WEEK 12: Mechanical Design

Assignment

Design a machine that includes mechanism+actuation+automation+application.

Build the mechanical parts and operate it manually.

Document the group project and your individual contribution

Sand Drawing Machine - Group Project

The Sand Drawing Machine is a creative automation project that combines mechanical engineering, electronics, and software automation to draw patterns and shapes on sand using servo motors and a magnet-based actuation system. The machine simulates a zen garden-style drawing system where a ball or stylus is moved across a flat sand surface to trace intricate designs.

Our project fulfills the criteria of mechanism, actuation, automation, and application

Actuation: Servo motors and a Hall effect sensor-based feedback system.

Automation: G-code generation and parsing for movement control.

Application: Artistic drawing, educational tool for CNC/G-code learning, stress-relief device.

This hardware setup enables smooth and accurate movement in both X and Y directions, forming the base for our automated drawing mechanism.

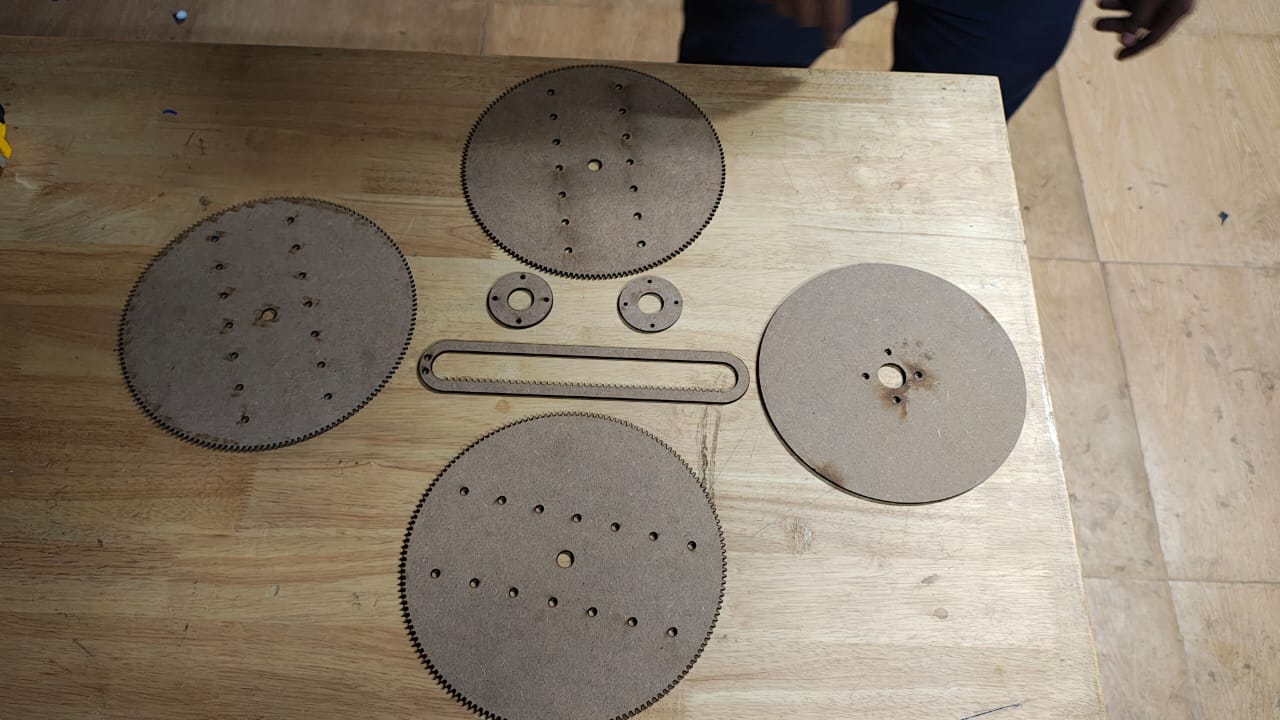

Hardware Screenshots

My Contribution: Electronics and Automation

I was responsible for the electronics, software, and automation aspects of the project.

