Electronics

Back

Electronic design

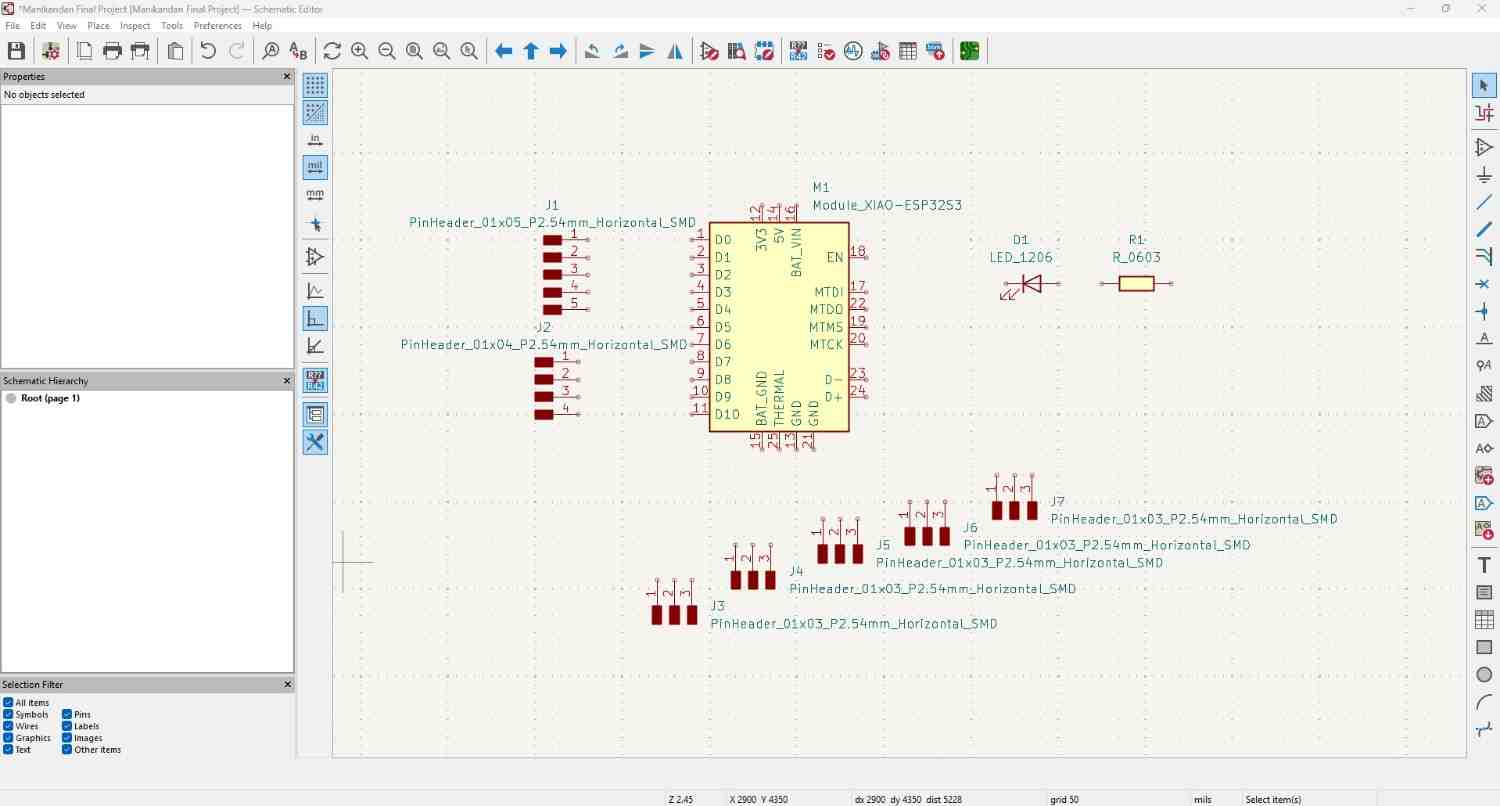

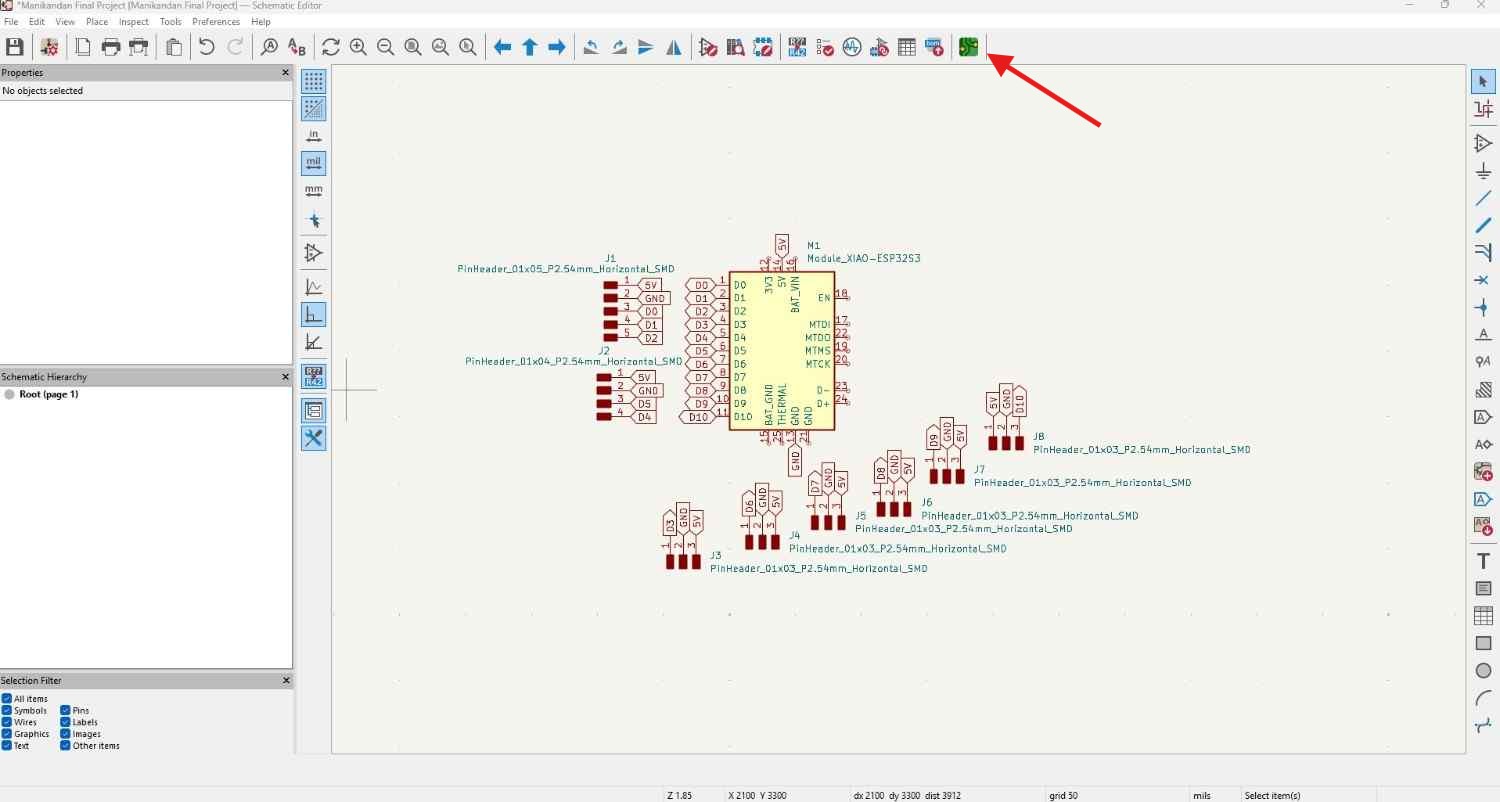

I start my final project PCB design with KiCAD

KICAD

KiCad is a free, open-source software suite for Electronic Design Automation (EDA). It allows users to design schematics and convert them into PCB layouts. KiCad supports multi-layer boards, custom footprints, and 3D visualization of PCB designs.

I import the Fablab library already in the Kicad, I recommend to you to dowload and upload it into your kicad software.

At first I load the microcontroller XIAO ESP32S3 board, then take the pin connectors according to my use.

