Mechanical Design

Back to HomeGoals

group assignment

(part 1 of 2)

- Design a machine that includes mechanism + actuation + automation + application

- Build the mechanical parts and operate it manually

- Document the group project

(part 2 of 2)

- Actuate and automate your machine

- Document the group project

Individual Assignment

(part 1 of 2)

- Document your individual contribution

(part 2 of 2)

- Document your individual contribution

Group Assignment

Project Overview

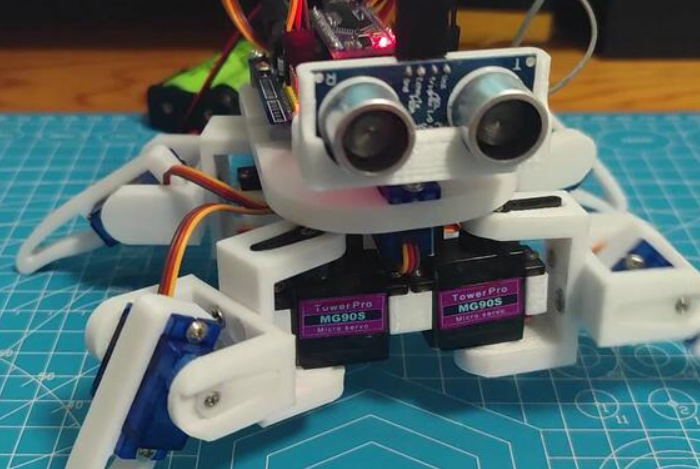

In the 12th week of Fab Academy’s “Mechanical Design” assignment, we were tasked with designing and building a machine that includes a mechanism, actuation, automation, and application. According to the assignment requirements, the first phase focuses on structural design and manual operation. Based on my interests and skills, I decided to design and fabricate a desktop quadruped robot.

Although I was unable to form a team with current Fab Academy classmates due to personal reasons, I took the initiative to invite my friend Harvey Pan to collaborate on this task. He is currently studying mechanical engineering and plans to join Fab Academy next year. In our collaboration, I was mainly responsible for design, modeling, 3D printing, and structural assembly, while he focused on motion mechanism design and mechanical calculations.

1. Project Inspiration and Background

While determining the project topic, we referred to a variety of open-source robotics projects and industrial design cases, including Boston Dynamics’ Spot biomimetic robot, global Arduino Quadruped projects, and my personal preference for “biomechanical aesthetics.”

We chose a quadruped robot as our design goal for the following reasons:

- It represents a typical motion mechanism in biomimetic robotics, offering both challenge and feasibility;

- Servo motor control is relatively intuitive, making it suitable for rapid testing of structure and actuation;

- A desktop-sized robot is easier to fabricate, debug, and demonstrate, and can be expanded into a more complex platform in the future;

- As a product design student, I found the integration of appearance and structure particularly suitable for my skillset.

2. Team Background and Collaboration Method

| Name | Academic Background | Main Responsibilities |

|---|---|---|

| Lynch Li (myself) | Industrial Product Design | Project topic proposal, early concept and sketches, structural design, 3D printing, assembly, spatial layout of electronics |

| Harvey Pan | Mechanical Engineering | Kinematic analysis, servo arrangement logic, leg DOF design, SolidWorks modeling and technical evaluation |

We adopted a remote collaboration method: online sketching, voice discussions, file sharing, and local fabrication. We communicated via Tencent Meeting, WeChat, and shared documents, revising the leg joint layout four times before finalizing a 2 DOF per leg design.

3. Design Goals and Function Plan

✅ This Week (Phase 1: Mechanical Design):

- Complete conceptual design, preliminary modeling, and servo layout logic;

- Implement 2 DOF per leg (hip and knee);

- 3D print all mechanical parts and complete full assembly;

- Ensure servo bracket structures are stable and reliable;

- Conduct mechanical testing without powering up the electronics.

🔁 Future Plans (Phase 2: Automation and Application):

- Use an appropriate microcontroller to control all servos;

- Design basic gait control program for forward/backward movement;

- Integrate Bluetooth or WiFi module for remote control;

4. Design Process in Detail

1. Concept and Sketching Phase

We started by discussing multiple design options through hand-drawn sketches, focusing on the following questions:

- Should each leg have 1 degree of freedom (1 DOF) or 2 degrees of freedom (2 DOF)?

