7. Computer Controlled Machining

Make (design+mill+assemble) something big

An idea behind this weeks assignment was to learn cnc path cutting and the sofware.

I am learning more about different types of cnc milling methods and developing a

well and effecient workflow. I began my workflow for this design in cinema 4d.

Which is a 3D modeling program that is great for design and animation for personal &

commercial use. I was originally designing a shelf layer that had unseen led lights

located on the underside of the shelf. This would act as a multi-layer led shelf

that was designed to go with a large scale project. That project was put on hold

as cost was beyond budget and not proper planning of every step wouldn't allow lets

of last minute changes and implementations that have frequented this asssignment.

So after creating the model in Cinema 4D, I export the object as an .stl file which

was saved and viewed in windows as a 3d file. I had preset parameters for the file

those parameters were adjust for a random large size board that was big enough to fit

the design in mind. I wanted the mill cut to be deep enough to store/hid electronics

and wiring, depending on which way I decided to go with the final appearance. So the

dimension of the inside cut are 4mm deep by 11mm wide. A 1/8 & 1/4 sized bits were

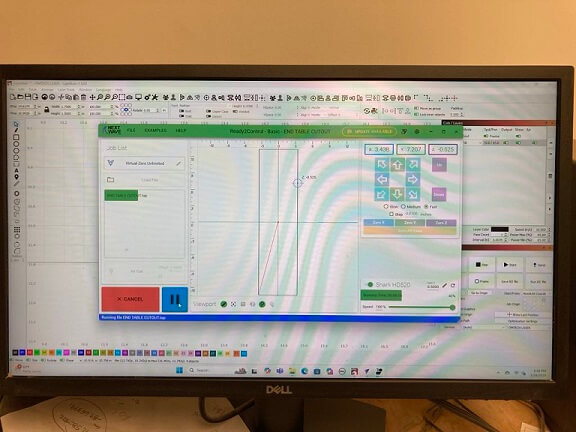

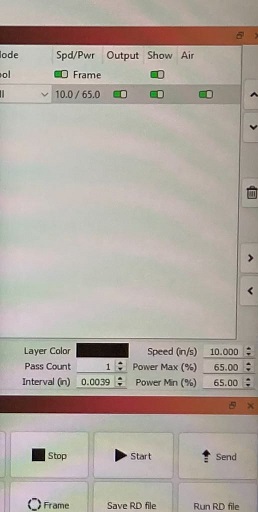

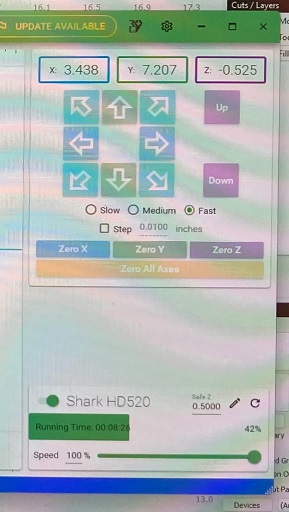

used for milling. On the next wave sofware the speed is set to 10 and power to 65.

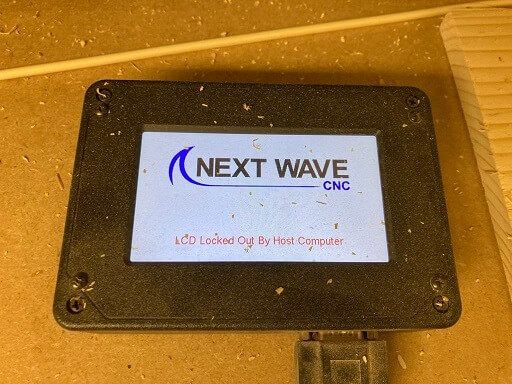

This Shark Next wave machine is really nice and I noticed a saftety feature. While

the machine is in operation, the mini lcd touch command screen is locked.

Gallery

Here are a few pictures in the Woodshop

Cutting outside path

Next wave software showing path being cut

Justyn wearing a mask in the woodshop = safer lungs

Tracking cutting path

Another view of the action

lcd screen locked while machine is active

Me sanding off the rough edges

Another great shot of the Next Wave in action

Both paths being completed

Close up to a great cut

Getting rid of debris with air tool

Speed and power settings

Waiting on the job to finish