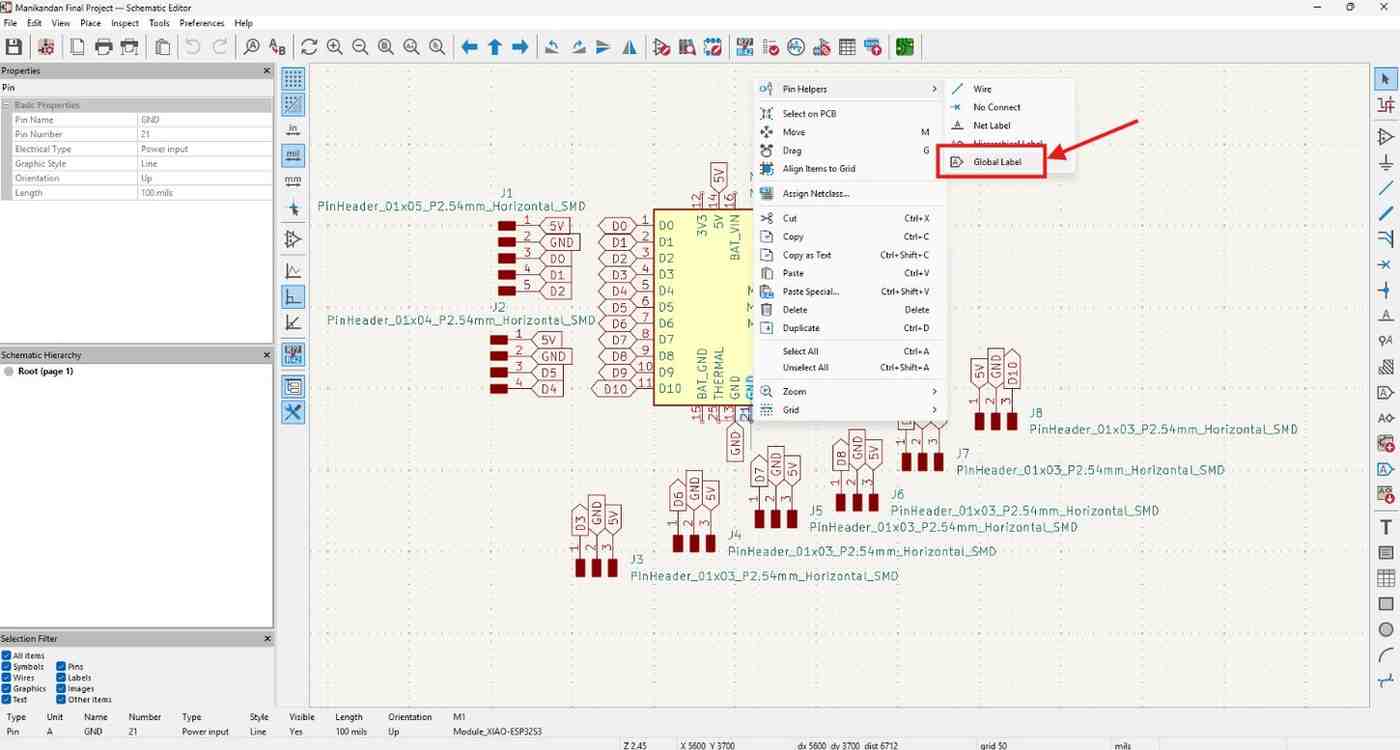

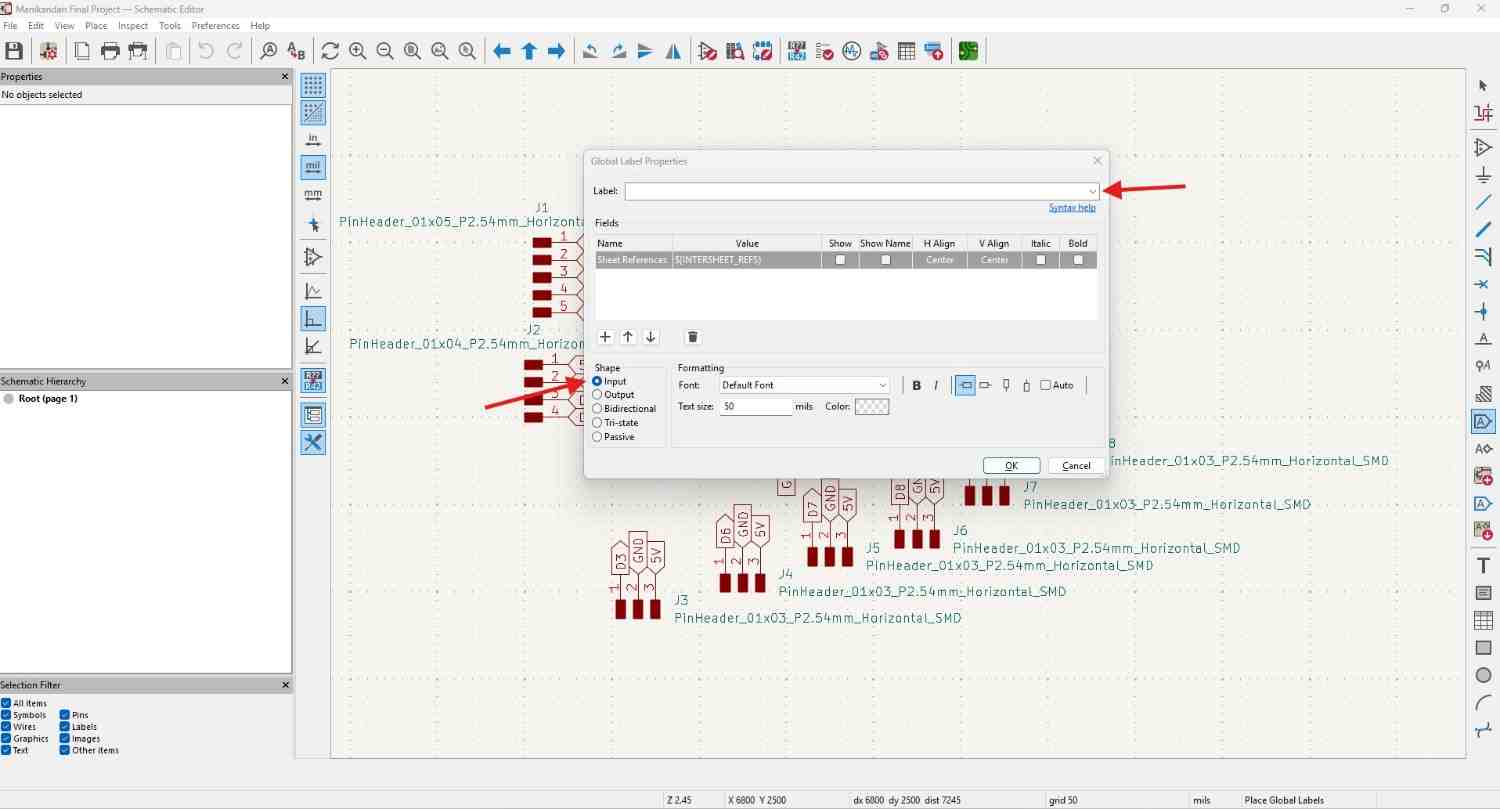

Instead of connecting wiring I set it all by lable, it is very useful whenever you want to change the connections after checking your footprint we can easily change by using those.

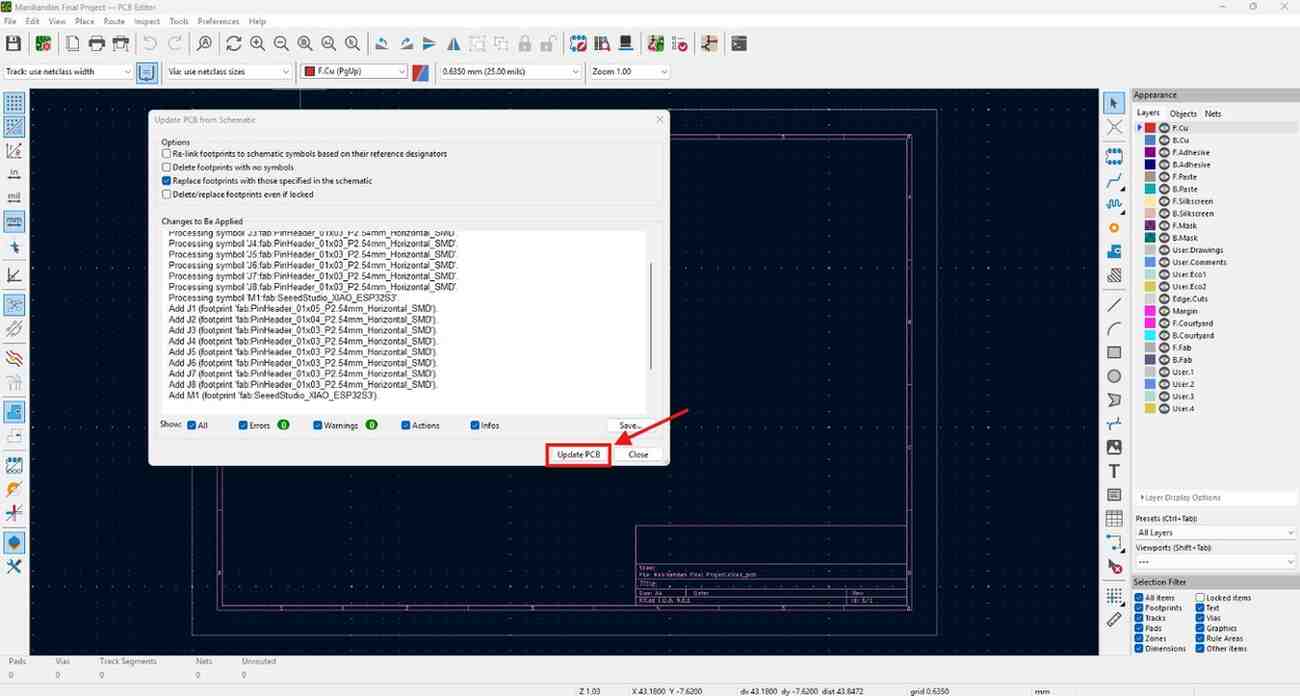

After setting all the connection of my board I go into the PCB editor

We should update our current model whenever we did some changes in the schematic editor.

