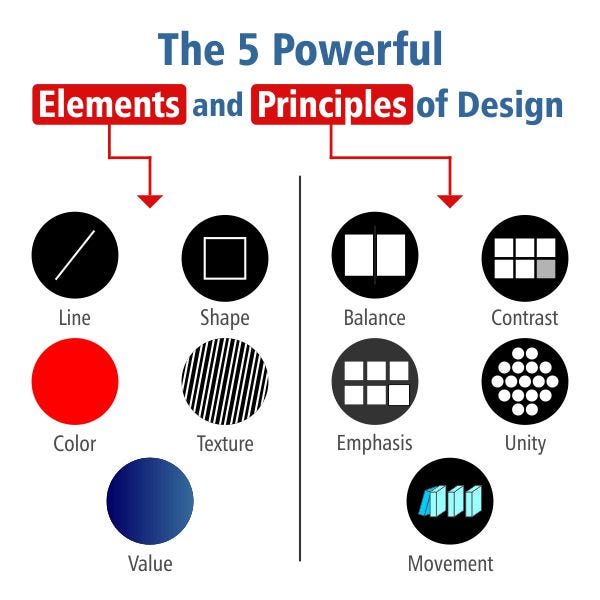

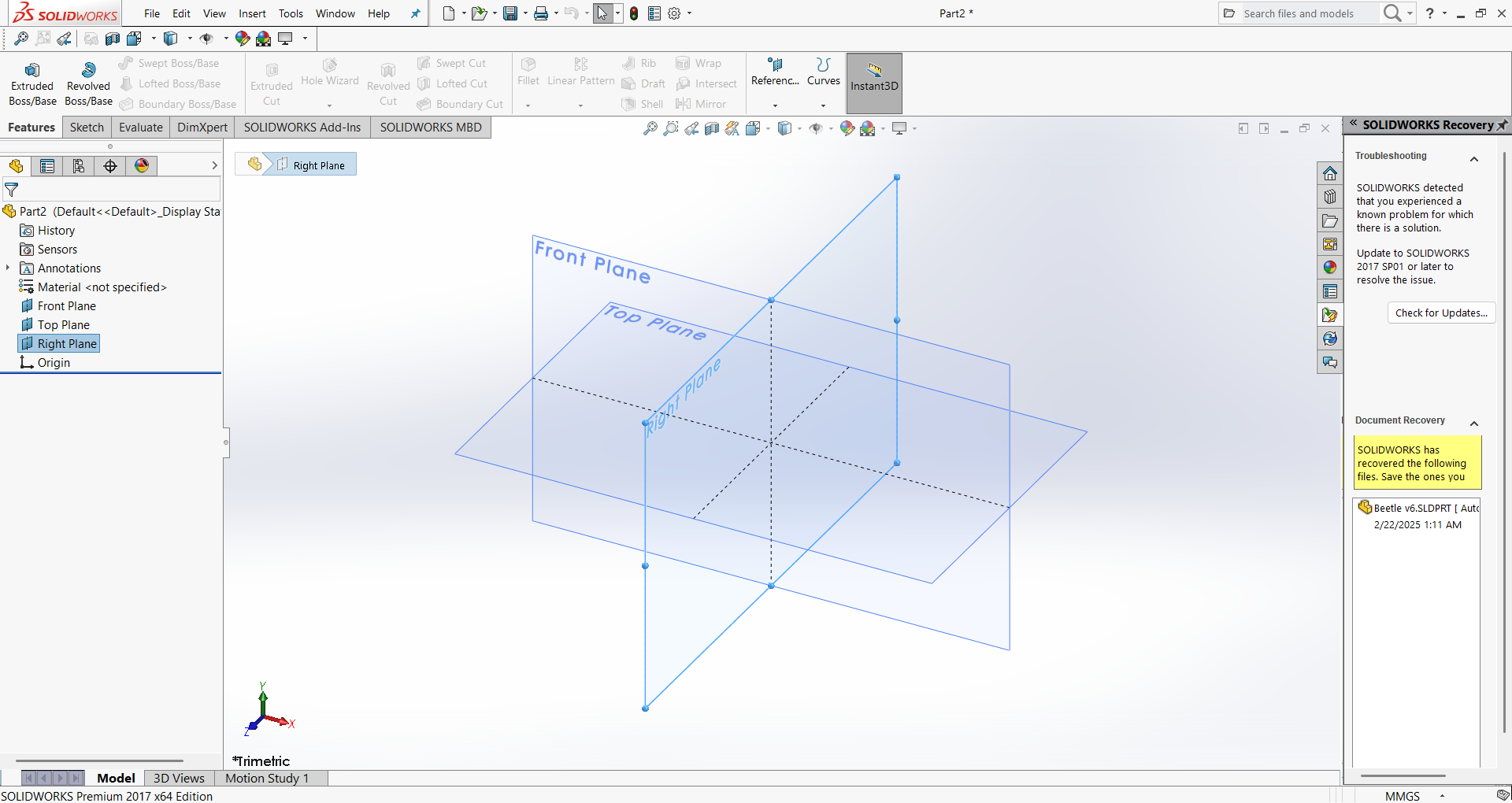

2. CAD softwares

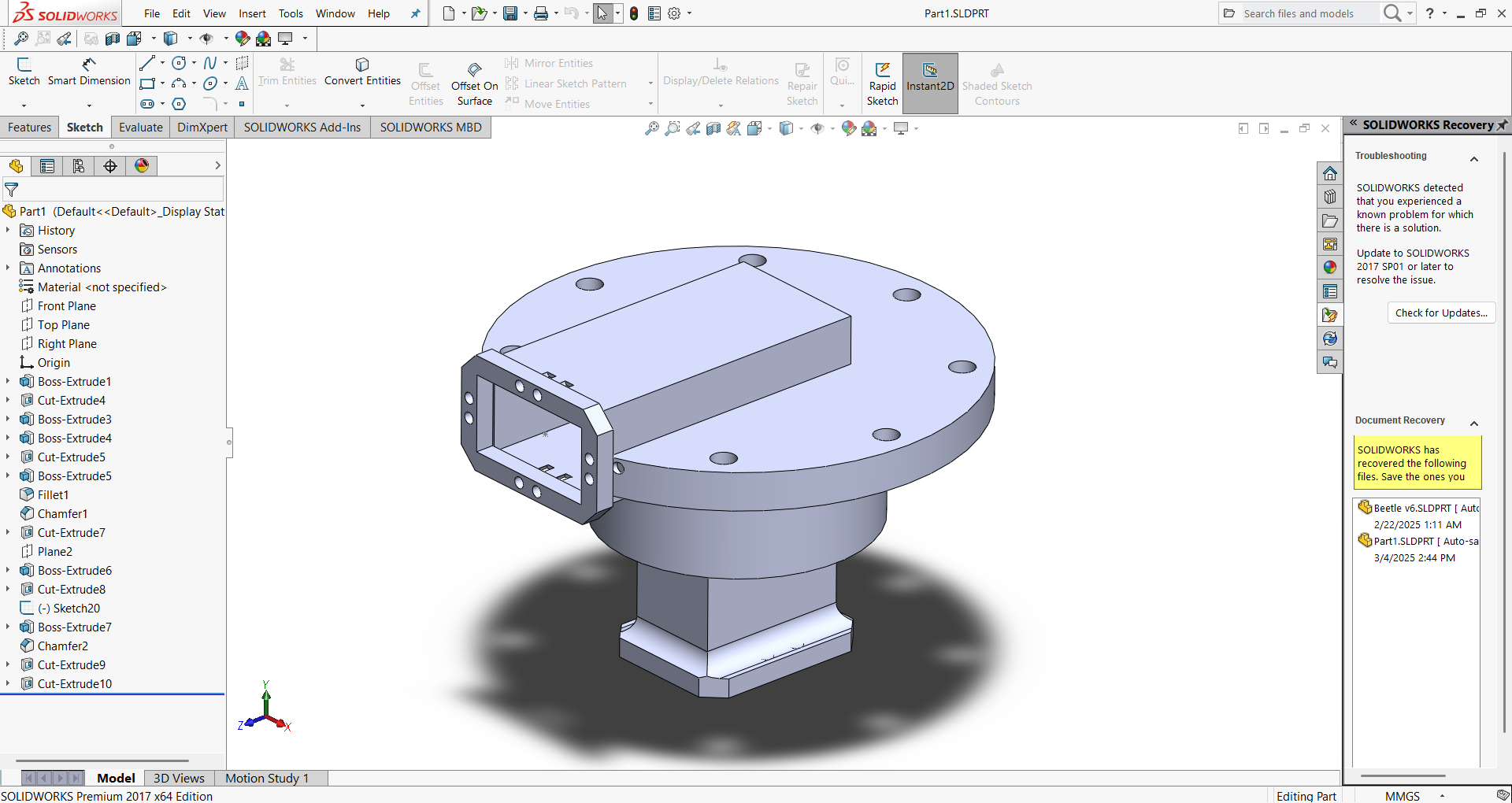

