13. Moulding and Casting¶

The Assignment¶

-

Group assignment:

-

Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

-

Compare printing vs milling molds

-

Individual assignment:

-

Design a mold around the process you’ll be using, produce it with a smooth surface finish that does not show the production process, and use it to cast parts.

Progress¶

-

Grupp assignment

- [ ]- Review the safety data sheets for each of your molding and casting materials.

- Make and compare test casts with each of them.

- Compare printing vs milling molds.

-

Induvidual assignment

- Design a mold around the process you’ll be using, produce it with a smooth surface finish that does not show the production process, and use it to cast parts.

Research¶

This week research was about learning about the material i am going to use this week, and styudy the safety sheets of the mateials. The material i am going to use are the following: - Asocret M30 - Jesmonite AC100 0ö

Group assignment¶

Link to group site Molding and Casting

By reading the safety data sheet on some molding materials we can see that some of them are really not any safety consorne same time as other raise very high safety concerns.

There fore it´s very iportant always to loook at the safety data sheet and know the material your working with. When working with those materials you should always take precausion mention on safety datasheet. Even safety datasheet dose not exist its always wise to use - Protective goggles. - Use gloves. - Protecting clothes.

And when the safety data give any clue that the material can have any affect on your respiratory system then wear if ventilation is poor or nif the material gives any fumes from using it.

Molding and casting assignment¶

This assignment wa little bit out of my area, i have never think of how to mold and cast it has never run trough my mind that i will ever do mold and casting.

So when i got this assignment i was unsure how to do this.

After i done the reaserch i just jump in the deep end of the pool and startet to work on that assignment.

I started by making som ideas about what to do and decided to design and print out a little squera pyramid and make the silikon mold whit that object. My instructor Andri did not like that idea it was to simple and it´s not so easy to work the surface on the PLA i was thinking to use.

So i changes curs, and decided to use the shopbot machine to make the mold from vaks, make the silikon mold whit that vaks mold and then use the silikon molde to cast the Jesmonite product. I decided to make som little sprit candle holder.

Making the vaks mold¶

To make the vaks mold i used the shopbot machone in the lab, and to make the carfing file i used Vcarve this program was in the control computer for the shopbot there for i used that computer for that work.

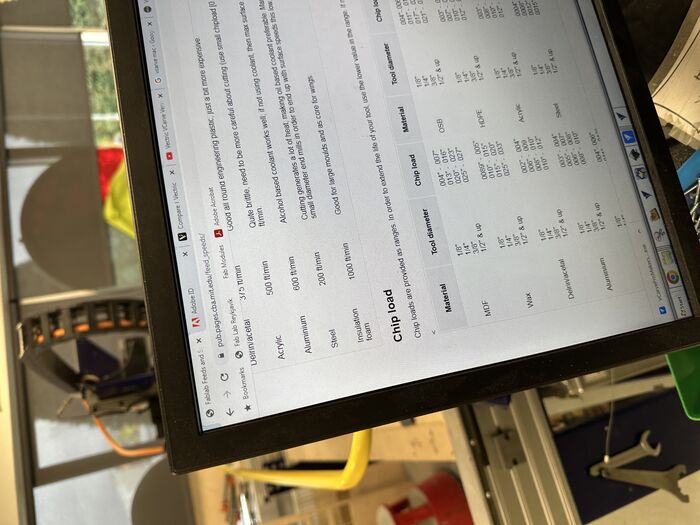

Here is how i made the cdarve file i made three circels on different sizes then i told the x carve program where and how to carve. to set up the endmill and have the right settings i needed to look at the chip load table and calculate the speed and feed rate.

