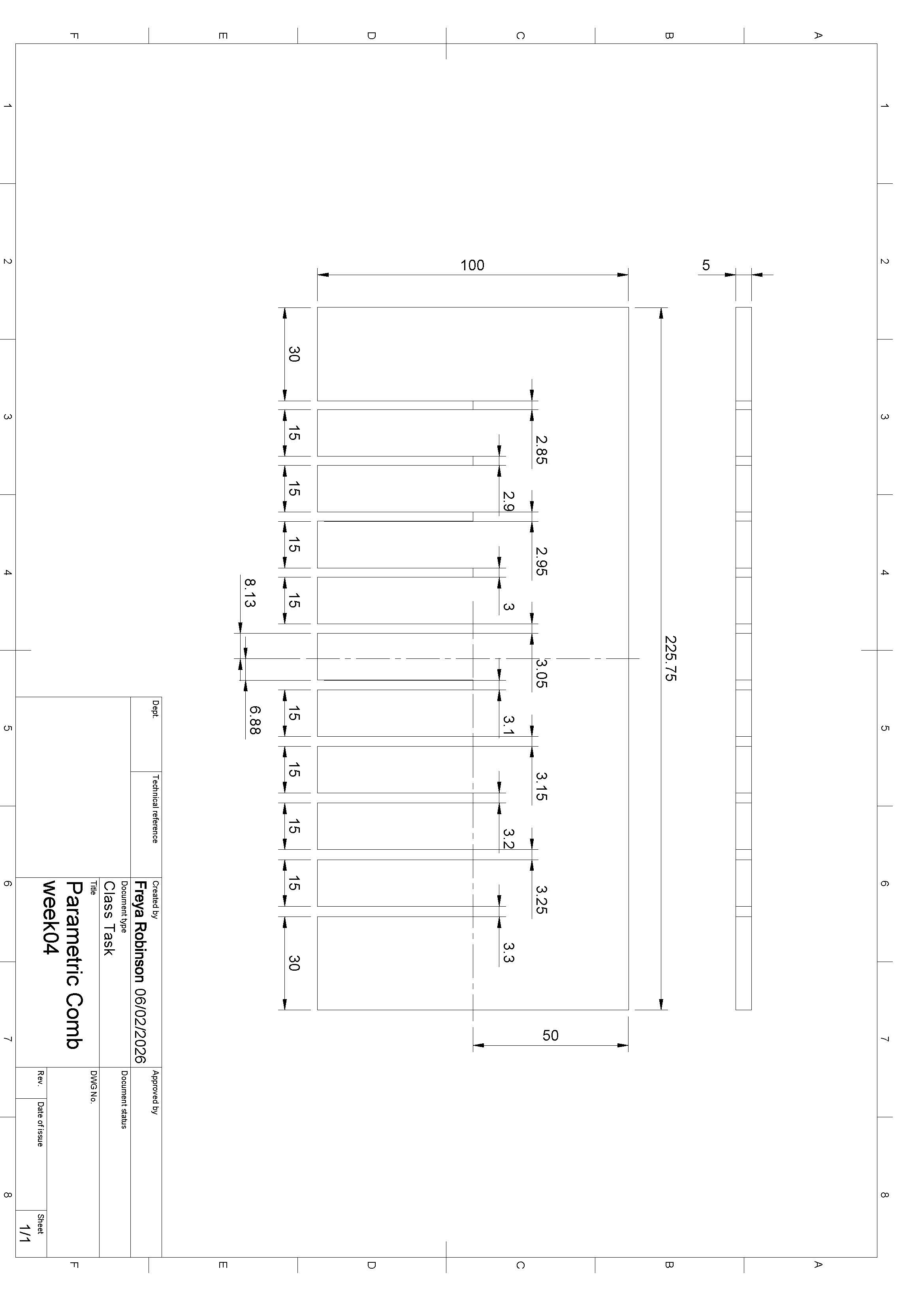

Parametric table - Fusion

Parametric Comb - Fusion

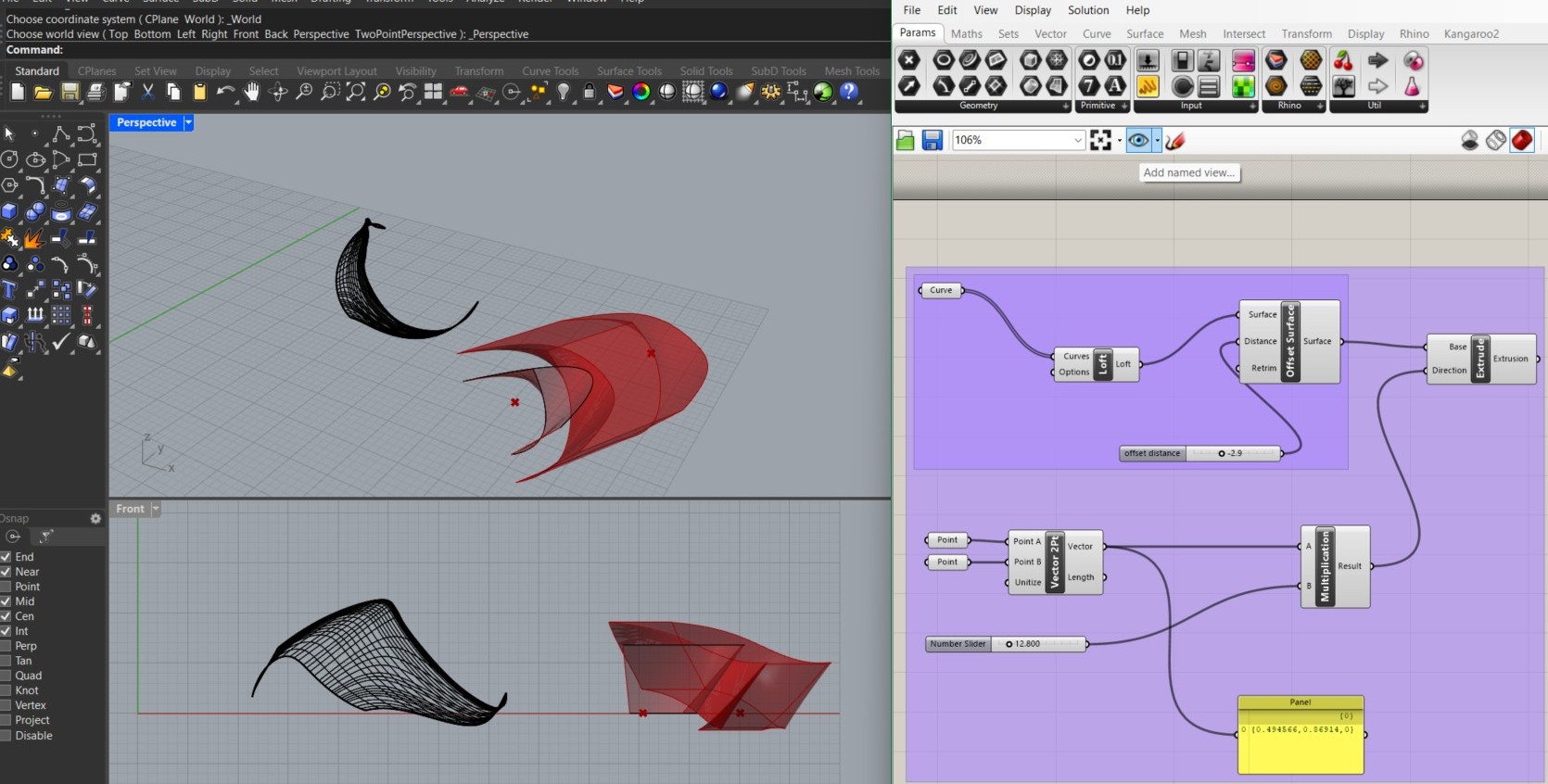

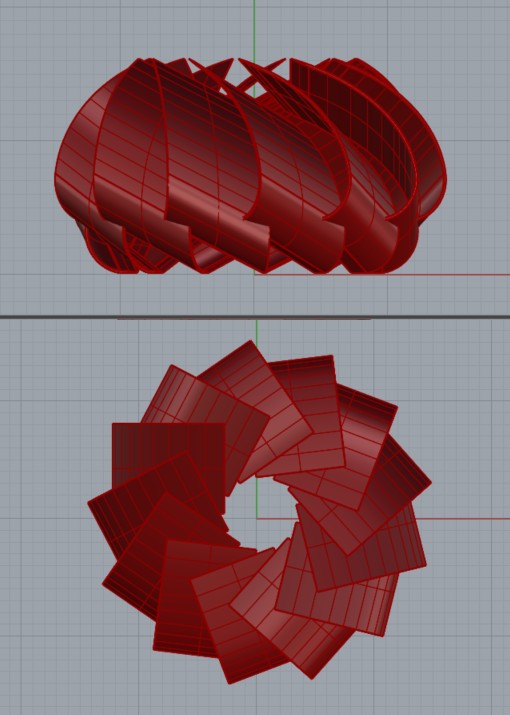

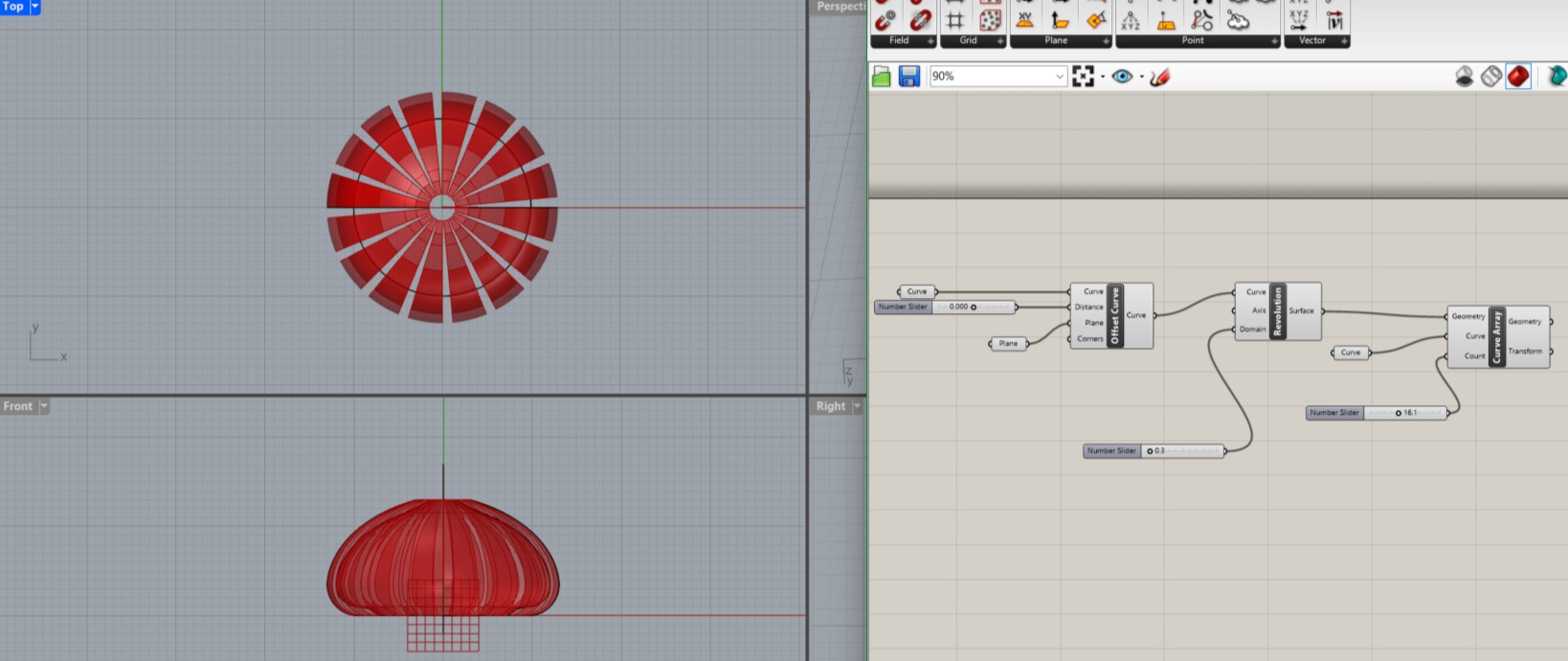

## ### Rhino & Grasshopper #### Offset & Extrude  #### Array & Attractor Varying array with slider

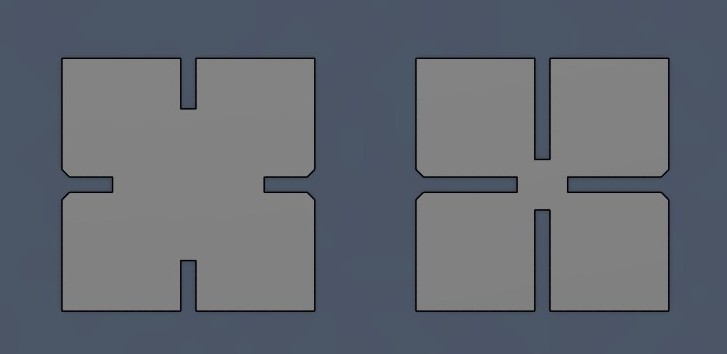

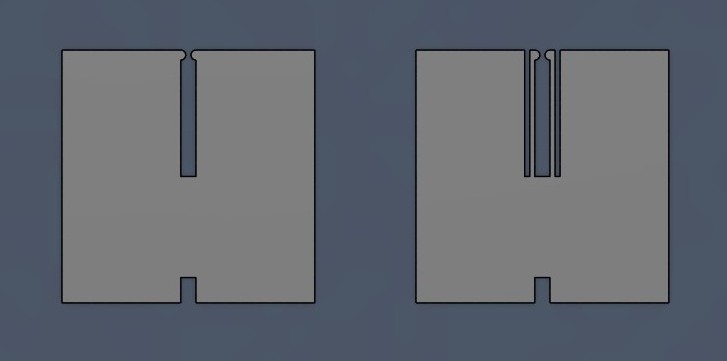

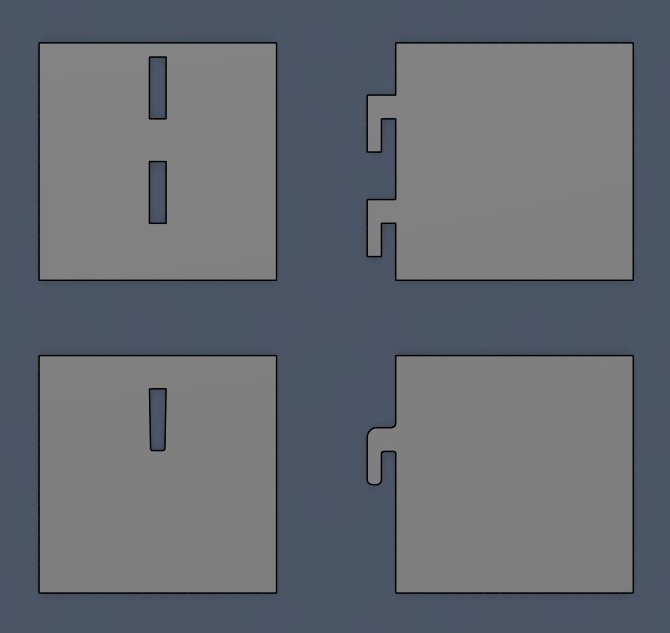

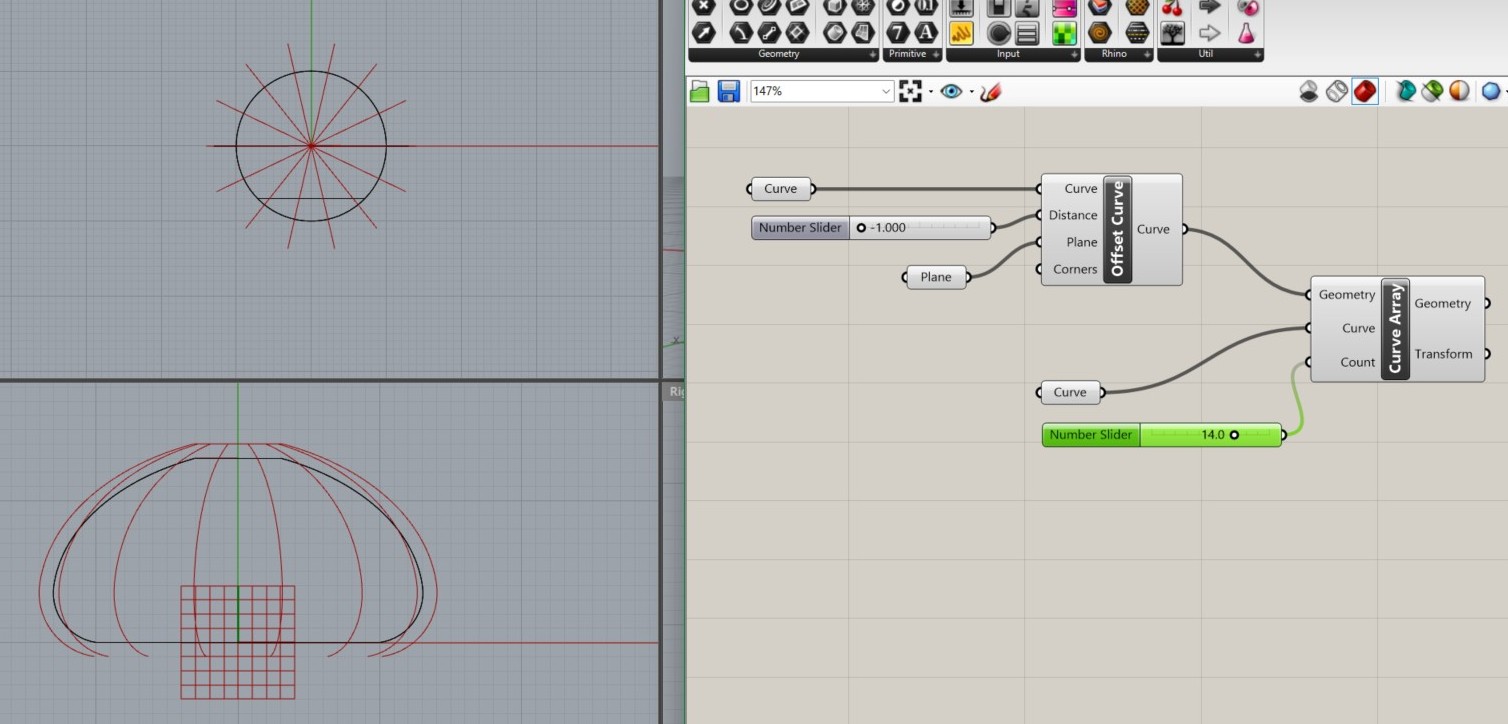

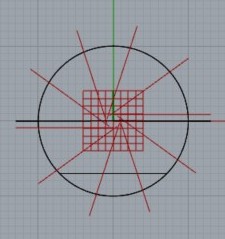

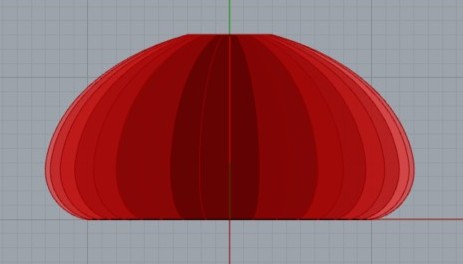

## ## Assignment ### Parametric Joints - Fusion Setting up designs to test for effectiveness of different lasercut joining methods. By setting up a base