Week 8 : Electronics Production

We are building upon skills from previous weeks to complete this week’s tasks. For our individual task, we are to make and test a microcontroller development board that we designed. For our group task, we are to characterize the design rules for our in-house PCB production process and submit a PCB design to a board house.

PCB Board Milling

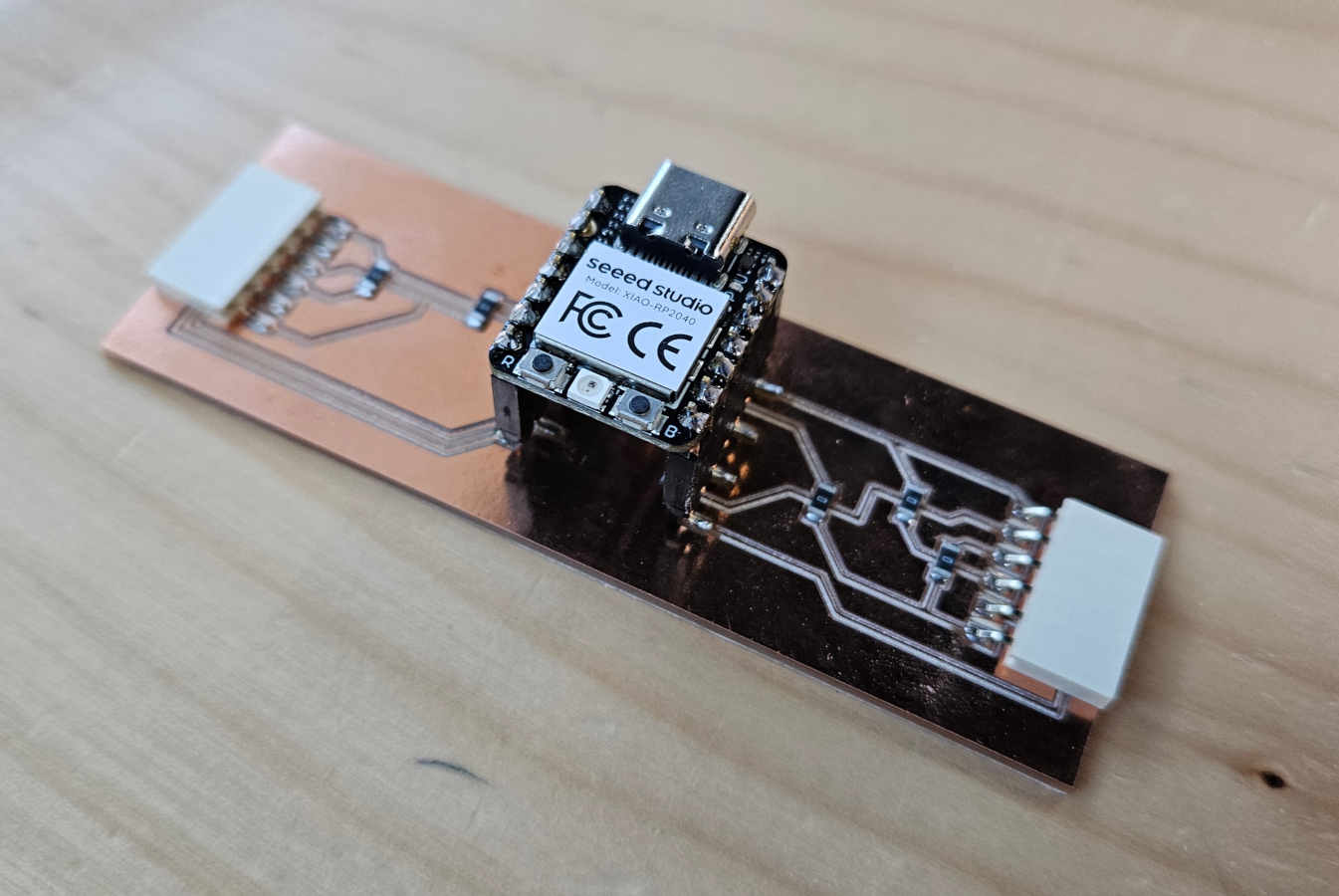

I will be taking the design I created in KiCad from electronic design week to make my own development board with the Bantam Tools Desktop PCB Milling Machine.

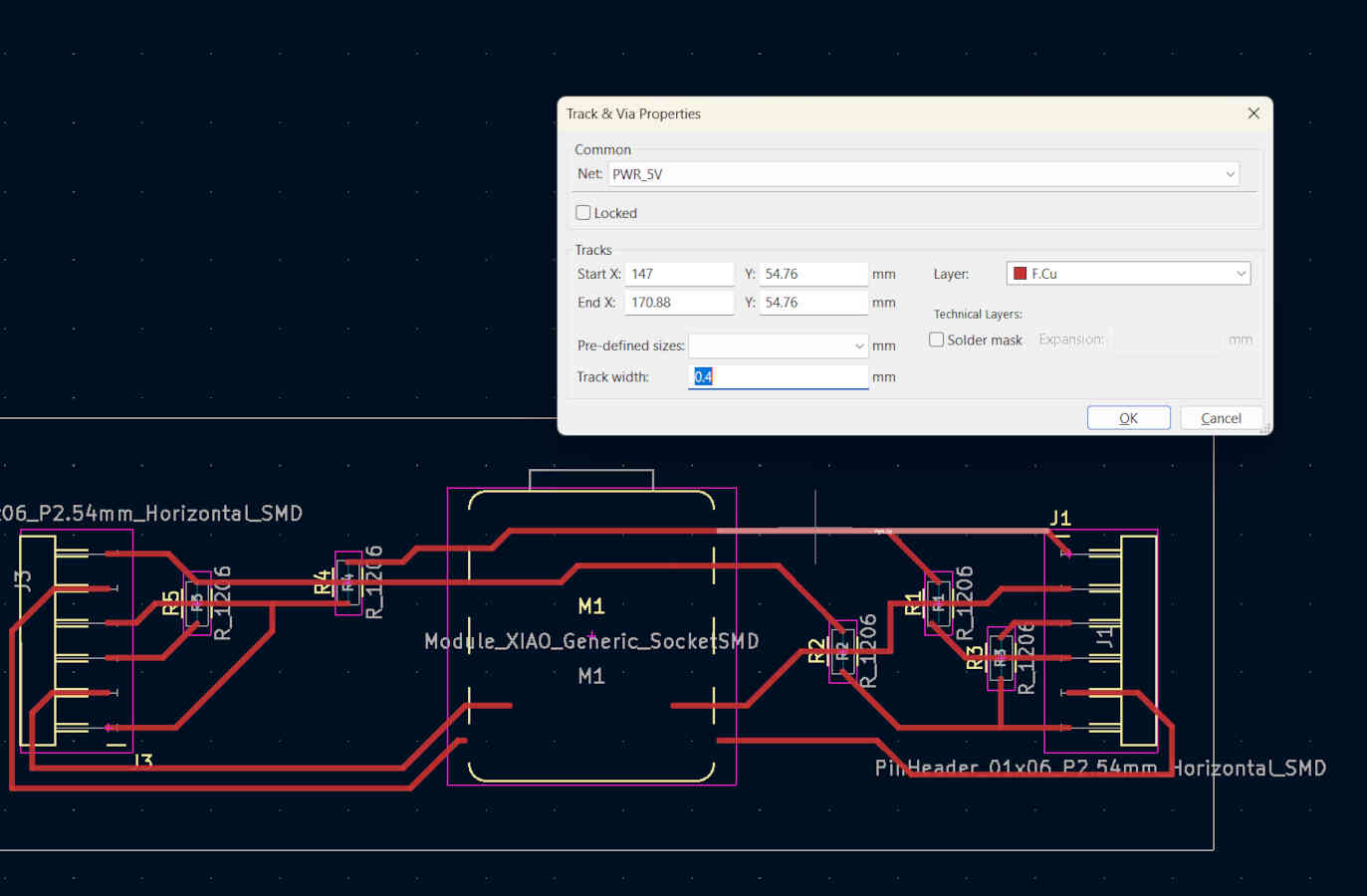

- Even though the design is already made up in KiCad, there are a few design features to check/edit. I didn’t realize the stroke weight of the trace lines are set in KiCad and not in the milling software. The default stroke is too thin even for a 1/64 tool bit. You can change the stroke by selecting the trace and hitting “E”. This will bring up a window where you can enter whatever a measurement in mms. Its default is 2mm and I doubled it to 4mm.

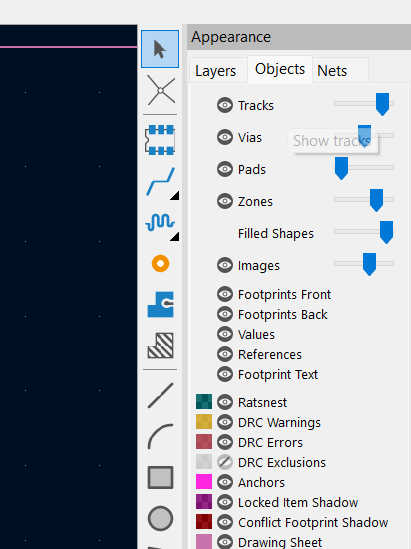

- There are also “pads”/descriptions that are opaque and may be blocking views of your path. Thanks to Augusto, he showed me that in the objects tab you can change the opacity of these marks. There were some messy ends of traces and now you can easily clean them up

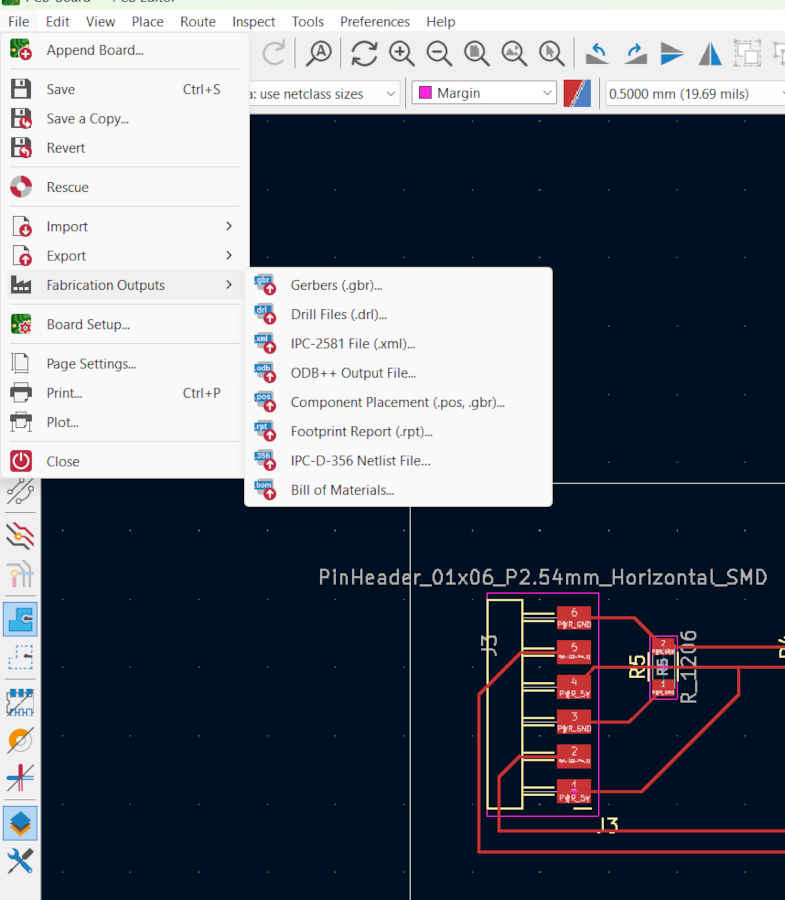

- Once you are happy with your file and the design, you need to save the file in the appropriate format for the milling machine. Go to “File”, “Fabrication Outputs” and choose the file type Gerbers(.gbr)

- Now we get to the milling software. Install Bantam Tools Desktop Milling Machine Software (not Legacy)

- Once you load your files, materials, and put in the appropriate settings, it’s time to start cutting. For a more detailed breakdown of how to run and load the CNC Mill, take a look below in the group assignment section.