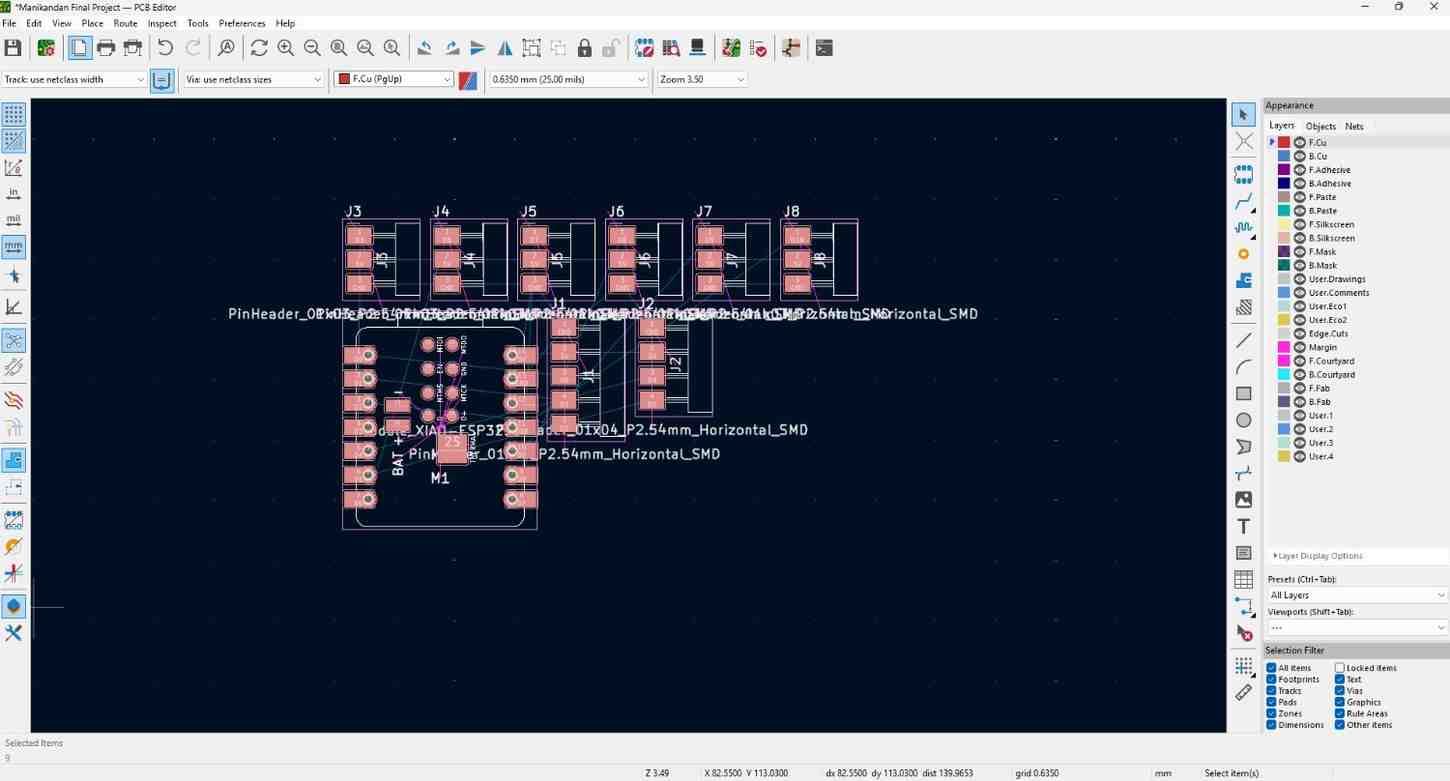

After give the update our footprint design will appear like this, then we need to rearrange our components where we want.

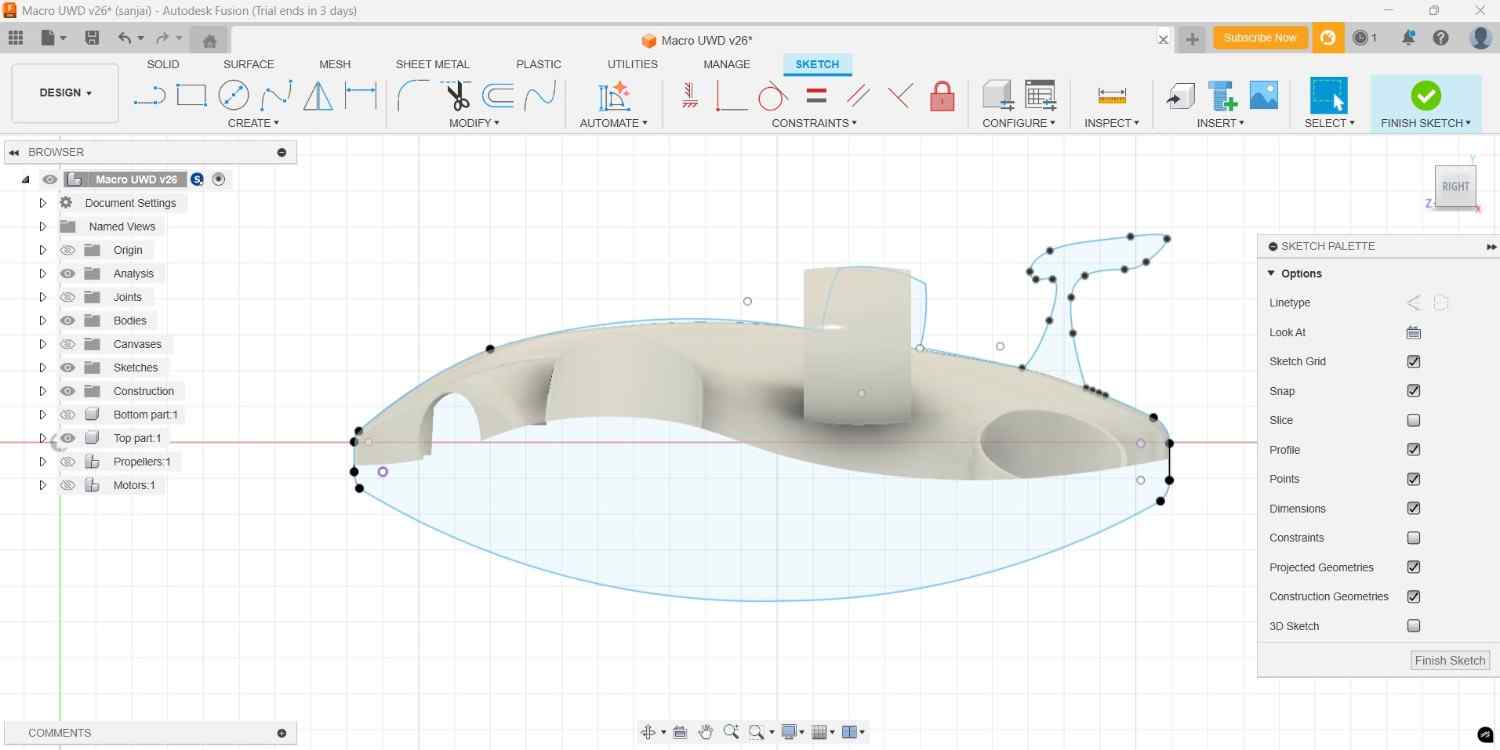

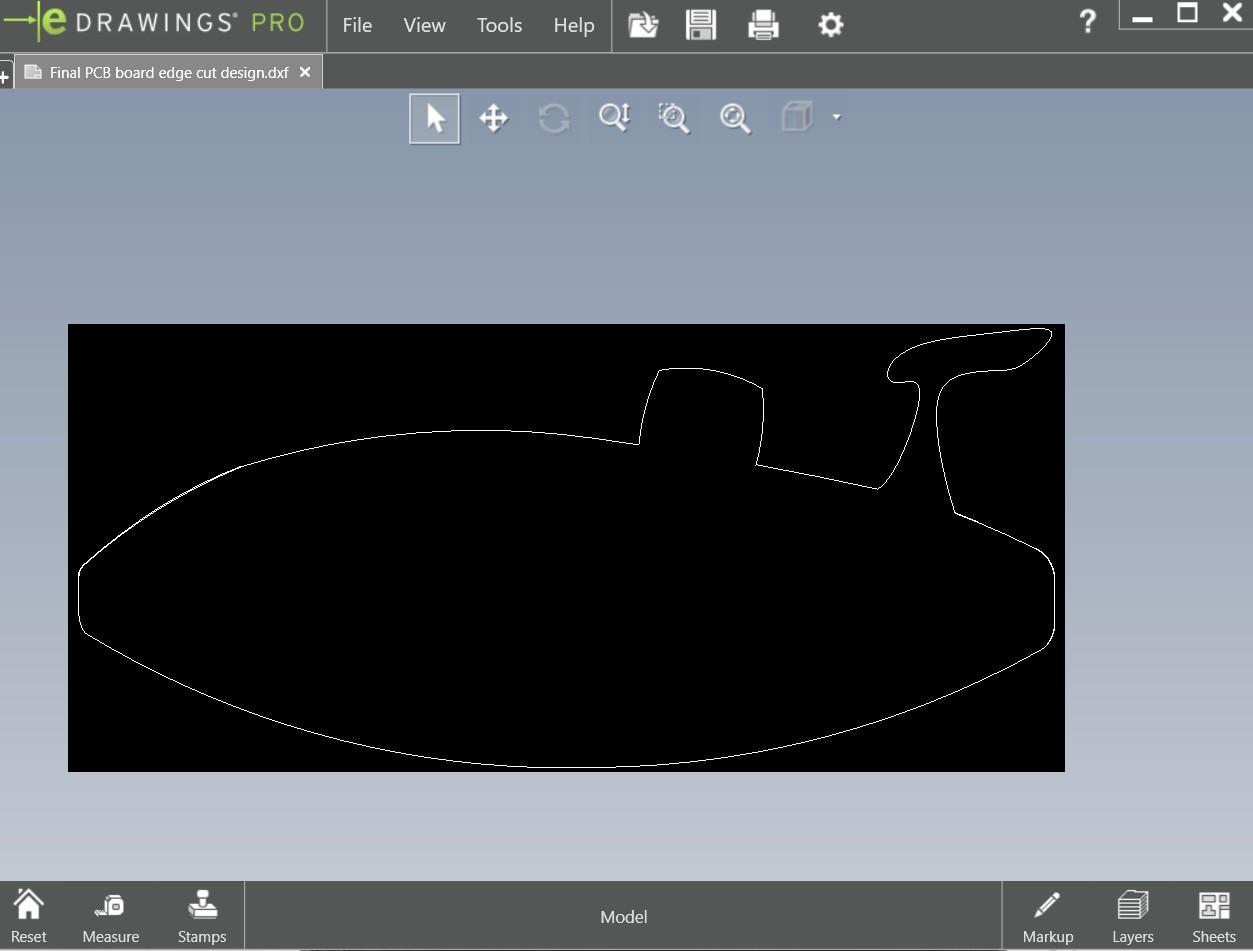

For the edge lines I planned to do different, instead of giving the box or round I aimed to cut the PCB board like my drone shape.