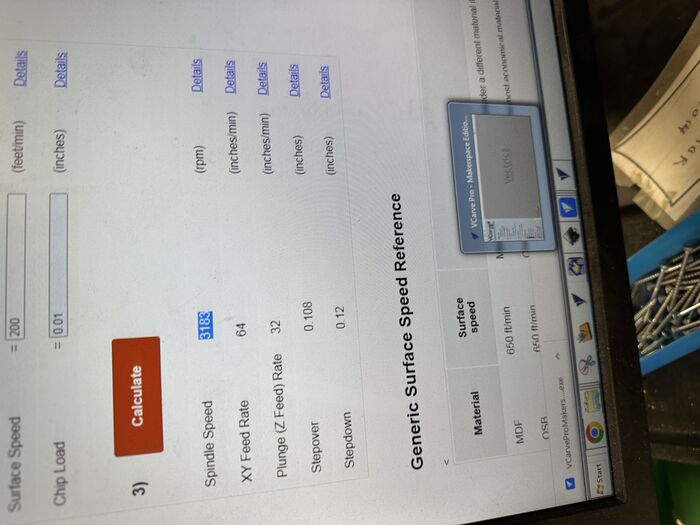

On thes two pictures wee see the chip load table on that tabe we look at the material we use and the endmill size and then we can see the chipload that we need to have, we use that in the settings showed in later pictures.

In the second picture we set in tha chipo load and calculate spindlespeed an feed rate.

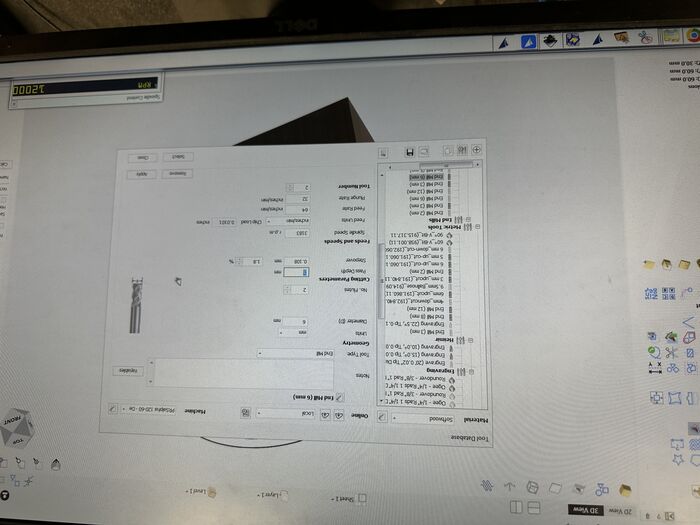

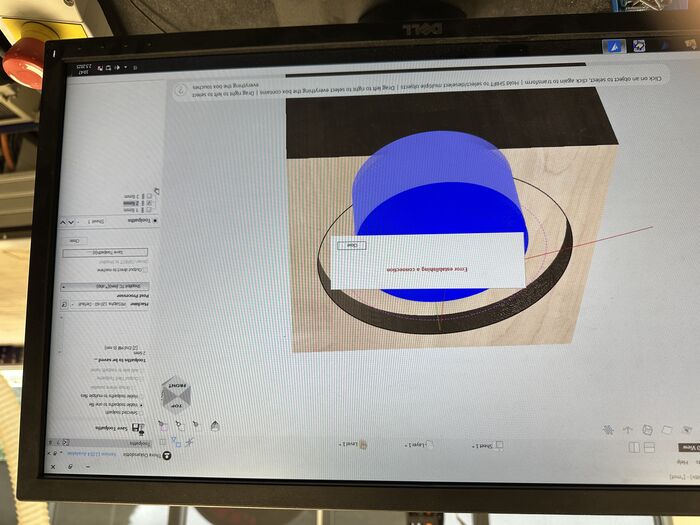

On these two pictures we can see various settings like the spindel speed we use feed rate, plung rate,and more. in the second picture we see the final result from the program.

This is the settings i used on all the toolpaths i used.

- 6mm up cut endmill

- plunge rate 32 Inches/min

- feed rate 64 inches/min

- Spindil speed 3583Rpm

- step down 0,12mm

- step over 0,108mnm 40%

Then it was time to get the material to themachine and make her ready to mill the material, set the axis X,Y and Z

Here are som more pictures showing ow to secure the material on tha machine.

We put the vaks on the plan of the machine and use some homemade clamps to pin it down.

Then it´s time to start the machine an let it mill

These two pictures show the ongoing milling process. We can see well here how little the vaks brick is.