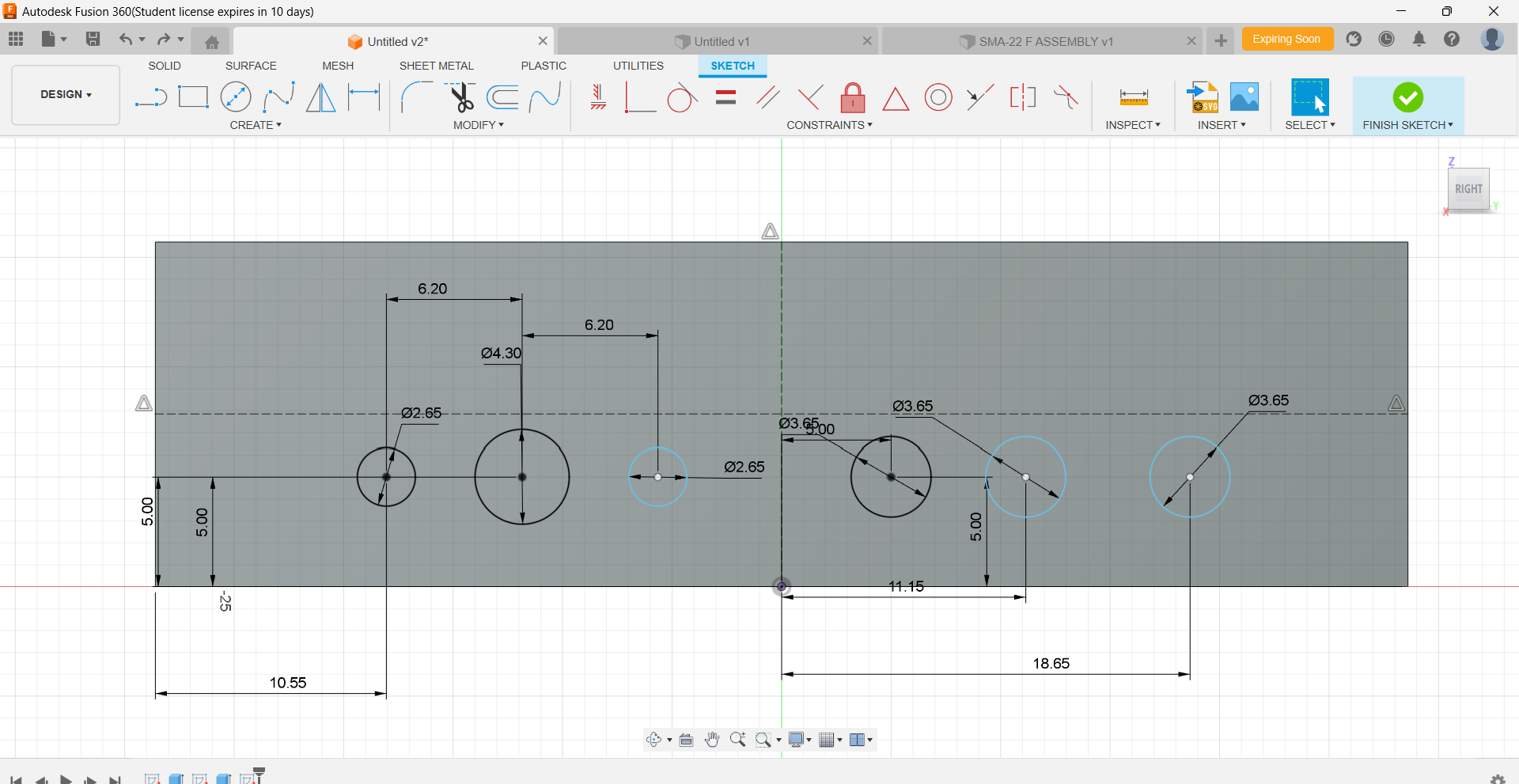

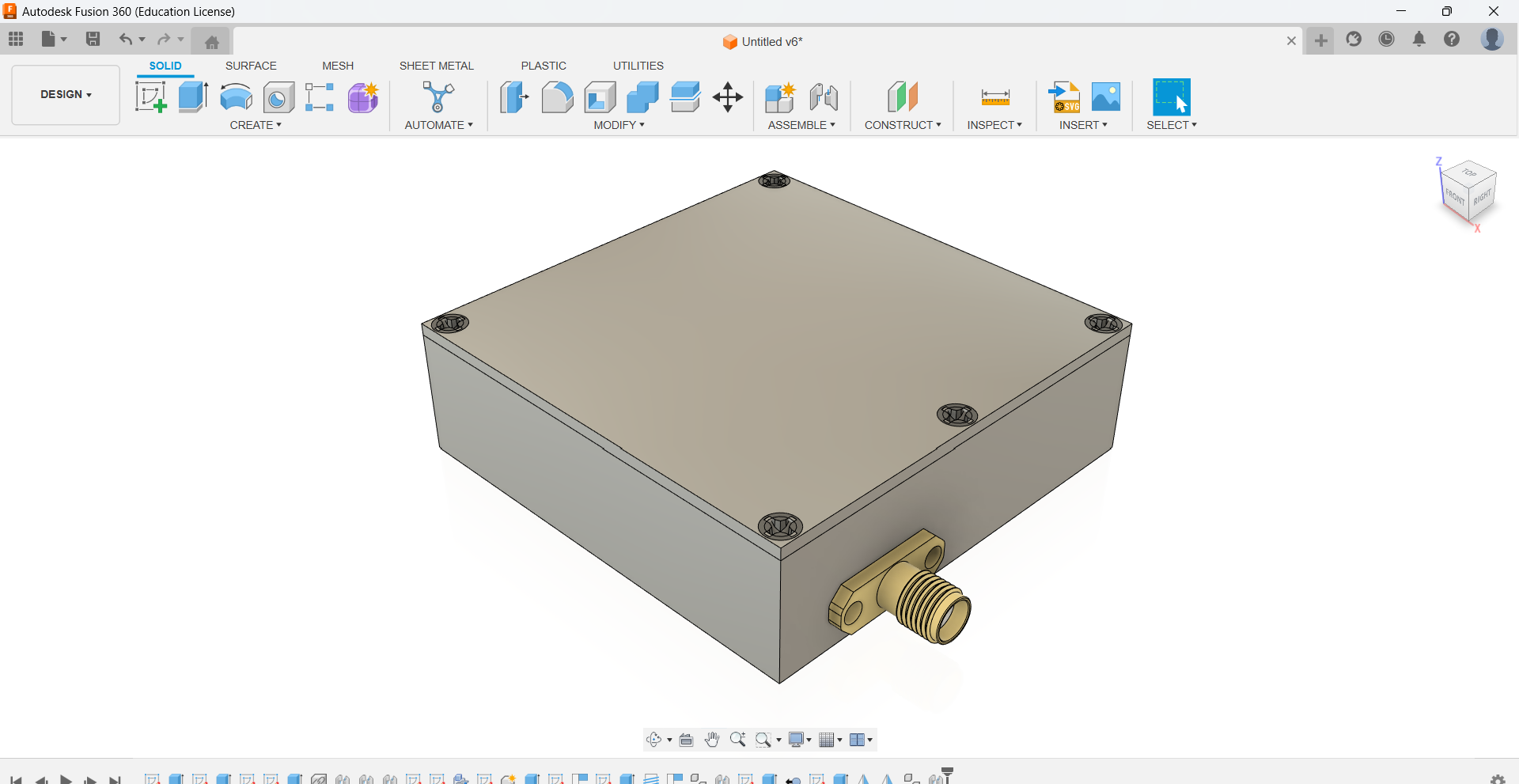

I used Solidworks and Fusion 360 because :