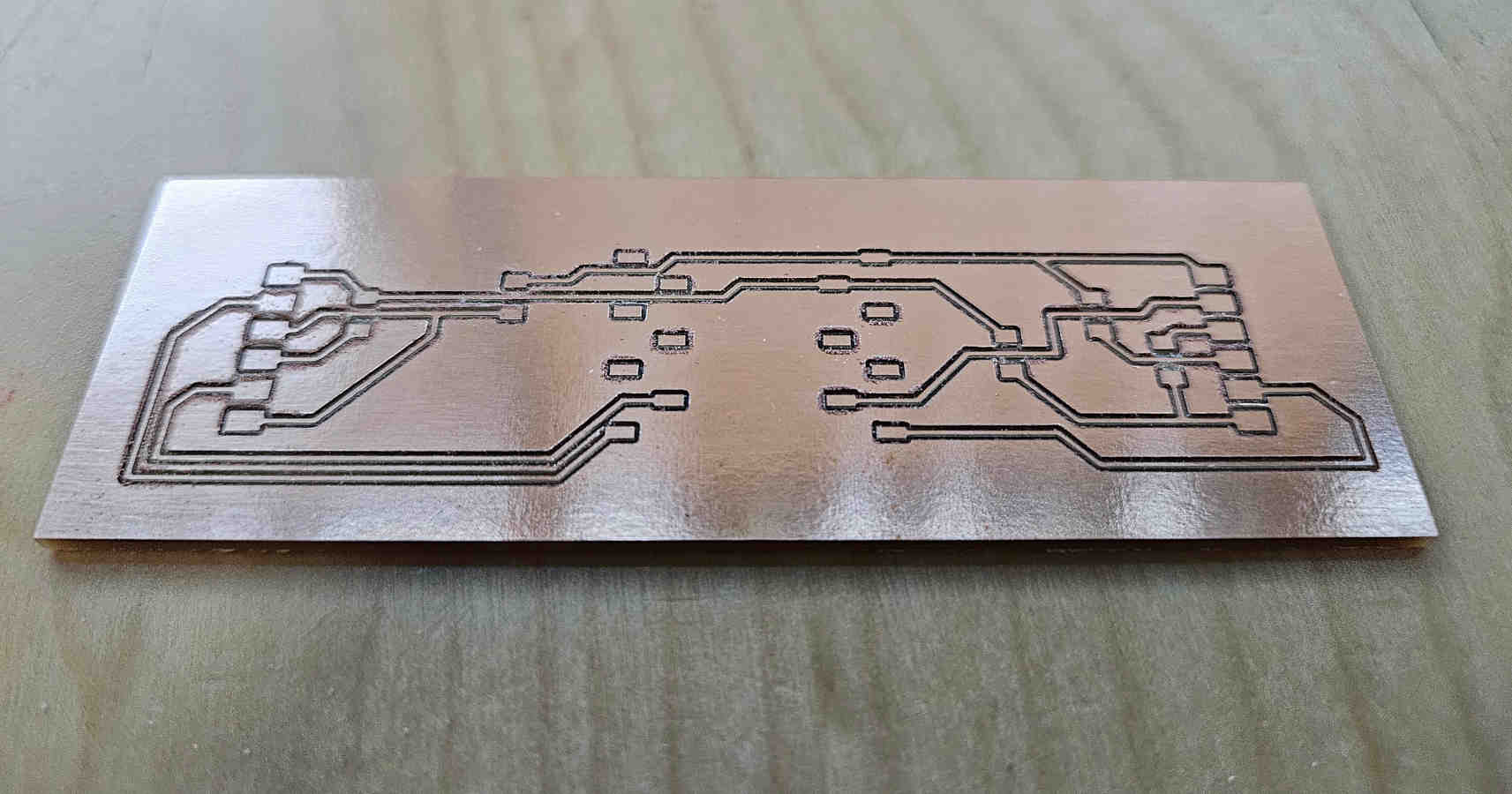

- Press play and watch magic or mayhem ensue.

- Even if you have your measurements, file, and apply your material properly, this can still be a finicky process and lots can go wrong. Luckily my first board SHOCKINGLY turned out great. I did run extras, to prep for future failures and none of my boards turned out the same with the same settings. A bit also broke in the process.

Soldering and Testing

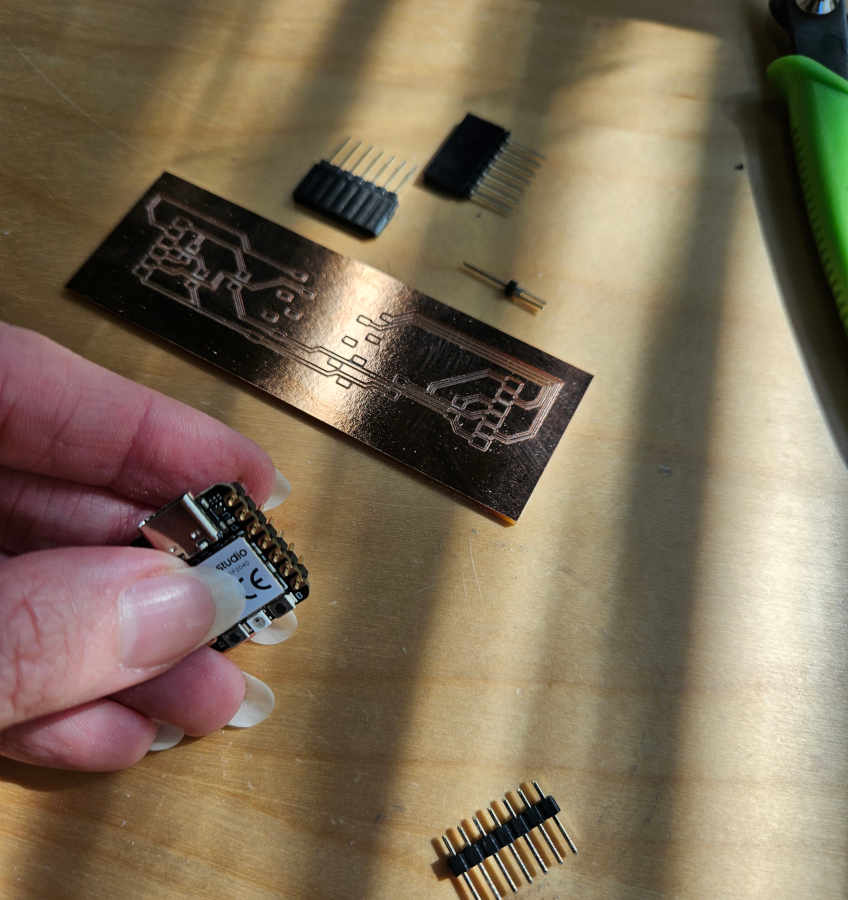

- Now that we have our PCB board milled out, we got to solder our micro controller, pinouts, resistors, and any other addition components.

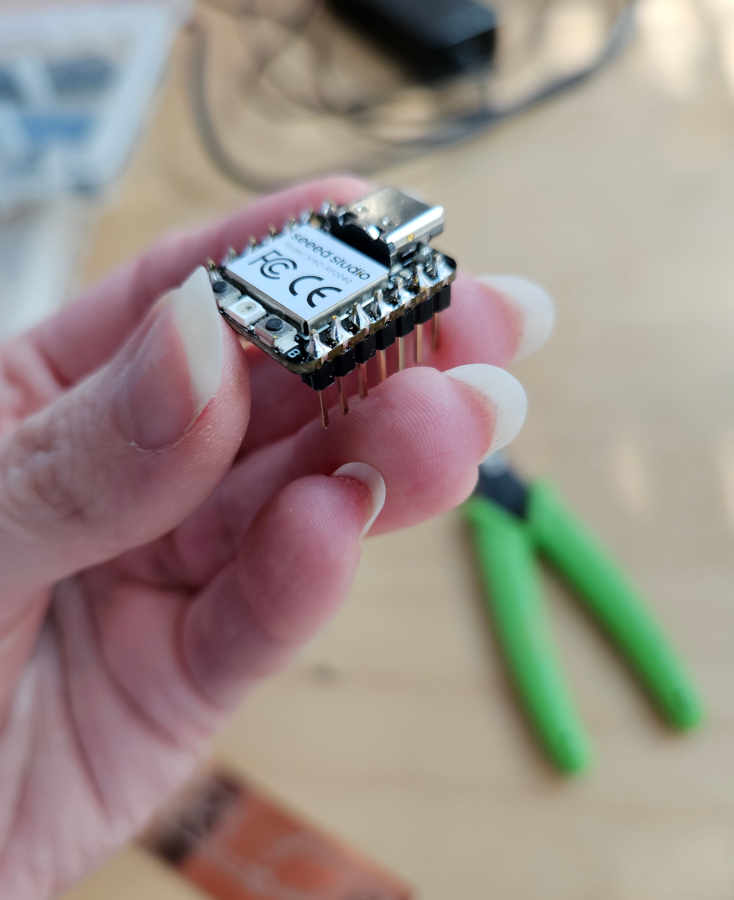

- I do have experience soldering and somewhat enjoy it. I decided to have a pin header mount for my micro controller to help with testing and dealing with multiple variables while still learning and being a beginner. So, I first soldered pins to my micro controller.

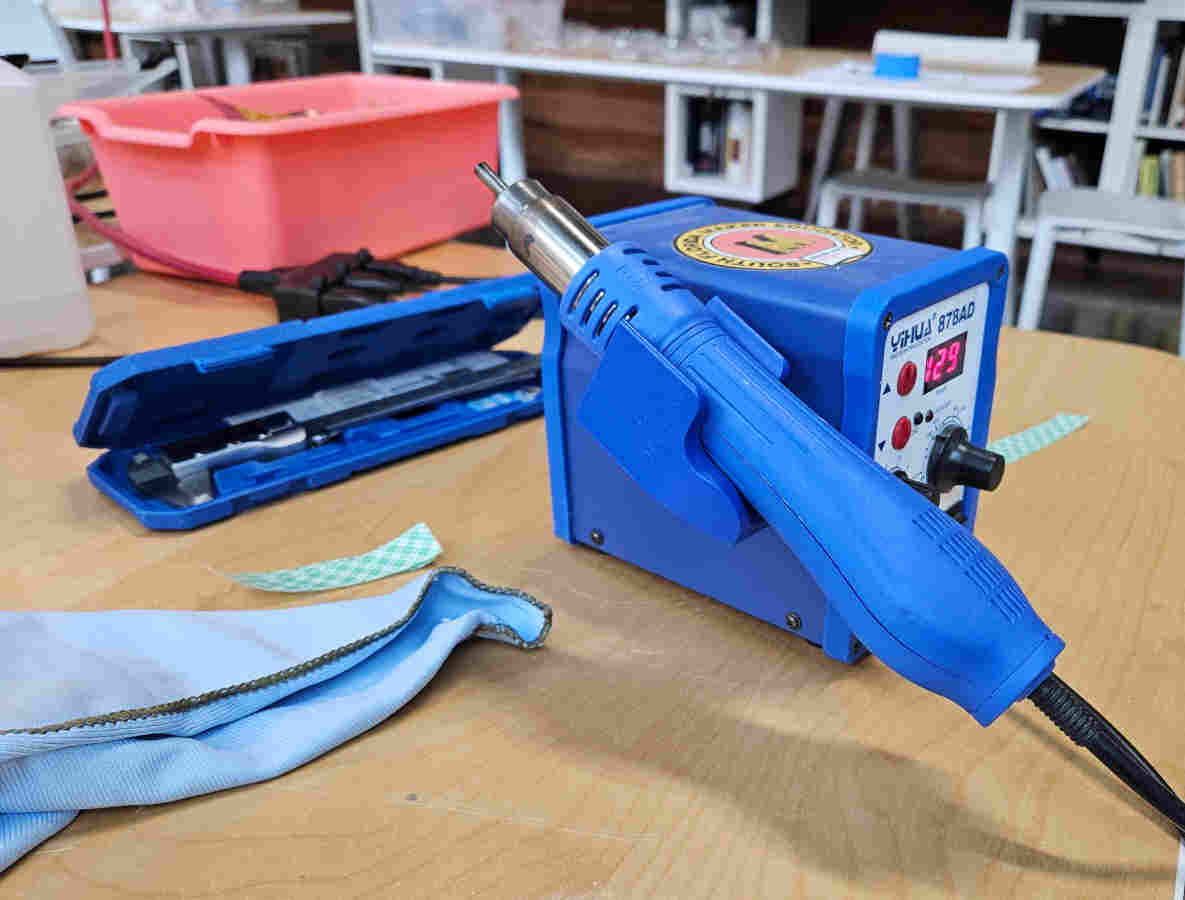

- I thought soldering would be a breeze on the board, but for the board and the rest of the soldering we are using a paste vs the wire. I have never used solder paste before and there was a bit of a learning curve. The paste is applied with a syringe and to heat it, you use a narrow-tipped heat gun.

