6. Electronics Design

Group assignment:

Use the test equipment in your lab to observe the operation of a microcontroller circuit board(as a minimum, you should demonstrate the use of a multimeter and oscilloscope)

Document your work on the group work page and reflect what you learned on your individual page

Individual assignment:

Use an EDA tool to design a development board that uses parts from the inventory to interactand communicate with an embedded microcontroller

For this week's assignment I was to create a pcb in an EDA Tool that

can communicate or interact with a microcontroller board.

I used Kicad 9 to design this board

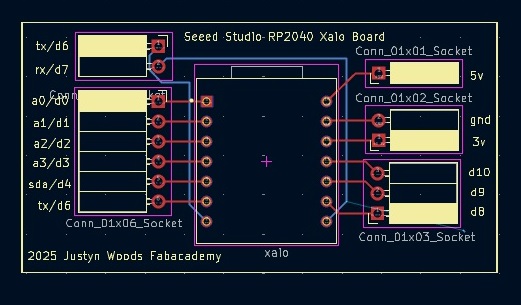

Designing board pic 1

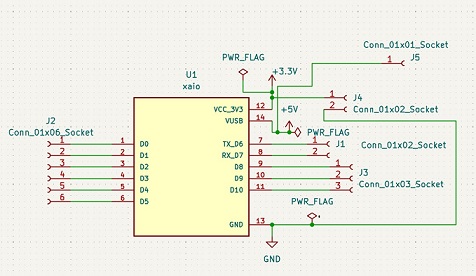

Designing board pic 2

Pics

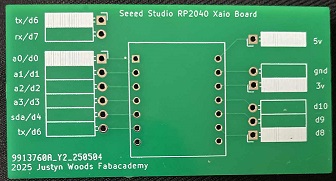

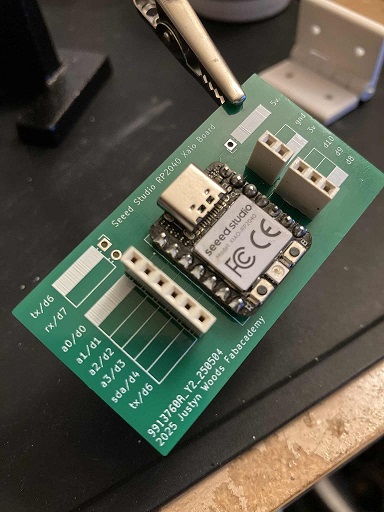

Fresh off the press

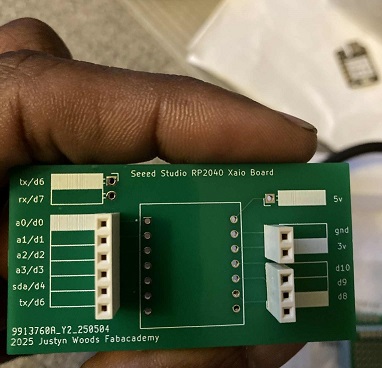

Holding the board after soldering

PCB on workbench