- Should servos be concentrated in the torso or distributed across the legs?

- How can we maintain balance and center of gravity?

- How can parts balance strength with printability?

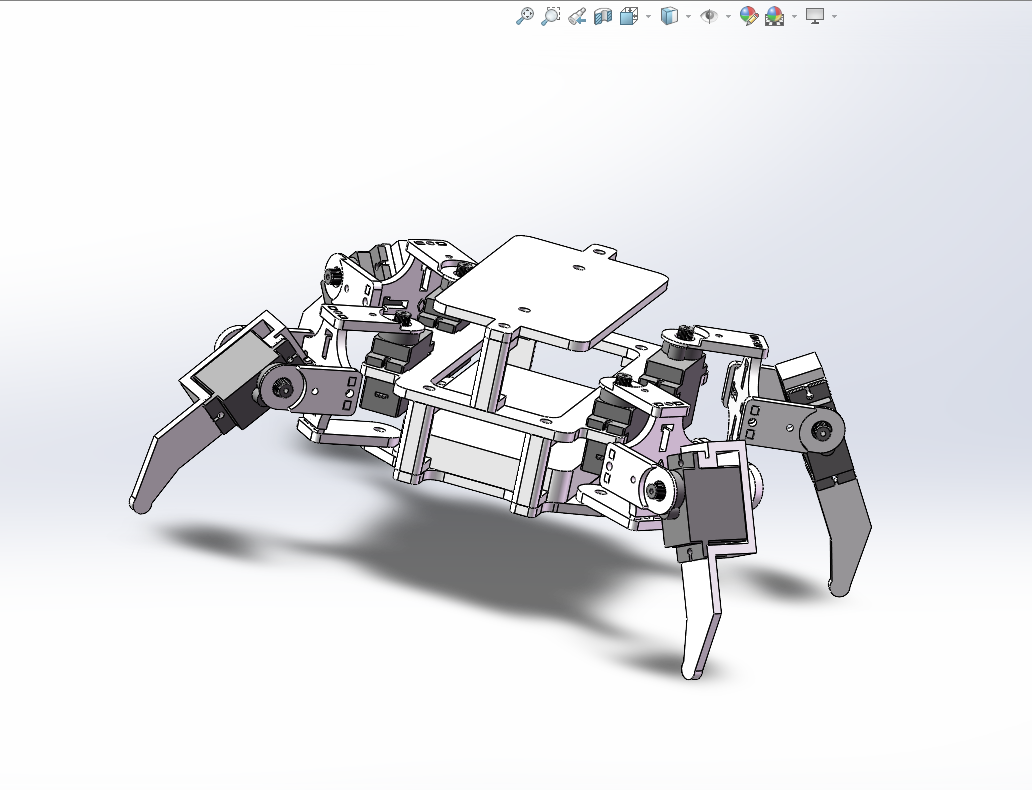

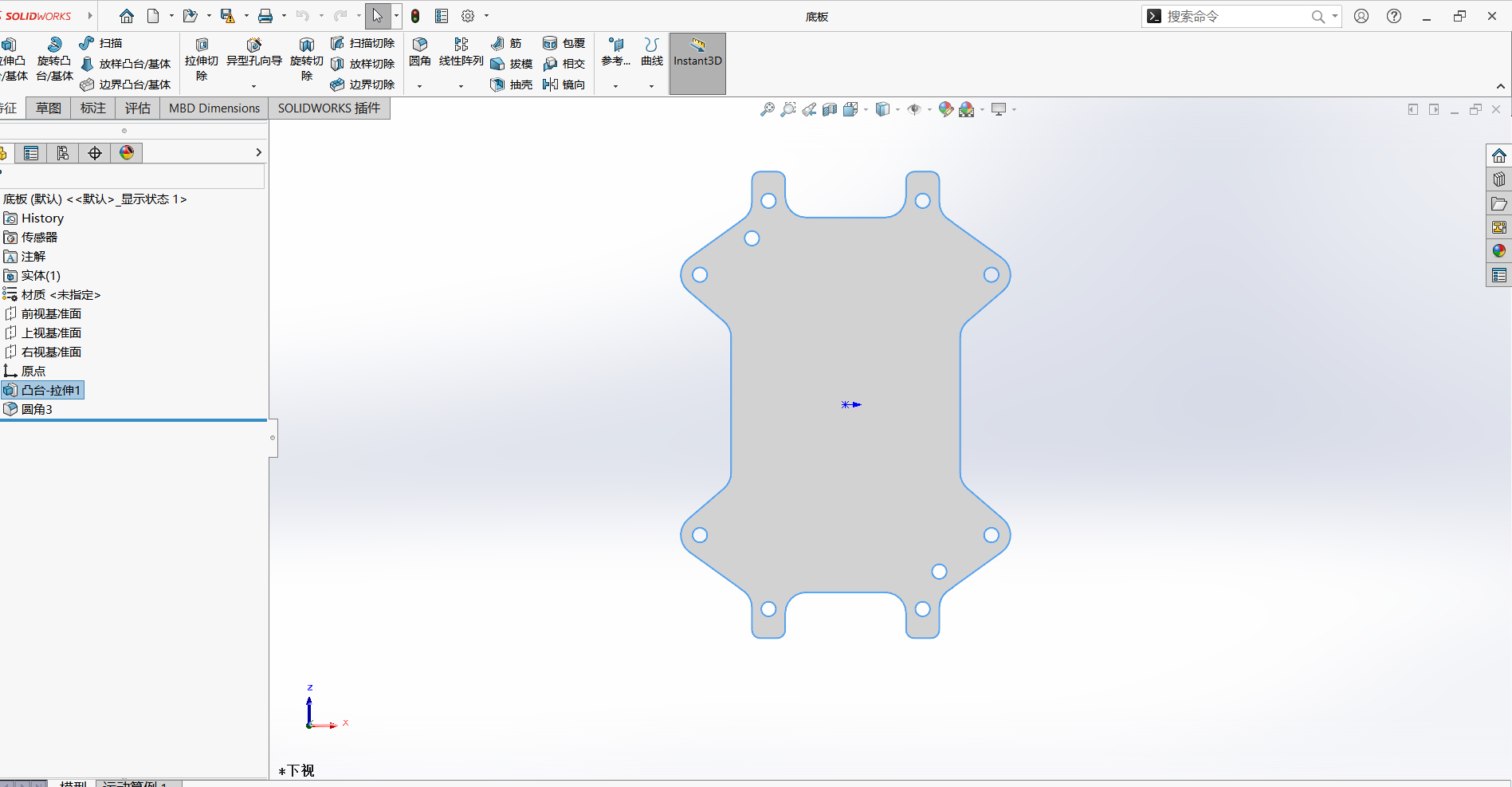

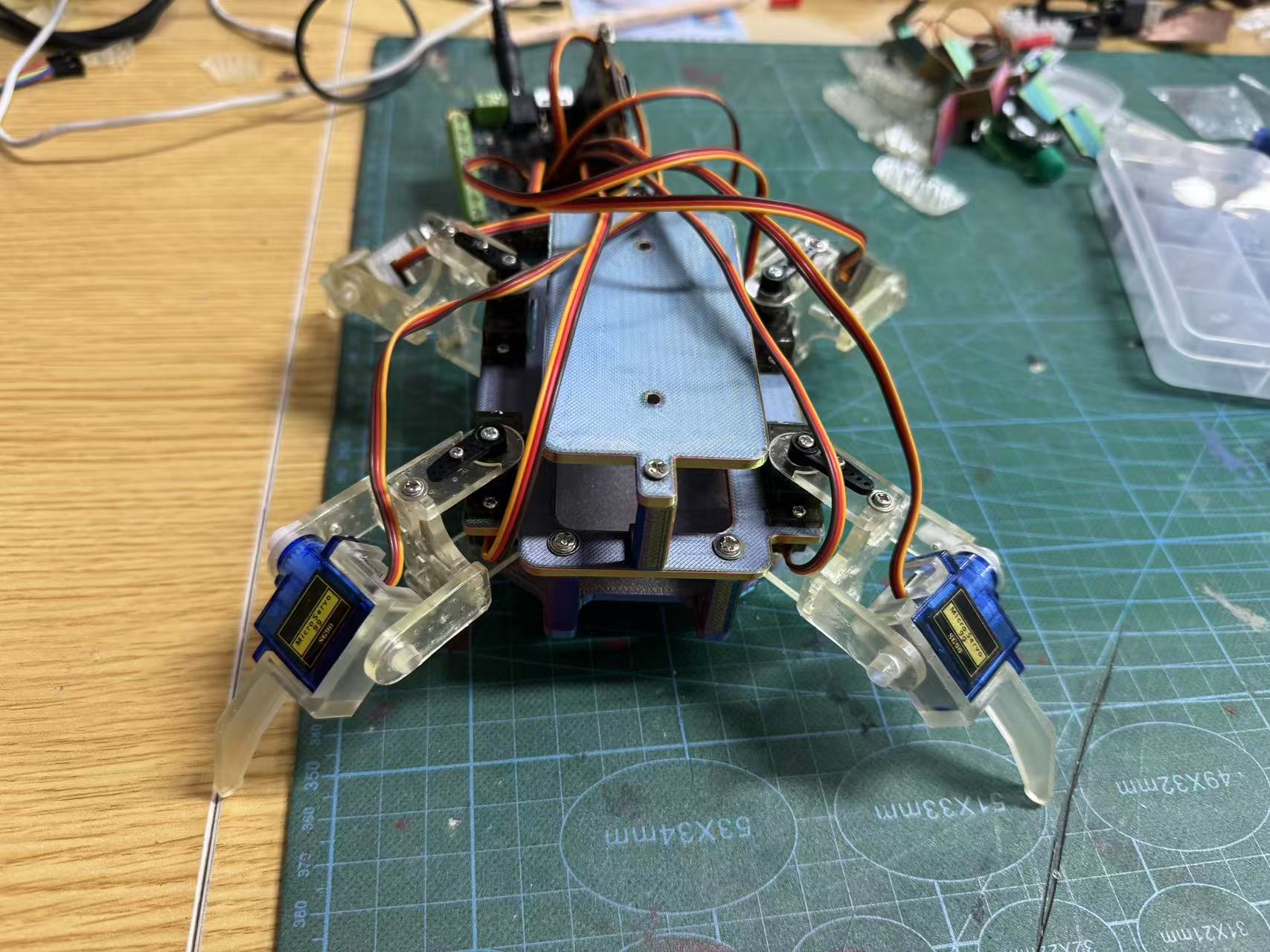

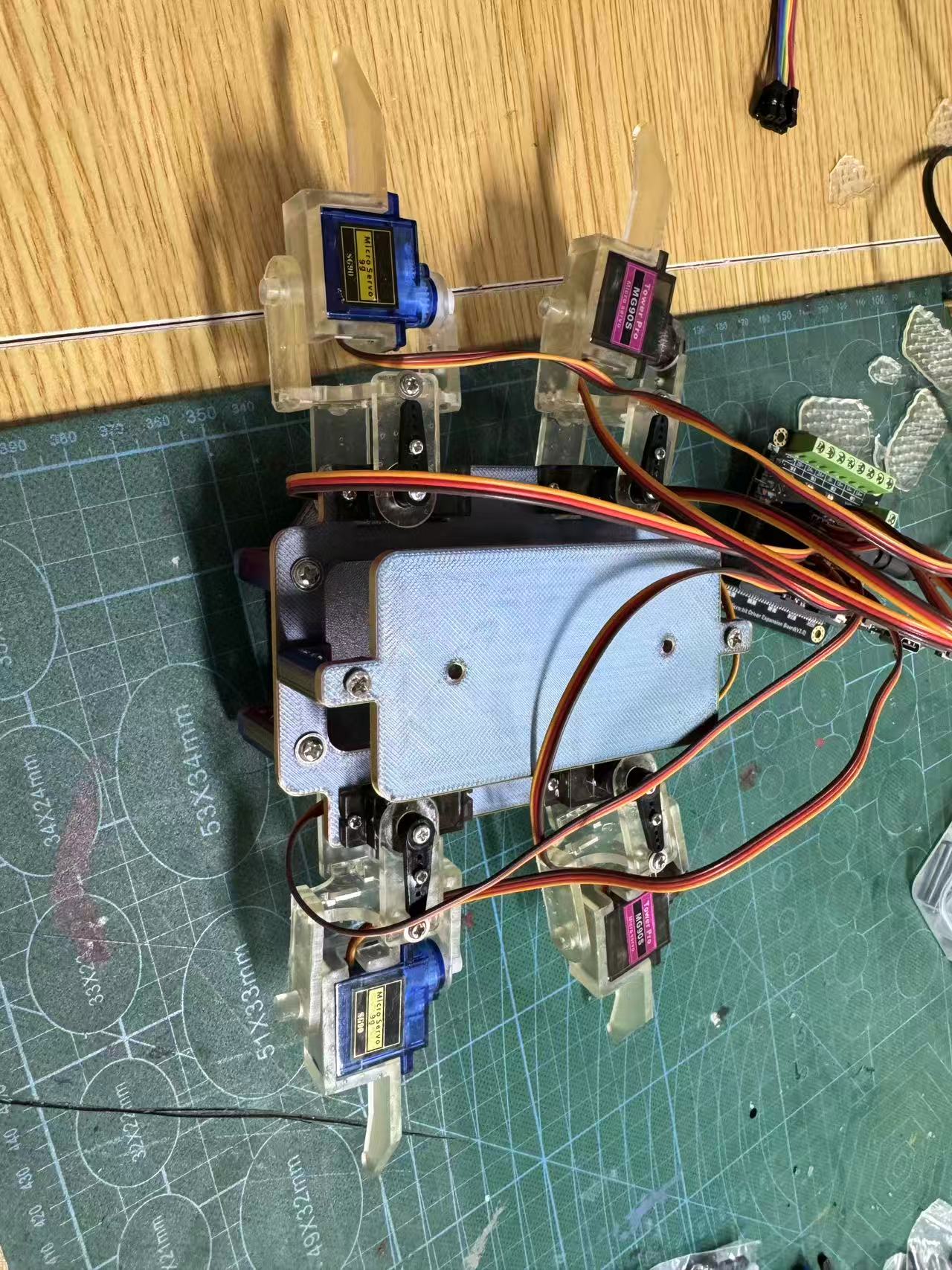

We finally decided on a 2 DOF quadruped structure, with each leg driven by two SG90 servos—one controlling the hip joint (horizontal swing) and the other controlling the knee joint (vertical lift). Harvey took charge of translating these sketches into SolidWorks models, continuously checking with me on the manufacturability of the appearance and structure.