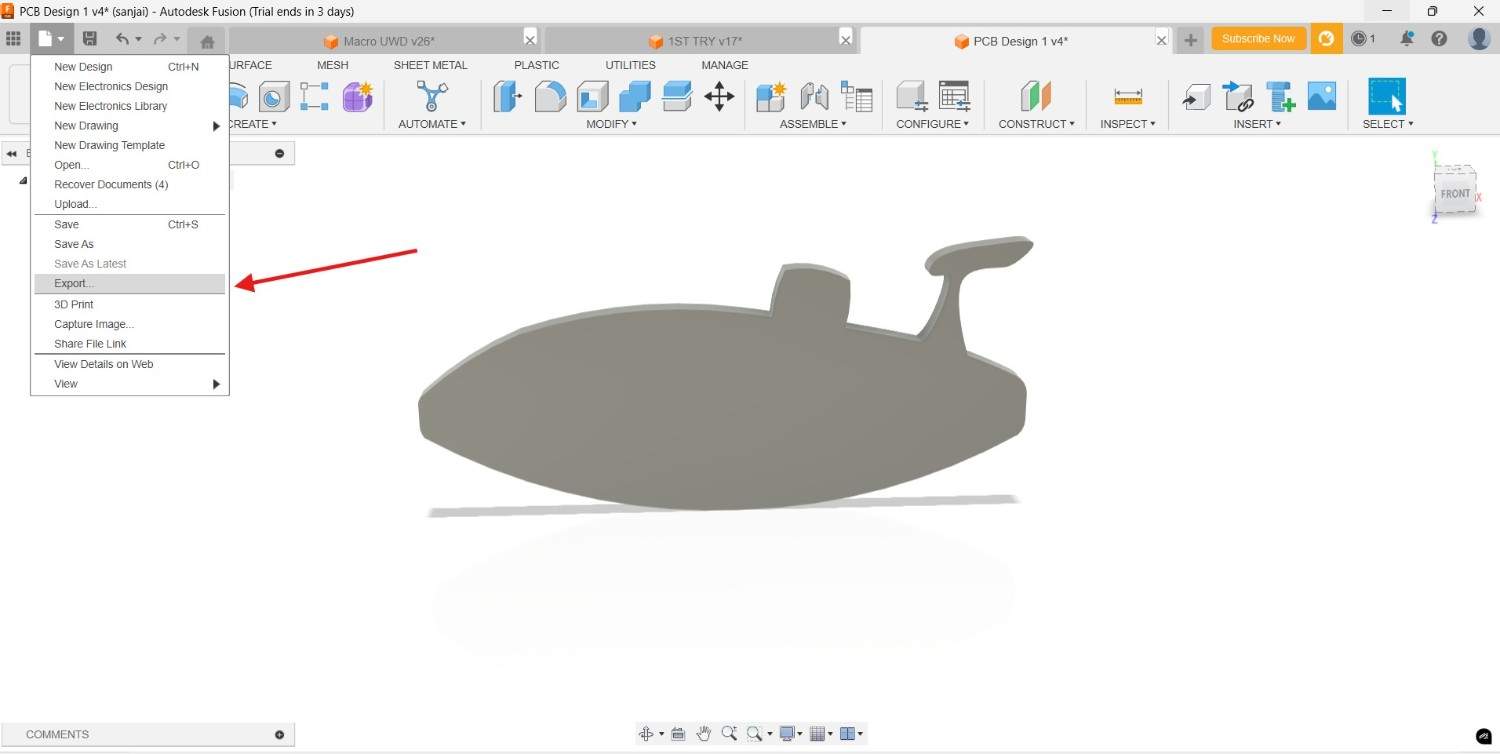

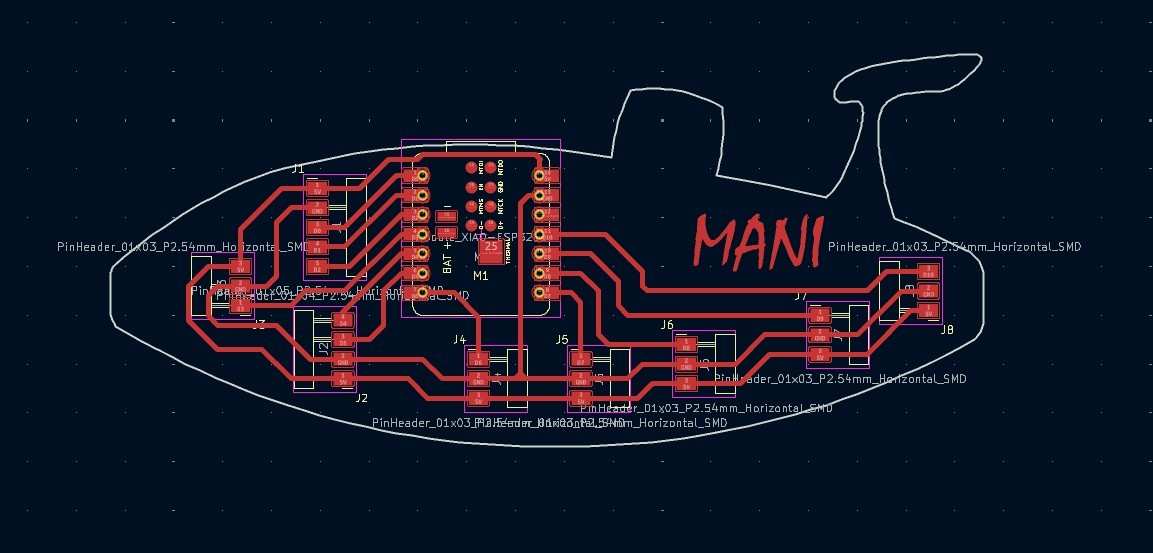

So I open the Fusion 360 and took my drone as reference and draw the outer line for the edge cut.

Then I extrude it by using the extrude command because the design is not the proper design so we should be contraint it before export it.

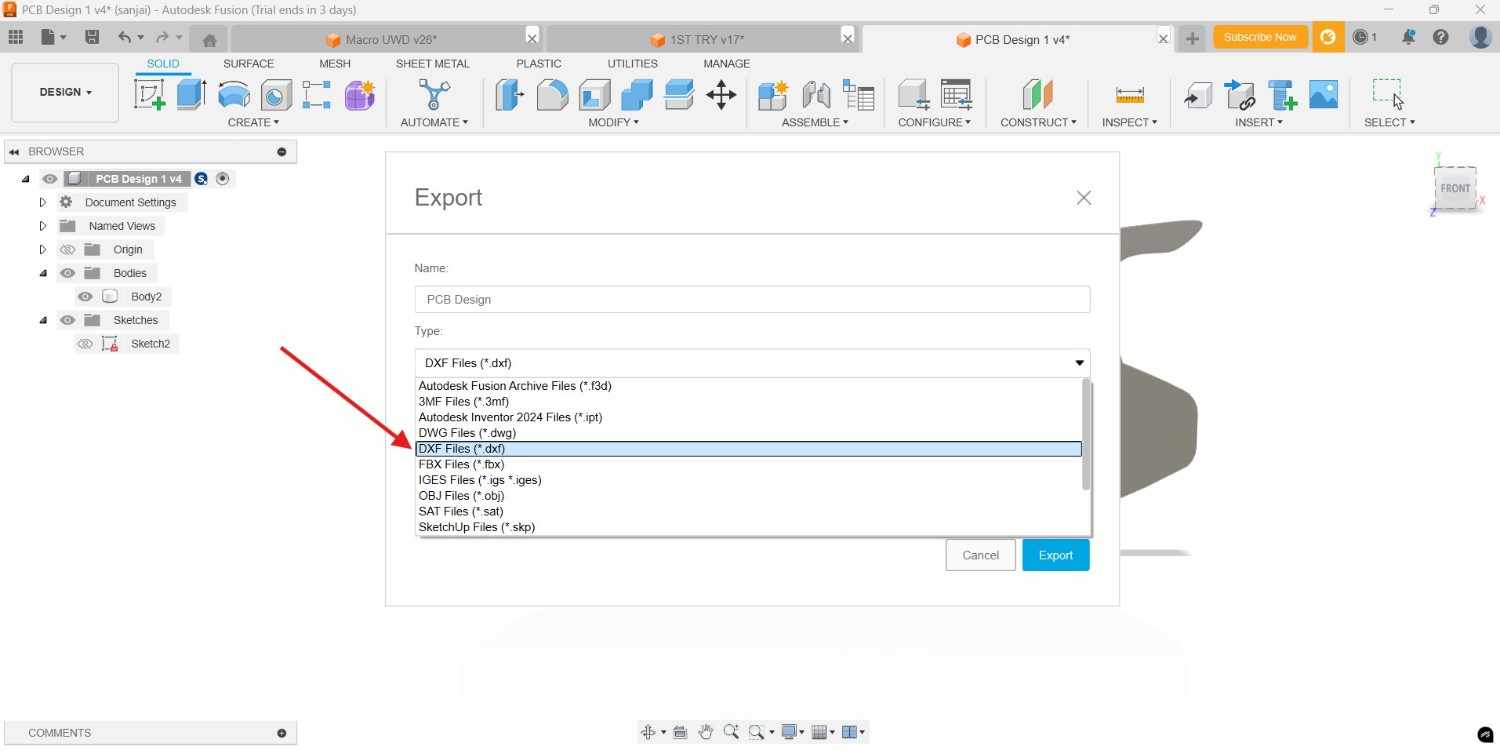

I export it into DXF file to import the Kicad. Kicad will support the DXF format so there is no issue