Overview

The Sand Drawing Machine is a polar-coordinate CNC robot that creates intricate geometric patterns in sand

using a combination of:

-> Linear motion (radial arm movement)

-> Rotational motion (circular sweep)

-> Pen lift mechanism (servo-controlled)

Reference Link

ESP32-Powered Tabletop Kinetic Sand Drawing Robot Tabletop Sand Robot1.2 Key Features

2. Pattern Generation: Predefined shapes (circles, spirals, flowers).

3. Image-to-Gcode Conversion: Draw custom images.

4. Real-time Status Monitoring: Check machine state.

5. Emergency Stop & Homing: Safety and calibration functions.

Hardware Design

Componenets List| Component | Specifications | Purpose |

|---|---|---|

| ESP32 | Dual-core, Wi-Fi | Main controller |

| NEMA 17 Stepper (x2) | 1.8°/step, 12V | Linear & rotational motion |

| Servo Motor | 180° rotation and Linear rotation | Pen up/down mechanism |

| Hall Effect sensor | SS49E | Detect a reference (home) position |

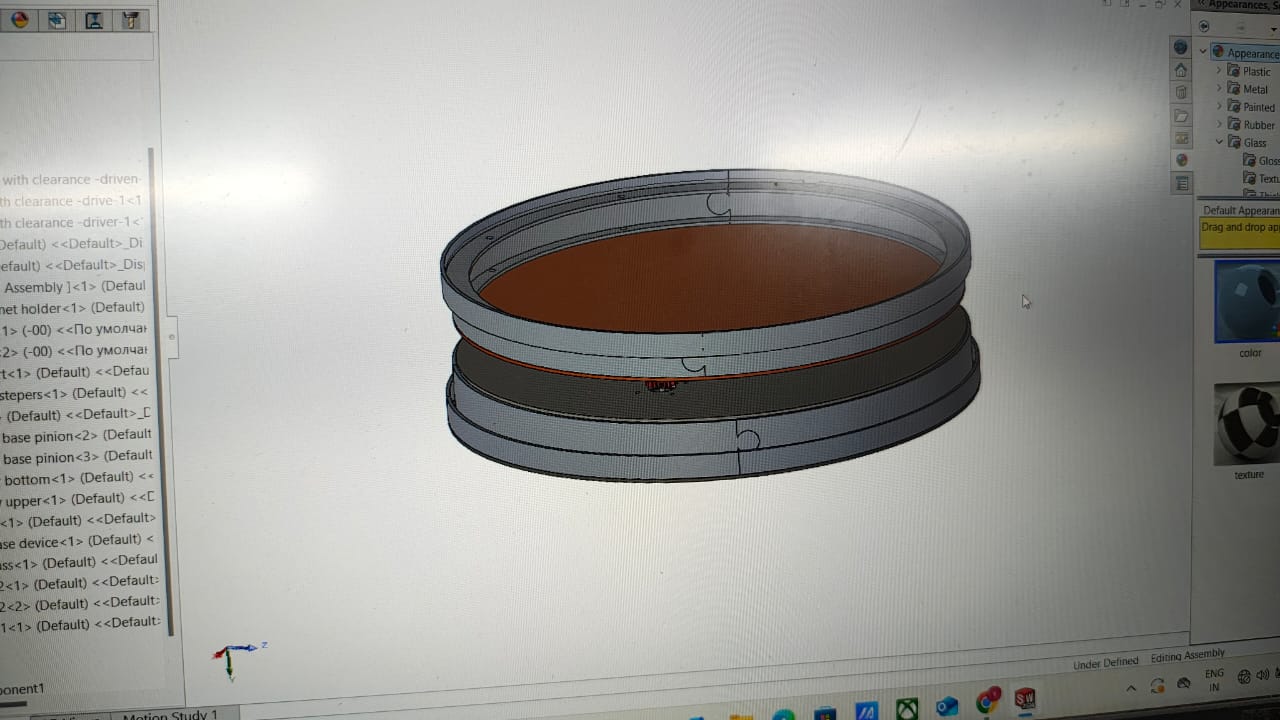

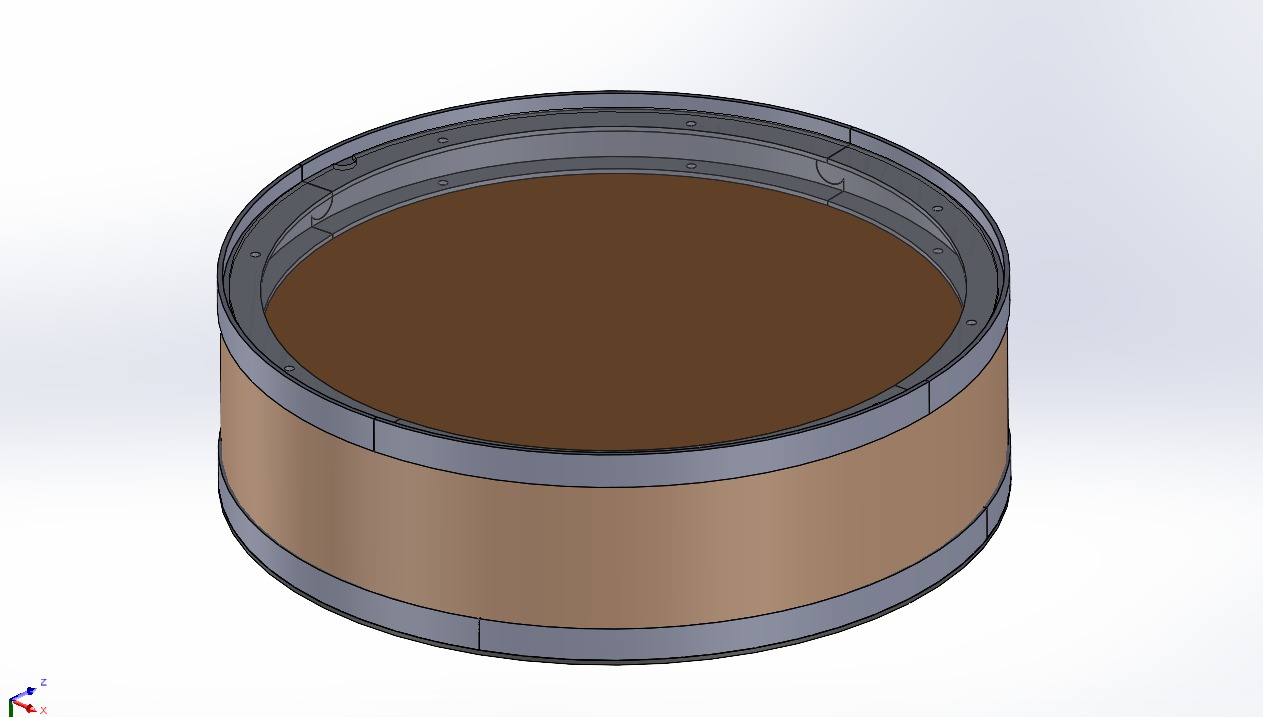

Mechanical Design

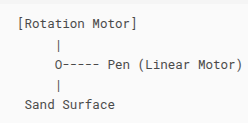

Polar Motion System

Rotational Axis: Stepper rotates the entire arm.

Linear Axis: Stepper moves the pen radially.

Pen Mechanism:

Servo lifts/lowers the drawing tool.

Conceptual Diagram: Polar Coordinate Robot Arm

Firmware (ESP32 Code)

Key Features

-> Wi-Fi Access Point (AP) Mode: Hosts a web server for remote control.

-> G-code Interpreter: Parses commands (G0, G1, M3, M5, G28).