When the milling is done it´s time to mix the silicon and poor it into the vaks mold.

That silicon i used is two factor silicon from Zermack that we mikx 50/50 and then we have to mix it well in a bowl, when we have stear it to geater for a while we poor that silicon in the waks molde and let it dray fr few hours Here is everything about the silicon

![]()

After the silicon have been poor in to the molde it lokks like the first picture

Then on the second picture we see the silicon when its dry already.

On these two pictures we see how the silicon mold looks like when its ready.

Jesmonite¶

Then its time to make the jesmonite ready for pooring in to the silicone mold

Jesmonite is two factor material that consist of powder and liquid that need to be mixed to geather by the right ratio, if it is not in the rigt ratio it will be very fragil.

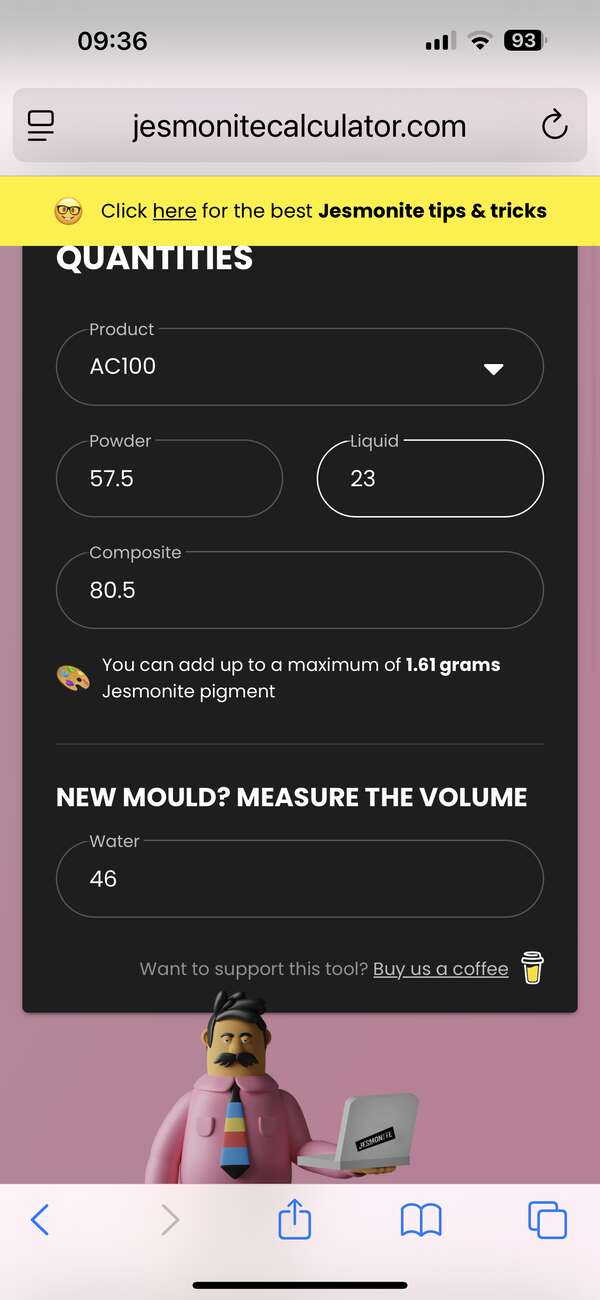

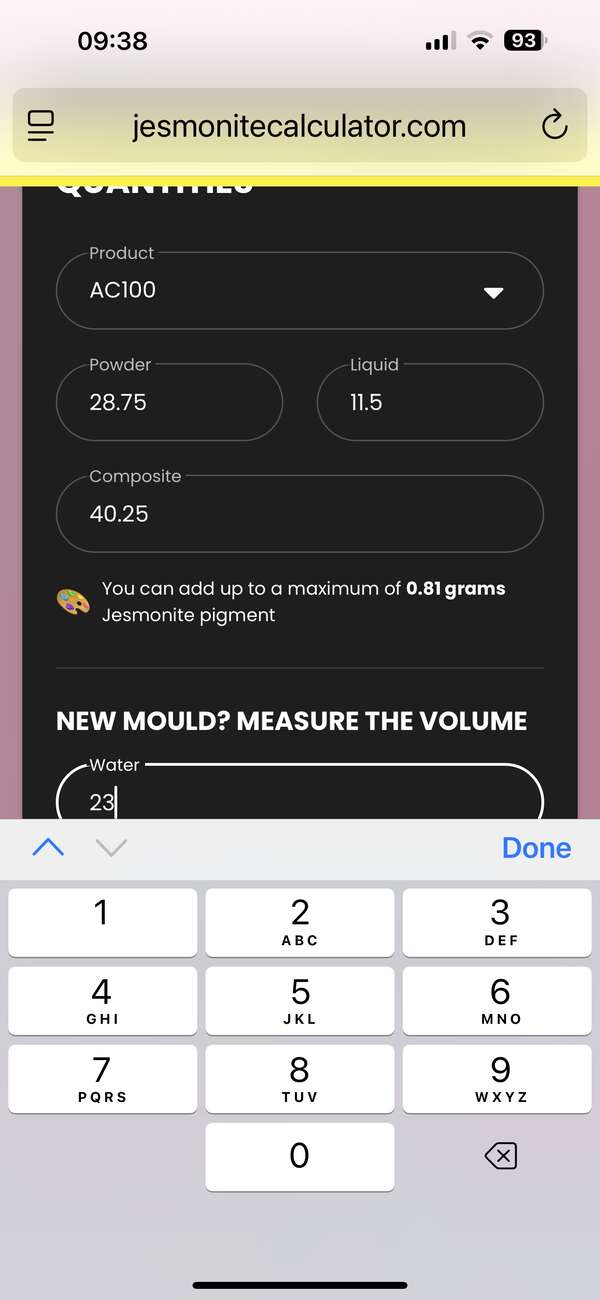

The ratio is supposed to be 2.5:1 by whight of the material, the simpliest way to find rigt ratio is to put water in the mold and measure the whieght of the water and put that water weight