I am also checking that whether is it came without broken by using the e drawings, its just the dxf viewer

I import it into the Kicad and rearrange the components positions within only inside the edge cut, then by using the trace I connected teh componets

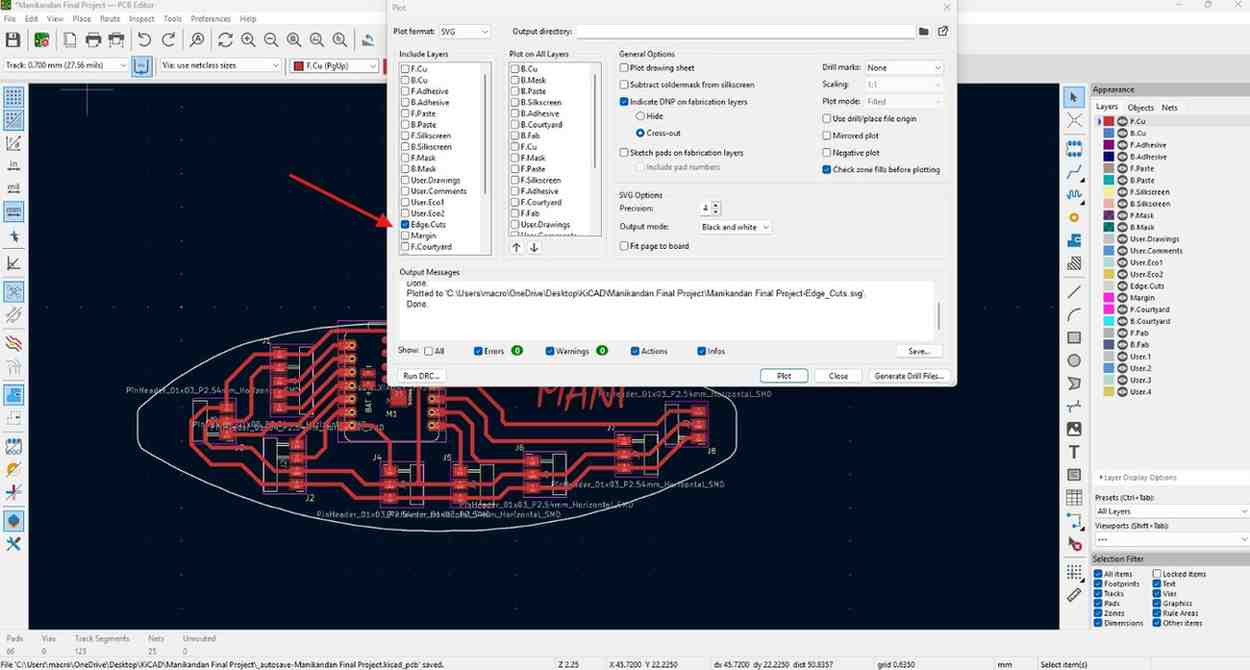

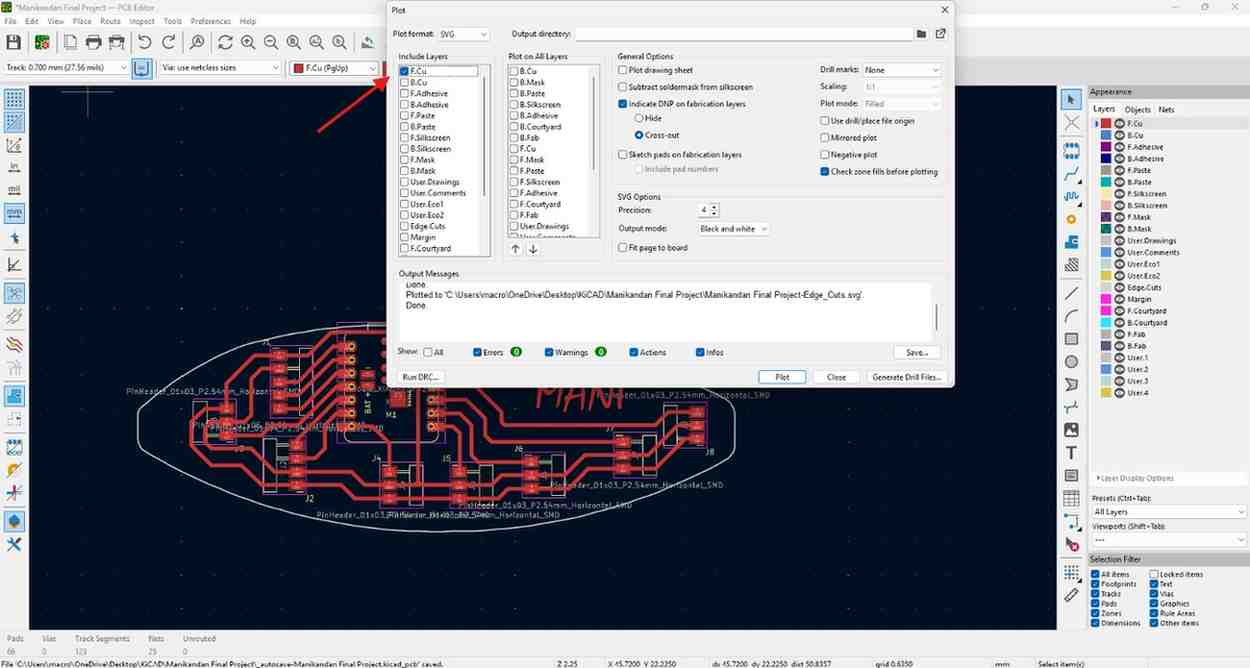

To export it I used the SVG export option in Kicad

Electronic Production

MODS

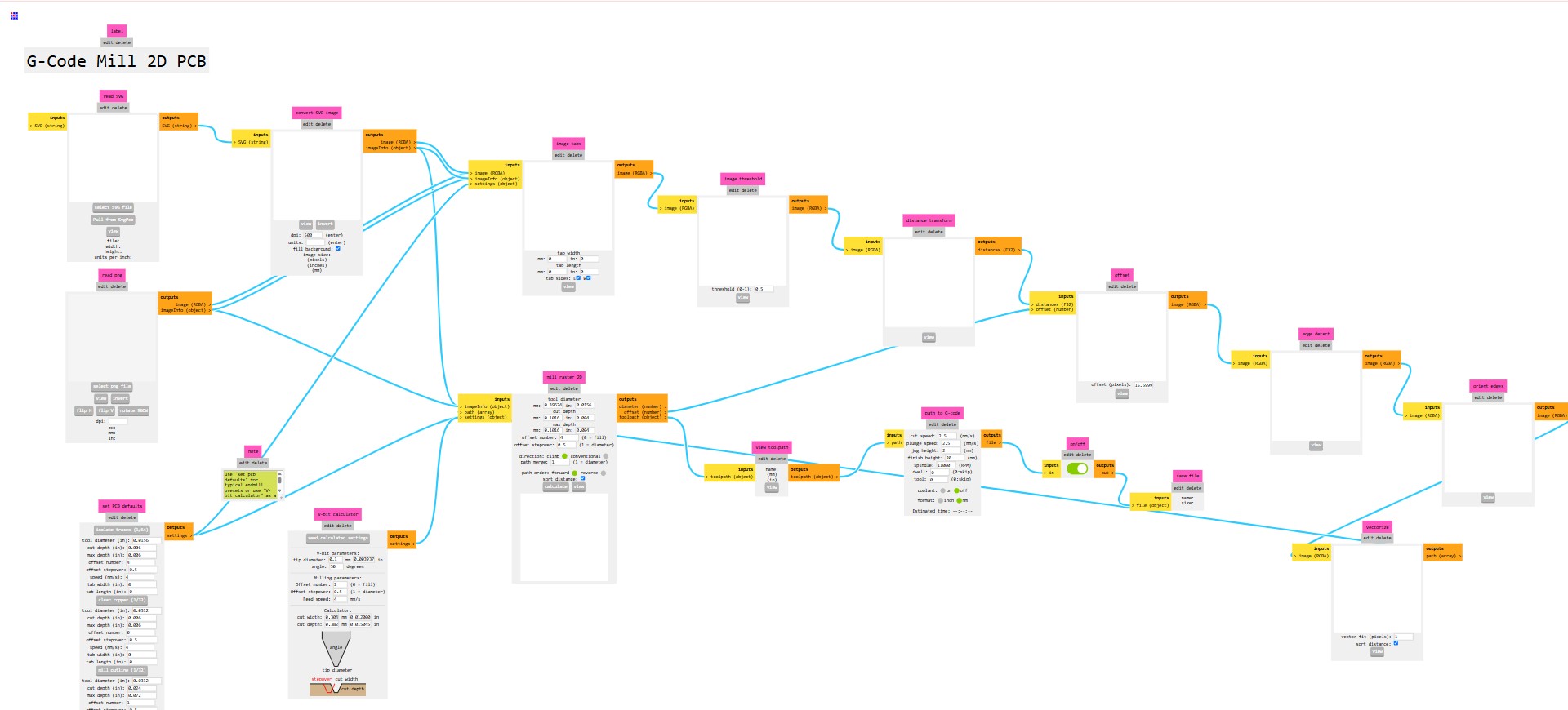

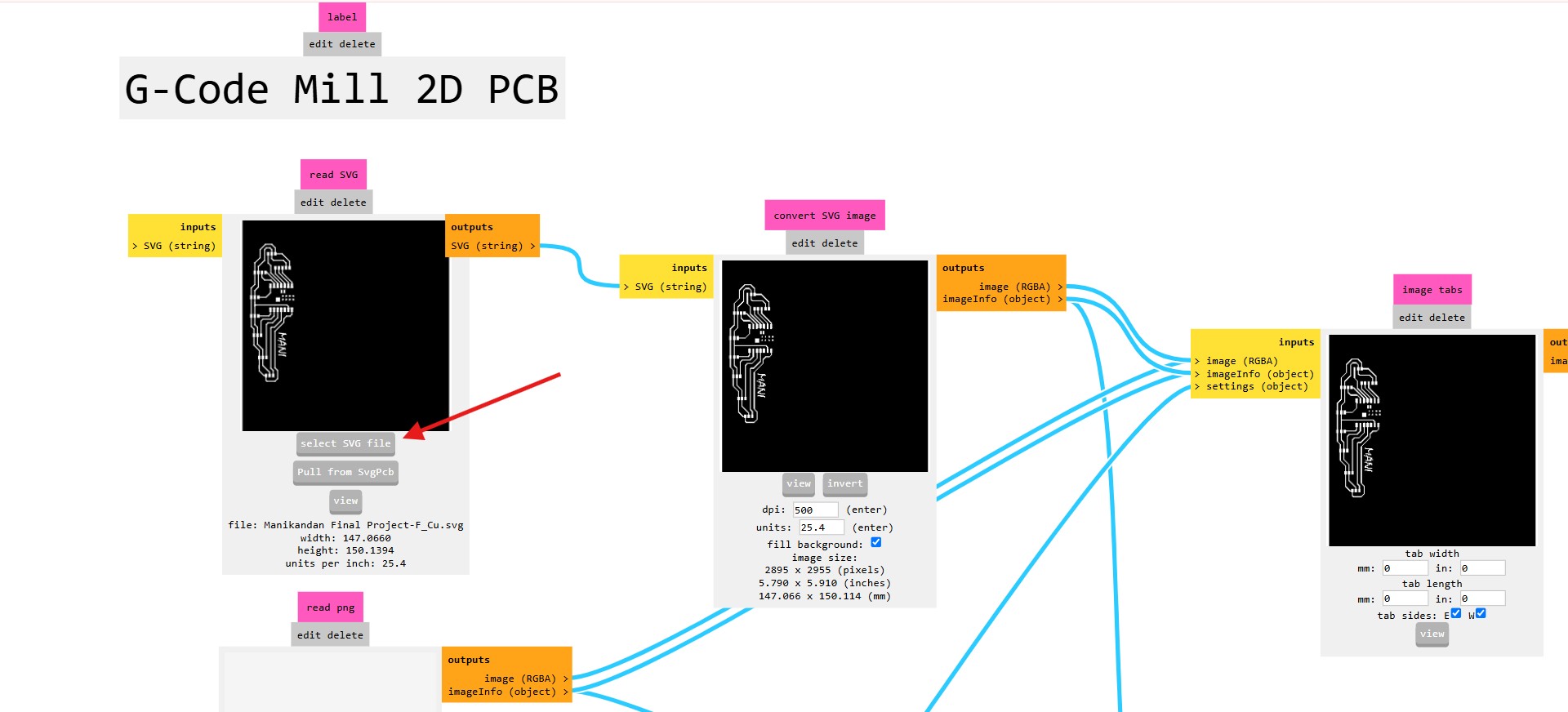

MODs (Machines, Objects, and Devices) is an open-source software tool developed by MIT's Center for Bits and Atoms. It provides a modular, browser-based interface for controlling digital fabrication machines like laser cutters, vinyl cutters, and CNC mills. Users can create custom toolpaths from various file formats (e.g., SVG, PNG, STL). It allows real-time editing of fabrication parameters using a node-based flow system. MODs is lightweight and runs locally in a browser, offering flexibility for custom workflows. It's especially popular in Fab Labs and educational environments.