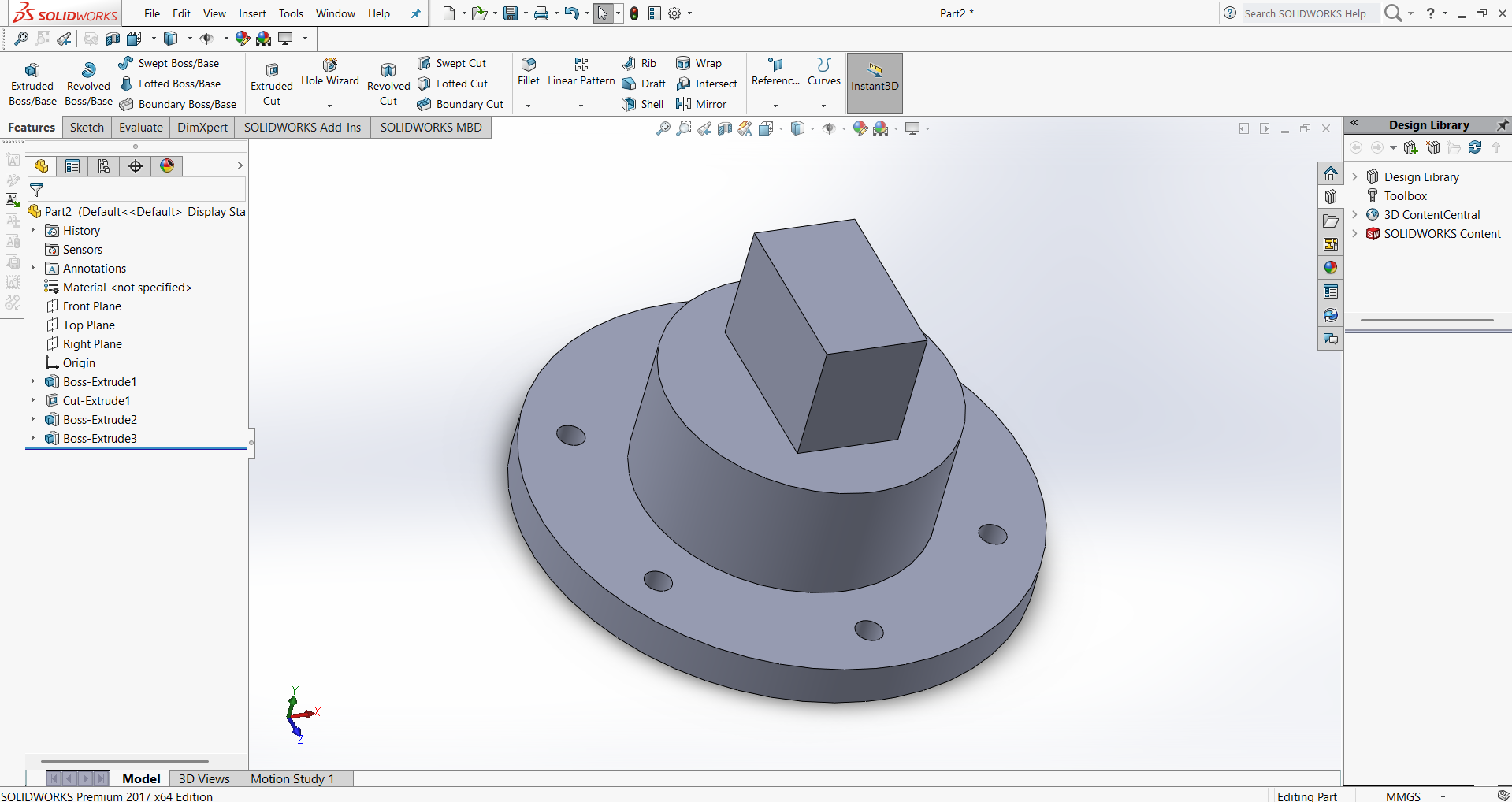

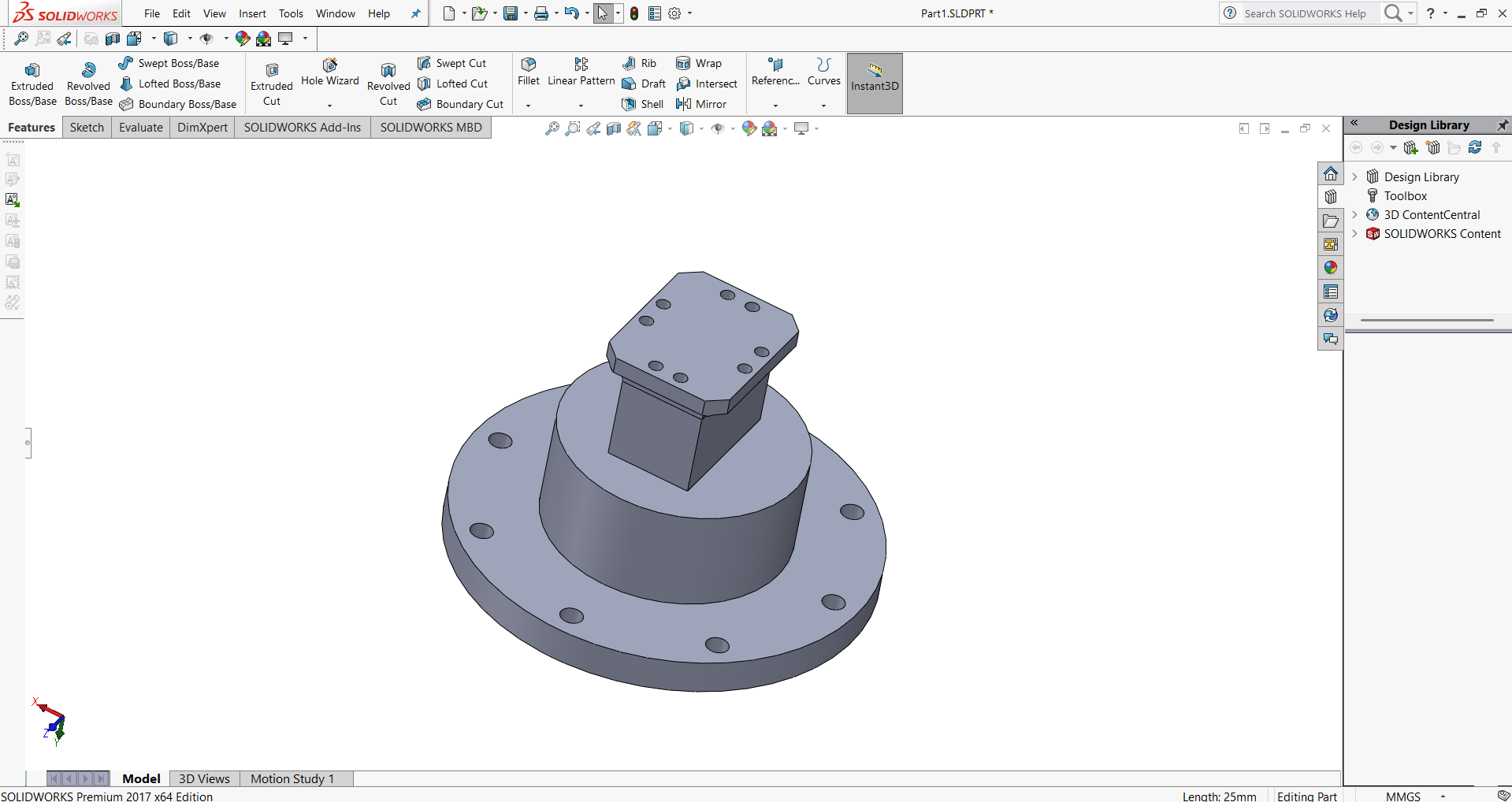

SolidWorks is used in the industrial equipment industry to design and develop machinery, tools, and other equipment. The software helps in creating 3D models of the equipment, simulating its performance, testing for safety and durability, and optimizing its design for efficiency and productivity.

Autodesk Fusion 360 is a cloud-based software application that helps users design, engineer, and manufacture products. It has features for 3D modeling, simulation, and collaboration.