geometry using defined functions they all remain linked & defined by the same base dimension (slot_width / slot_length / test_square / offset). These can be used in an equation structure with numbers & in combination, changing the applied dimension result whilst basing it on uniform 'rules', e.g. slot_width. slot_width + offset. slot_width + offset * 2. #### Pressfit & Chamfer These squares to test the effectiveness of a simple connection methods at different lengths, using 'slot_length * 2' to drive the longer version.  #### Snapfit & Flexture Slightly more complicated, this style of connection requires the 2 parts to actively engage & may require different tolerances depending on material  #### Slotfit Required more attention when designing to understand that the resting edge of the hook lining up with the base of the slot results in the edges of the squares being perpendicular. How would tweaking the male & female parts could affect the join with further testing slot: Smoother slotting/unslotting with a snugger joint - Taper inwards or a recess on top edge hook: Secure fit whilst strengthening fingers - Fillets at corners & thickness/shape of finger  ## Implementation ### Parametric Design - Rhino Using the imputs we went over in class as a base, I tweaked how they were configured in grasshopper & what geometry in rhino file they apply to. I started with getting a rough outline to act as a guidelines, getting a curve I liked using the polyline command I then mirrored & joined the curves into one polyine. #### Grasshopper Using 'offset curve' with a number slider to vary the diameter to the curve I drew. World plane ZX + parrallel grid to offset inside.* 'curve array' to make it form a radial pattern on the circle base, to change the amount of segments this creates I add another number slider. When trying to connect this after the offset it didn't work, I needed to reassign the geometry & realised the grasshopper functions don't have to be linked to apply to the same geometry. However by switching the order & relinking the nodes, the offset variable applies to the segment array at the same time.  ##### Experiments > *Offset results change depending on plane reference, parrallel XY created an offsetting about the center.  > 'Extrusion' node based off of sketch curve & changing the 'direction parameter' + 'curve array', used to 'bake' conceptual radial blades for structure  > 'Revolution' set up around the z-axis to extrude the array segments by a varaible amount.  > Radial array applied to surface  # #### Development Going back into rhino to add more detail to the 'ribs' (original curve) by looking at how it interacts with the baseplate & designing slots to secure the components. Design of a foot component (plane perpendicular to rib profile) that sits under the rib to provides support & connects to the base plate. Further: top plate, bottom slots, additional rib joints