12. Mechanical Design & Machine Design

This week the group of seven of us created a Machine that drops a creature from the ceiling when prompted by a motion sensor. This was a fun group project and we learned a ton together. Our group documentation site is located here: Group Link

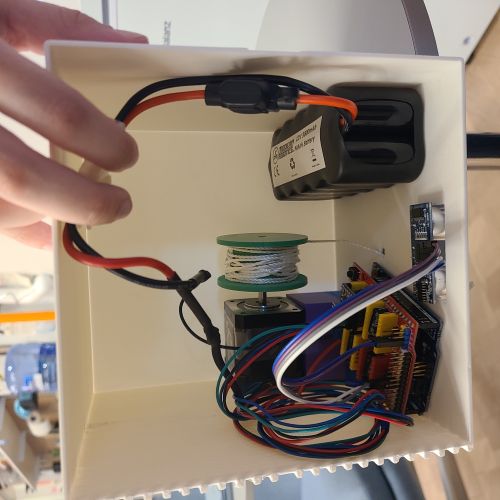

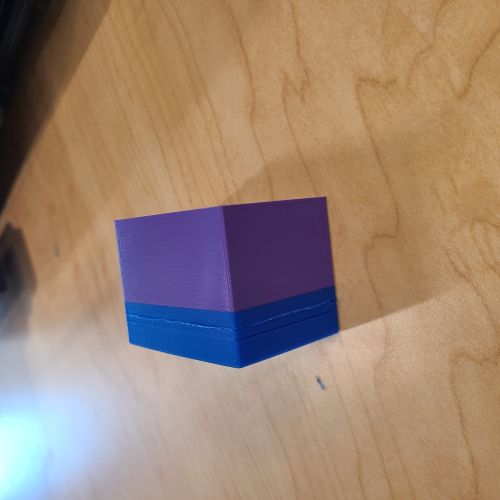

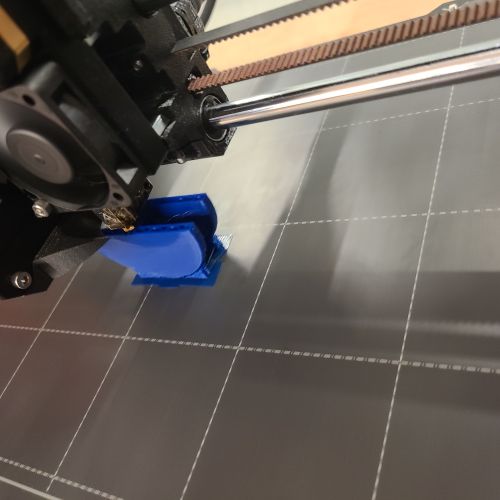

I designed a platform for the motor to sit on using Fusion 360. The motor couldn't sit on the floor of the box as it would interupt the motor revolutions and cause the string to tangle. I 3D printed a block about the same size of the motor to lift the motor off the floor of the box by about an inch. This made for enough clearance for the spool to rotate freely and keep the string from tangling.

I also did a tremendous amount of parts and pieces scavaging in the lab. I searched for hinges, nuts, bolts, braces, different types of string, etc. The funny discovery I made is that when we lacked certain resources like brackets, etc, we attempted to print these items using the 3D printer but always with negative results. The pieces seemed to snap and crumble so for sturdiness and sustainable strength metal components are probably best.

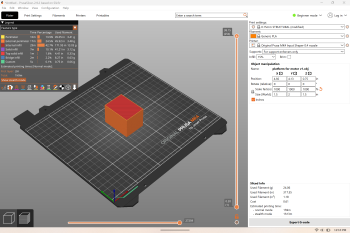

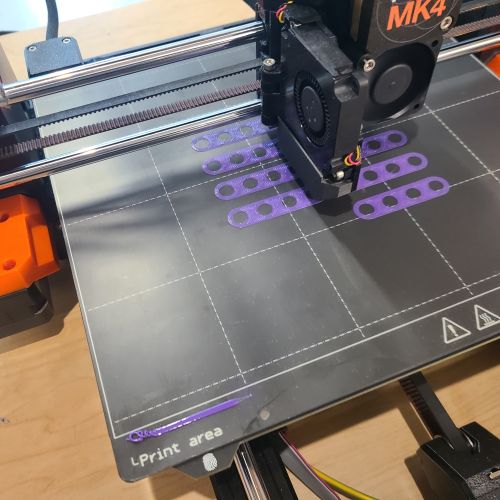

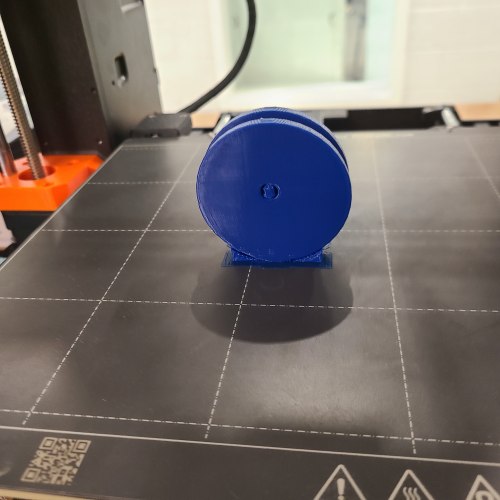

I worked on the first 2 versions of the spool used to lower the creature from the box. I first found a spool design on printables.com but the design itself had a few characteristics that would not work well with our project. First the hole in the middle of the spool was more than twice the size needed and would be way too large to fit around the motor spindle. Second we need the middle of the spool to be thicker so that it would require less rotations from the motor to lower the creature. I then designed a new spool on fusion 360 but intially added too many supports in prusa slicer. As a result, while weeding out the extra supports that were printed I eneded up breaking the spool. After printing another, once I removed the supports, the inner hole cracked and as a result the spool was slightly too big. A teammate designed a new one that was even thicker but had an accurate shaped hold. I also noticed that the hole I created was not perfectly centered the new green spool worked out incredibly well.

I also worked on creating a hinge as we couldn't find any made of metal in our workshop. I was able to find some hinge prototypes on printables.com but they were very difficult to remove the supports and I ended up breaking several. We were finally down to once hinge and when we attempted to screw it to the box it ended up breaking as well. The idea was to add a hinge to the final lid which would create an enclosure for all the components while being able to access the interior for charging the battery when needed. A hinge would allow the door to lift. In the end my teammates came up with the idea of creating a hinge out of cable ties and that seems to work just fine.