in a Jesmonite calculator then the calculator will tell you how much powder you need and how much liquid to fill that mold i did this calculation and found out that to fill molde that takes 23 grams of water you need 28.75 grams powder agains 11,5 gram liquid i did also do this calculation with 46 gram of water. the result is on the following pictures.

Whe you have mix those material to geather we stear them to geather for a while and when you think its enohug you stear little bit more then its time to poor the mix into the silicon molde.

Final product

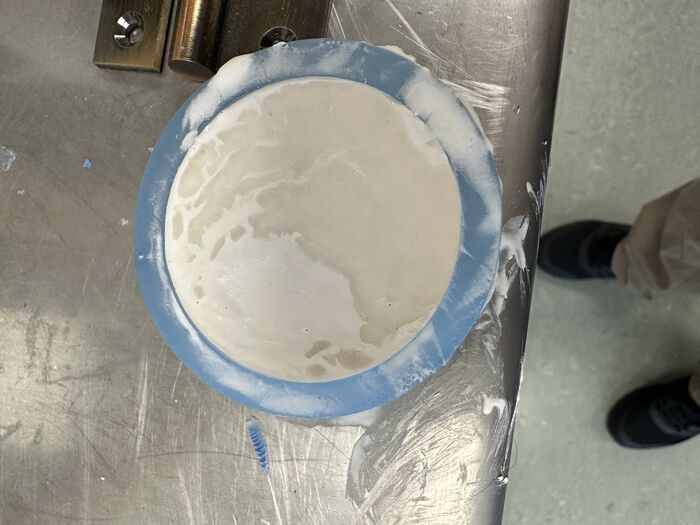

Here is a pictures of the final outcome of the Jesmonite casting, there was very few bubbles but othervise it´s look good.

Cement¶

I did also try to cast from Cement, the cement i use is the type Asocret M30 but that faild completly when it dry it was just in pieces and did not come out of the mold in one piece ee pictures. i probably didint add enough water to the cement, i was to selfsecure mixing it cause i have been working alot with cement and always mixed it just by my eyes but that did compleatly fail this time.