Electronic Production - Group Assignment

Objective of This Week

The goals of this group assignment were:

- Characterize the design rules for the in-house PCB milling process, including:

- feed rate

- spindle speed

- plunge rate

- cut depth (traces and outline)

- tooling dimensions

- successful trace/spacing limits

- Document the workflow for sending a PCB to an external boardhouse, for comparison with the in-house process.

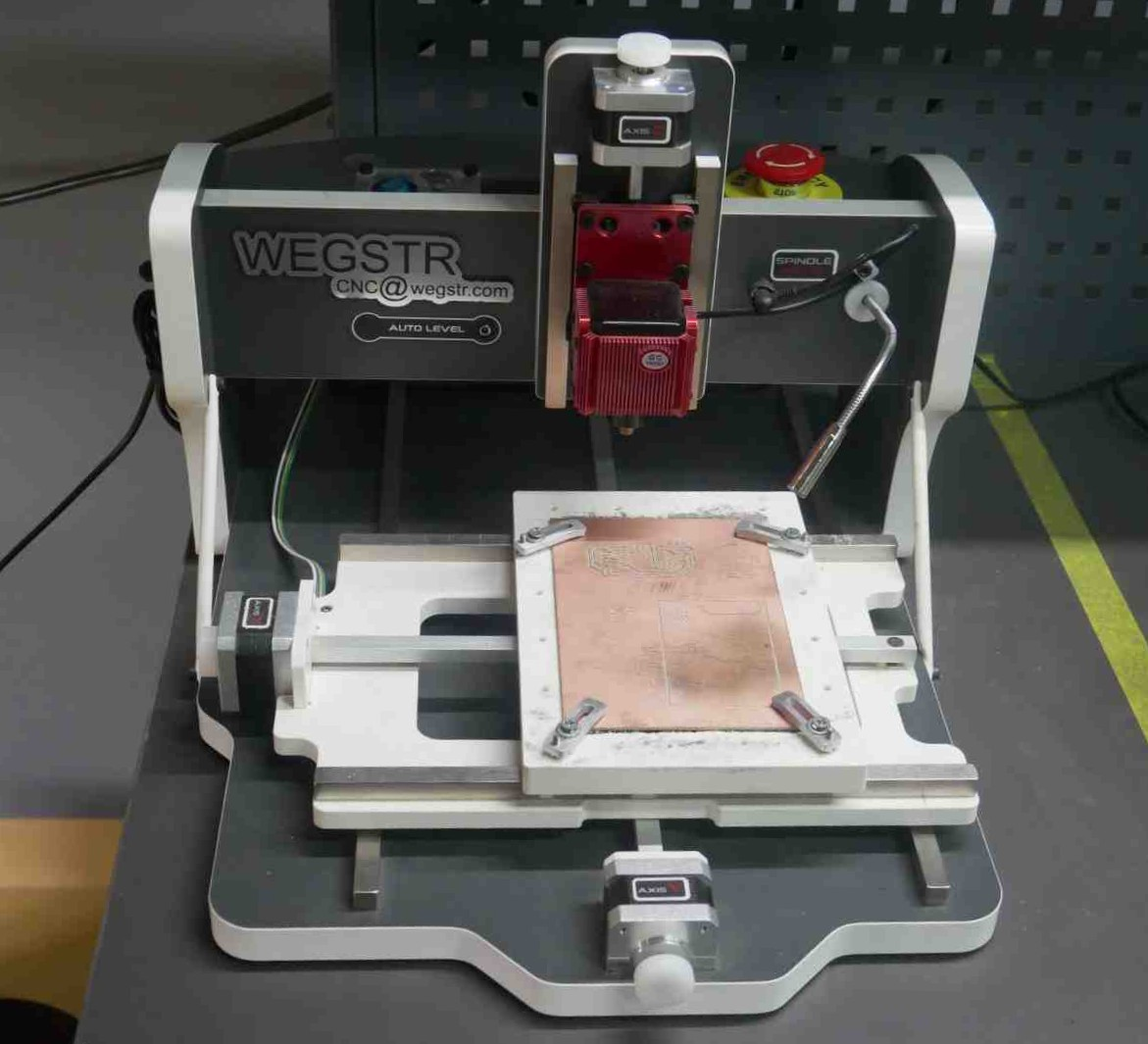

- Test and document the capabilities of our Fab Lab's PCB milling machine — the Wegstr PCB Milling Machine.