-> Stepper Motor Control: Uses AccelStepper for smooth motion.

-> Homing Routine: Uses endstops to find zero position.

Algorithm

1. Initialization:

-> Start Wi-Fi AP (ssid: iTN-FORGE/s, password: ForgeXForged).

-> Configure steppers (STEPS_PER_MM = 80, STEPS_PER_DEG = 200/360).

-> Attach servo (PEN_UP_ANGLE = 90, PEN_DOWN_ANGLE = 0).

2. G-code Processing:

-> G0/G1 (Linear Move):

Converts X (angle) and Y (radius) to stepper steps.

Moves motors asynchronously (stepper.run() in loop()).

-> M3/M5 (Pen Control):

M3 -> Pen down (servo.write(0)).

M5 -> Pen up (servo.write(90)).

-> G28 (Homing):

Moves motors backward until endstops trigger (digitalRead(HOME_PIN)).

Web Server Endpoints:

| Endpoint | Description |

|---|---|

| /upload | Receives G-code |

| /status | Returns machine state (ready/busy/homing) |

| /home | Triggers homing |

| /stop | Emergency stop |

| /clear | Clears G-code buffer |

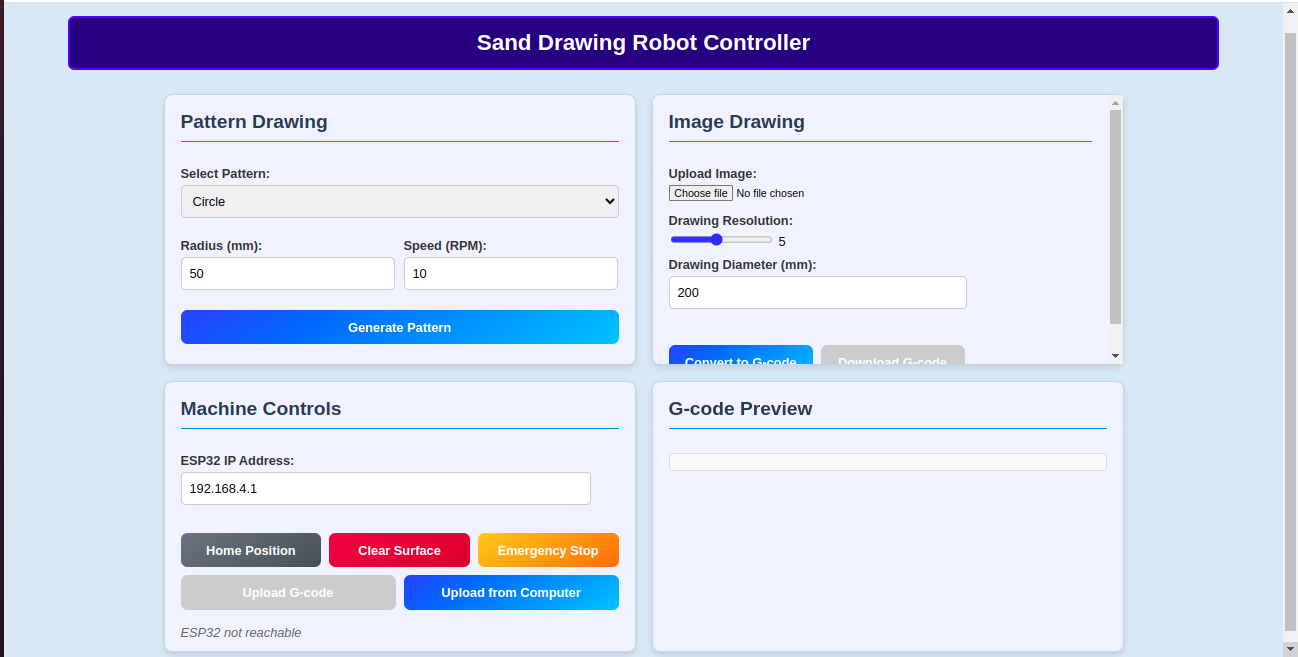

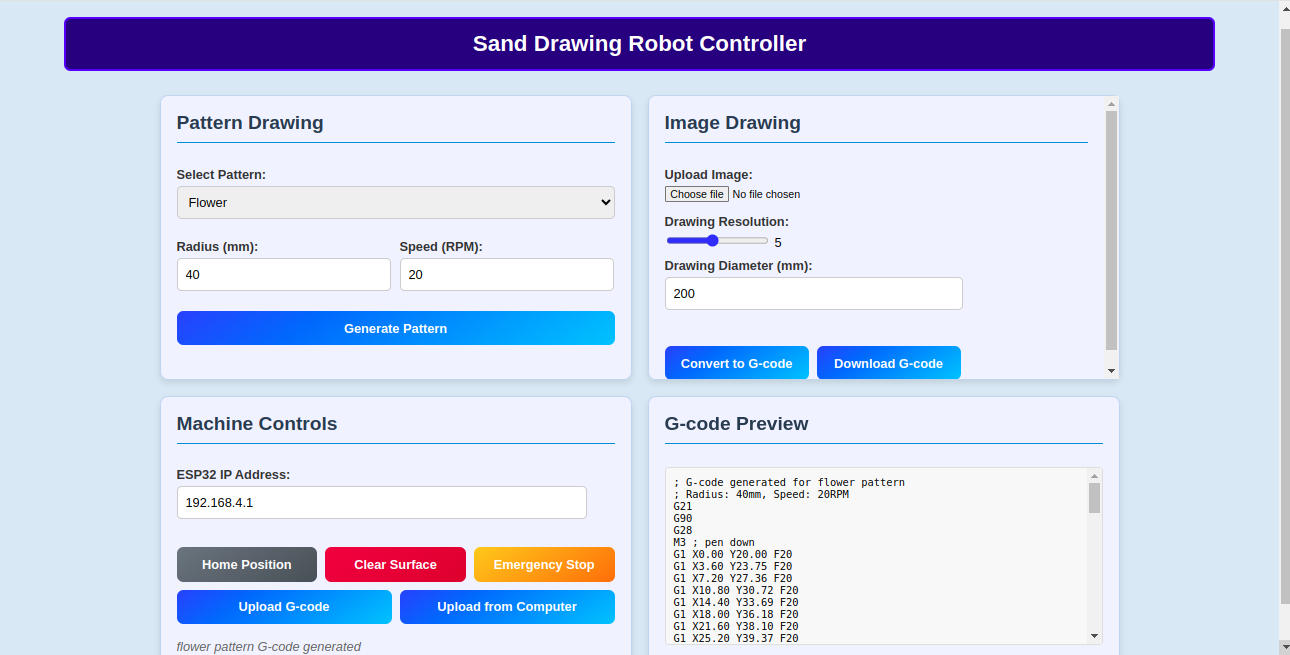

Web Interface

Key Features -> Pattern Generation: Circle, Spiral, Flower.

