Week16

Assignment: Wildcard

Software used: Solidworks, Coreldraw

For this wildcard assignment, I have chosen the Laser cutting machine. Will create a simple DIY Camping Stove.

Metal Laser Cutting :

Metal laser cutting machines are advanced computer-controlled (CNC) tools that utilize a highly focused, high-power laser beam to cut through various types of metal precisely. This non-contact process offers exceptional accuracy, speed, and versatility, making it a preferred method in numerous manufacturing and fabrication industries.

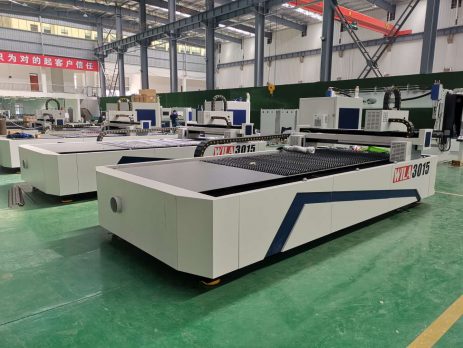

Machine model: WILA CNC Machine Tools Inc : Model WILA 3015

A local sheet metal cutting company, G.M.Metal Industries, provided adequate training and permission to operate the machine.

Image from the company page: Link

How it Works:

The fundamental principle involves generating an intense laser beam (typically from a CO2, Fiber, or Nd:YAG source) and directing it through an optical system to a cutting head. This head focuses the beam onto the metal surface, creating a concentrated spot of energy that melts, vaporizes, or burns through the material. An assist gas (like oxygen or nitrogen) is often blown through a nozzle at the cutting point to help eject molten material, cool the cutting area, and prevent oxidation, resulting in clean, high-quality cuts. The CNC controller precisely dictates the movement of the cutting head along a predefined path, allowing for intricate and complex designs.

Types of Metal Laser Cutters:

While there are several types, the most common for metal cutting are:

Specification of the Model: WILA 3015

Laser sourse: Raycus (China)Model: RFL-C2200. The Raycus RFL-C2200 is a continuous wave (CW) fiber laser manufactured by Wuhan Raycus Fiber Laser Technologies Co., Ltd. in China. It's known for its high electro-optical conversion efficiency, strong anti-reaction ability, and suitability for thin plate cutting. The RFL-C2200 can be either air or water cooled and offers a wide modulation frequency range. |

Cutting Head: Raytools Model: 111/112. Modular design with easy maintenance, automatically focal position adjustment, No-contact height sensor, Horizontal lens, 3 cover glasses to protect collimation & focus lens and IP65 class dustproof prevention. |

Driving system: FUJI Servo Motor with high precision, control cutting speed and position, stable running without vibration. |

Cooling system: TONGFEI Chiller double control double temperature. Exclusive for Laser machines, cooling system: multiple protection functions, passive arm terminals and remote control terminals, easy to achieve centralized CNC control and monitoring, System components are made with internationally renowned brands to ensure that the equipment has excellent quality and good reliability. |

WILACNC Fiber Laser Cutting Machine is produced with efficient and ecological fiber laser technology with proven reliability and flexibility.

Unique features:

MACHINE BLOCK: WILACNC Fiber laser features a rigid frame for min deflection under the load. The frame steels are of German origin and designed using SOLIDWORKS 3D programming and made with quality steel improved Q235, using the latest technology. Feature:

|

Design

For designing the stove, I have used Solidworks. Here are the steps for designing

I have started creating the side panels and then completed the assembly. Here are the steps to create side panels. |

First, create an extrude for 2mm since the sheet metal we are using is 2mm thick. |

Create a slot using Extrude cut feature |

Use the mirror feature to copy the slot |

Create a extrude cut for opennings |

A small projection for the top plate to seat |

Now the other side plate, following the same process. |

Fillet all the corners since the sheet metal edges can be sharp and might hurt us while using. |

Create the top plate for same 2mm thickness |

Assemble all the parts to check are the parts fit correctly without overlaps. |

Create the nested file using Coreldraw so that it will be optimised during the laser cuttting process |

Manufacturing Process:

Software working flow screenshot not available because the industry didn't allow. But video is attached at the end.

|

Setting the origin to zero of the workpiece. |

Final cut parts from the process. |

Video files for setting up the file and the laser cutting process.

Finishing and Fitting:

Parts from laser cutting |

Imperfections due to laser melting and small bob form at the edges |

These imperfections will be trouble for assembling the pieces, so as a finishing process, we need to grind the edges. |

Grinding the imperfections using the grinding wheel |

Video Link

Working file: LINK