- Be mindful of amounts of solder and how close you get the heat gun to your board. You do not need to get super close to your board to activate the solder. I got to learn from Augusto's mistake of get to close and potentially melting plastics or burning the board.

- I applied more soldering than I should have in fear of it not adhering well. I also was a little shaky and when I went to add the pin header I smudged a little bit of solder. I thought nothing of the "background" of the board and assumed the overflowed solder from the pinouts to the board would not be an issue. After some thought, I had a hunch, and checked if it would be an issue before soldering more parts. Tom pointed out that if I had milled out the entire copper background that would be the case, but since I didn't, the copper in the background acts as ground and I would most likely have a circuit issue. Welp, I tried to remove the solder and the board was not going to let me have my way.

- On to board 2! I learned quickly from my mistakes and handled the solder and components with extra care. It can out pretty darn clean if I do say so myself.

- Time to test my Frankenstein of a board and see if it can come to life!

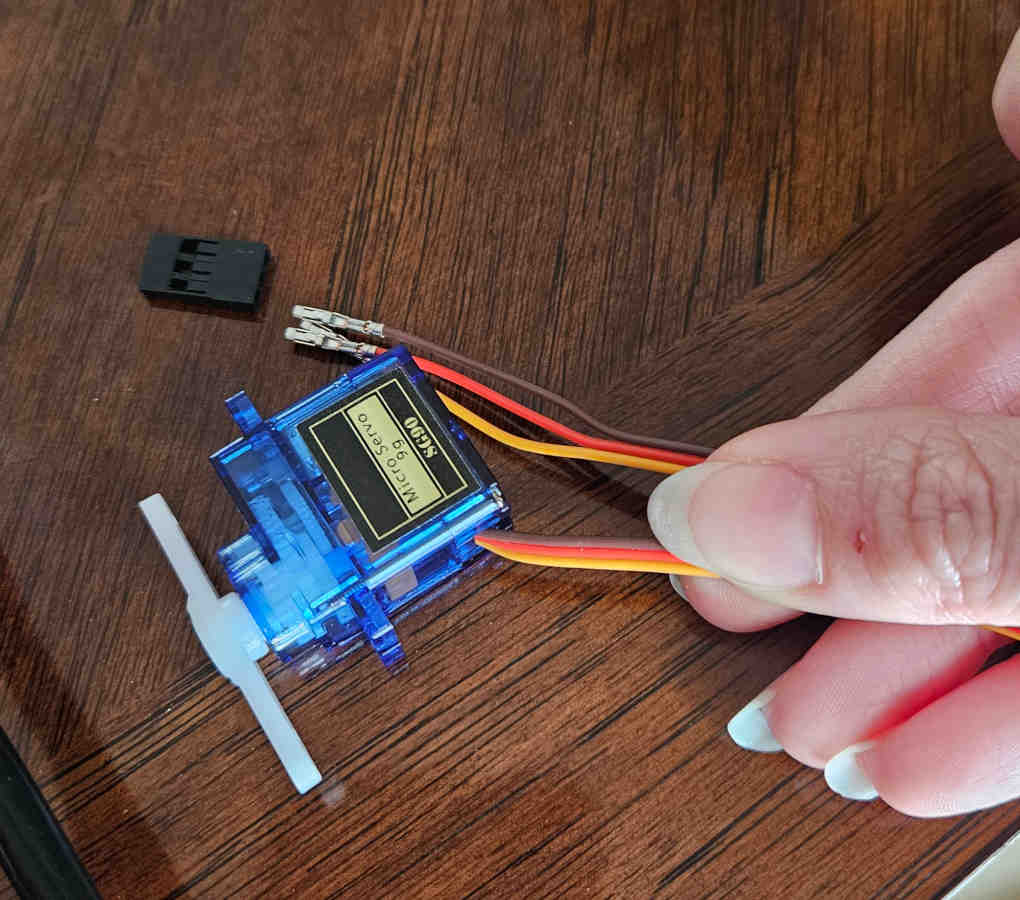

- I will be using a servo motor in my final project and wanted to test that in a basic manner just to make sure I'm headed in the right direction.

- If I have learned anything from this course, it's that Murphy's law is the ever looming supreme controller of all design and fabrication processes!

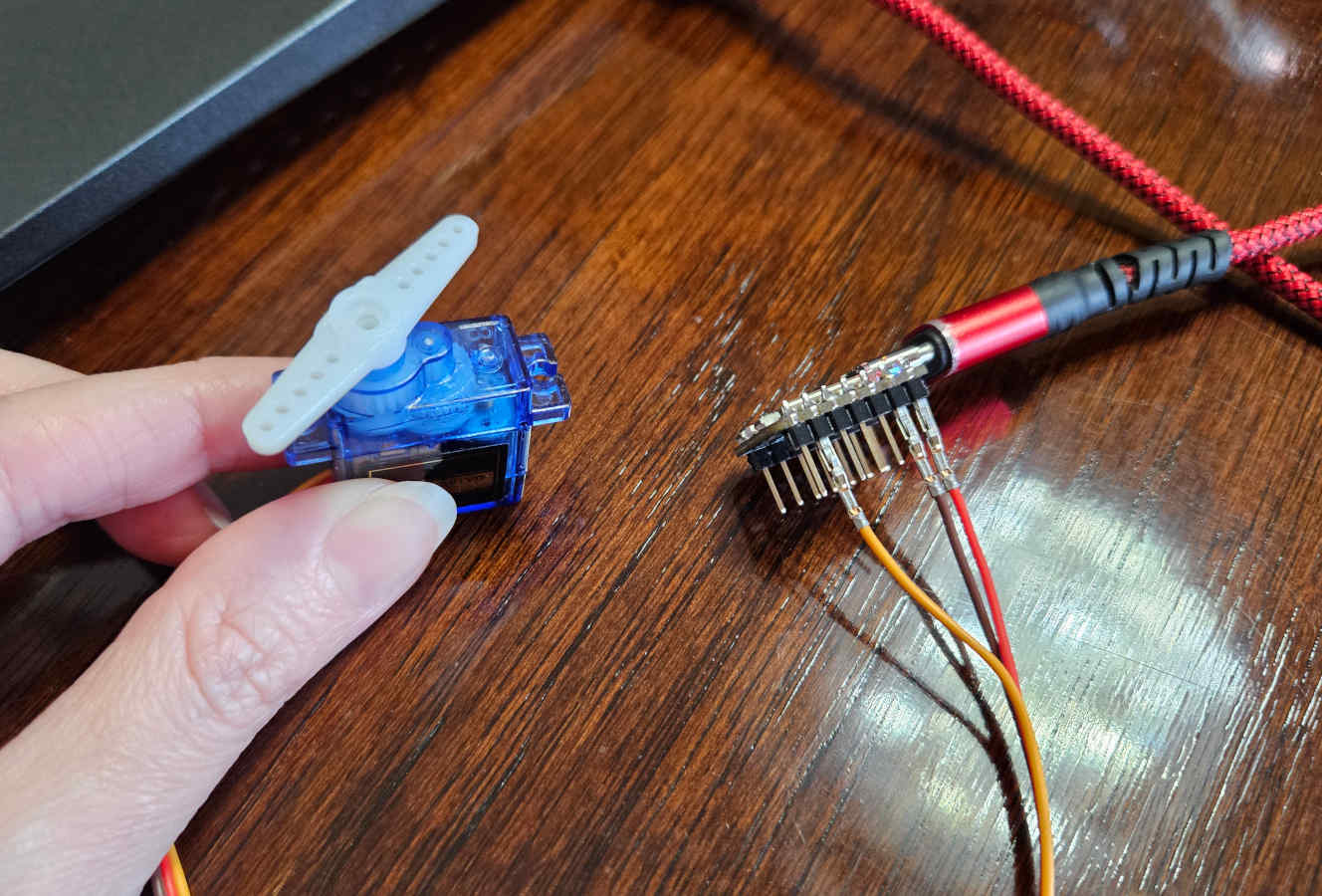

- I designed my board before having a servo motor in my hand. I had made my traces from the rp2040 to the female pinouts in the order of power, signal, then ground. Looking at the servo I have, I checked the wire order and it was set up as signal, power, ground. Luckily, I didn't have to redesign and remake a new board. I realized you can take the wires from the servo out of the end case(gently!) with an exact knife. And rearrange the wire order.

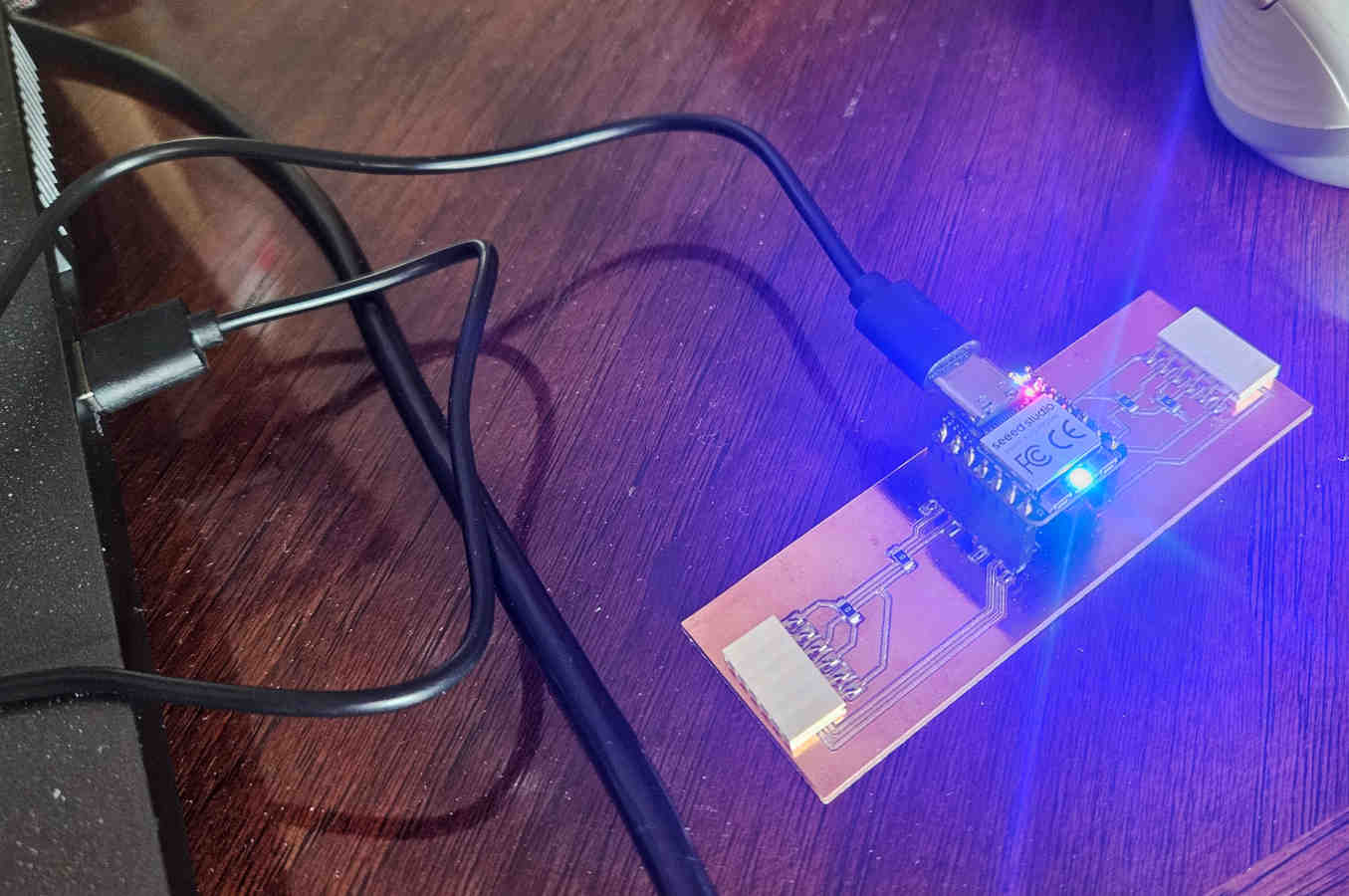

- After that fun detour, I connected my board to the computer and rebooted it to be visible/connect to Arduino. The rp2040 has two little built in LEDs that are on when connected. Yay the chip seems good!

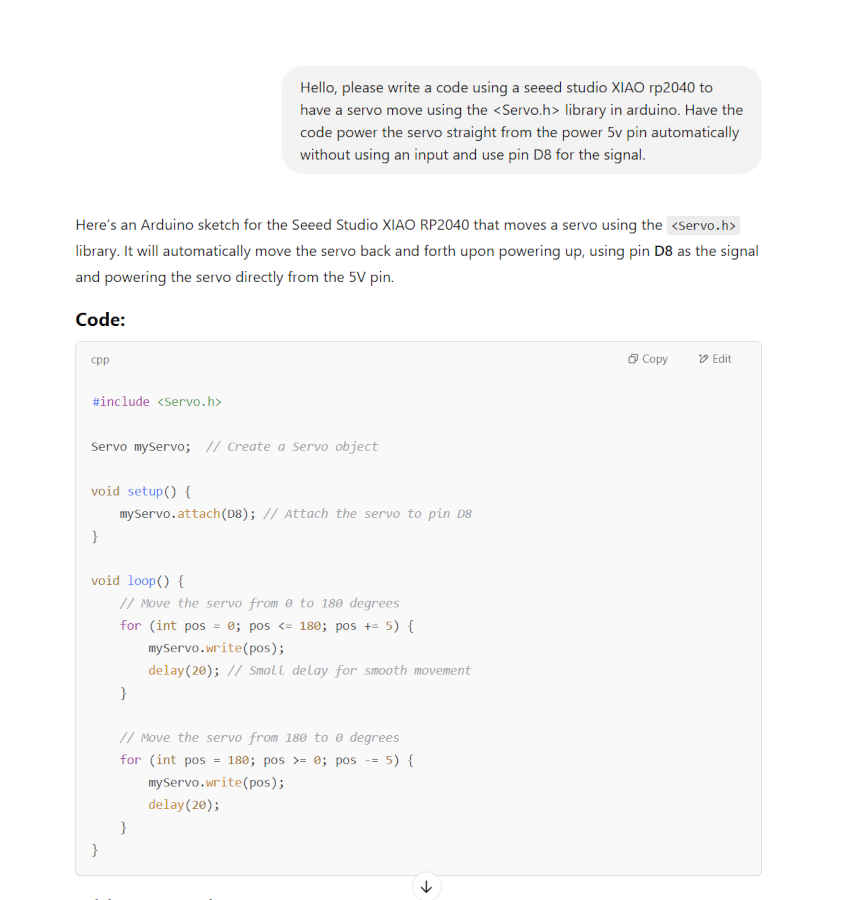

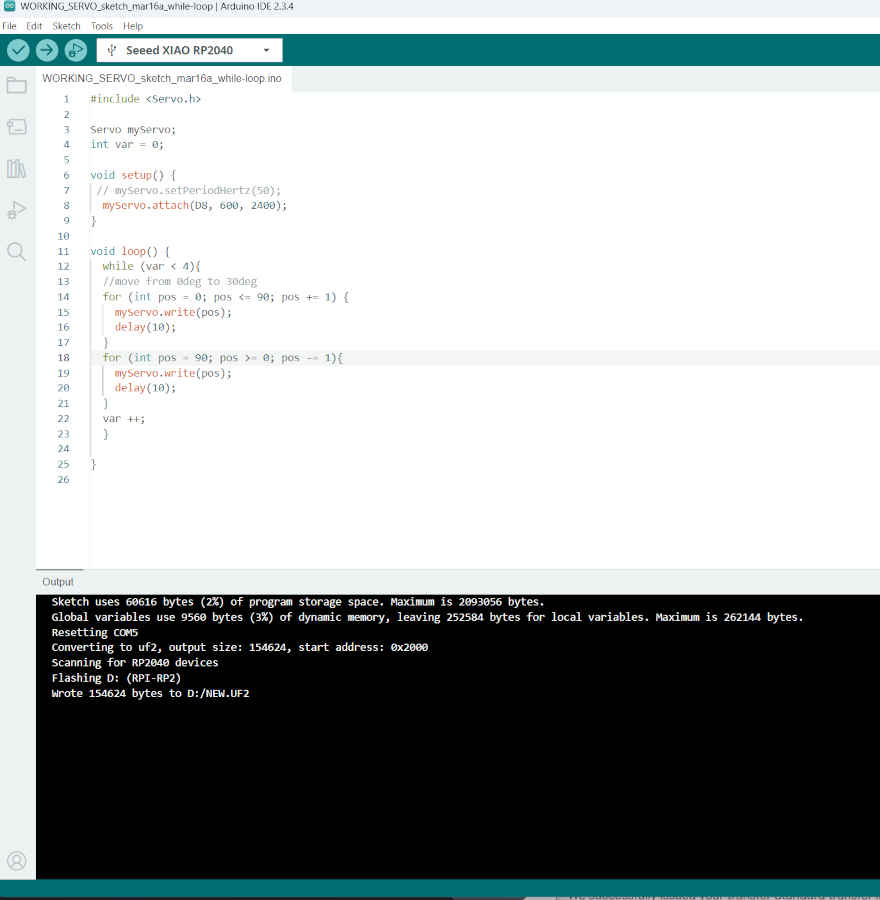

- Now we need to add code. I’m still not very comfortable at all with coding, so I visited my pal chat GPT. I tried to review it and thought it made sense. I put the code into Arduino, verified it (which Arduino found no errors) and uploaded it to the rp2040.

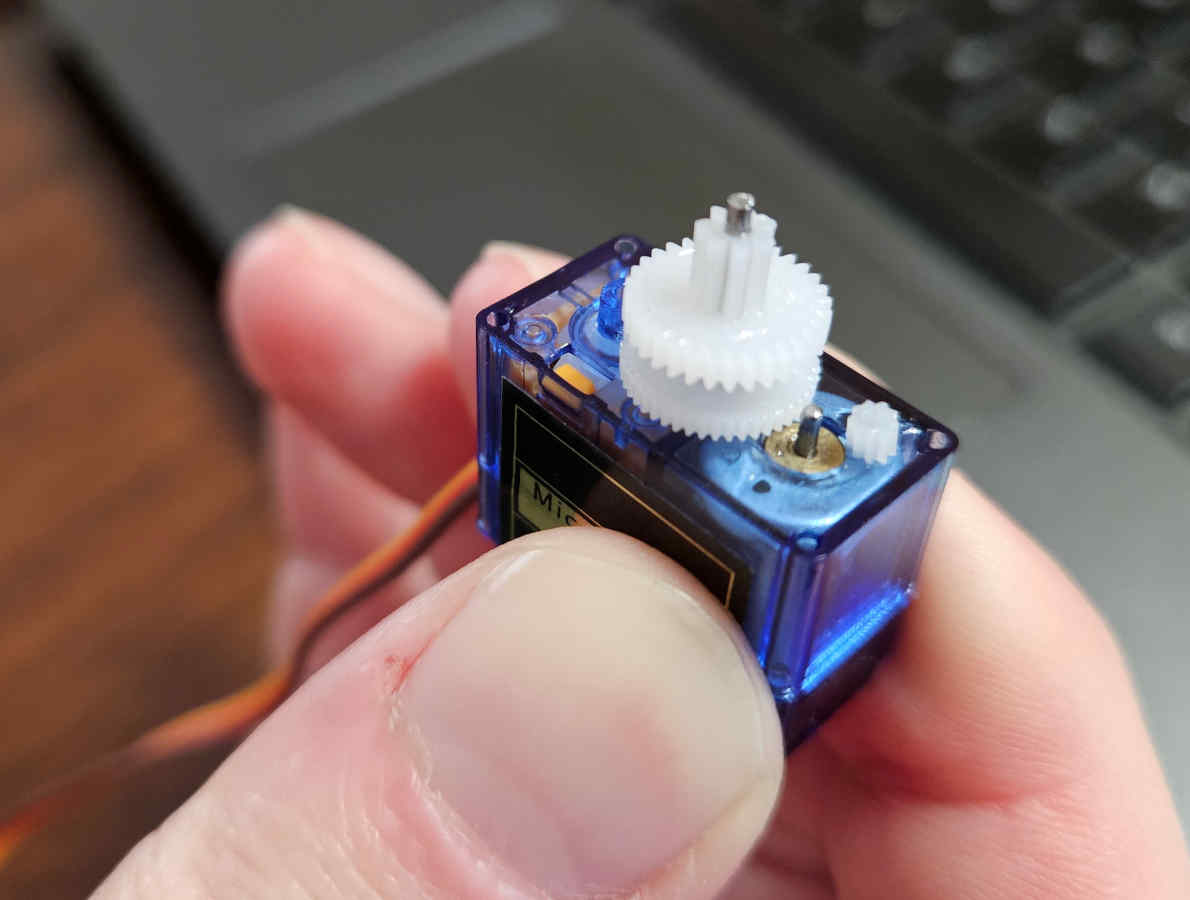

- With the servo plugged in and the code uploaded there should be movement. I can hear and feel the servo is on but there's no movement. What could the problem be? I checked the code to make sure I indicated to move to a different position. I did, I had the code going from 0 to 180 degrees. I thought maybe that servo isn’t made to move that far. So, I tested 90 degrees and 30 degrees with the same results. There could be something wrong with this servo but I didn’t have a spare one on me. I scoured the internet for help and a different code. Tried a different code that looked even better and cleaner. Same results. I connected the servo straight to the micro controller instead of through the board. Same results. I went back to the servo being the culprit and decided to investigate. I opened the servo and there lied my problem. There was a gear not in place. I rebuilt the brand-new servo to how it was supposed to come, and voila it works.

- It can be extremely frustrating when you are learning something new and there are so many unknown variables that can go wrong, it sometimes feels impossible to isolate or know how to approach it without additional guidance. But its very rewarding when you do get to figure it out.

Group Assignment

PCB Production Process

For both the individual and group assignments this week we are using the Bantam Tools Desktop PCB Milling Machine to mill PCBs from copper sheets using a 1/64" flat end mill.

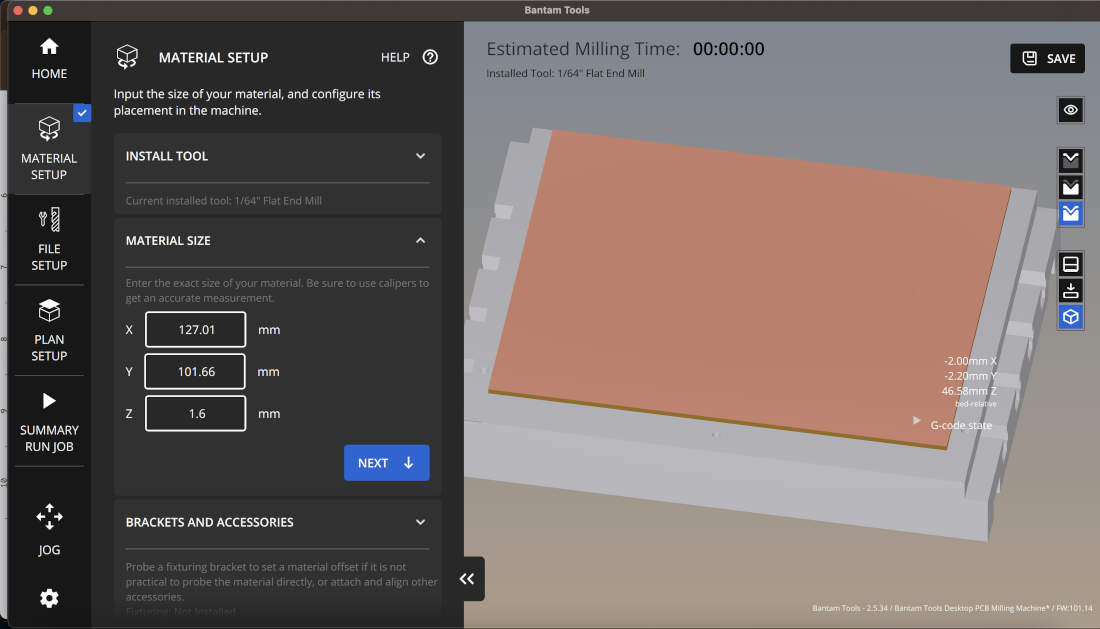

Starting off, we made use of the following tools, materials, and software for this process:- We turned on our PCB mill and opened up the software. We loosened the collet and then installed and tightened the 1/64” Flat End Mill we wished to use and we made sure to use double-sided tape to adhere the copperboard, the material of the circuit board, onto the CNC plate.

- Using Calipers we measured the board’s length, width, and thickness and inputted the info into the software. Additionally we also measured the thickness of the tape and programmed an additional Z-offset due to the height of the tape.

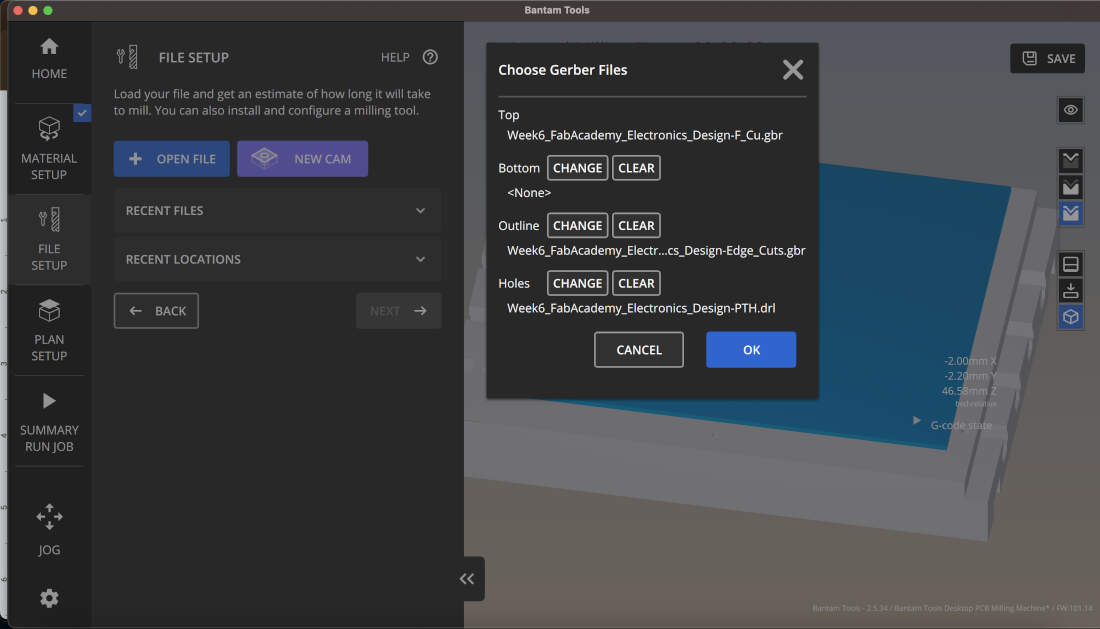

- The next step in the process is importing your PCB Gerber files (.gbr) into the Bantam Tools software. When doing so you have to make sure to start off with selecting your file ending in “-F_Cu.gbr” first as the “F” means front and in the software translates into the Top of the PCB. If you had a back to your PCB, you would flip it over and make sure that you upload your “-B_Cu.gbr” file into the Bottom slot, but we do not have to worry about that here. Uploading the “-F_Cu.gbr” is only the start, to upload the outline, the perimeter of your PCB that is to be cut, you have to upload the “-Edge_Cuts.gbr” file. If your PCB has holes then upload the “-PTH.drl” file to cut out your PCB’s vias or drill holes.

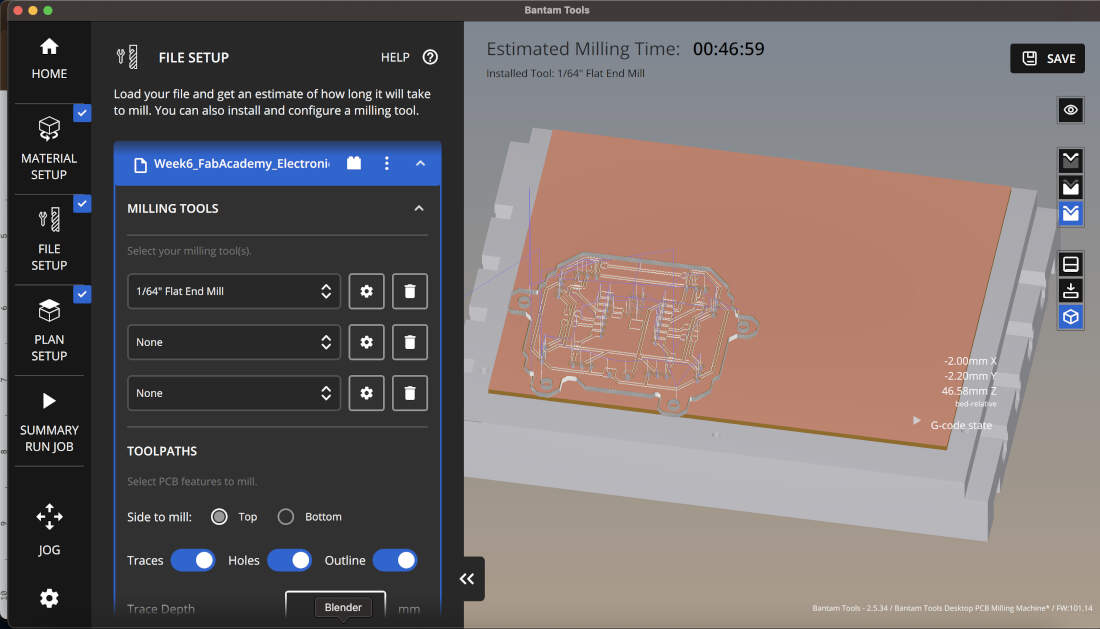

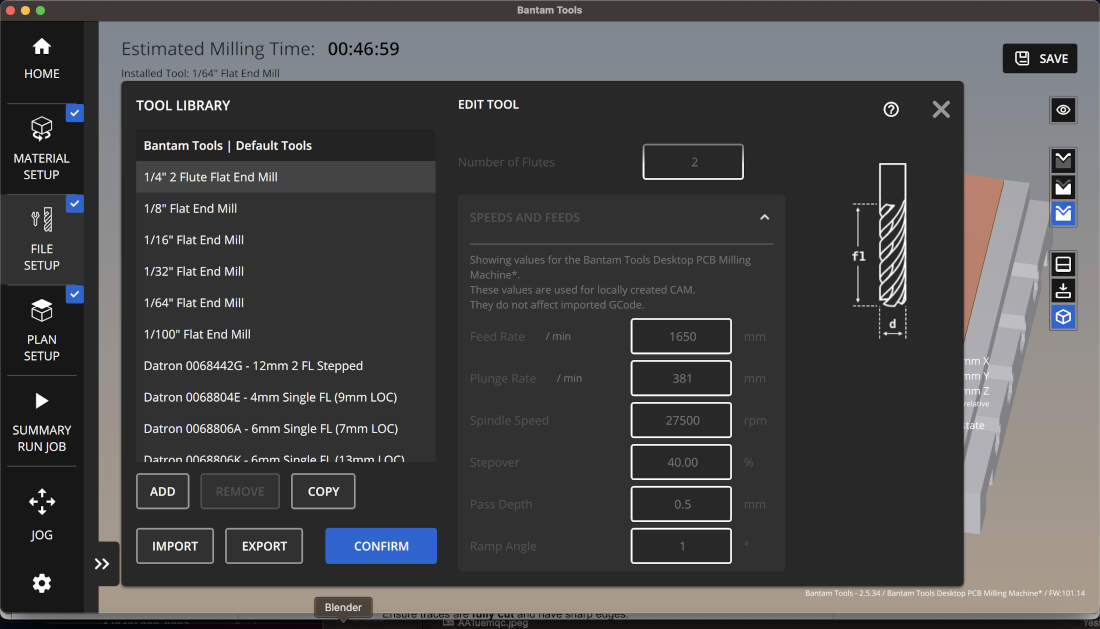

- Once the files are uploaded you can assign the 1/64” end mill for the traces, pads, vias, and outline. You also have the option of involving other end mills in the process if you so choose. You can also edit the Toolpaths by altering which side you are milling, trace depths and clearances, or the rotation of the board itself. Depending on the end mill you choose, you can also further edit feed rate, plunge rate, spindle speed, stepover, pass depth, and ramp angle.

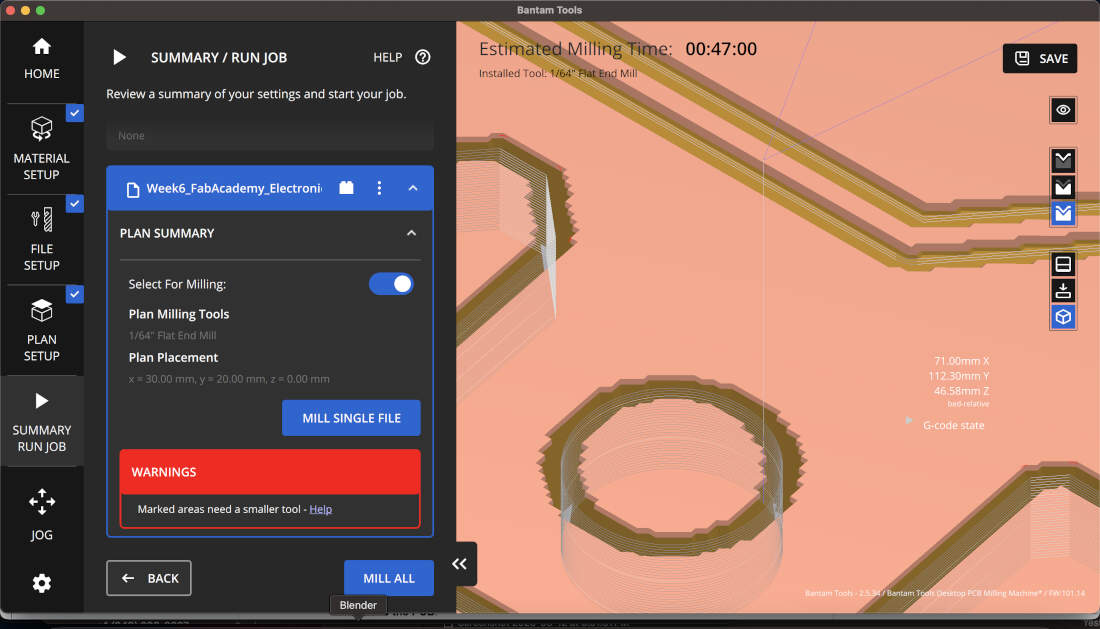

- When the G-code is generated, the software simulates your design and warns you if traces are too close together to prevent shorts or if there are other errors in your design.

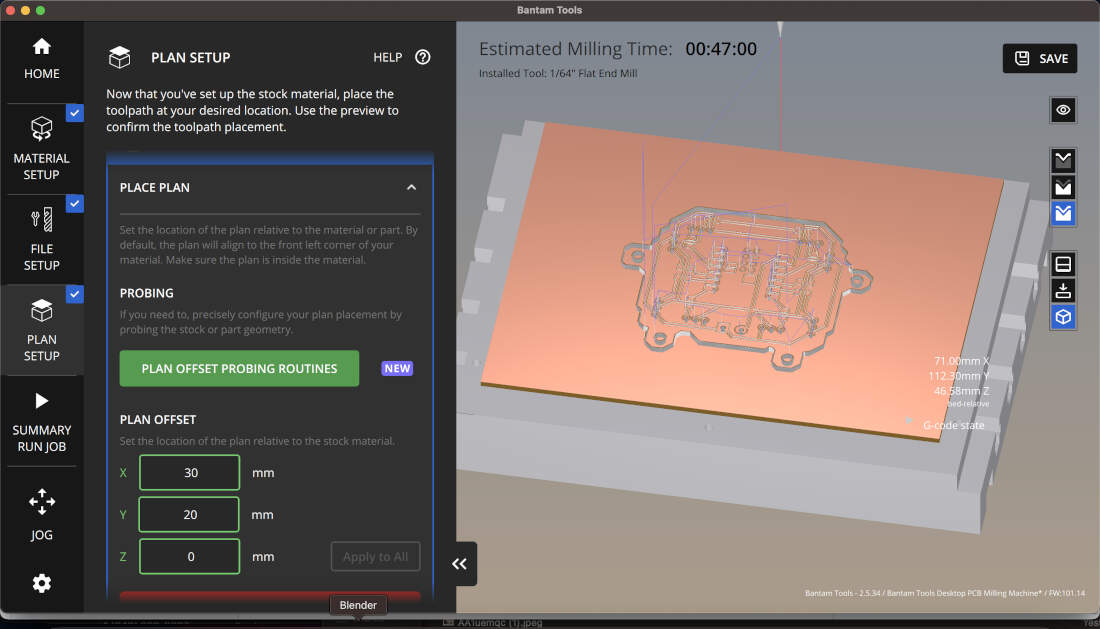

- After the file set-up you only need to offset your design so you can mill it where you choose to. Don’t inefficiently mill it out in the middle of the board like in the visual. That is just for show but if milled out there it would be a waste of material.

- Once you're satisfied with the settings, you can send the board to the mill. If you receive warnings like those shown above, they may indicate legitimate design flaws that need correction. However, in some cases, they are superficial, occurring because the CNC cannot create sharp angles and instead fillets them.

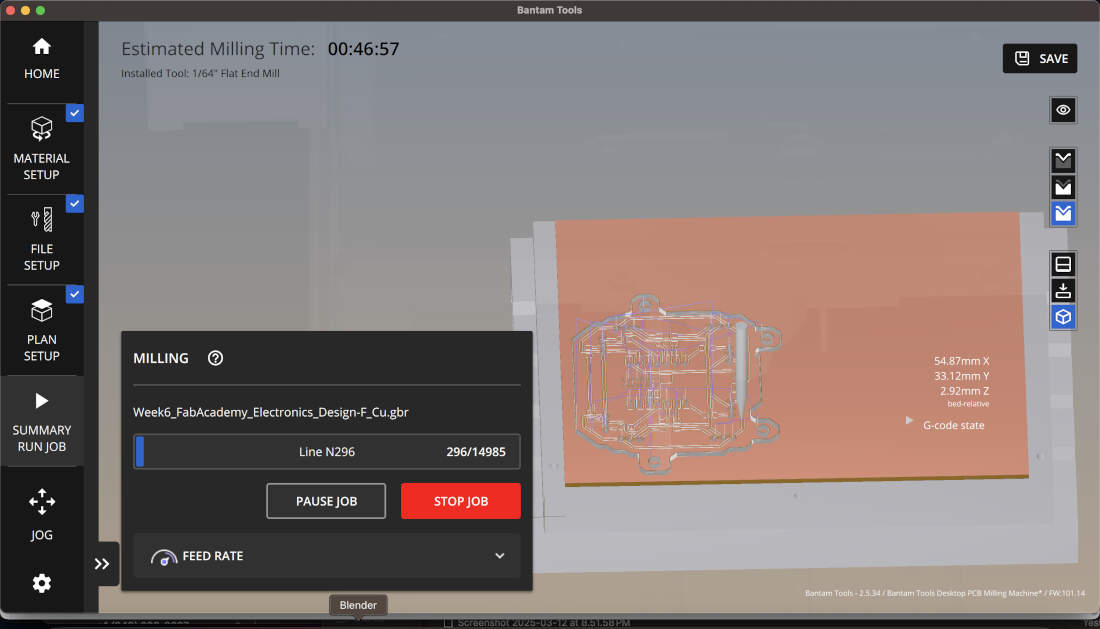

- Monitor the board, ensure there is a proper cut depth, pause to adjust if necessary, and when done, inspect the traces to ensure they are fully and properly cut with shard edges. If needed, and if the board has remained in the same position as before, you can do a second pass at deeper settings.

-Remove the PCB from the mill plate upon job completion. Pry it upwards with a flat tool and avoid bending or cracking the board, it is very delicate. Wipe the PCB with isopropyl alcohol to remove debris, and a fine bristle brush also helps.

- Using a multimeter to check that traces are correctly isolated is a good move. Shorts, if any are present, can be fixed with a knife or fine sandpaper.

Board House Submission Process

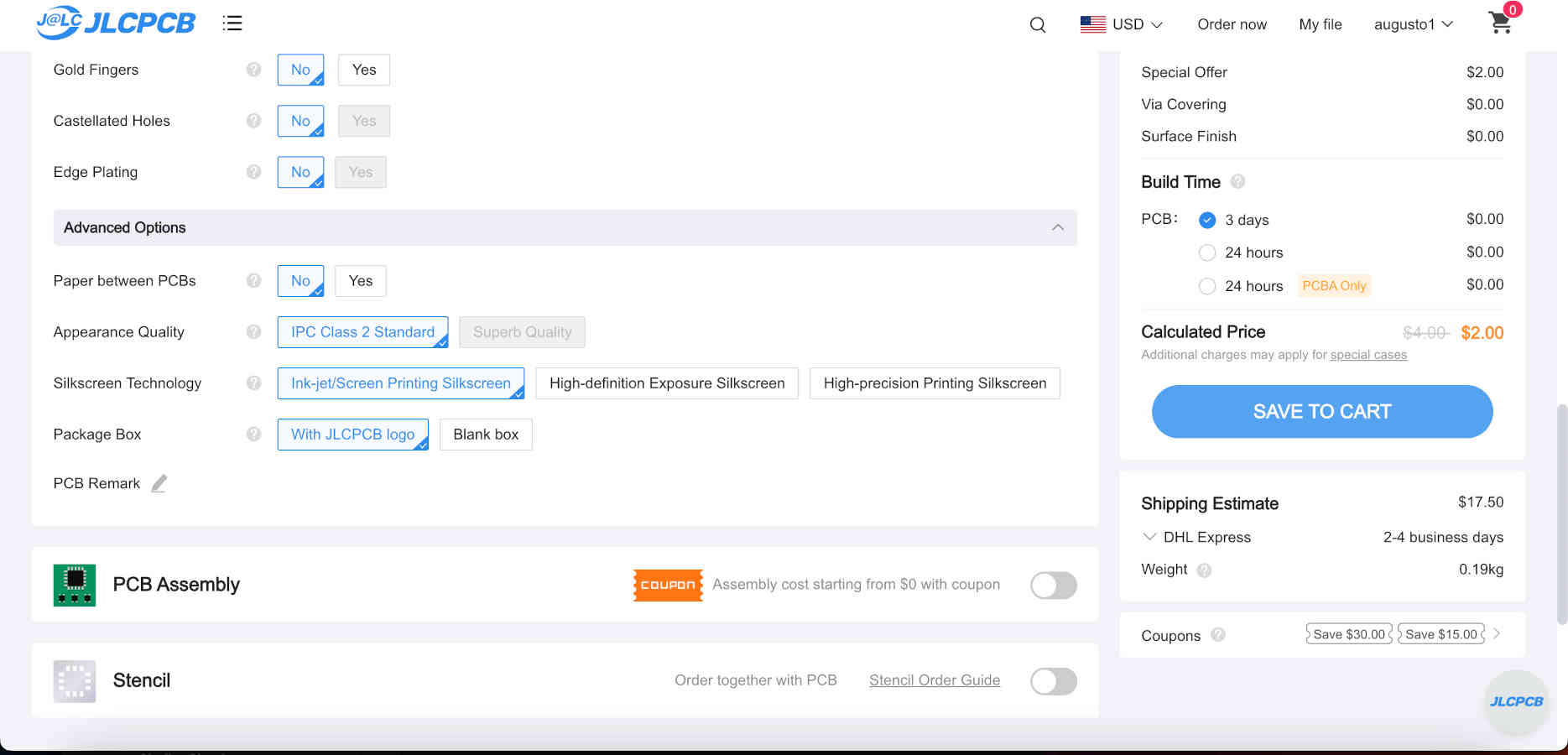

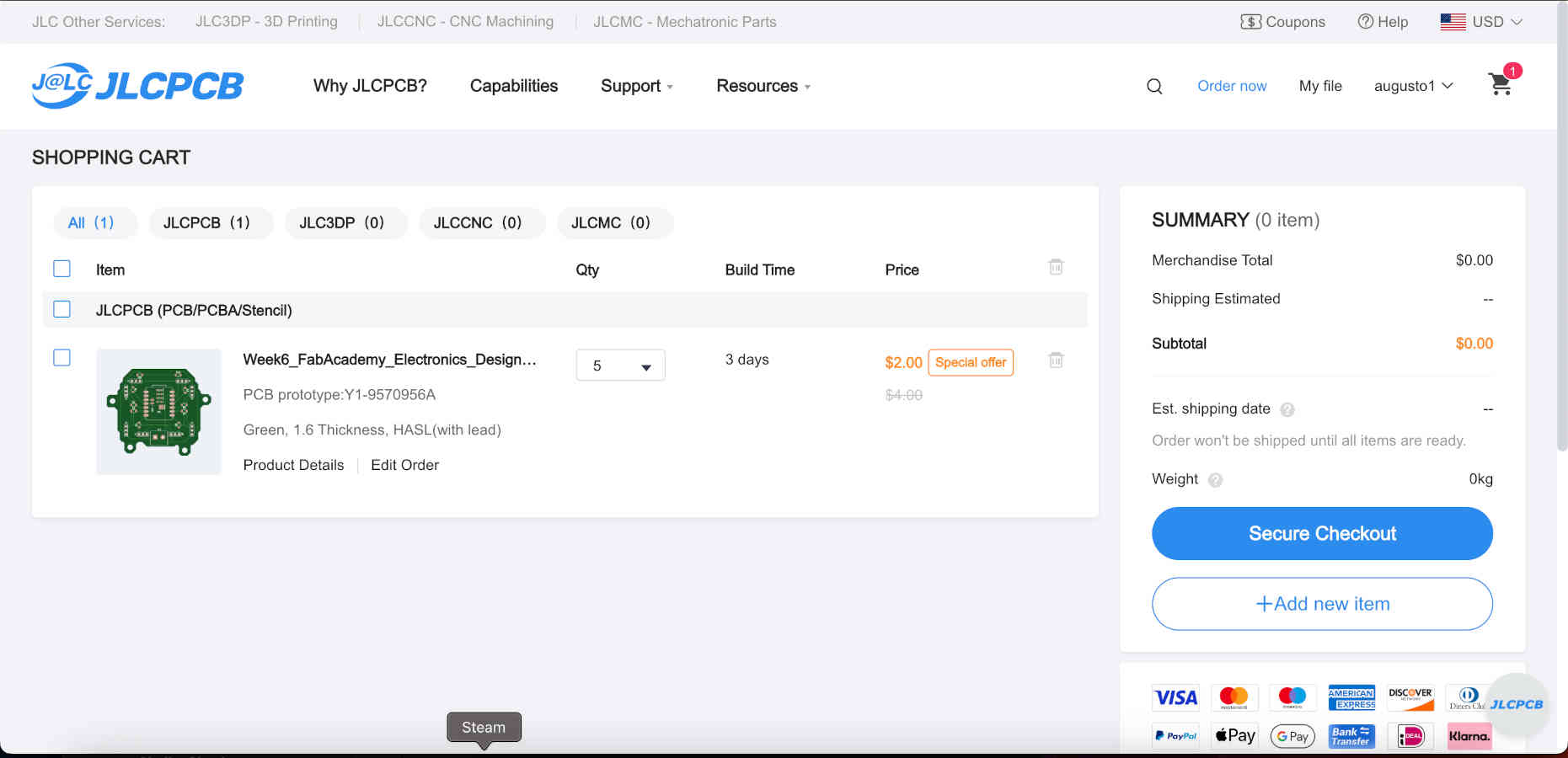

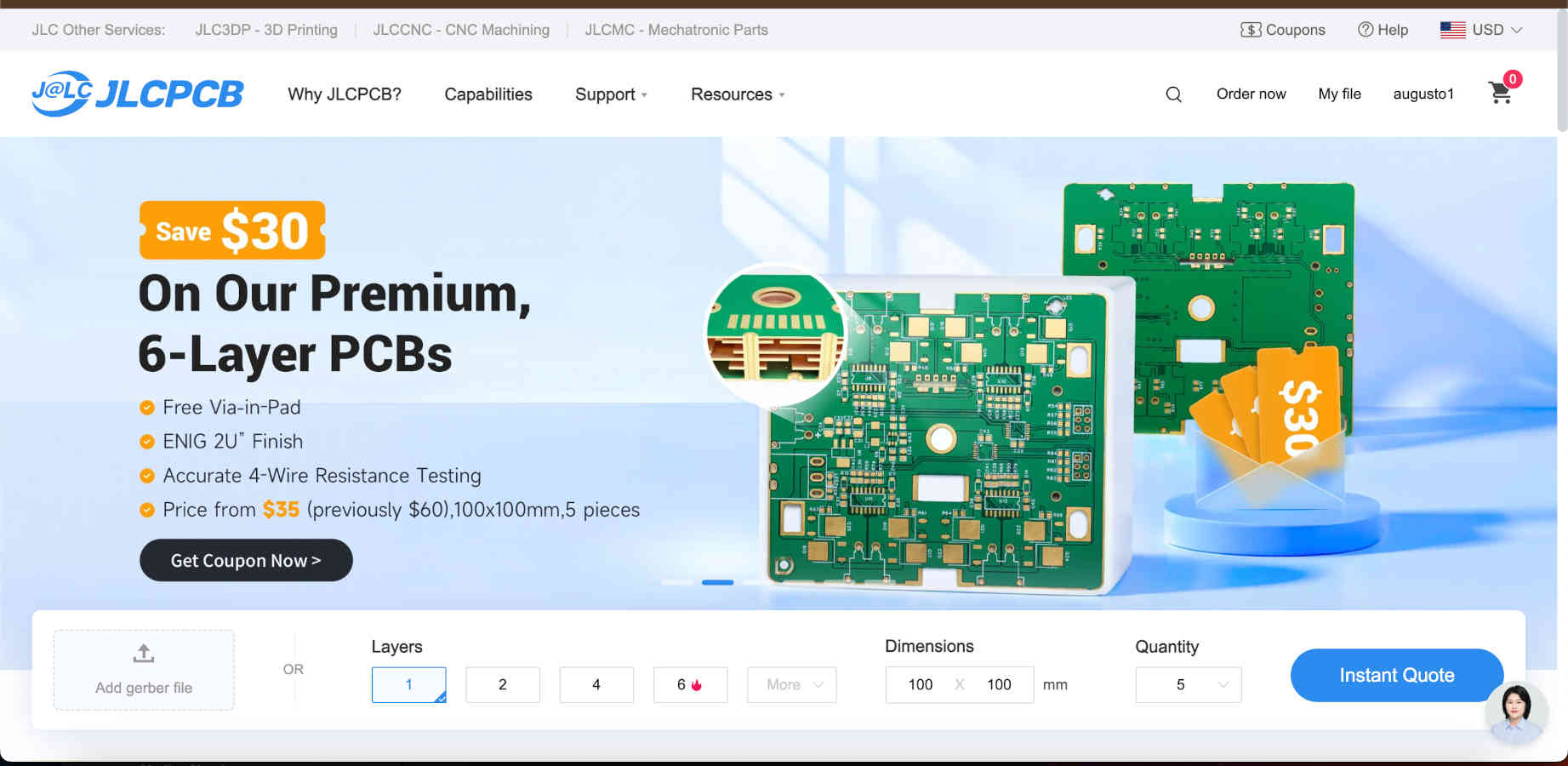

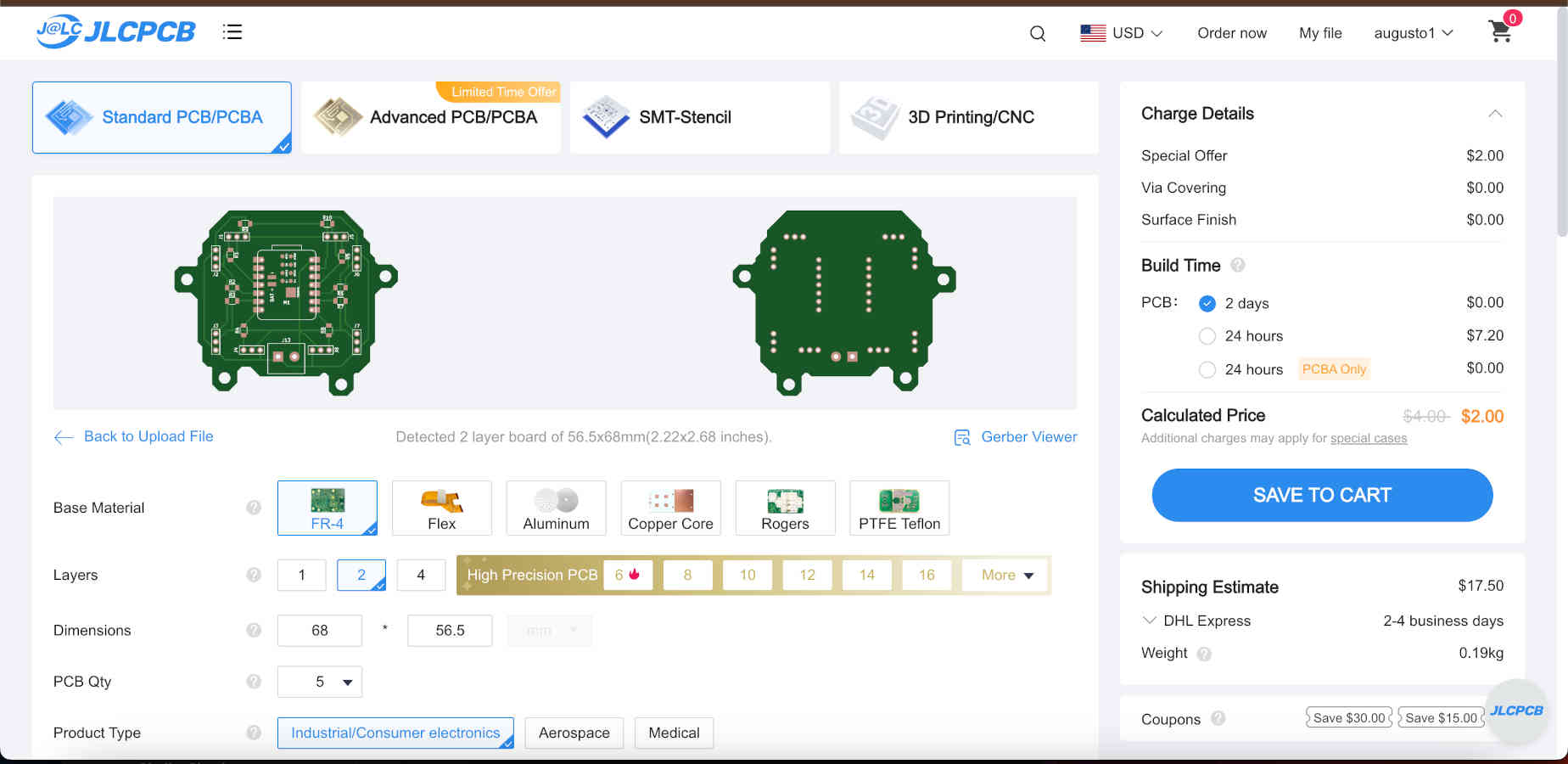

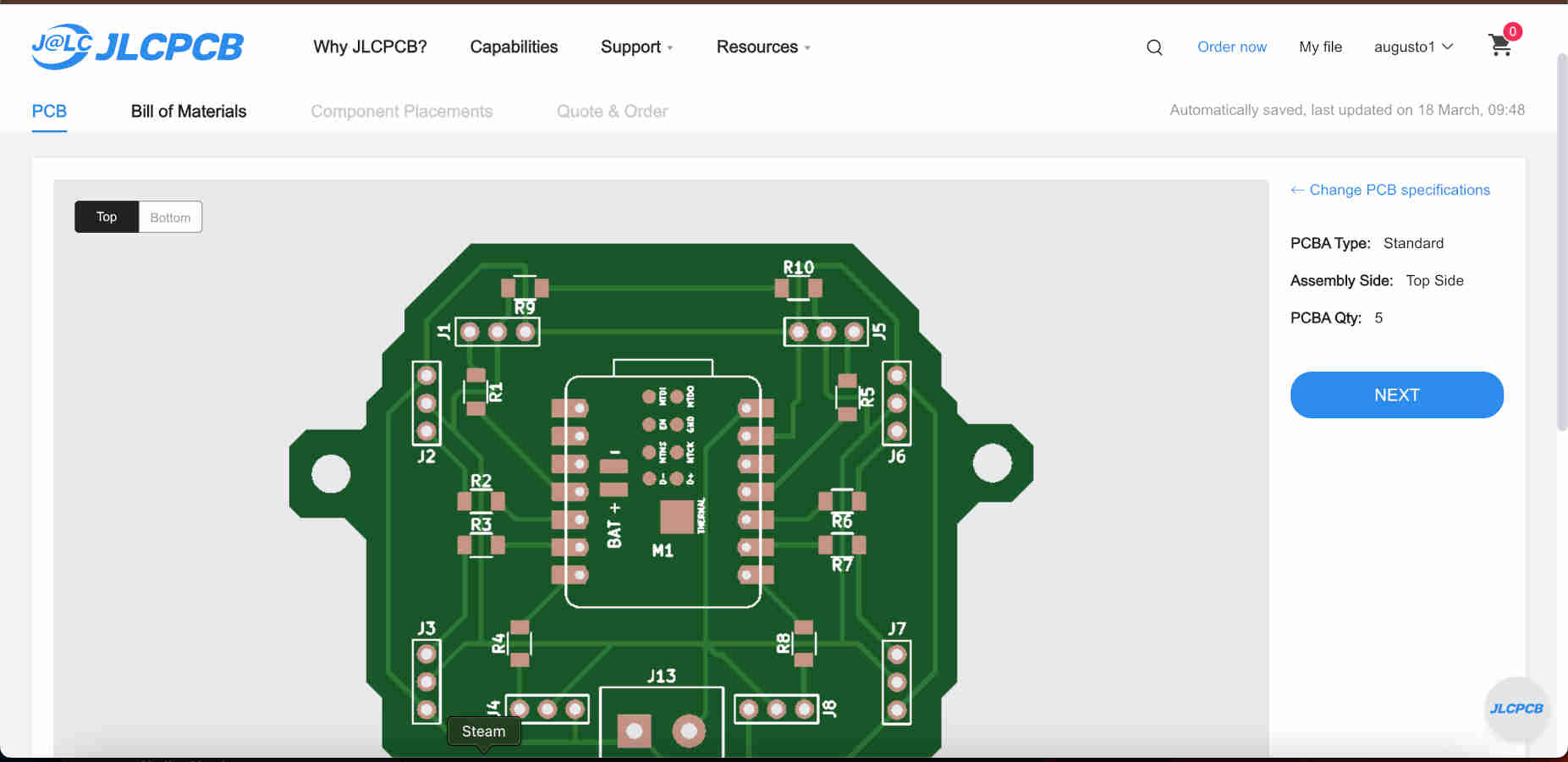

The board house we chose was JLCPCB. Based on some reviews we’ve read it seems like a rather reputable website with a user friendly interface. It was really simple right off the bat. We chose to get started with a quote by uploading a zip folder with our gerber files and selecting the 1 layer PCB option.