Challenges & Solutions

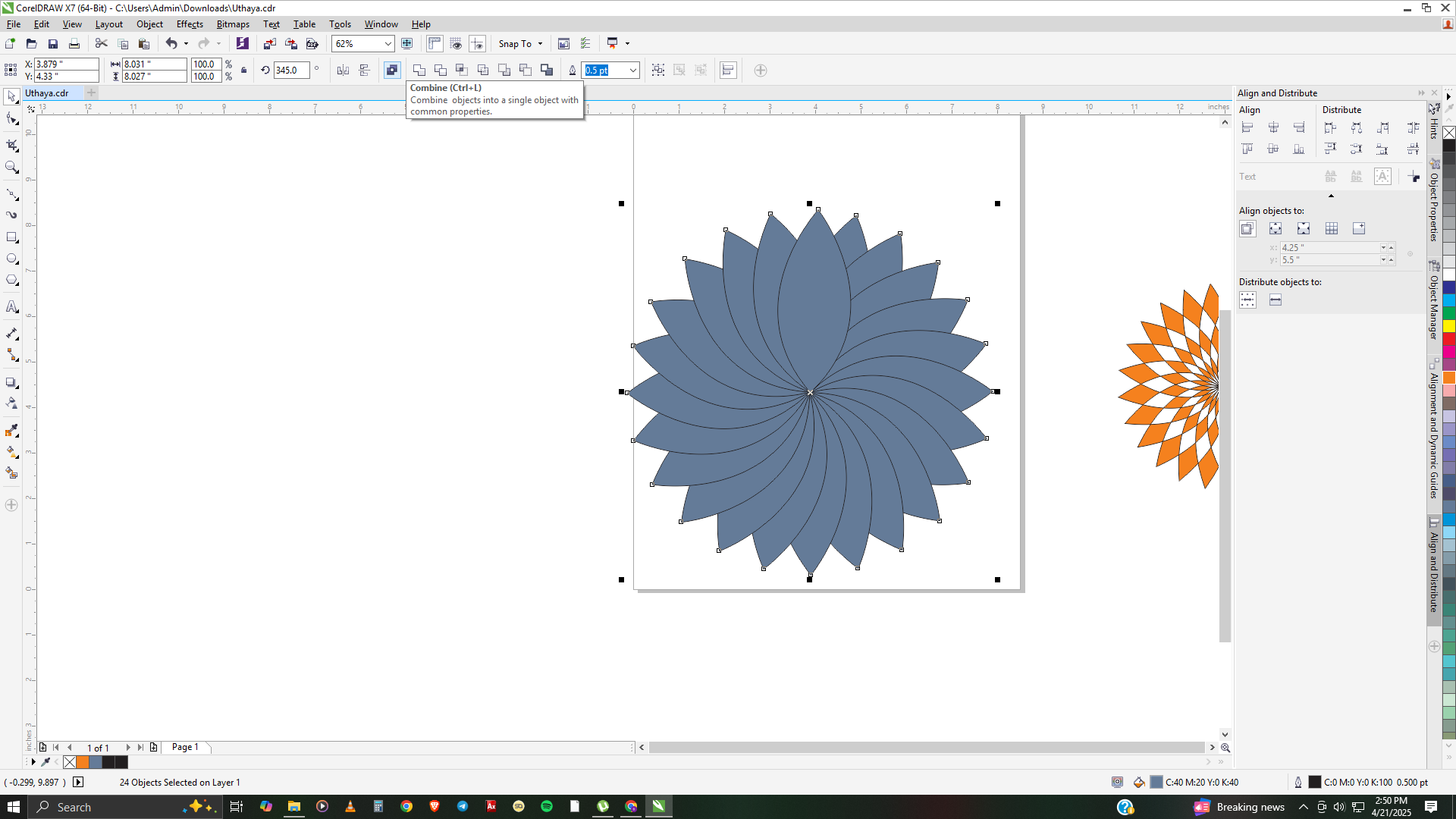

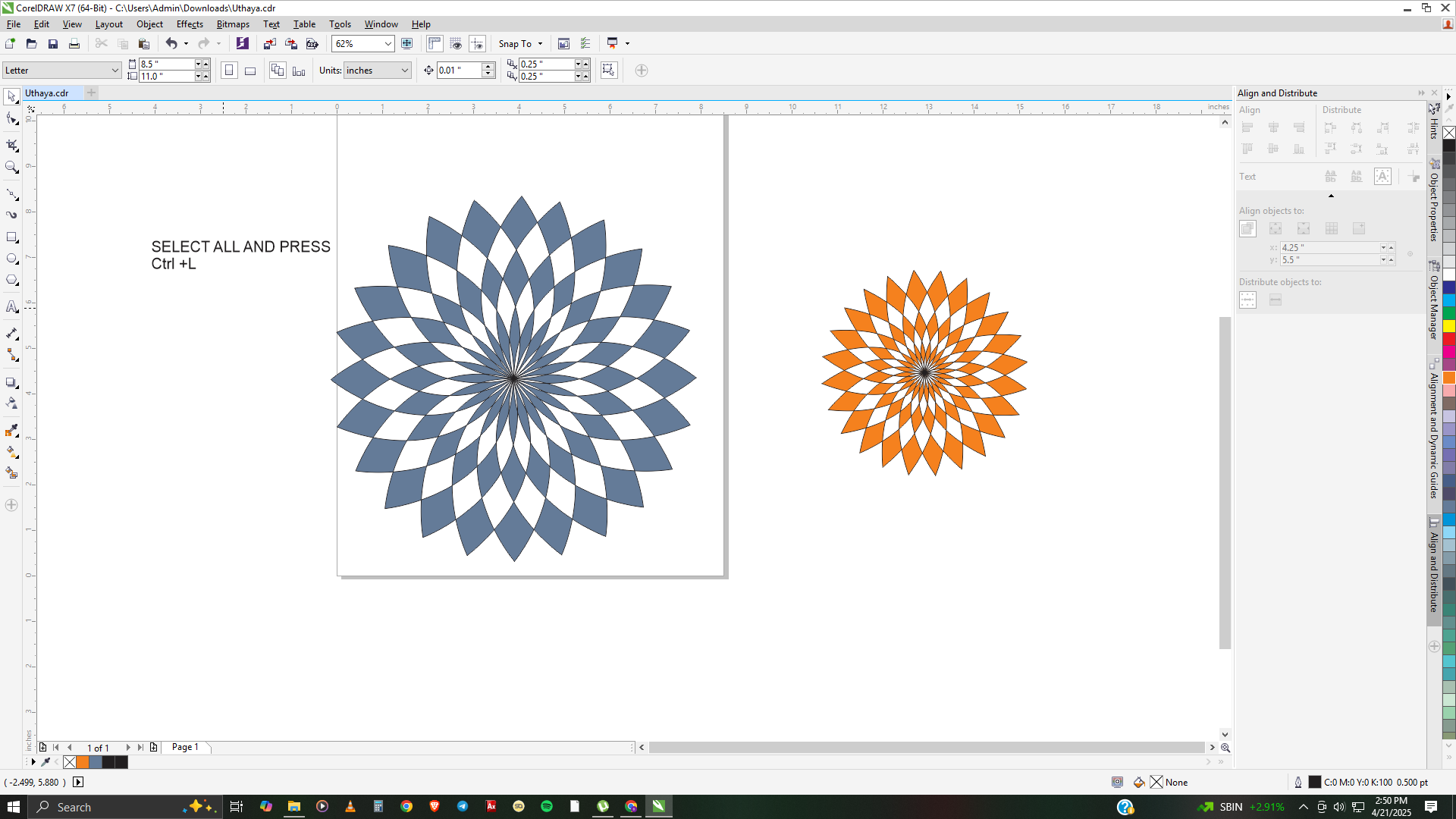

1️⃣ Understanding the Tool Palette & Features

🔹 Challenge: Initially, navigating through the tool palette and understanding the functions of different tools in Fusion 360 and SolidWorks was overwhelming.

✅ Solution: I followed tutorials, experimented with different tools, and referred to official documentation to understand their applications.