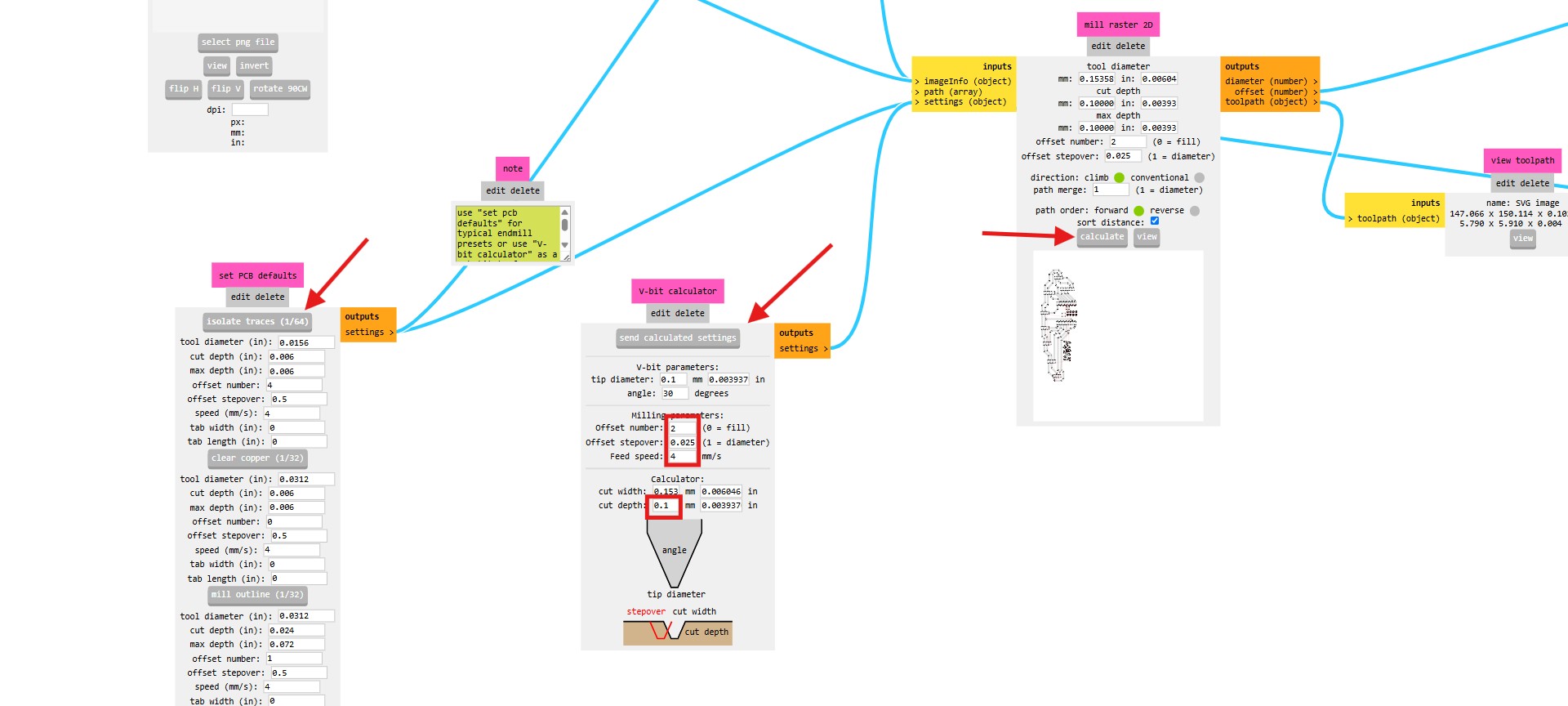

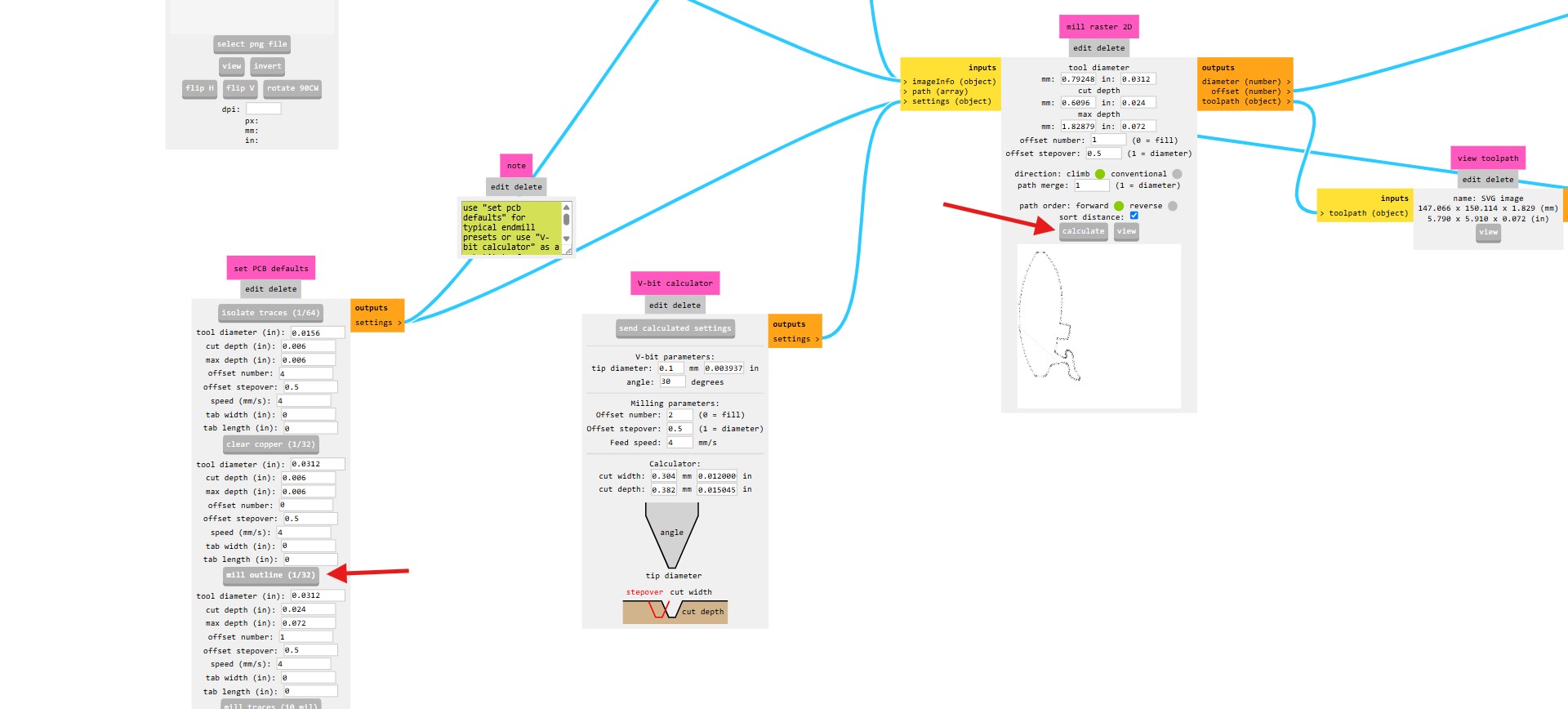

For my PCB milling I need a tool path so I use the MODS to generate the gcode

Right-click to open a program and go to the G-code 2D PCB Milling, after enter into that load files PNG/SVG for processing (Right click>Program>open program>G-code - mill 2D PCB)

After open the Gcode pcb mill we should load our SVG file of our pcb design

Then I set the parameters according to my machine capability, every machine has good capability with some certain parameters

After done those all I give the calculate, so it will download the gcode of our design

Further I did the edge cut as well to take out the gcode

Wegstr

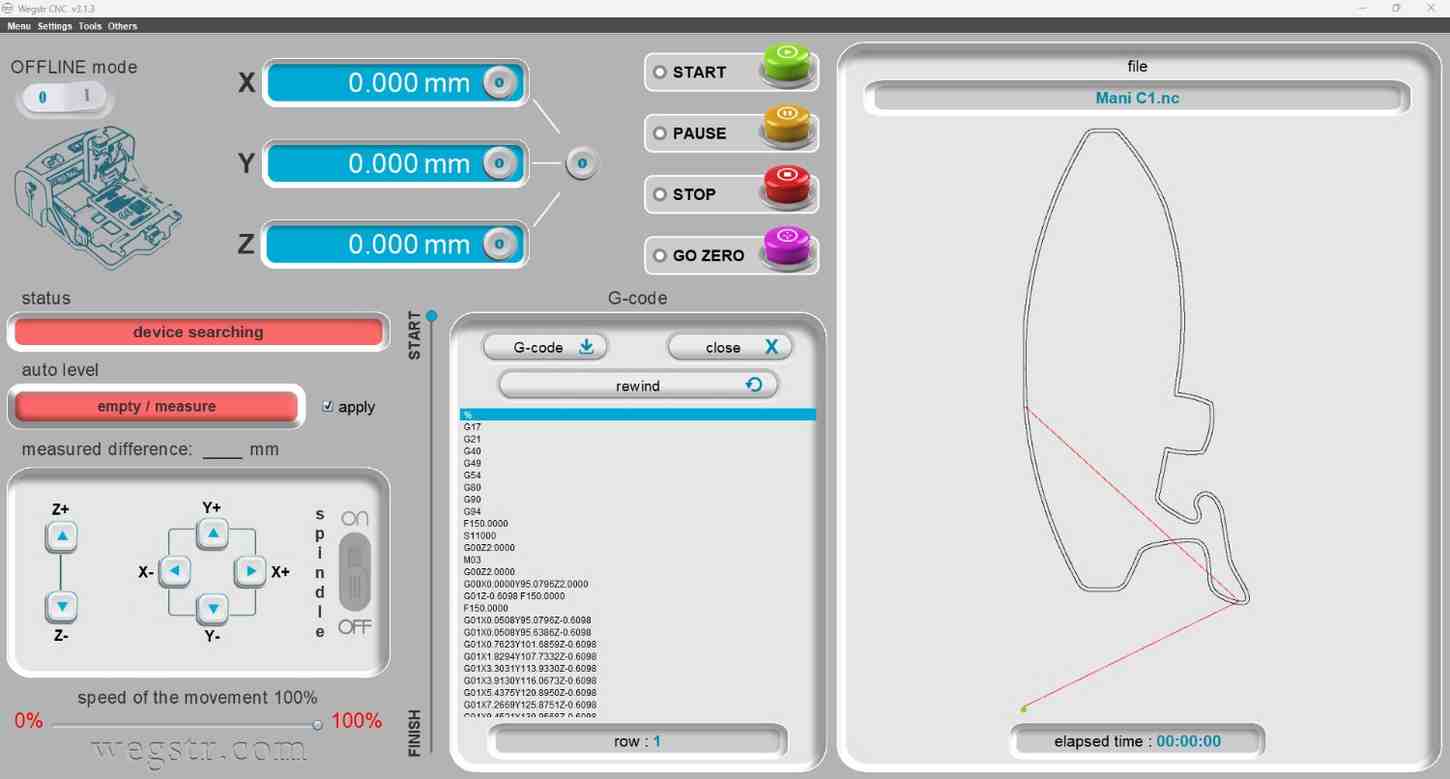

Wegstr provides free CNC Controlling Software for operating its milling machines on Windows, macOS, and Linux. It enables basic operations like PCB milling and engraving. For designing toolpaths, Wegstr recommends Cut2D Desktop.

