The scope of My Fantasy Flair project

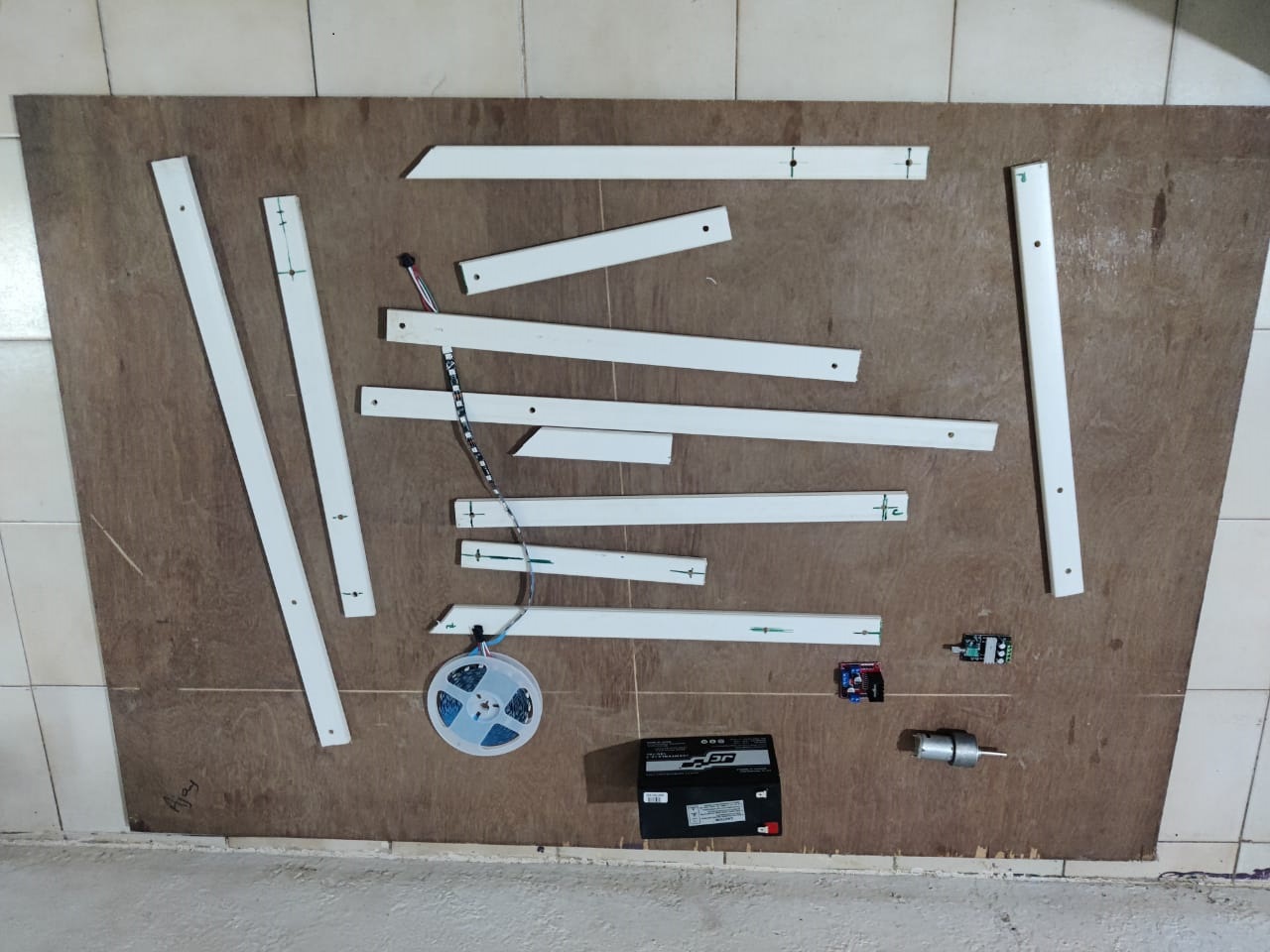

The scope of my Fantasy Flair project is to design, fabricate, and demonstrate a compact, wearable flapping wing mechanism using accessible digital fabrication tools and embedded electronics. The primary goal is to simulate realistic wing movement for use in cosplay, stage performances, and educational settings. The project involves mechanical design using CAD software, manufacturing of parts through CNC, laser cutting, and 3D printing, and development of a compact control system using a microcontroller and motor driver. The system is powered by a DC motor and controlled via custom code, offering adjustable wing motion parameters. Emphasis is placed on lightweight, modular construction for wearability, ease of assembly, and aesthetic appeal. While this version is a functional prototype, the broader scope includes potential extensions into animatronics, interactive art, and STEM education. The project reflects the interdisciplinary capabilities of Fab Labs, blending creativity with engineering to produce expressive, kinetic wearable systems.

