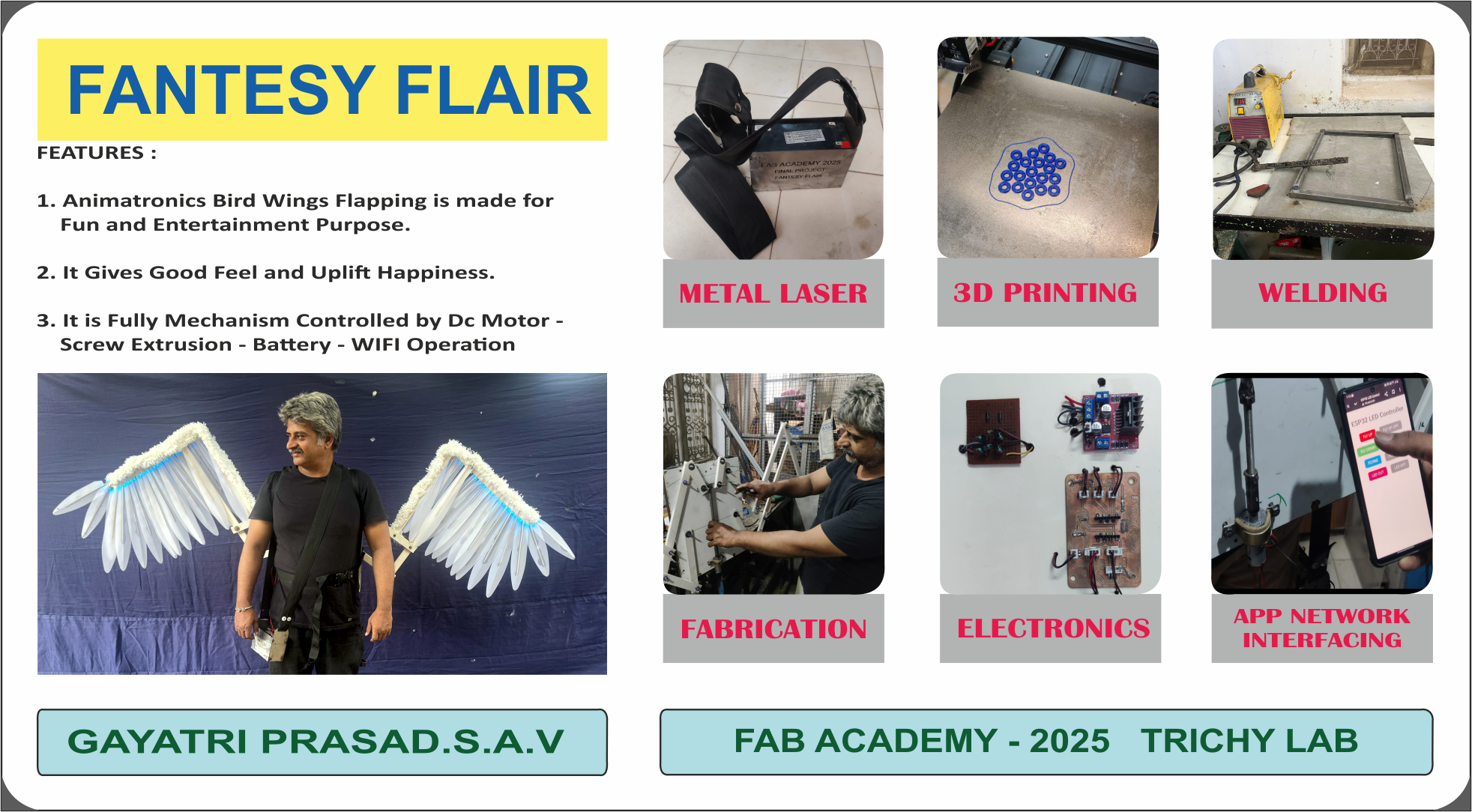

Final Project: Animatronic Flapping Wing System

What does it do?

The project simulates realistic bird-like wing flapping using a wearable mechanism controlled via a WiFi-enabled ESP32 board.

Who’s done what beforehand?

Several makers have attempted servo-based wings, but i integrate custom fabrication, wireless control, and embedded electronics.

What did you design?

- Mechanical wing frame

- Actuator mount

- Wearable harness

- Custom PCB

- Control interface

What sources did you use?

- Fab Academy archive

- ESP32 datasheets

- KiCad Fab libraries

- Mechanical linkage studies

- YouTube builds

What materials and components were used?

- D.c 12v 30 rpm motor

- electric casing pipe

- PLA

- Mild steel

- Foam feathers

- ESP32

- L298N driver

- Linear actuators

- 12V battery

Where did they come from?

- Local hardware and FabLab stock

- Online stores (Robu.in, Amazon)

- New battery

How much did they cost?

Bill of Material

| Product Name | Description | Price | Quantity | Total Price | |

|---|---|---|---|---|---|

| Square Pipe (Mild Steel) | 10 feet | ₹50/ft | 1 | ₹500 | |

| Motor to screwrod Coupler | 16mm | ₹377 | 1 | ₹377 | |

| DC Motor | 12V 30RPM | ₹350 | 1 | ₹350 | |

| Battery | 12V 7 amps | ₹750 | 1 | ₹750 | |

| Battery case in sheet metal | lasercut charges | ₹500 | 1 | ₹500 | |

| Wire | 14/36 Multi Color | ₹100 | 1 | ₹100 | |

| Limit Switch | DC Motor Cutoff | ₹100 | 2 | ₹200/ | |

| Motor Driver | Manual Direction | ₹180 | 1 | ₹180 | |

| Motor fixture | 1.5inch Pipe clamp | ₹10 | 1 | ₹10 | |

| Wing Materials | Electric casing pipe 20 feet. | 1 feet ₹8 | 20 | ₹160 | |

| Rgb Led | 10feet | ₹500 | 1 | ₹881 | |

| bag belt,lock,rivit etc | 5meter,1,24no | 350 | 1 | ₹350 | |

| 2 inch,1 inch bolt,nut,washer | 24 no | 80 | 1 | ₹80 | |

| Grand Total | ₹4,438 | ||||

What parts and systems were made?

- 3D-printed joints and supports

- Mild steel pipe weld frame

- Metal Laser-cut sheet metal Battery cover

- CNC-bent Battery cover

- Custom PCB board for ESP32 + L298N

What processes were used?

- 2D Design

- 3D Modeling

- Metal Laser Cutting

- welding

- lathe work

- 3D Printing

- PCB Milling

- Embedded Programming

- Soldering

- Web Development

What questions were answered?

- How to ensure symmetric motion using actuators?

- How to integrate WiFi control with wearable mechanics?

What worked? What didn’t?

- Worked: Mechanical motion, web-based control, actuator strength

- Didn’t: D.c motor torque limitations, PCB v1 noise (solved with capacitor)

How was it evaluated?

- Peer testing

- Mentor reviews

- Usability feedback

- Live performance demo

What are the implications?

Foundation for wearable animatronics in entertainment, theater, and education.

Linked from this page to any weeks that you worked on your final project

Project Slide