For this week’s assignment, I explored the use of a Wazzer Waterjet to cut a 2mm aluminum sheet into a custom-designed shape. This was a completely new digital fabrication process for me and a perfect fit for the Wildcard assignment.

About the Wazzer Waterjet

The Wazzer is a compact desktop waterjet cutting machine. It works by forcing a high-pressure stream of water mixed with abrasive particles to cut through tough materials with high precision.

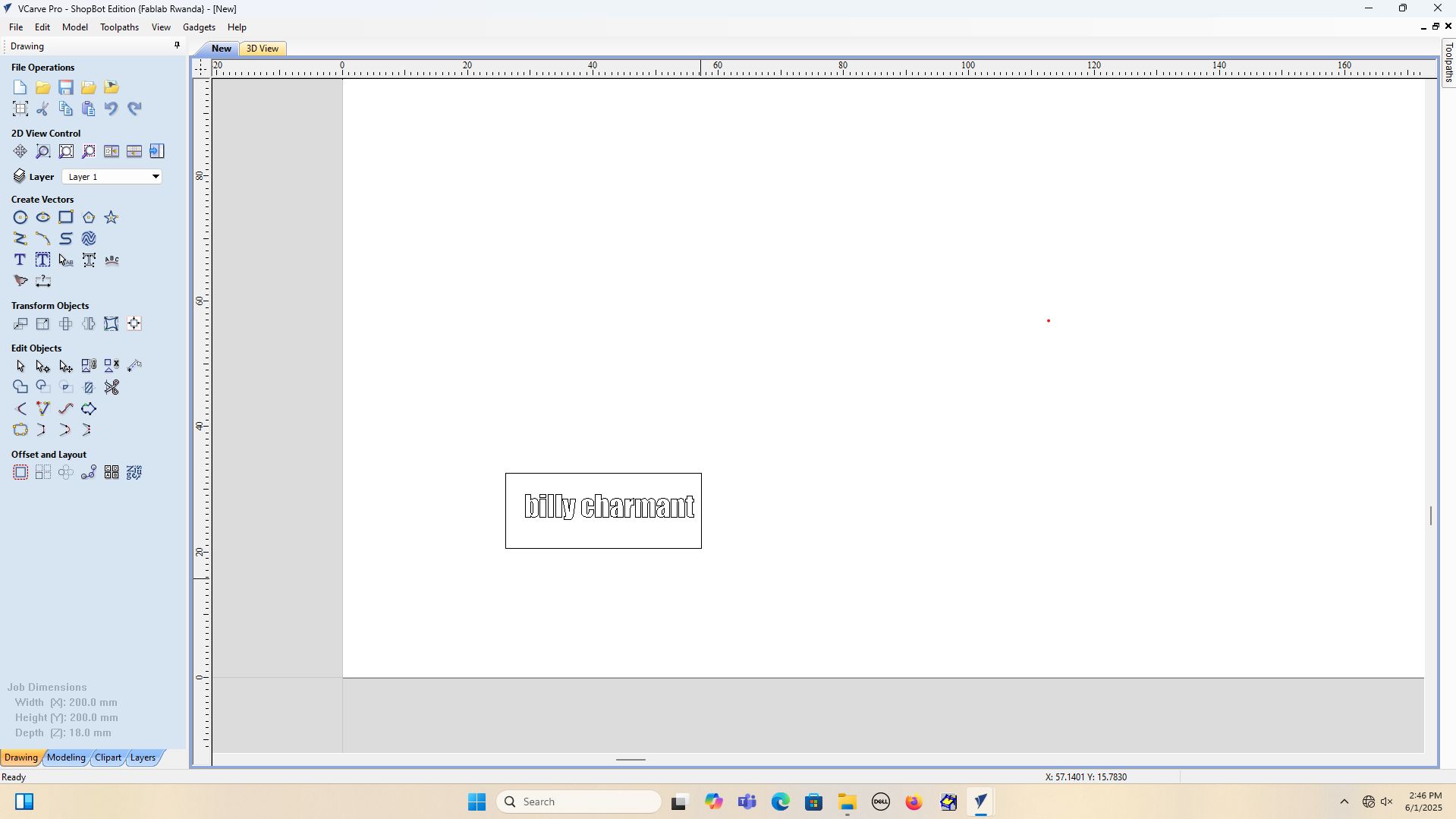

Designing in V-CARVE

I designed my names in rectangular frame which will be for cutting and names are with good font which is very artistic, after completing the design I exported the sketch as a .dxf file.