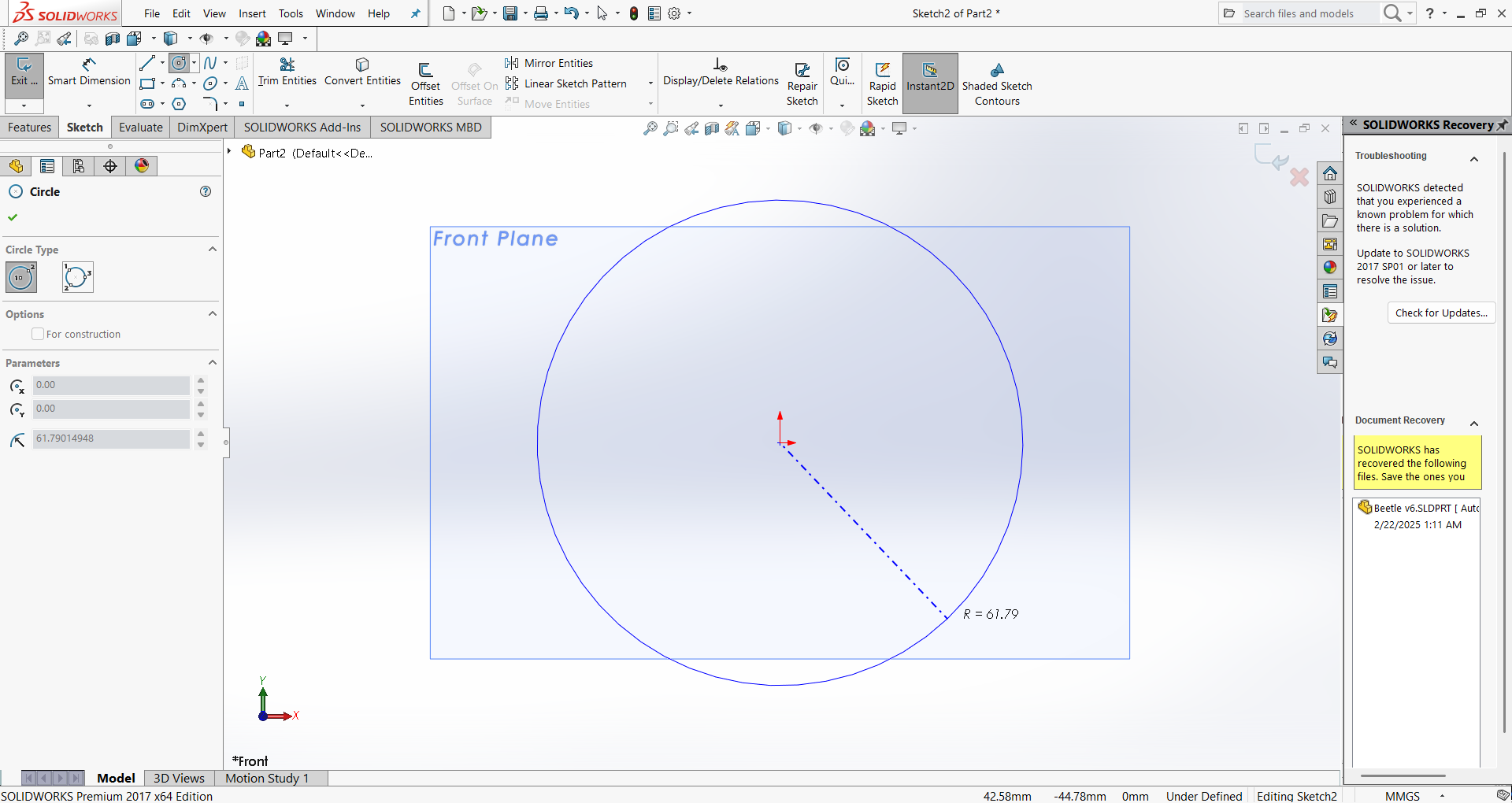

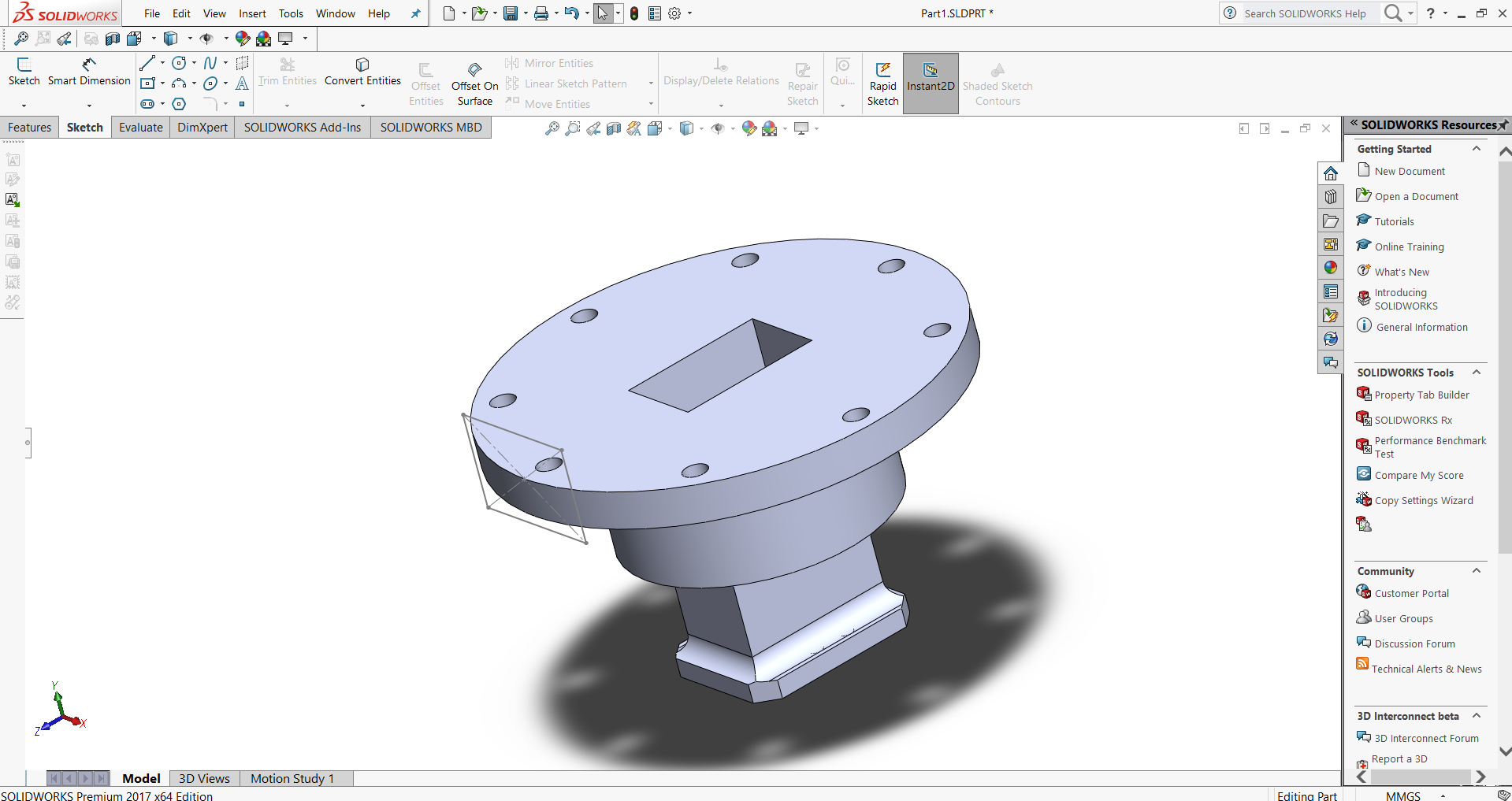

2️⃣ Difficulty with Orthogonal Views

🔹 Challenge: Switching between top, front, and side views in orthogonal mode felt confusing, and aligning sketches correctly was tricky.

✅ Solution: Practiced by drawing simple objects in multiple views and used the view cube and constraints to align sketches accurately.