Wegstr PCB Milling Machine

The Wegstr is a compact, desktop PCB milling system used for rapid prototyping of single-sided and double-sided PCBs. It removes copper mechanically instead of using a chemical etching process, making it safe, clean, and eco-friendly for lab environments.

It accepts Gerber and Excellon files, enabling direct workflow from any standard PCB design software.

Approximate Cost: ₹3,00,000

Specifications

| Feature | Specification |

|---|---|

| Working Area | 140 mm (X) × 200 mm (Y) × 40 mm (Z) |

| Spindle | Brushless motor, 11,000 RPM, 3.175 mm bit diameter |

| Repeatability | ±0.02 mm |

| Stepper Resolution | 0.004 mm per step |

| Recommended Feed Speed | 60 mm/s |

| Max Feed Rate | 170 mm/min |

| Connectivity | USB (1.x–3.1 compatible) |

| Power Input | 100–240V AC, 50/60Hz |

| Dimensions | 380 × 460 × 290 mm |

| Weight | 7 kg |

| Supported Materials | FR4, aluminum, plastics, brass, copper, wood |

| Software | Wegstr Controller |

Safety Precautions

| Safety Aspect | Precaution |

|---|---|

| Ventilation | Ensure the room is well-ventilated to avoid inhaling FR4 dust. Use extraction if available. |

| Workpiece Stability | PCB must be placed firmly and evenly. Loose material causes tool breakage or uneven milling. |

| Electrical Safety | Use original power supply. Avoid overloaded circuits. |

| Bit Condition | Inspect V-bits and end mills regularly. Dull bits lead to rough traces and broken copper lines. |

Design Rules Characterization

Through testing, we examined several parameters to determine the optimal settings for in-house PCB milling.

1. Minimum Trace Width & Spacing

- Safe minimum: 0.25 mm (10 mil)

- Below this, traces begin to merge or lift

2. Pad Size and Hole Diameter

- Pad size must be at least 0.5 mm larger than the hole

- Minimum drill hole: 0.8 mm (varies by drill bit)

3. Board Edge Clearance

- Maintain ≥ 1 mm between copper and the board outline

4. Copper Isolation Width

- Isolation width must be equal or greater than tool diameter

- Example: For 0.4 mm tool → isolation ≥ 0.4 mm

5. Tool Path Overlap

- Important to ensure full isolation of traces

- Insufficient overlap leaves copper residues

Design Test Procedure

1. Selecting a Test PCB Design

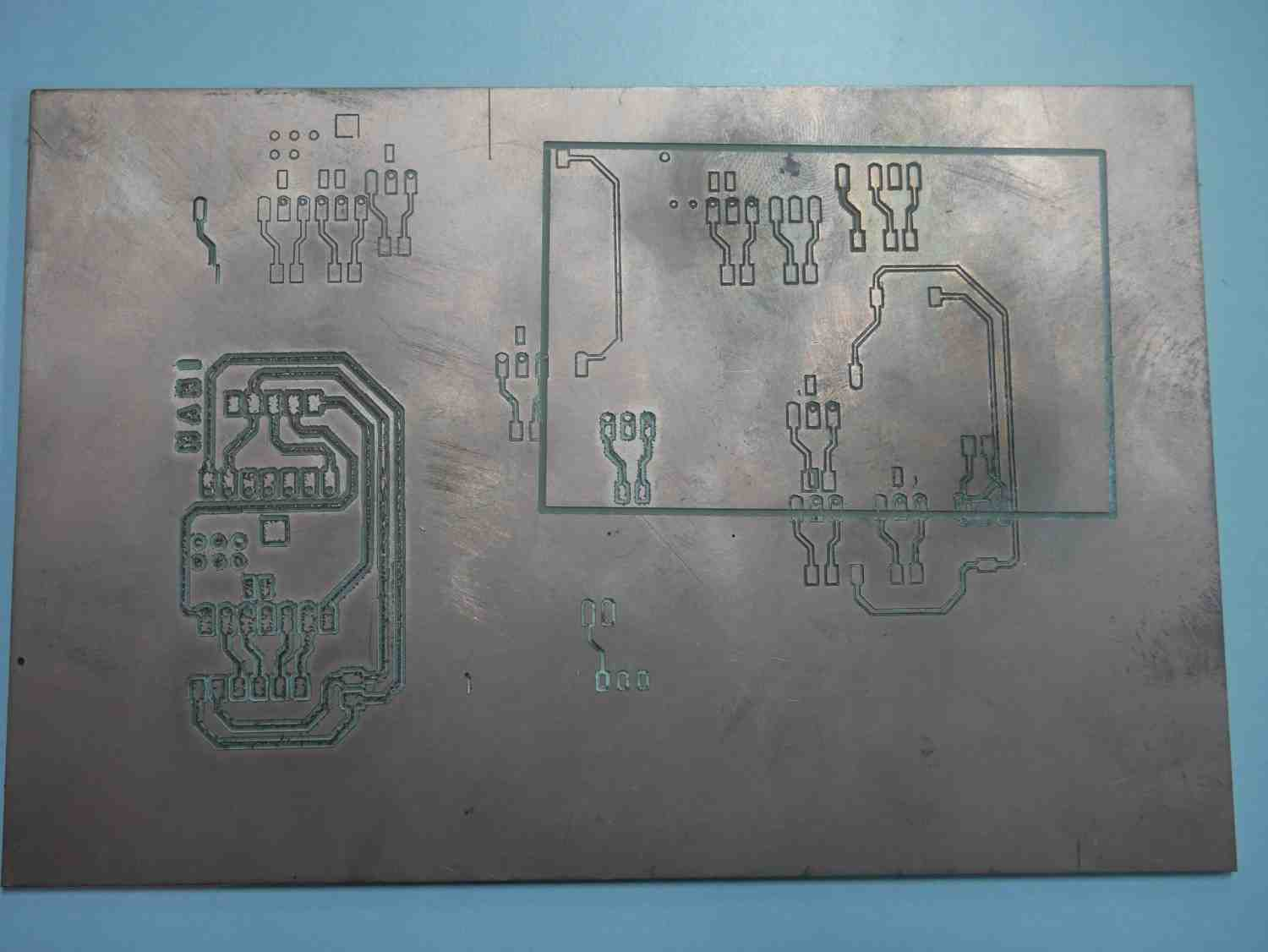

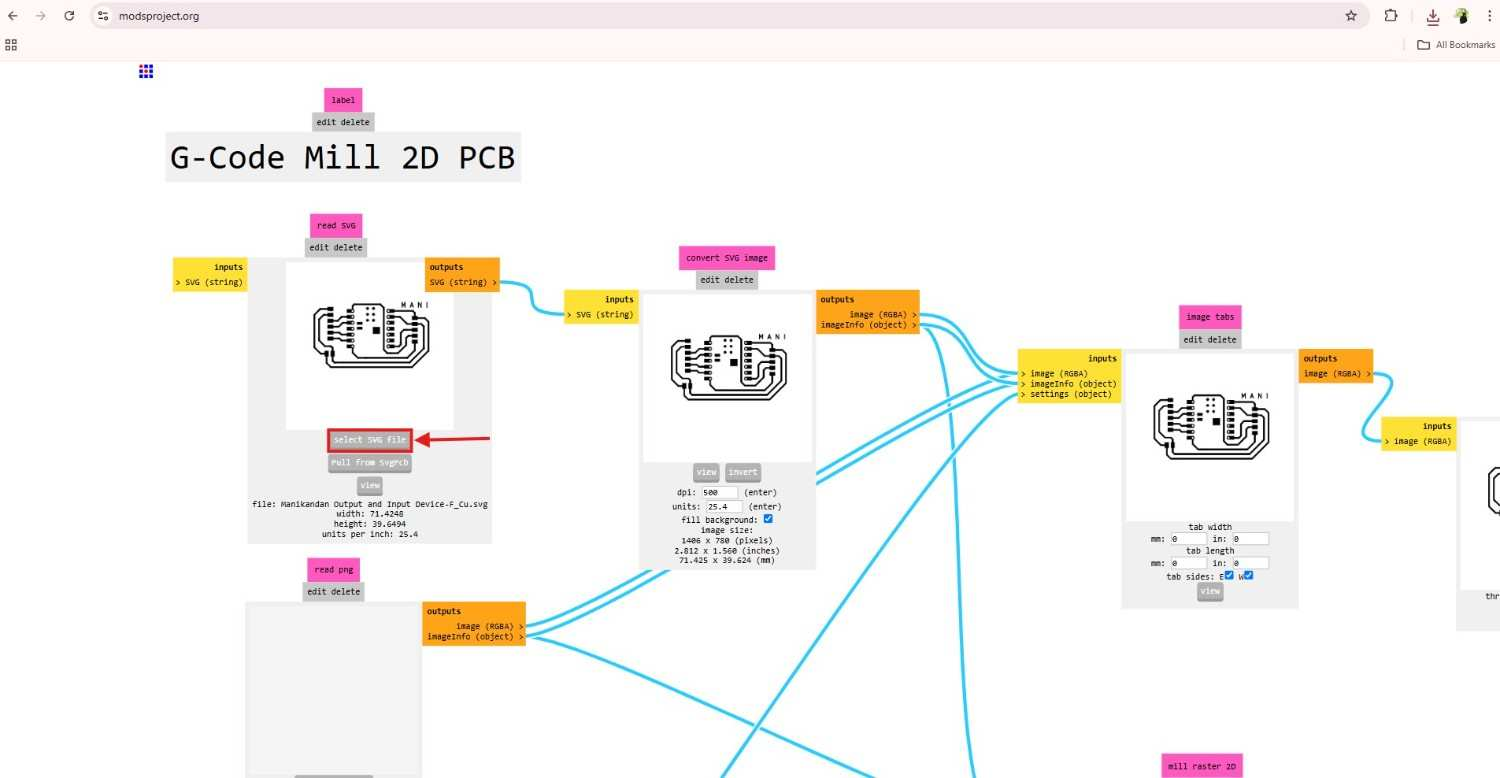

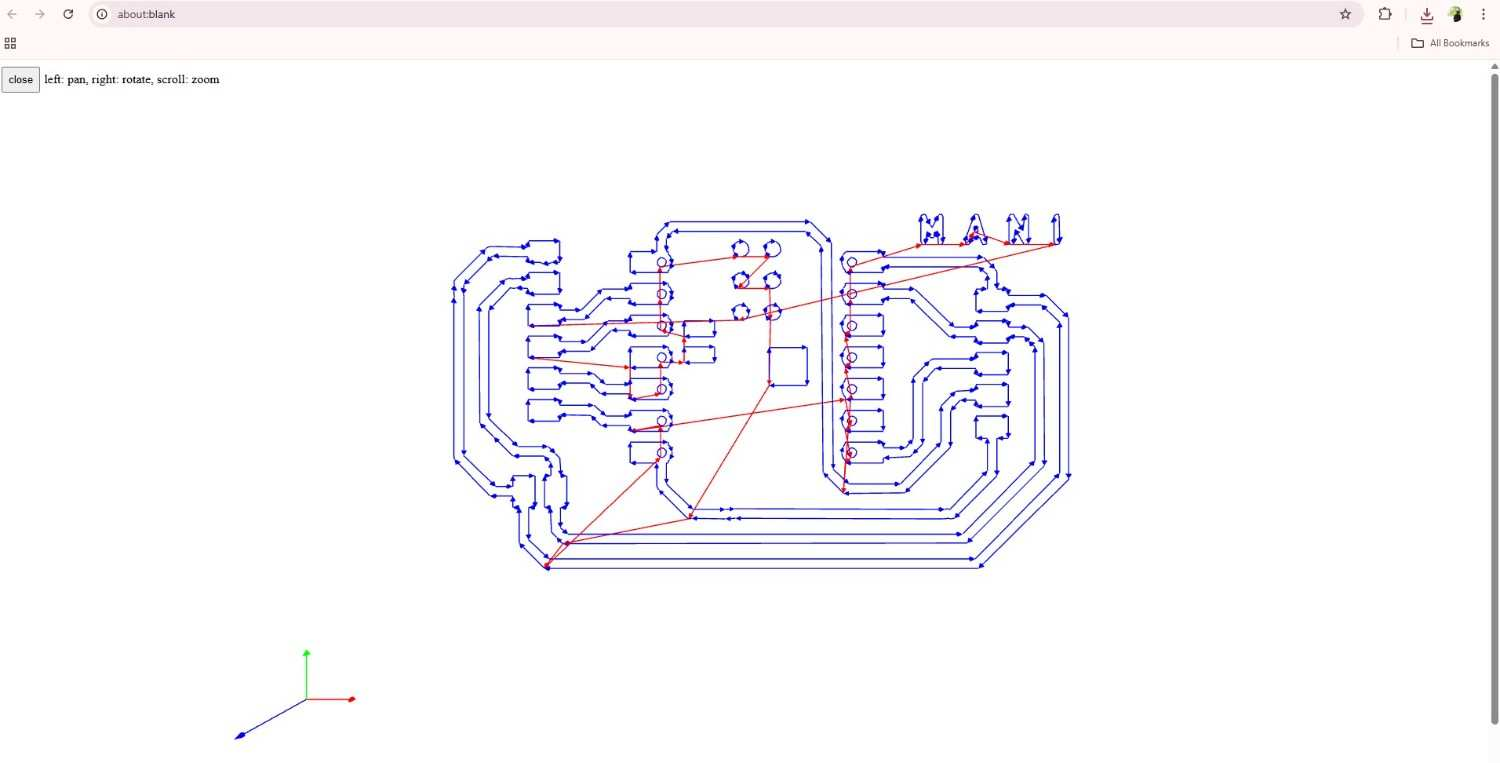

For characterization, we used a PCB designed by Manikandan from the electronics production assignment. The design was exported as SVG, which is compatible with MODS for toolpath generation.

2. Creating Toolpaths in MODS

MODS is widely used in Fab Labs for converting PCB images to G-code.

Steps:

- Open MODS in the browser

- Right-click → Program → G-code: PCB 2D Milling

- Load the SVG/PNG file

- Set tool parameters

- Export G-code

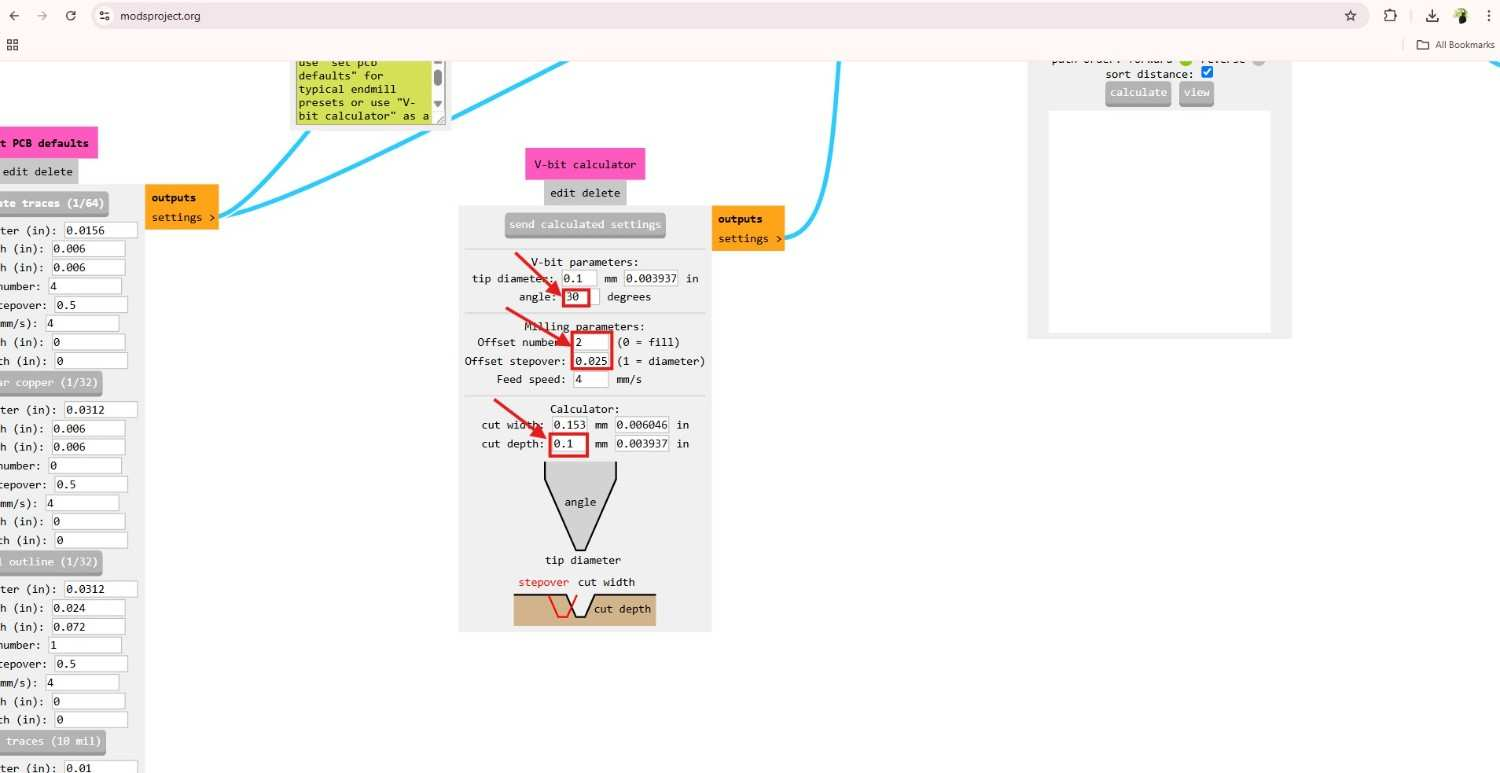

Tool Used:

- 1/64 inch V-bit (30°)

- Parameters calculated using a dedicated V-bit calculator

3. Testing Milling Parameters

We carried out multiple tests by changing:

- cut depth

- feed rate

- spindle speed

- tool diameter

- offsets

The goal was to determine the set that produces clean, unbroken traces.