What will it do?

This project is a mechanical bird flapping wing mechanism powered by a battery , 100 RPM DC motor and linear action. The wings flap using linear rods and linear bearings. Features include motorized wings, Bluetooth control, LED lighting, LDR sensor input, and a motor cutoff switch for safety.

Who has done what beforehand?

- Fab Academy: Similar projects like robotic wings, animatronics, and LED displays.

- Maker Community: Reciprocating screw rods are common, but flapping via screw rod is less common.

- Animatronics: Advanced mechanical birds use servos or actuators, but this is a simpler DIY-friendly approach.

What will you design?

- Mechanical frame in mild steel,wood and flapping linkage system in plastic

- Screw rod-driven linear mechanism

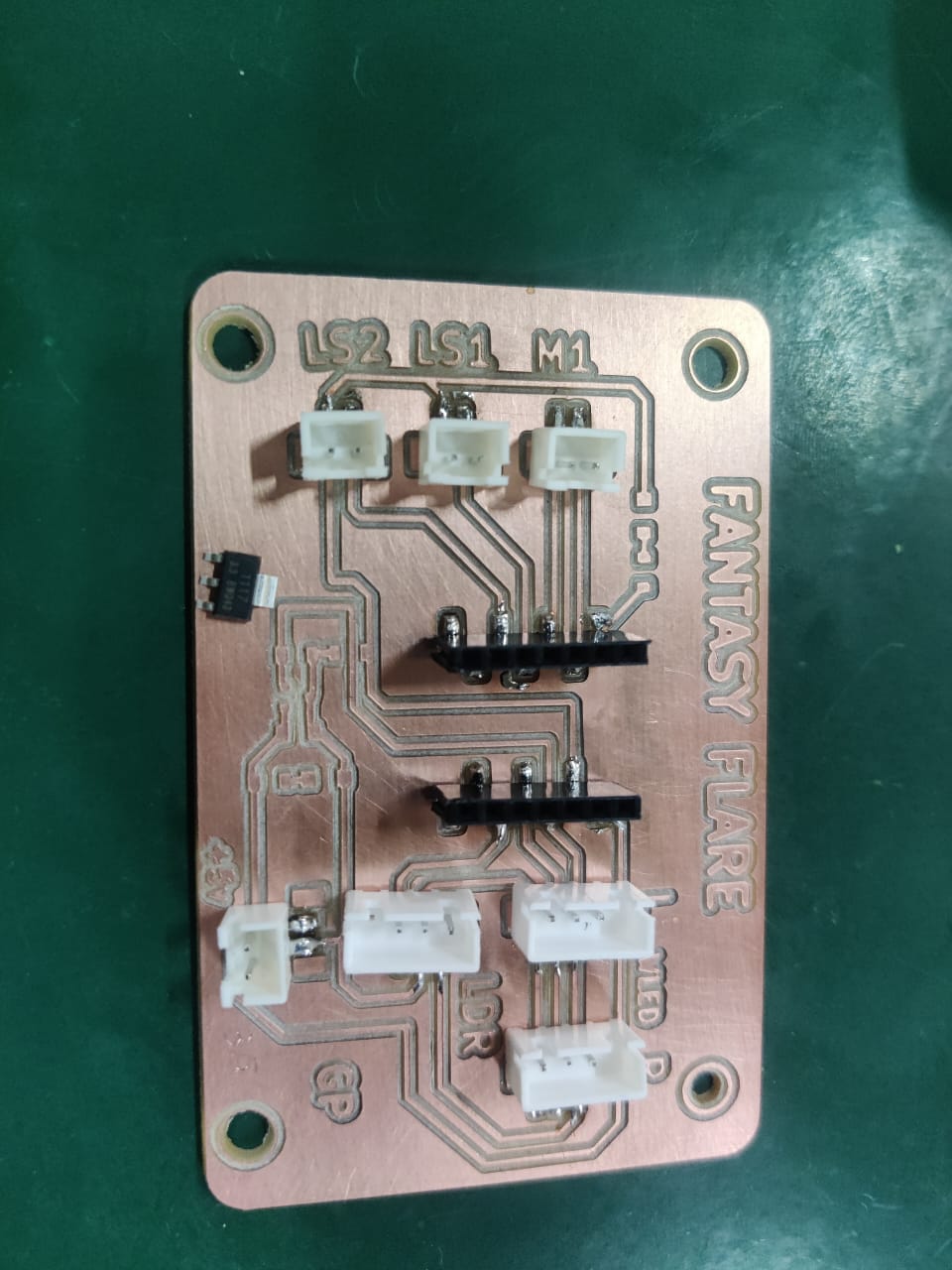

- Electronics setup: motor driver,speed controller, sensors, Bluetooth, LEDs

- Arduino-based control software

- Electronics enclosure (metal laser-wildcard)

What materials and components will be used?