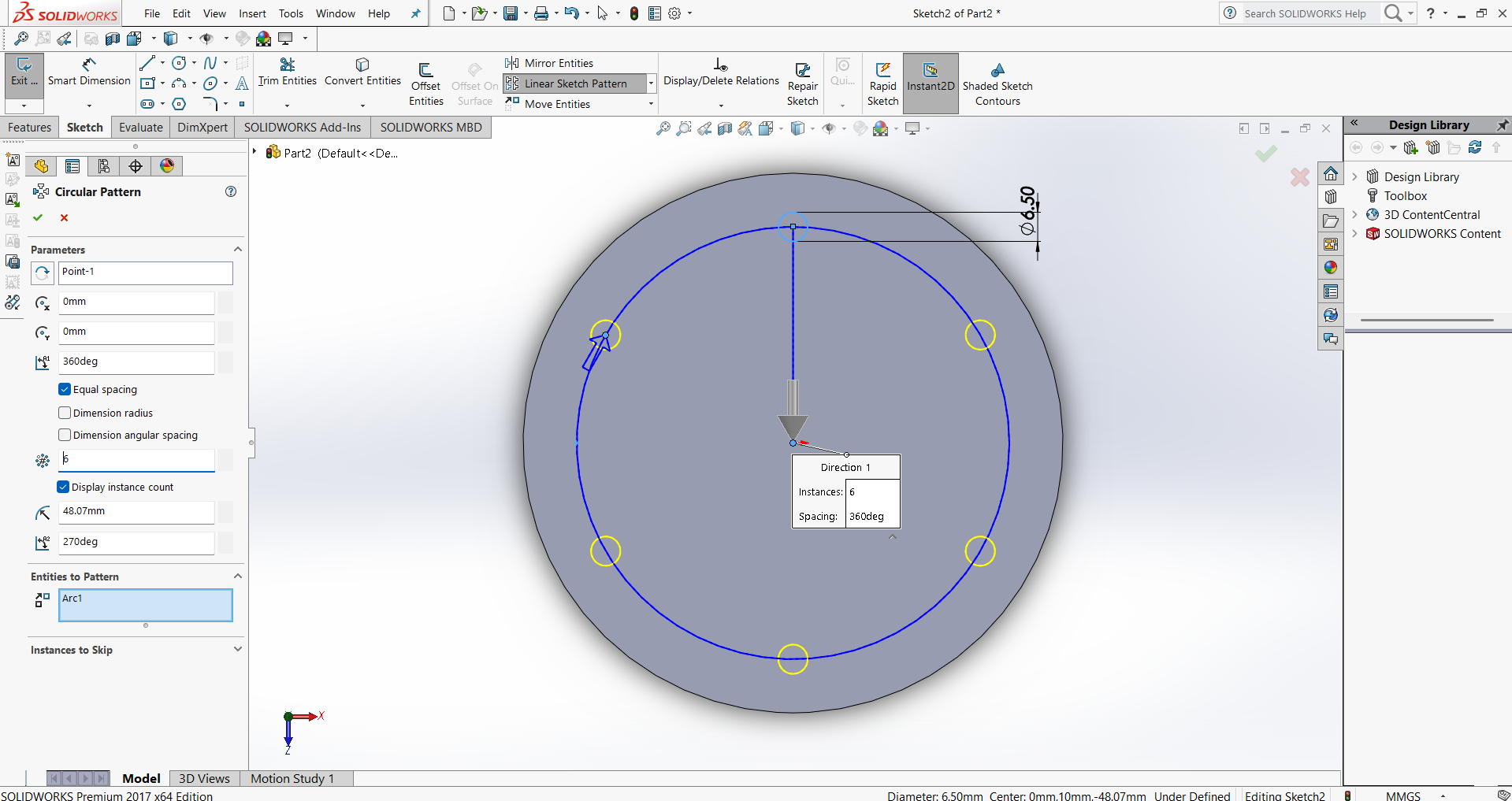

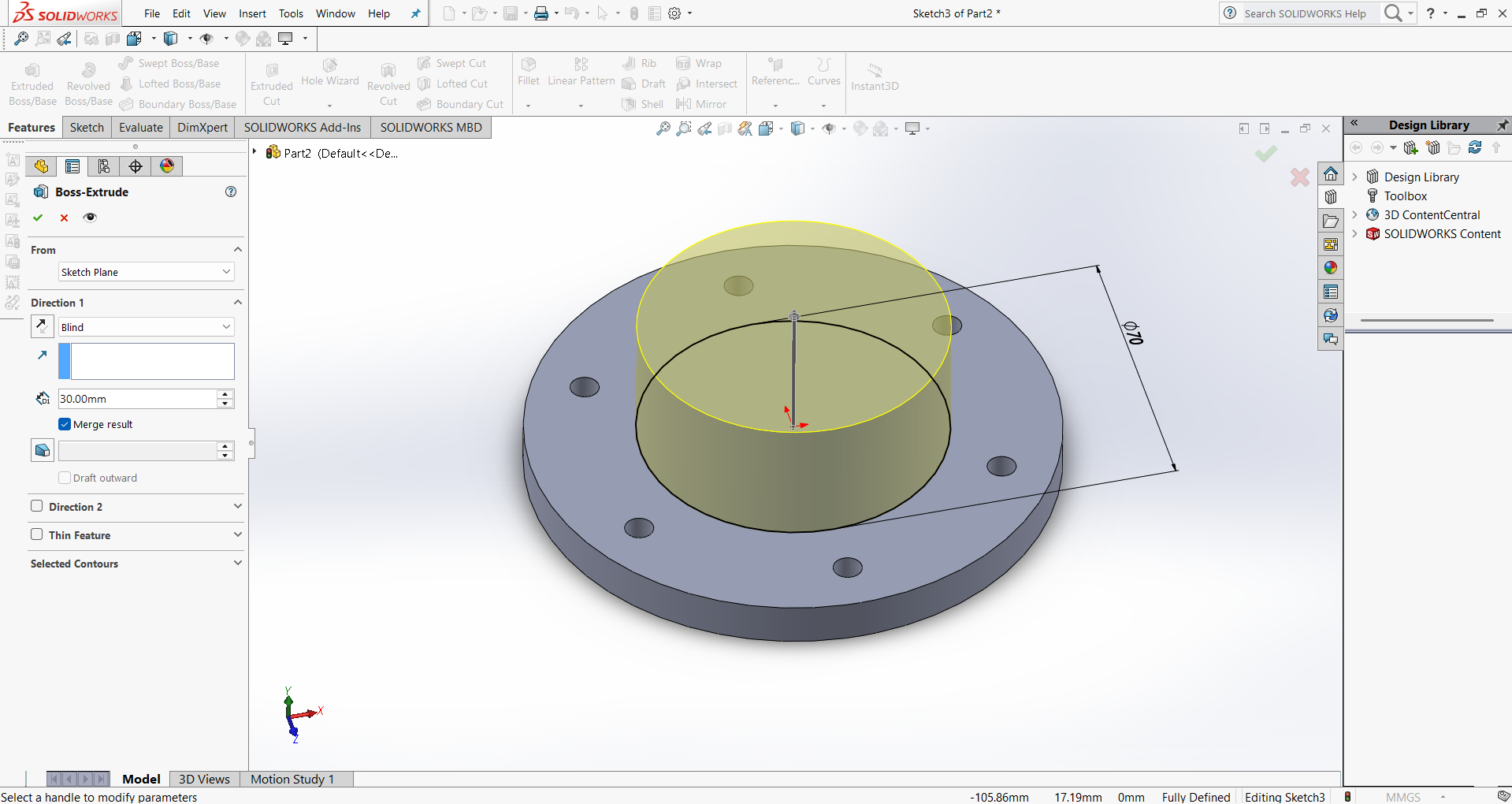

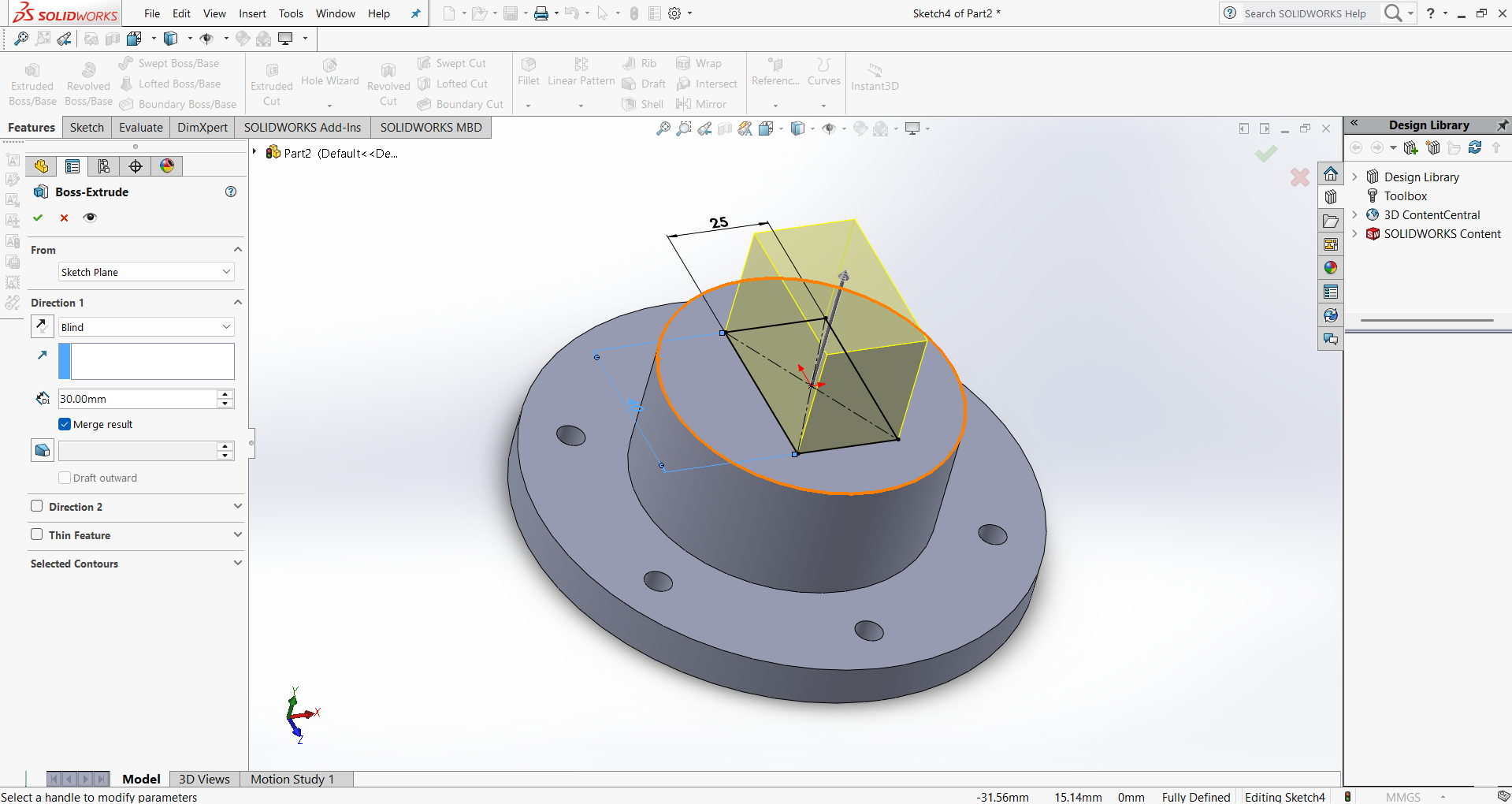

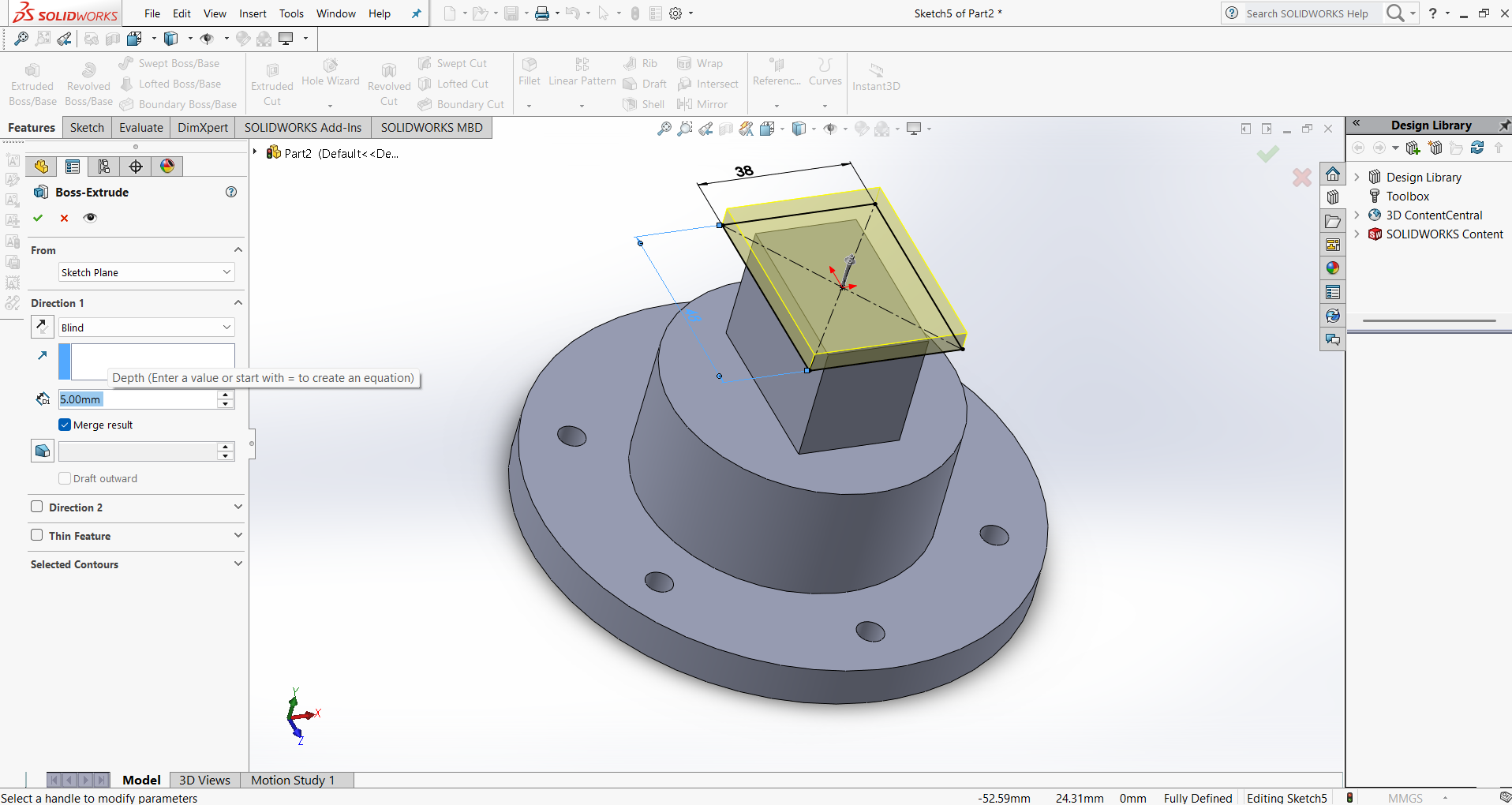

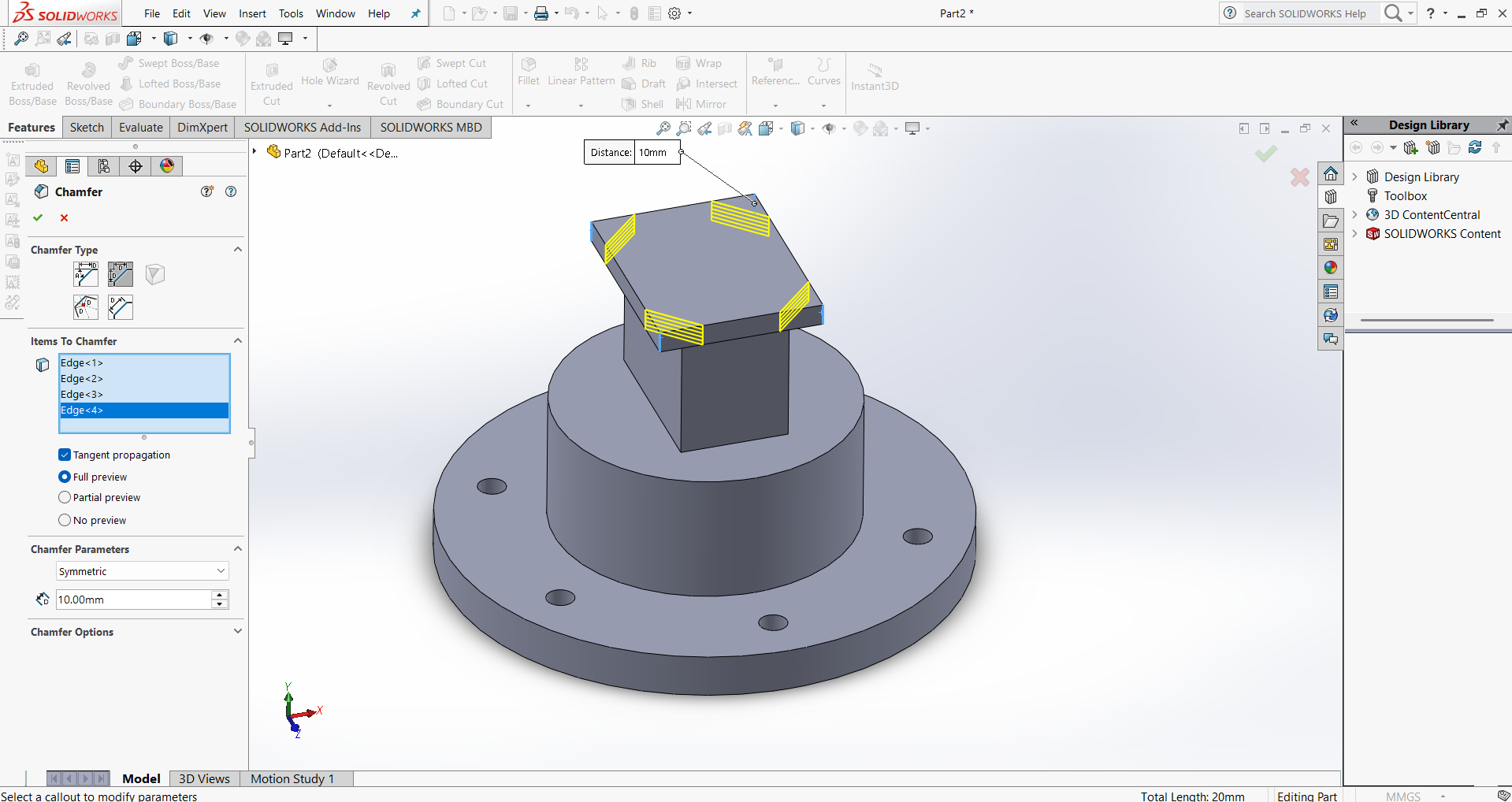

3️⃣ Struggles with Parametric Design

🔹 Challenge: Initially, I faced issues in defining constraints and dimensions for parametric modeling, which caused unexpected errors when modifying designs.