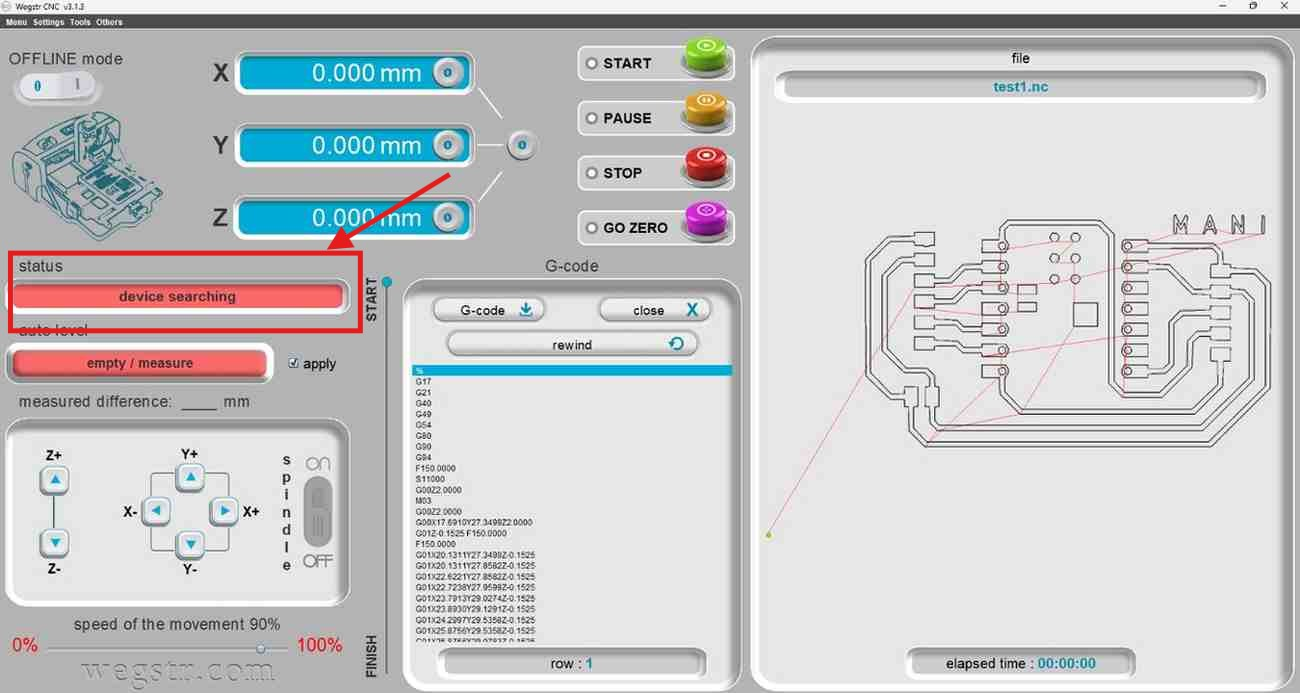

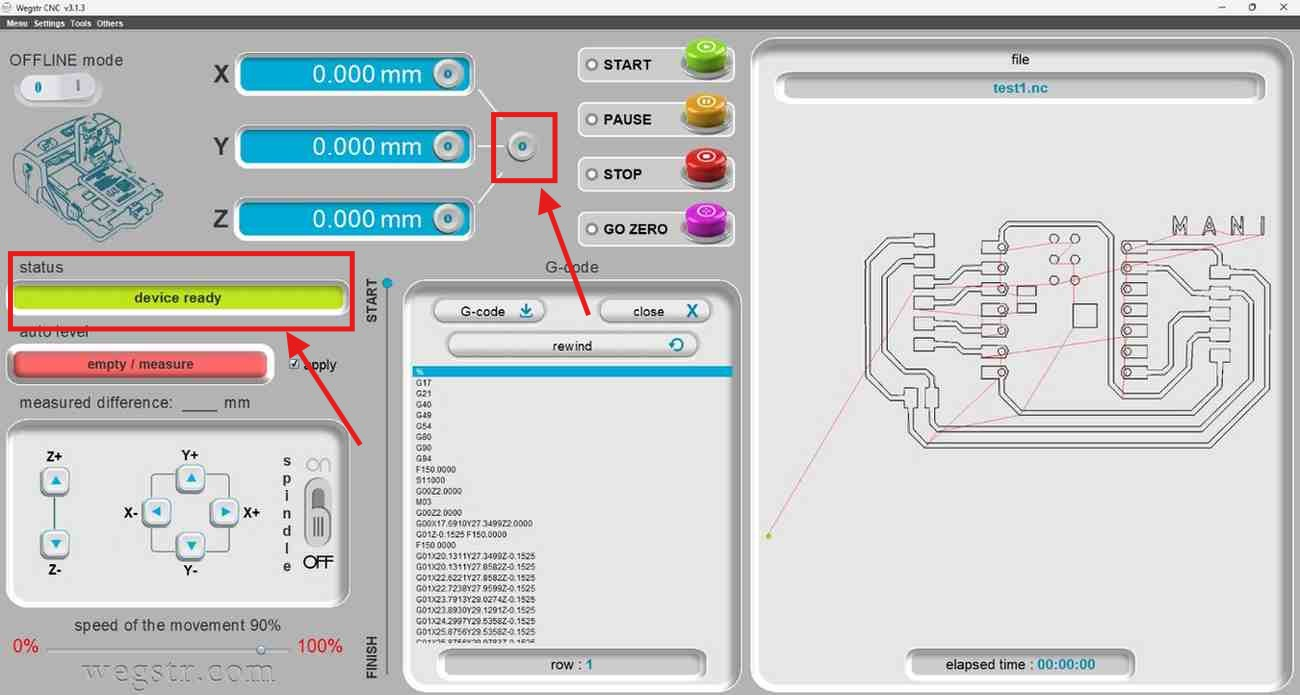

4. Milling on the Wegstr Machine

Machine Setup Steps

- Fix the copper-clad board securely on the bed

- Insert the 30° V-bit into the spindle

- Manually adjust Z-height (auto-leveling unavailable due to missing leveling wire)

- Lower slowly until the tip just touches the copper

- Set this as Z = 0

- Load G-code in Wegstr software

- Start milling

Important:

The V-bit is extremely delicate. Excessive Z-depth will break it immediately.

5. Observations and Iterations

The first few attempts failed:

- traces were broken

- copper was overcut

- depth too high

We modified MODS parameters repeatedly until we achieved clean milling.

This testing allowed our group to understand:

- proper Z-depth

- safe spindle speeds

- workable trace spacing

- correct isolation parameters

- optimal bit selection

Final Results

After multiple experiments, we were able to:

- Identify suitable design rules for PCB milling in our lab

- Achieve reliable trace quality

- Understand limitations of the Wegstr machine

- Develop a repeatable workflow for milling PCBs in-house