Materials:

- plasic 1.5*.75 inch casing pipe / plywood 13 *18 .25 inch thickness

- PLA for 3D printing washers

- MS squre pipe 1.8 mm wall thickness

- Fasteners screw,nut,bolt etc

Components:

- DC Motor (100 RPM)

- Screw rod and nut (M12)

- Linear rod (LM12UU)

- Linear bearings (LM12UU)

- LED strip (WS2812/RGB)

- LDR sensor

- ESP32 / Arduino Nano + HC-05

- Motor driver (L298N/DRV8833)

- Motor speed controller

- Limit switch

- 12V/5Ampspower supply

- Upto 12V buck converter

Where will they come from?

- Local electronics store

- Online: Amazon, Robu.in, PrayogIndia

- Fab Lab: laser cutting, 3D printing

- Scrap materials from old machines

How much will they cost?

| Item | Estimated Cost (INR) |

|---|---|

| mild steel pipe | ₹300 |

| DC Motor 100 RPM | ₹300 |

| DC Motor 100 RPM | ₹300 |

| Screw Rod + Nut | ₹250 |

| Electric casing pipe | ₹80 |

| Battery | ₹750 |

| LED Strip (1m) | ₹150 |

| LDR Sensor | ₹200 |

| plywood | ₹300 |

| Motor Driver (L298N) | ₹200 |

| Switches + Wires | ₹300 |

| PLA Filament (150g) | ₹100 |

| Features | ₹500 |

| Total | ~₹1,800–₹2,000 |

What parts and systems will be made?

- Flapping mechanical assembly

- Electronics circuit with sensors and actuators

- Bluetooth-based control system

- Optional: PCB and enclosure

What processes will be used?

- Laser cutting

- Metal Laser cutting

- 3D printing

- Soldering

- Assembly and alignment

- Arduino programming

- Optional PCB design

What questions need to be answered?

- What torque is needed for reliable flapping?

- Is LDR placement responsive and accurate?

- How to tune screw rod for smooth travel?

- Is the cutoff switch reliable under use?

- Do power sources for LED and motor interfere?

How will it be evaluated?

- Wing flapping and light control via Bluetooth

- Sensor-based interaction using LDR

- Reliable mechanical operation with cutoff safety

- Clear documentation and uploaded files

- Creativity and integration of subsystems

What tasks have been completed?

- CAD design and modeling

- Component selection and sourcing

- LED, LDR, Bluetooth tested

- Breadboard circuit tested

What tasks remain?

- Full mechanical assembly

- Cutoff switch integration

- Final wiring and coding

- System testing and debugging

- Video documentation and GitLab upload

What has worked?

- Linear screw rod mechanism

- Bluetooth and LED control

- LDR sensor readings

What hasn't worked?

- Initial alignment issues in linkage

- Motor jerks due to weak power supply

- LDR needs better threshold filtering

What questions need to be resolved?

- Final tuning of gear ratio/stroke length

- Need for PWM motor speed control

- Minimizing backlash in screw system

What will happen when?

| Week | Tasks |

|---|---|

| Week 1 | Finalize design, CAD, laser/3D print parts |

| Week 4 | Assemble mechanics and screw rod |

| Week 12 | Wire electronics, integrate components |

| Week 15 | Code, test, fine-tune system |

| Week 19 | Record video, document, upload to GitLab |

What have you learned?

- Integration of mechanical, electrical, and software systems

- Screw rod precision depends on alignment and support

- Power management is crucial for smooth operation

- Thorough testing and early documentation are key

Summarise and communicate the essence of your project development

Fantasy Flair is a wearable animatronic flapping wing mechanism designed for cosplay, stage performance, and educational demonstration. Inspired by nature and fantasy aesthetics, the project integrates mechanical design, electronics, and digital fabrication. The wings flap realistically using a custom-designed linkage system driven by a DC motor, all controlled via a microcontroller. The structure was built using lightweight materials, and components were fabricated using CNC, 3D printing, and laser cutting techniques. The electronics were developed using KiCad and programmed to offer smooth motion with adjustable parameters. Throughout the development, iterative prototyping was used to improve the mechanical motion and aesthetics. This project showcases skills in mechanical design, embedded programming, and digital fabrication while serving as a foundation for future animatronics applications. Fantasy Flair demonstrates how Fab Lab tools can bring imaginative concepts to life and inspire creative engineering in education, entertainment, and the maker community.