Hey there! Welcome to Week 3 of Fab Academy. This week is all about diving into computer-controlled cutting. We�ve got two tasks lined up � one as a group and one on our own � and both are packed with hands-on learning. I�ll be focusing mainly on laser cutting, where I created my own construction kit, and I�ll also walk you through what I�ve learned about parametric design and why it�s such a game-changer when working with laser cutters. Oh, and we�ll touch on vinyl cutting too!

Group assignment laser cutting and scanning:

During this week�s group assignment, our primary focus was on laser cutting and material characterization. Collaborating as a team, we conducted a series of experiments and test runs on the laser cutting machine to better understand its capabilities and limitations. The main objectives of the group task were:

Understanding the Laser Cutting Machine:

A thorough exploration of the laser cutting machine was conducted

to understand its technical specifications, operational capacity, and

underlying principles. This included a deep dive into the types of lasers used,

their power ratings, focal length adjustments, and material compatibility. We

also examined the precision levels, cutting depths, and limitations based on

the machine�s design and capabilities.

Operational Knowledge:

We gained hands-on experience in operating the laser cutter, from initial

setup to executing precise cuts. This involved learning how to load

materials, configure the settings (such as speed, power, and frequency), and

troubleshoot potential issues. Additionally, we studied the importance of laser

alignment and focus adjustments to ensure optimal cutting results

and avoid material wastage.

Safety Precautions:

An integral part of this week�s assignment was understanding and

implementing comprehensive safety protocols for working with the laser

cutting machine. This included wearing appropriate personal protective

equipment (PPE), ensuring proper ventilation, and adhering to strict

operational guidelines to prevent accidents or material fires. Emphasis was

placed on maintaining a secure and hazard-free working environment to ensure

the safety of all participants and equipment.

Optimization Parameters:

We focused on determining the optimal speed and power settings

for various materials (wood, acrylic, metal, etc.) to achieve clean and precise

cuts. Additionally, we explored the Kerf value�the width of the material

removed by the laser�which plays a crucial role in ensuring dimensional

accuracy. By experimenting with different material types and thicknesses, we

calculated the most efficient parameters to minimize errors and material waste.

These values were recorded and serve as references for future projects,

enabling us to adjust CAD models parametrically based on real-world

laser cutting performance.

Material Science and Laser Interaction:

In addition to the technical aspects, we delved into the material

properties and how different surfaces interact with laser cutting

technology. This included studying factors like reflectivity, absorption,

and heat resistance, which influence how effectively the laser cuts

through various materials. Understanding this interaction is critical for

selecting the appropriate materials and settings for specific projects.

Post-Processing Techniques:

We also explored post-processing methods to enhance the appearance and

functionality of laser-cut pieces. This included engraving for

detailing, cleaning the cut edges to remove any burnt residue, and finishing

techniques like polishing or painting for a refined final product.

These optimized values, combined with a better understanding of

material-laser interactions and post-processing techniques, now serve as

essential guidelines for our individual assignments and projects. With the

established optimal settings for speed, power, and Kerf values,

we can confidently modify and adapt parametric CAD models for more

accurate, efficient, and personalized laser-cut designs.

Laser Cutter:

A laser cutter is a highly precise, computer-controlled

tool that uses a focused laser beam to cut, engrave, or etch materials

with exceptional accuracy. The laser beam is directed onto the material�s

surface, where it melts, burns, or vaporizes the material, leaving

behind a clean, sharp cut. Laser cutting technology is versatile and

widely used in industries such as manufacturing, prototyping, crafting,

and product design due to its speed and precision. It is

capable of cutting through a broad spectrum of materials, including wood,

acrylic, plastic, fabric, and metal, with the machine�s cutting

power adjusted based on the material's properties.

Laser cutting is particularly renowned for its ability to produce intricate

designs and complex geometries with minimal material waste. It is

ideal for creating detailed patterns, prototypes, and customized

products. The technology is valued not only for its precision and speed but

also for its ability to handle highly customized and detailed tasks that

traditional cutting methods may struggle with.

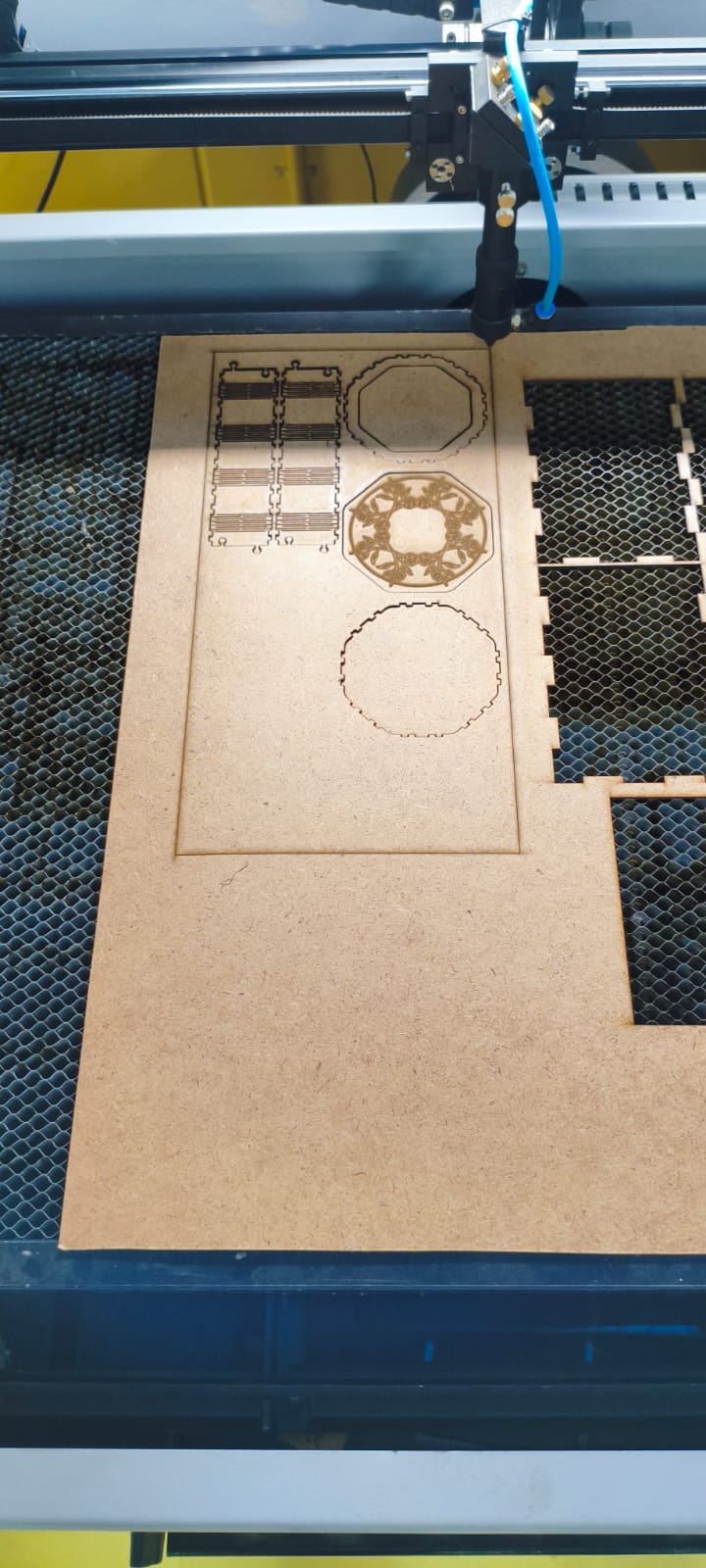

At our Trichy FabLab, we have access to a CO2 Laser Cutter,

which is specifically suited for cutting and engraving non-metallic materials

like wood and acrylic. During this week, we conducted a series of trials and

experiments on the CO2 laser cutter to better understand its capabilities,

settings, and material interactions, providing valuable hands-on experience in

laser cutting technology.

CO2 Laser Cutter Machine:

A CO2 laser engraving and cutting machine is a highly

versatile and powerful tool that uses a focused high-powered laser beam

to engrave, cut, and etch a wide range of materials with incredible precision.

The term "CO2" refers to the specific type of laser it utilizes�carbon

dioxide gas�which, when excited, generates a highly concentrated infrared

beam of light. This innovative technology employs a sealed CO2 gas mixture

as its laser medium, producing a focused, intense beam capable of

cutting through materials with exceptional accuracy.

The CO2 laser cutter is particularly effective at slicing through

a variety of materials such as wood, acrylic, leather, and even some metals,

leaving clean, smooth edges and allowing for the creation of intricate,

detailed designs. The machine operates by vaporizing or melting the

material in its path, which makes it ideal for applications ranging from highly

detailed crafting to industrial-scale manufacturing processes. Its

ability to produce sharp, intricate patterns with minimal material waste

has made it indispensable in fields like product design, prototyping,

and customized manufacturing.

With its user-friendly interface and computer-controlled

precision, the CO2 laser cutter offers professionals and hobbyists alike a

reliable and innovative solution for shaping and customizing materials. By

revolutionizing traditional cutting and engraving methods, it opens new

possibilities for creating complex designs and personalized products

in both small-scale and large-scale projects.