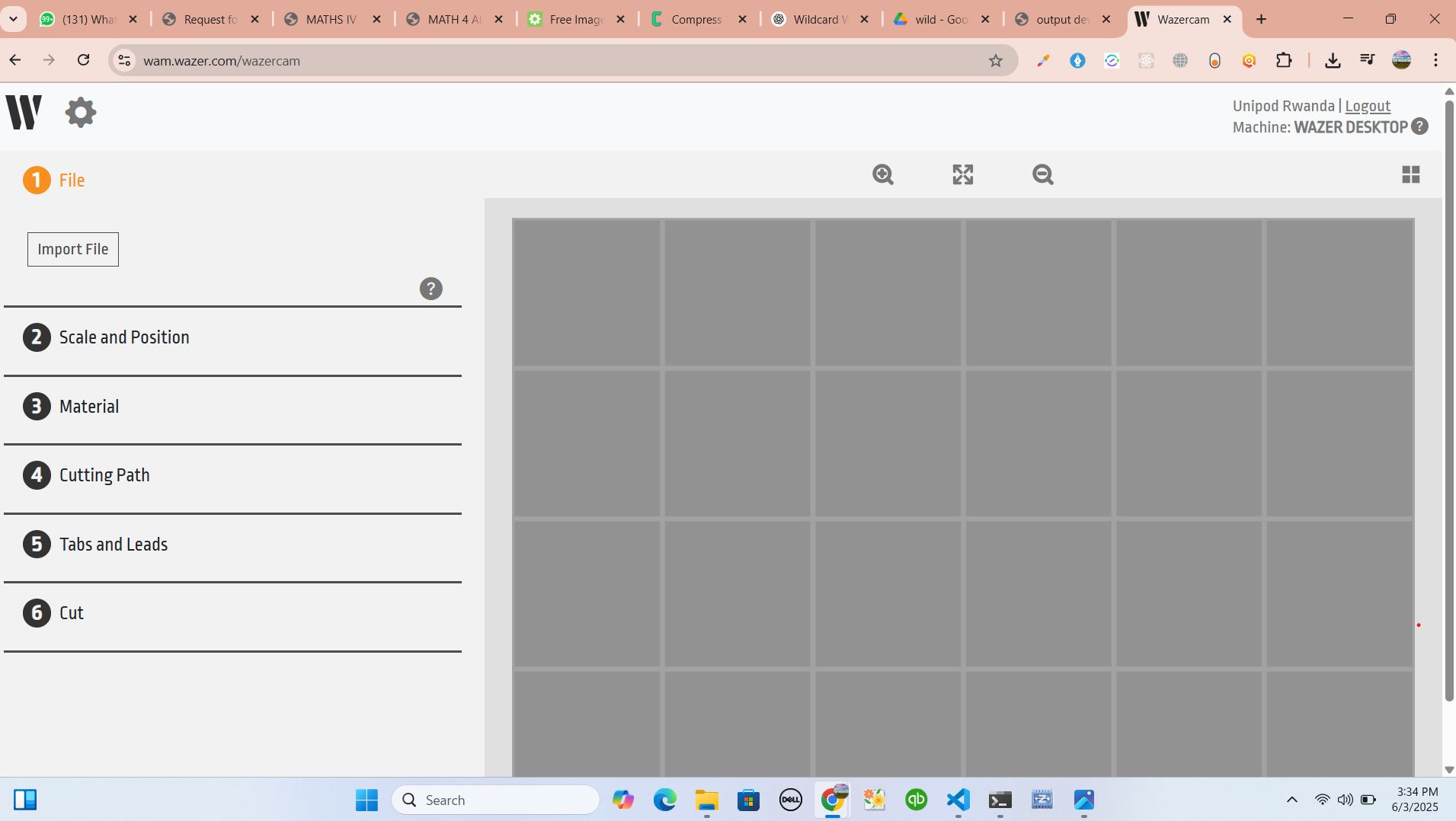

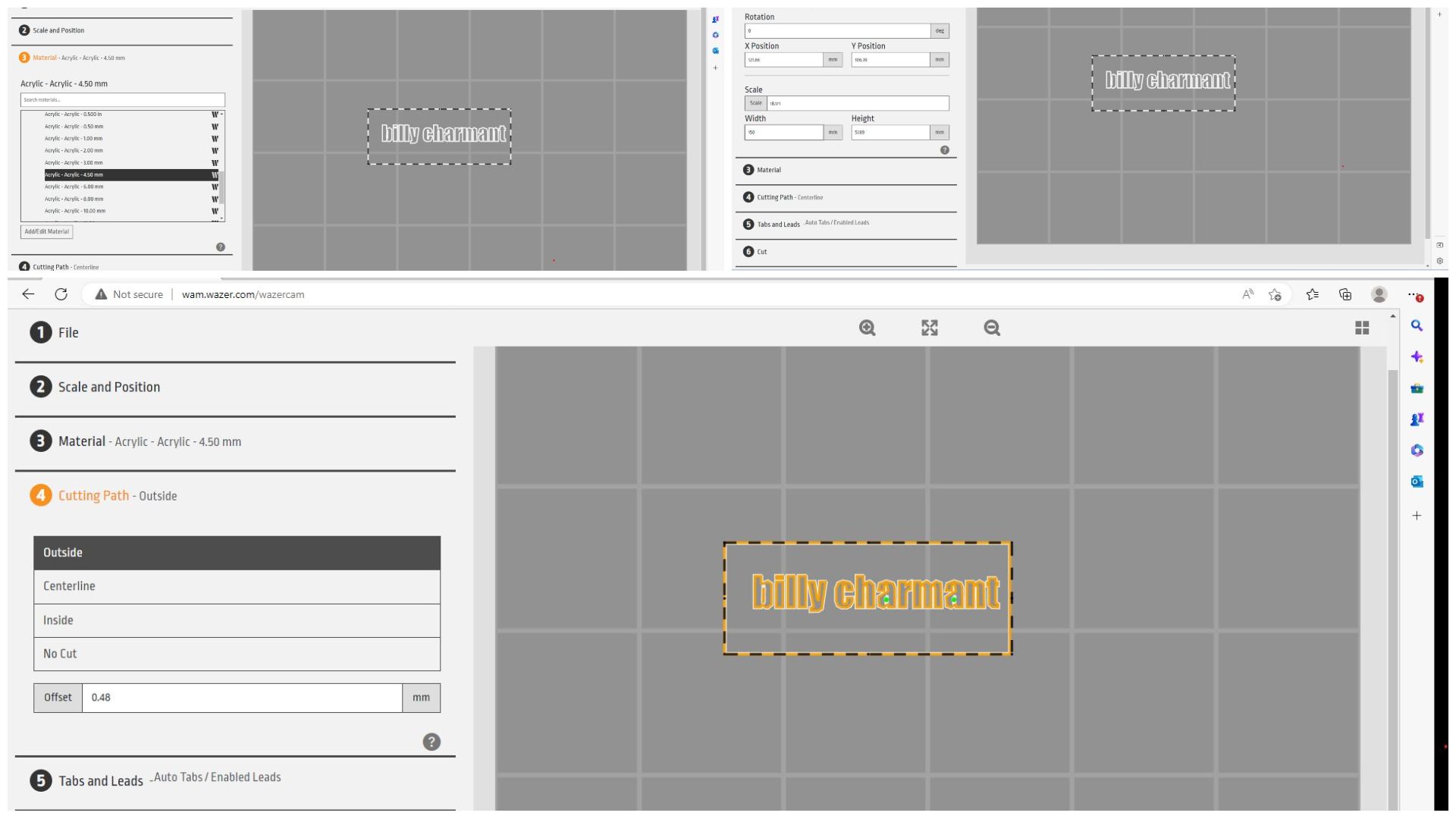

Preparing the Cut

after designing and exporting, I imported the DXF file into Wazzer CAM software. I set up the cut configuration by choosing:

- Material: 2mm aclilyc

- Cut speed and pressure

- Toolpath preview

Cutting stage

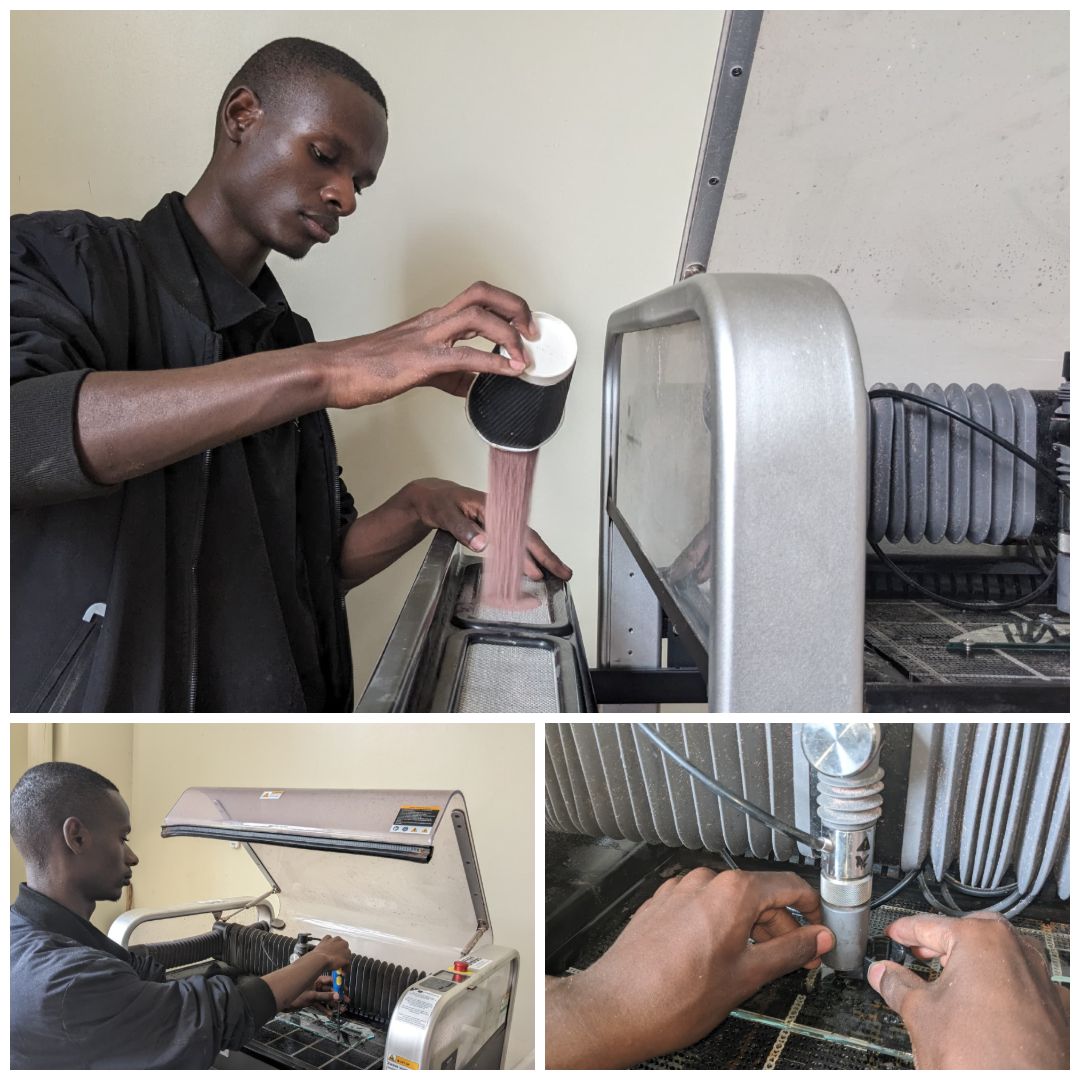

Before starting to run the job, I checked the machine if:

- Check Water Connection: the water supply is turned on and water is flowing properly to the machine.

- Check Abrasive Hopper: the abrasive container is filled. The Wazzer uses garnet abrasive.

- Check Water Level: The water level in the cutting bed if is above the material surface to reduce splashing and ensure even cutting.

- Secure the Material: I Clamped the aclyric sheet flat to the Wazzer’s bed.

- Zeroing the Head: I leveled the nozzle using plastic found on the top of nozzle head respecting the thickness of it between material and nozzle

- Dry Run: I Performed dry run without water/abrasive to verify the toolpath.

- Start the Cut: After confirming the settings I Began the actual cutting process and monitored it for pressure, noise, and movement.

Video while running job

while running this is the video showcasing how it was looking like

Once the cut finished, I removed the piece, cleaned it, and inspected the quality. The cut was clean and precise, showing the power of waterjet technology.

What I Learned

- How to safely operate a waterjet cutting machine

- CAM setup for a new type of machine

- The importance of abrasive type, pressure, and speed

- File preparation and fixturing for metal cutting