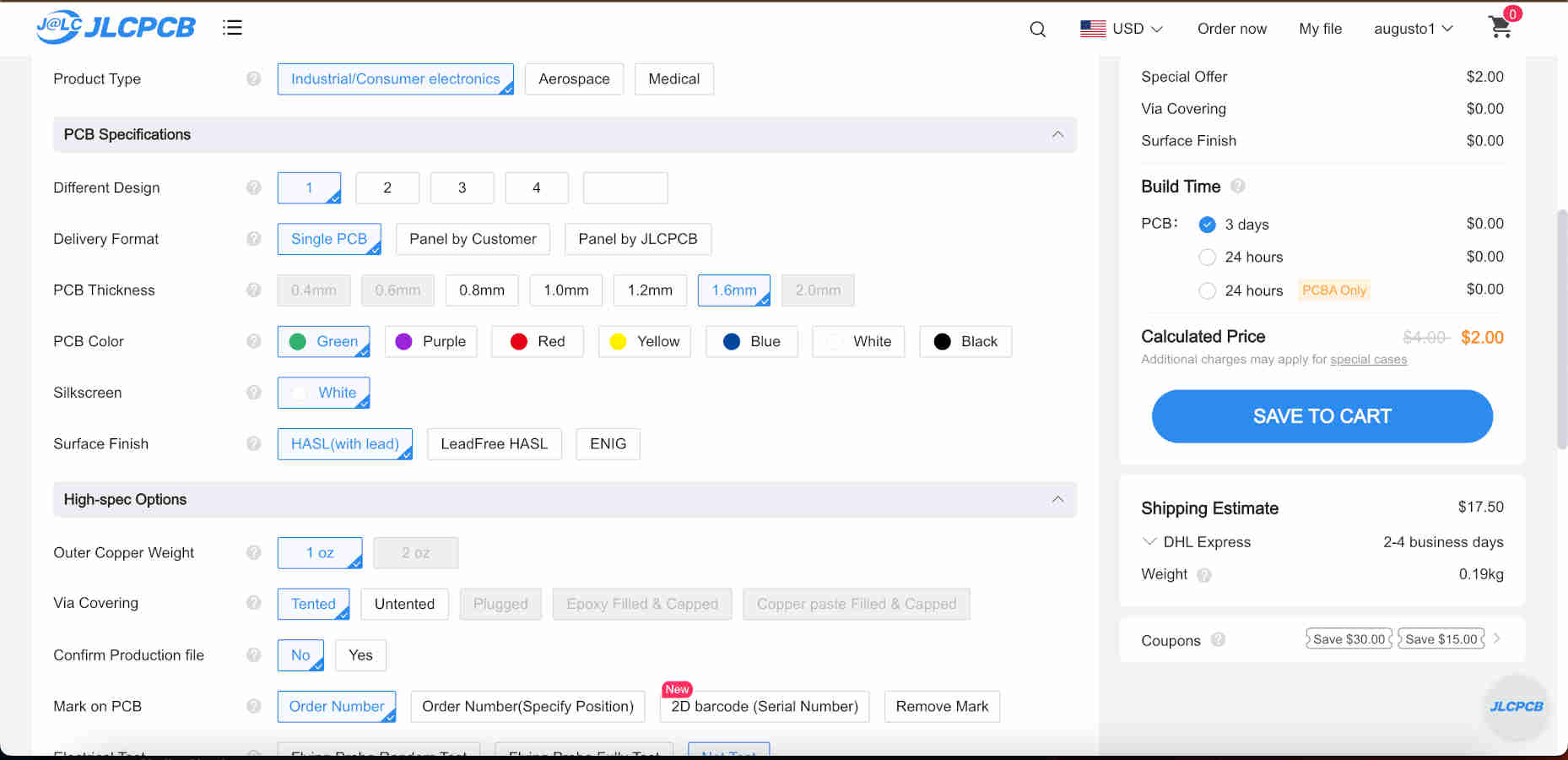

The interface was really easy to navigate and all we had to do was switch over to a 1 layer PCB option again. Everything else was left on the default options. JLCPCB automatically calculates the dimensions of your board based on the files uploaded. I can alter the board thickness if needed and I can change the color of the PCB for an upcharge.

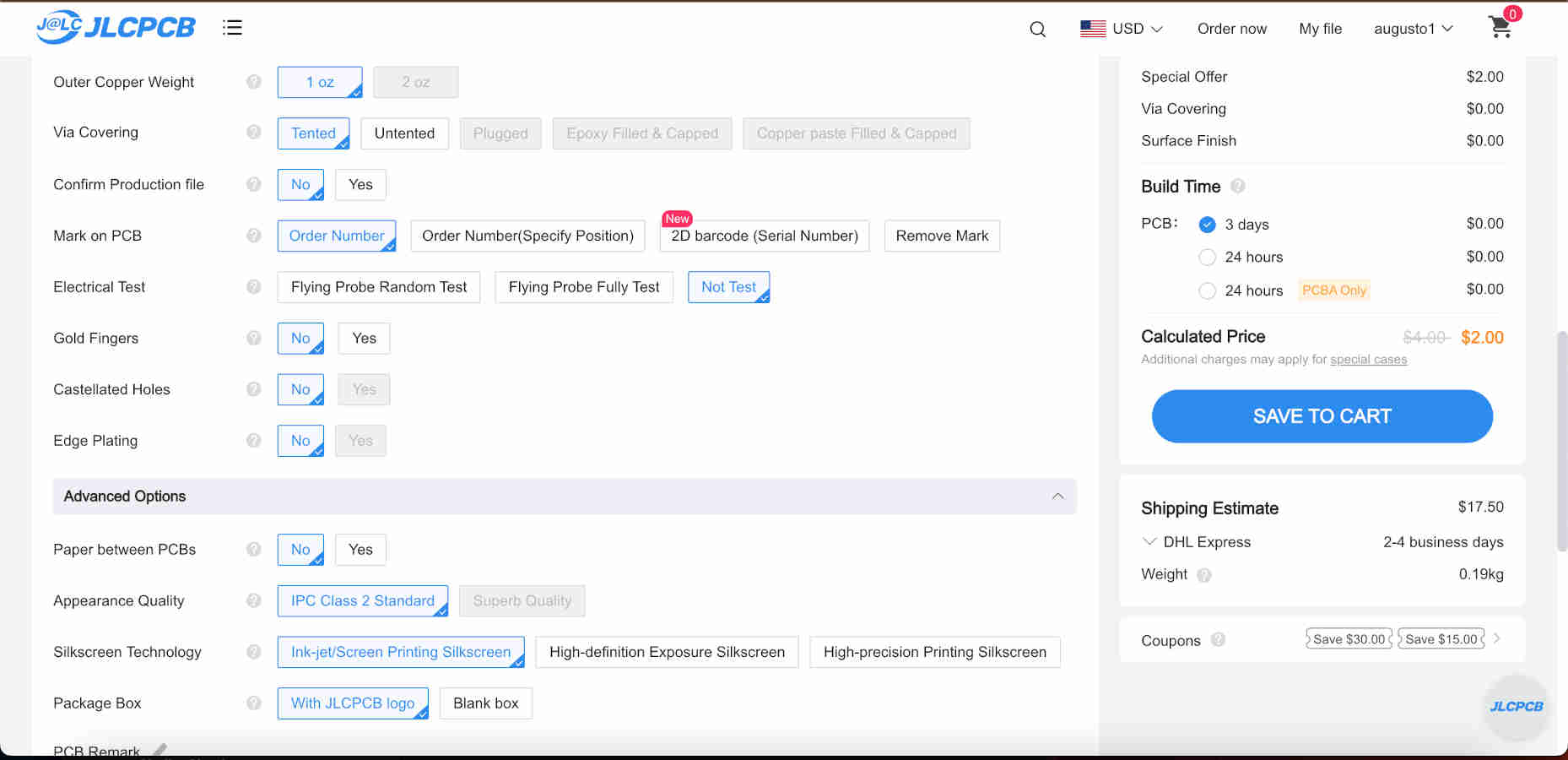

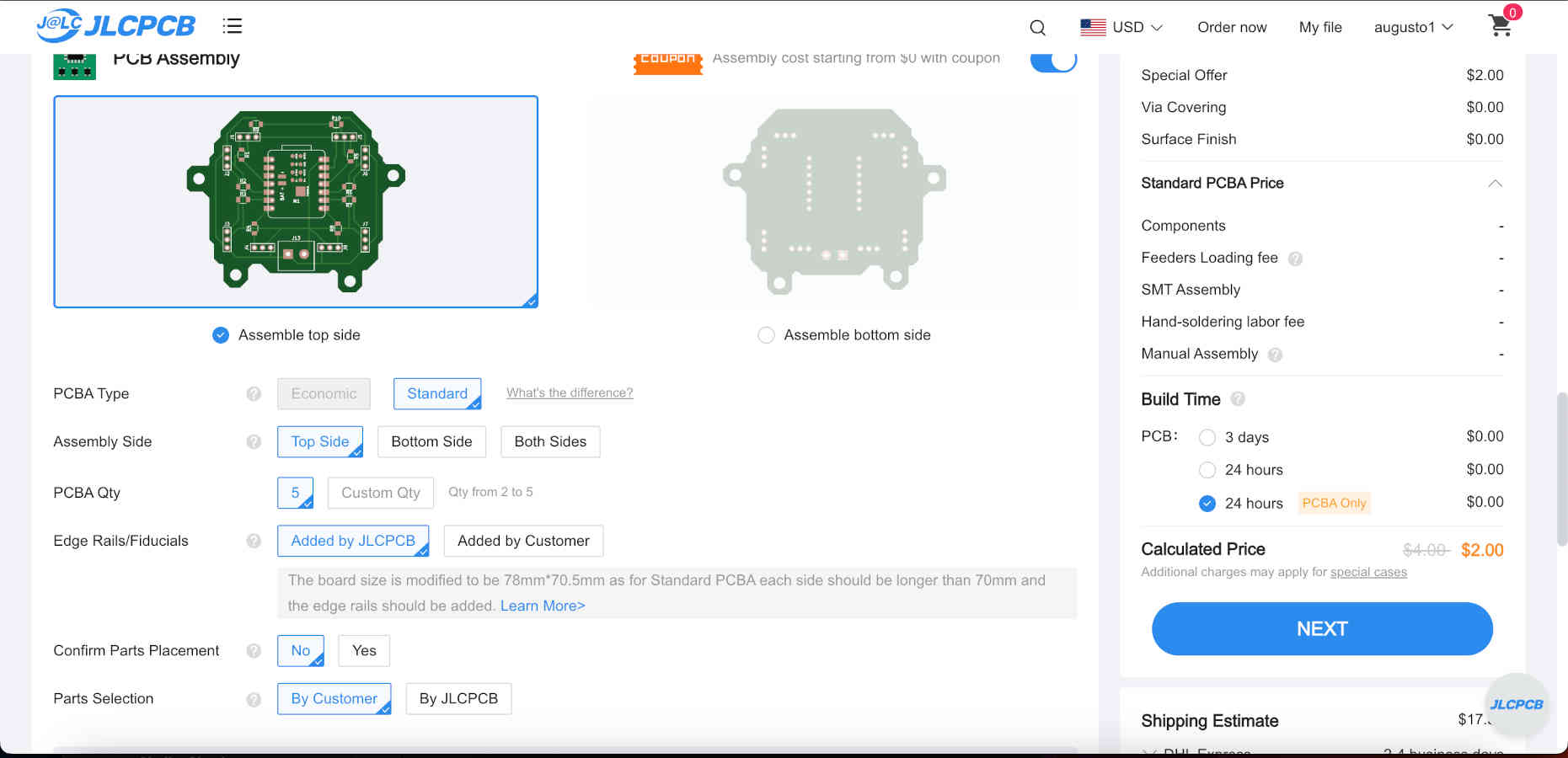

I can also request that my PCB gets assembled based on the components library that JLCPCB may have available at the given moment. Either the top or bottom sides can be assembled with the options chosen. If assembly is chosen, you’d have to secure a Bill of Materials and information regarding the designation and component position so that the manufacturer can properly source your parts and assemble them in the correct locations.

Once you’re satisfied with all the options selected, you can save your order to your cart and then secure your checkout. You’d proceed with inputting all your card and address information and finalize the transaction as you usually do everywhere else.