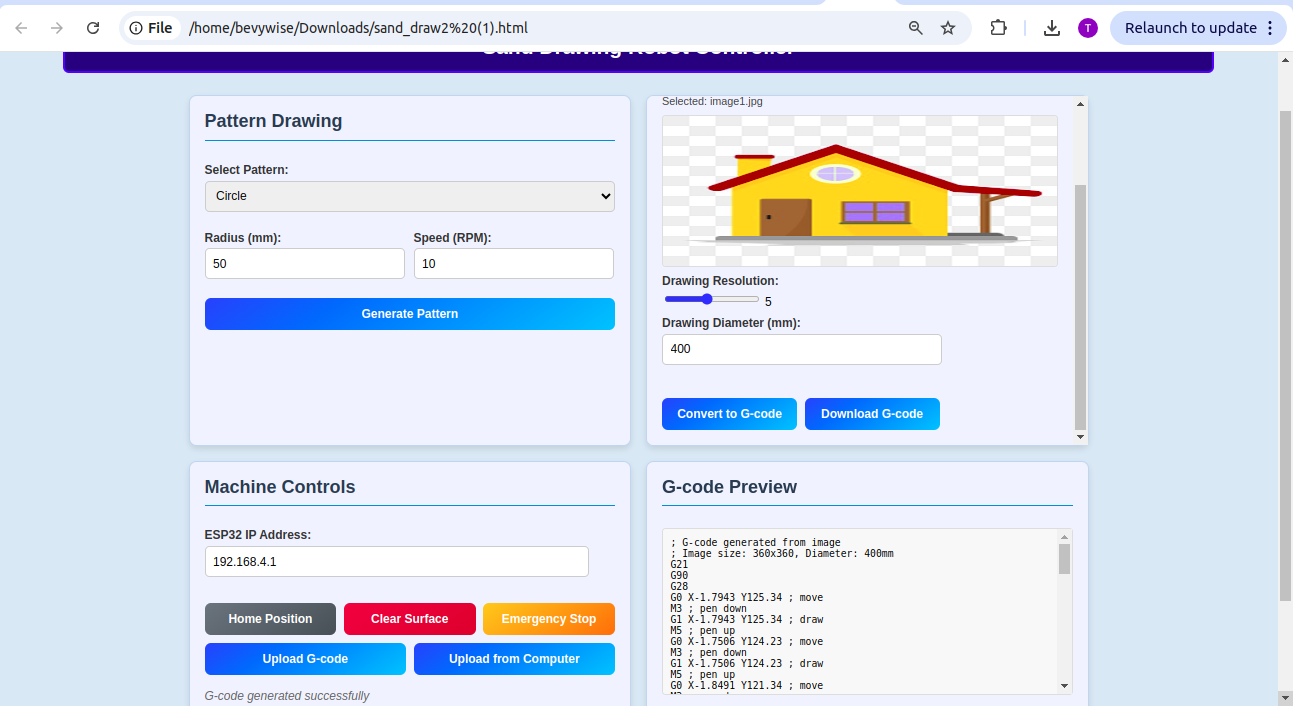

-> Image-to-G-code Conversion: Processes uploaded images.

-> Real-time Status: Checks ESP32 connection.

-> G-code Preview & Download.

Algorithm

Pattern Generation

Circle{

const angle = (i / 100) * 2 * Math.PI;

gcode += `G1 X${angle} Y${radius}\n`;

}

Sprial

{

const r = (i / 100) * radius;

gcode += `G1 X${angle} Y${r}\n`;

angle += 0.1;

}

Image Processing

-> Converts image pixels to polar coordinates.

-> Dark pixels - Pen down movements.

-> Sorts points by angle for continuous drawing.

ESP32 Communication

Fetch API for sending G-code

method: 'POST',

body: gcode,br> });

Status Polling (every 3 sec)

.then(res => res.text())

.then(status => updateUI(status));

Controls

Stop: fetch(/stop, {method: 'POST'})

Clear: fetch(/clear, {method: 'POST'})

WorkFlow Summary

1. User uploads image/selects pattern.

2. Web UI converts it to G-code.

3. G-code sent to ESP32 via /upload.

4. ESP32 parses and executes movements.

5. Real-time status updates in UI.

Troubleshooting

| Issue | Solution |

|---|---|

| ESP32 not reachable | Check Wi-Fi AP, CORS headers |

| Motors not moving | Verify stepper wiring & power |

| G-code upload fails | Increase fetch timeout, check server logs |

| Pen not lifting | Calibrate servo angles |

Conclusion

This system allows automated sand art creation with

-> ESP32 for motor control.

-> Web UI for easy pattern design.

-> Polar coordinate G-code for smooth drawing.

Hero shots

Webpage

Download Original Design Files

Click on the links below to download the Program: