3D Enclosure Design and Printing

Objective and Design Strategy

The aim was to design a compact, lightweight two-sided enclosure for my DI-FARM wearable device, which can be comfortably worn by a cow. The box needed to securely hold the PCB, sensors, battery, and tie mount points.

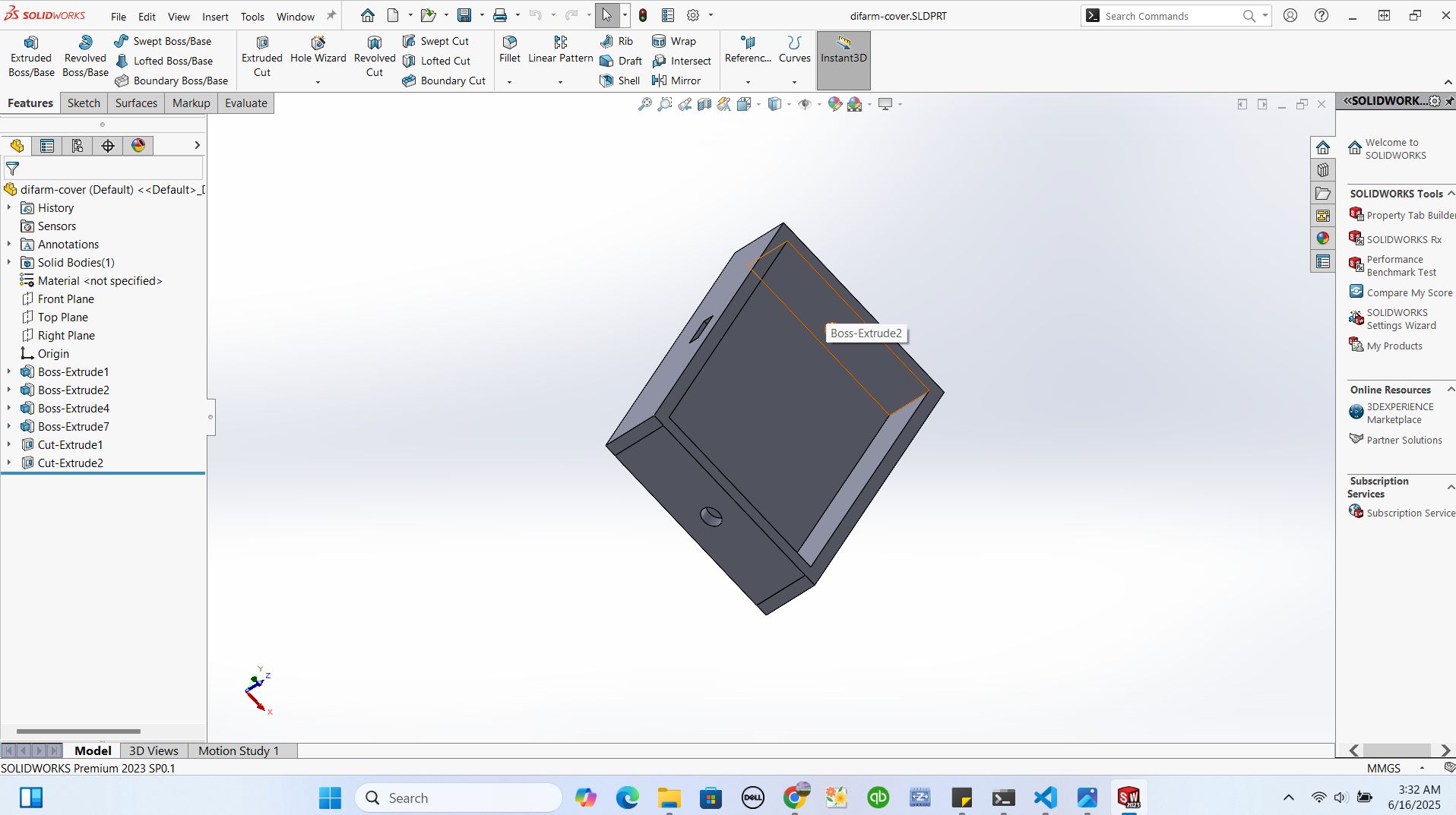

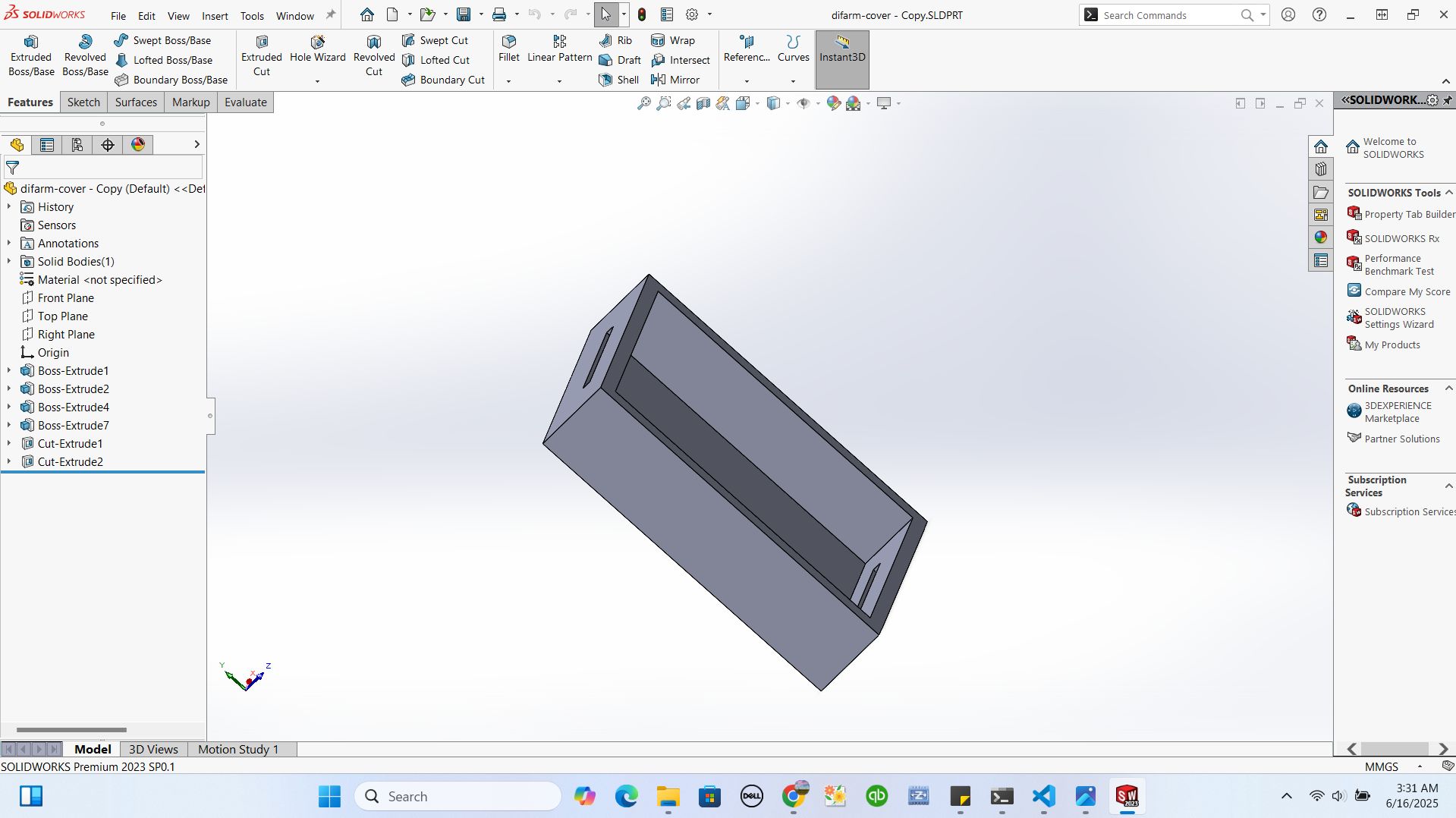

3D Modeling in Solidworks

I designed the enclosure using Solidworks. The design includes two parts: a base and a lid. The internal dimensions were tightly fitted to minimize size and weight, while ensuring all components could be housed safely.

Features and Component Placement

The base includes mounting support for the PCB, slots for sensor wires, and space for the battery. The cover includes temperature sensor hole and slots for ties were added to enable the device to be strapped on the animal securely.

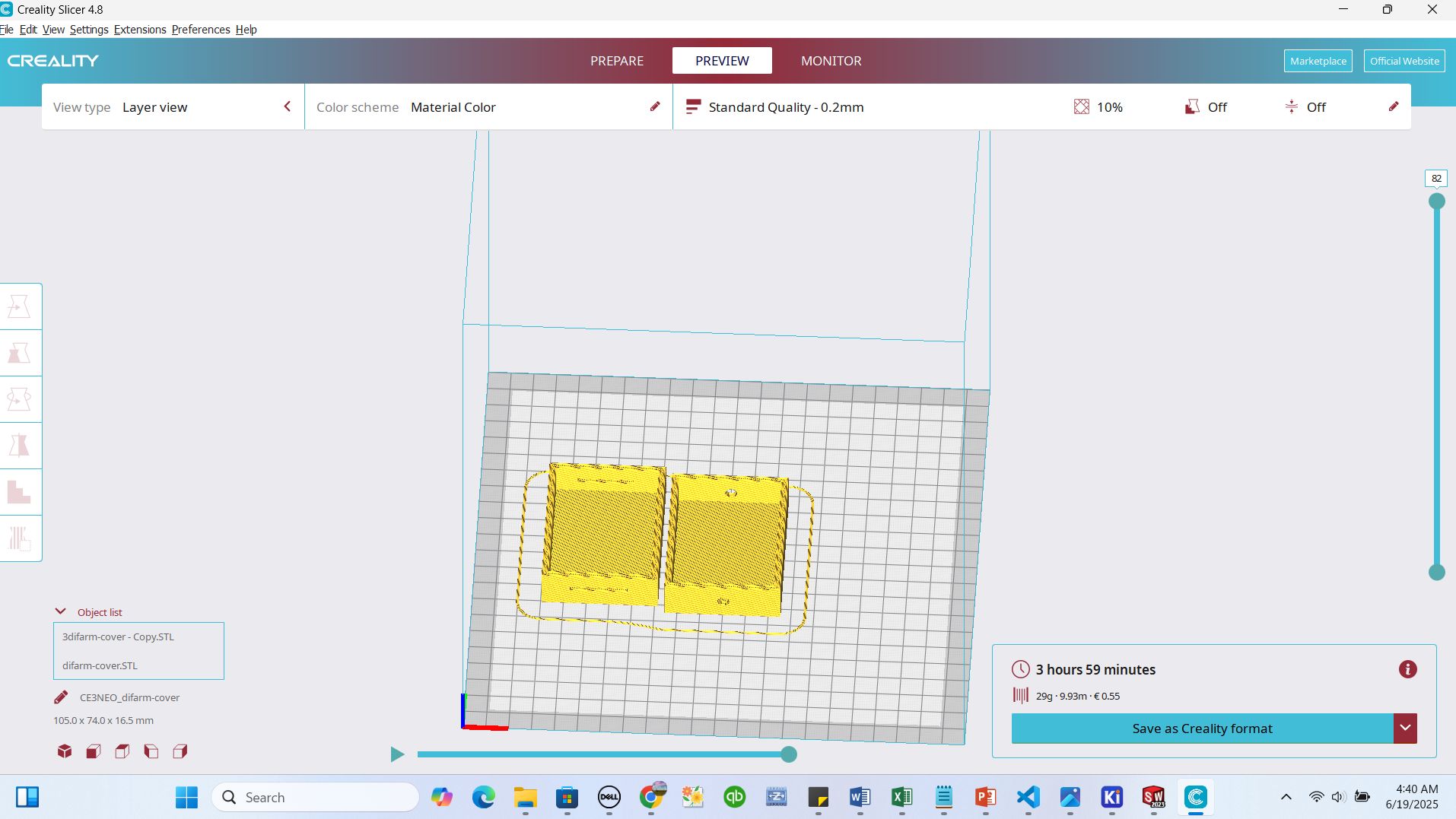

Exporting and Slicing

After finalizing the design, I exported the parts as STL files and imported them into Creality slicer. I used PLA filament with 0.3mm layer height, 20% infill, and supports enabled for the overhangs on the snap-fit areas.

3D Printing and Assembly

The parts were printed using a Creality Ender 3. The fit was precise and all components like PCB, sensors, battery were placed successfully inside. The tie could be looped through the side openings to attach the device to the cow.

Outcome

The final enclosure met the design goals of minimal size, secure fit, and comfortable attachment. It protected the electronics and allowed field use on livestock without adding excessive weight.