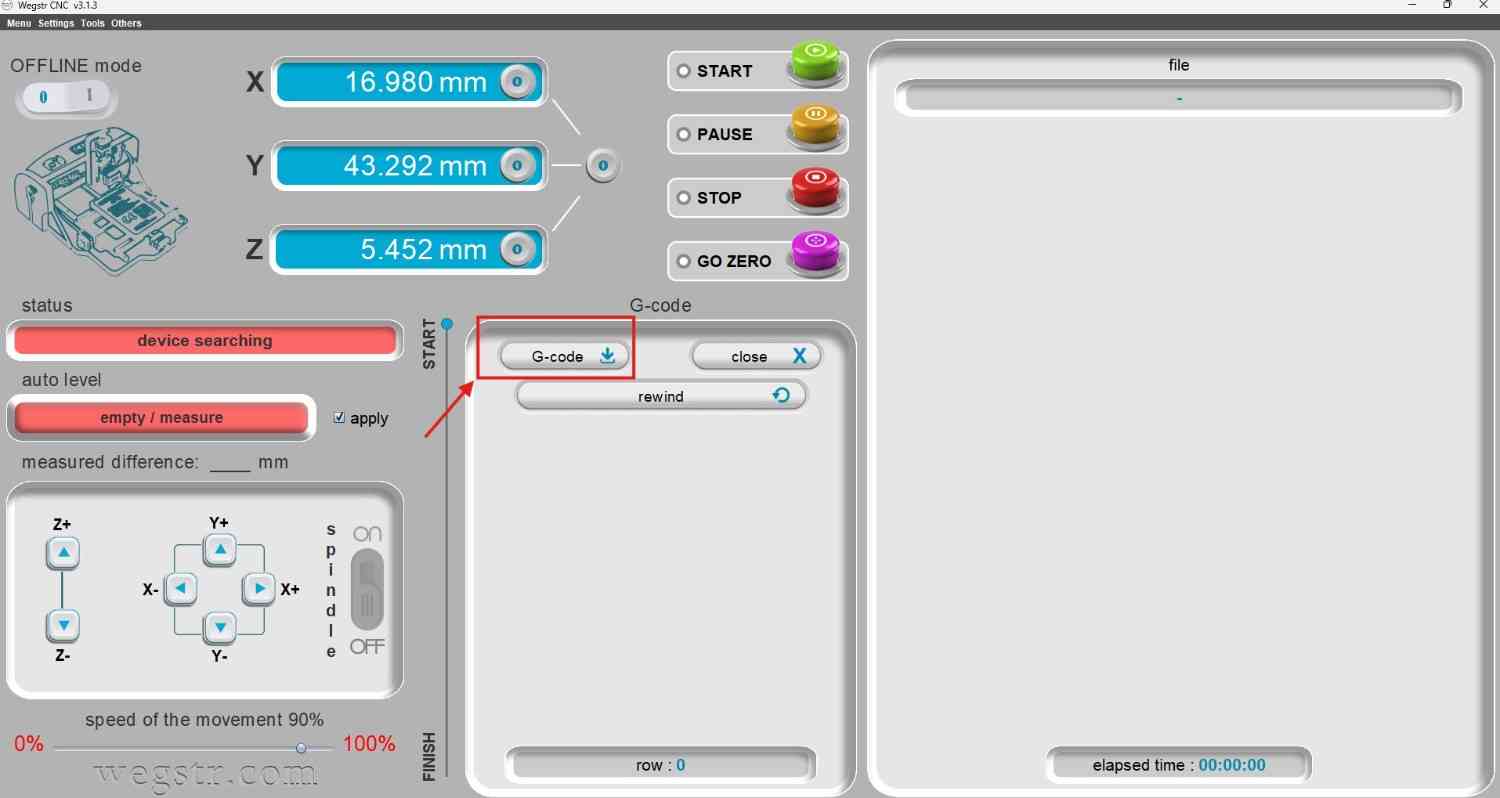

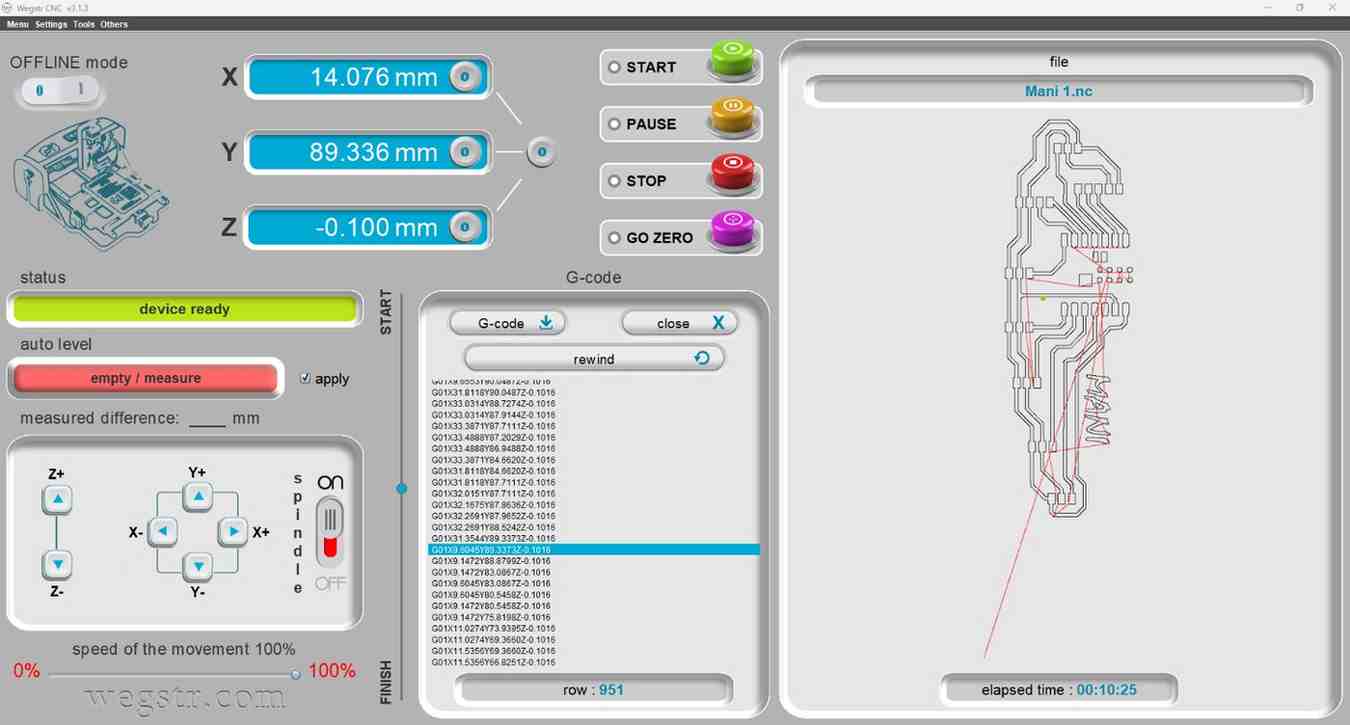

For the milling operation I used the Wegstr software to control our Wegstr machine. I import the gcode in the software

I check the gcode whether it is properly came or not once, Iset the position of the spindle where from I want to milling.

I also check once the edge cut before milling for the proper positioning

Milling Process

I start the milling process by Wegstr software,

I closely check the milling process to confirm the trace width came better as expected

After the milling I changed the cutting tool to the spindle without changing the X & Y axis, only changed the Z axis. Then set again zero to the edge cut.

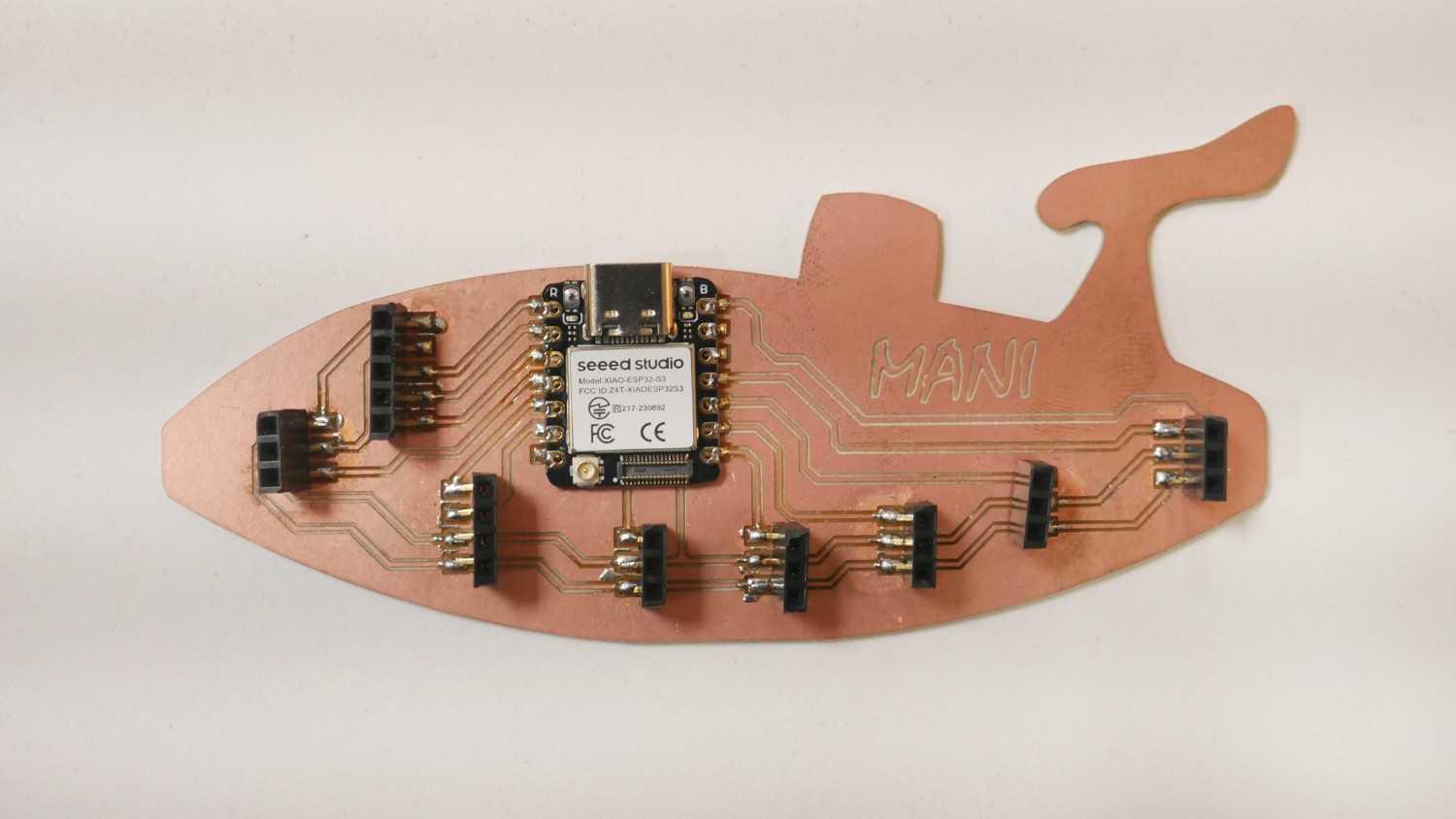

The cutting process done wihtout any damage

Milling also came good as I expected…

Soldering

I check the PCB board continuity test by using the Multimeter, after setting the continuity I check wiht the probe itself.

Then I place the probe at differnt places to confirm the milling came without any damage

After confirming everything I took the board to soldering the pin connectors and the microcontroller, I carefully soldering those