✅ Solution: I learned to apply constraints systematically, used dimension-driven design, and tested different values to see how the model responded.

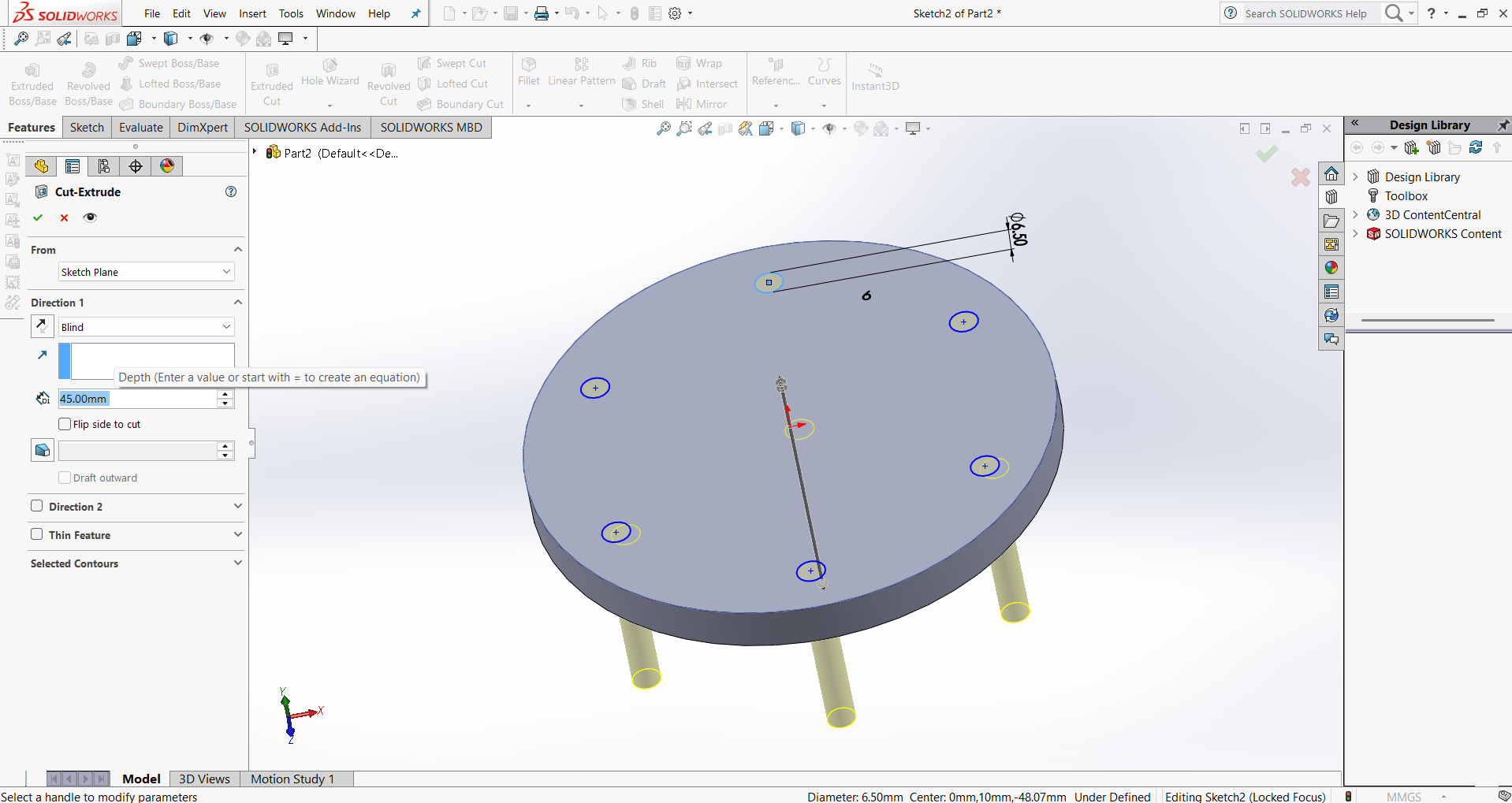

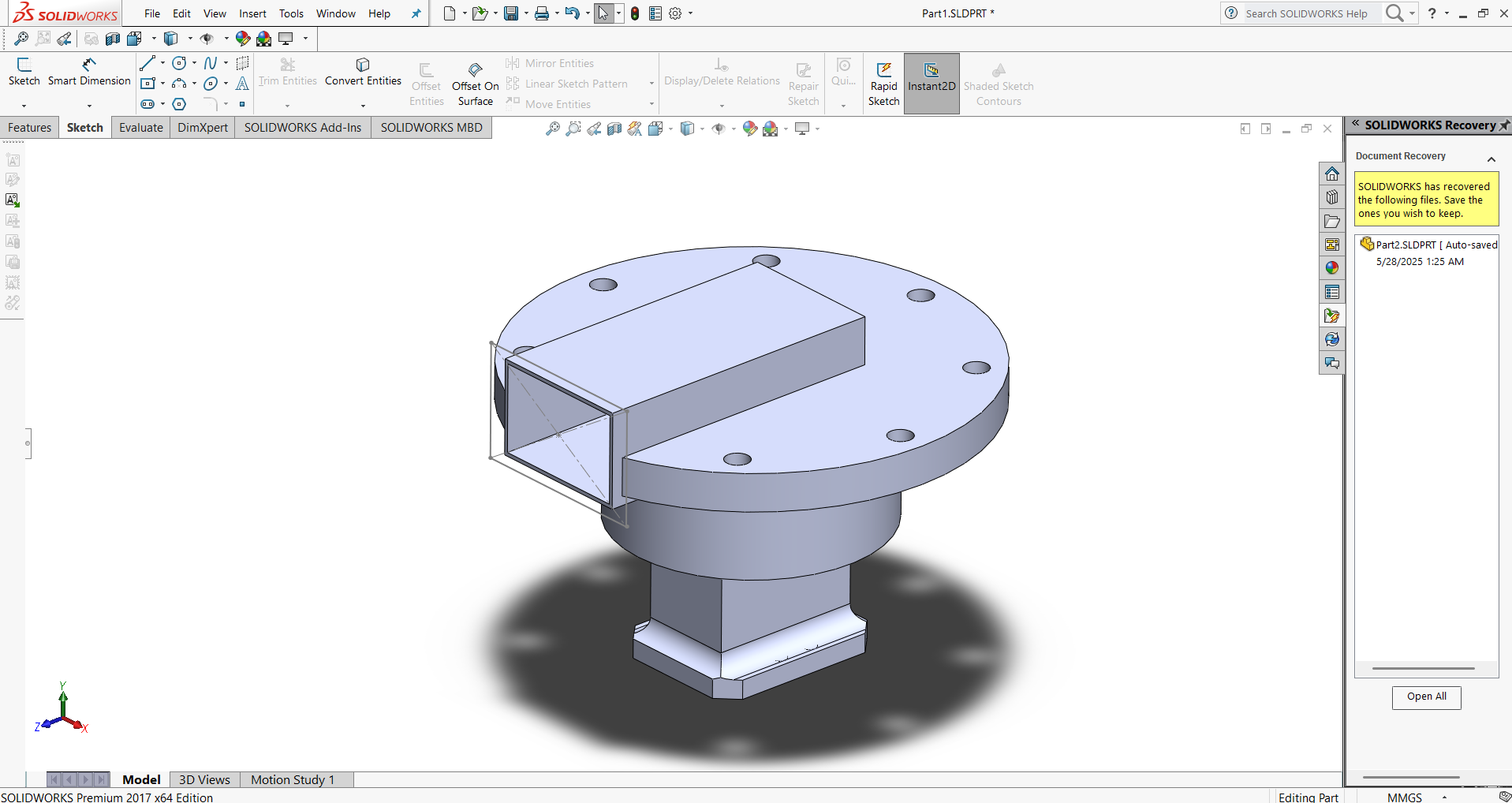

4️⃣ Performance Issues with Complex Models

🔹 Challenge: When working with detailed 3D models, the software lagged, making it difficult to navigate and edit designs smoothly.

✅ Solution: Optimized my workflow by using lightweight preview modes, reducing unnecessary details, and enabling performance settings in the software.

5️⃣ Exporting & Compatibility Issues

🔹 Challenge: Exporting files in the right format (DXF, STL, SVG) for fabrication sometimes caused scaling issues.

✅ Solution: Double-checked units and scaling settings, tested exports in different software, and ensured proper format selection for the intended use.

Each of these challenges helped me develop a structured approach to CAD modeling. With continuous practice, patience, and troubleshooting,

I gained confidence in using CAD tools for design and fabrication. 🚀