This week, we will focus on learning about the laser cutting machine and the vinyl cutting machine. The assignment will involve characterizing the laser cutter and working with parametric modeling.

This week’s group assignment covers the features of the laser cutter in our lab, such as kerf values, power, speed, and frequency through various tests.

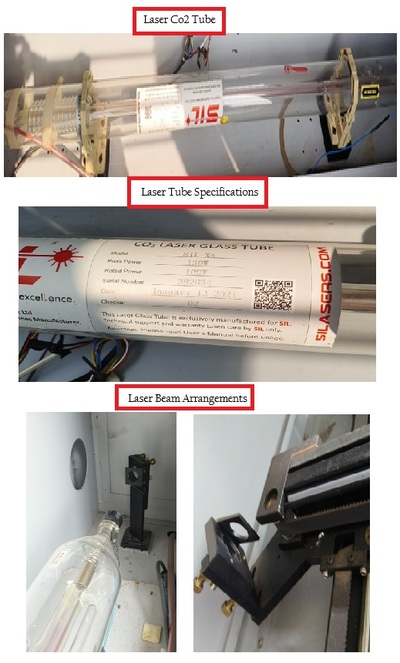

The Sanjivani Fab Lab owns a 100-watt CO2 Laser Cutting and Engraving Machine by India's first laser machine manufacturing company, SIL-Suresh Indu Lasers Pvt. Ltd.

Kerf is the width of the material removed during cutting, determined by the laser beam’s diameter and the material being cut. Measuring kerf when laser cutting is important for achieving accurate cuts.

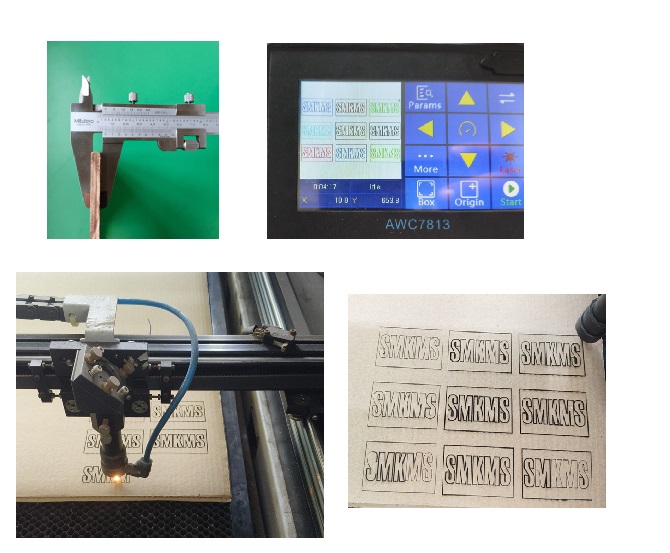

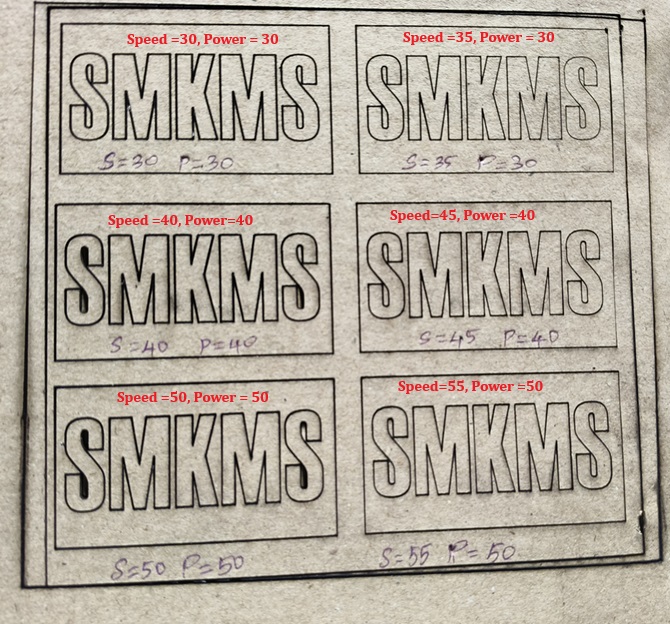

For testing, we chose 4mm cardboard and 6mm MDF. We first measured the kerf by creating name letters with a box in Inkscape. The experiment involved printing initials with varying speeds and power settings to analyze the results.

To understand how the machine works with different speed and power settings, the team designed a sketch in LASERCAD, saved it as a .dxf file, and imported it into the machine through LaserCAD.

After testing various values, we concluded that for a 4mm cardboard sheet, a clean cut at a speed of 30mm/s requires 70% power. We also calculated the kerf by measuring the dimensions before and after cutting.