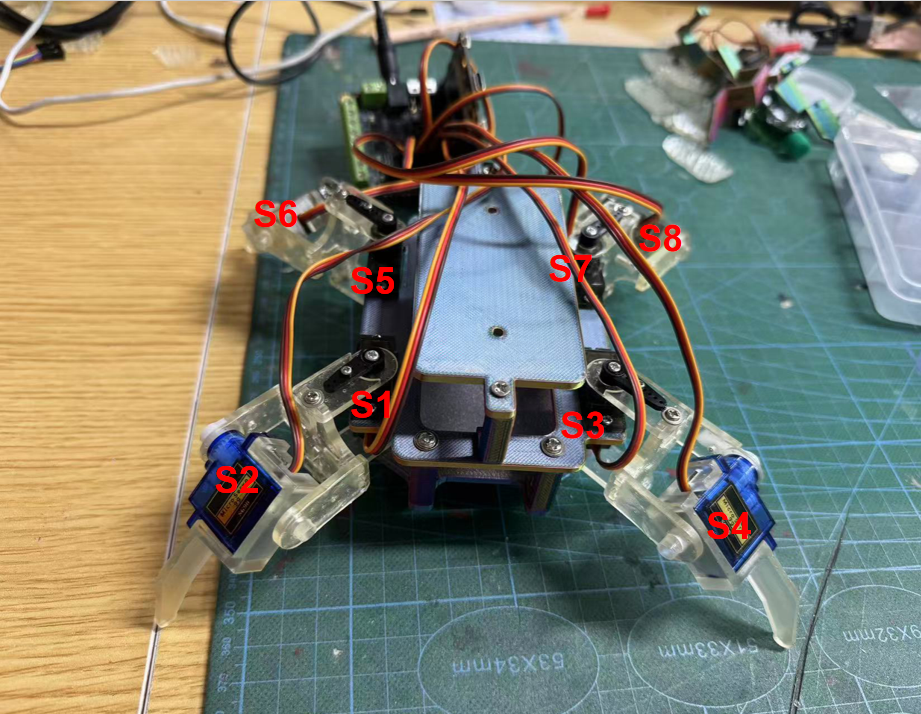

2. Servo Layout and Numbering Definition

| Servo ID | Position | Controlled Joint |

|---|---|---|

| S1 | Left front knee | Leg lift |

| S2 | Left front hip | Horizontal swing |

| S3 | Right front knee | Leg lift |

| S4 | Right front hip | Horizontal swing |

| S5 | Left rear knee | Leg lift |

| S6 | Left rear hip | Horizontal swing |

| S7 | Right rear knee | Leg lift |

| S8 | Right rear hip | Horizontal swing |

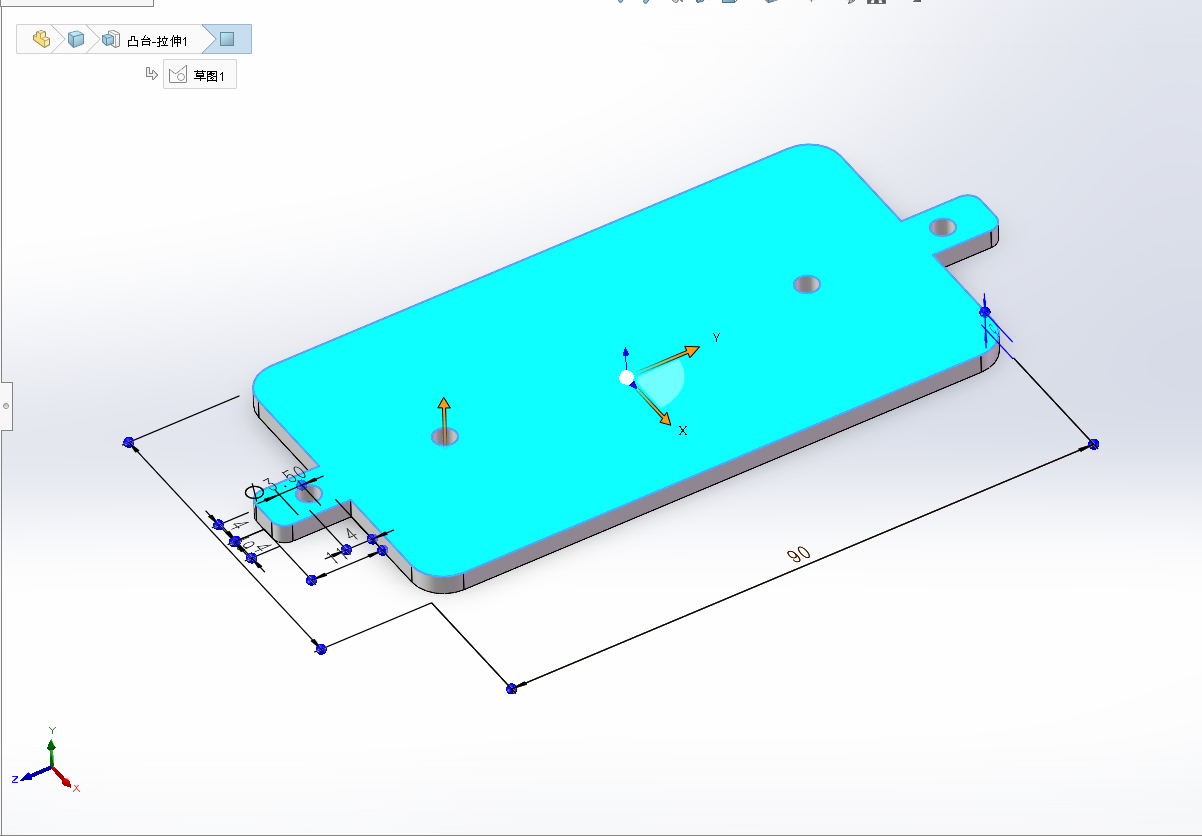

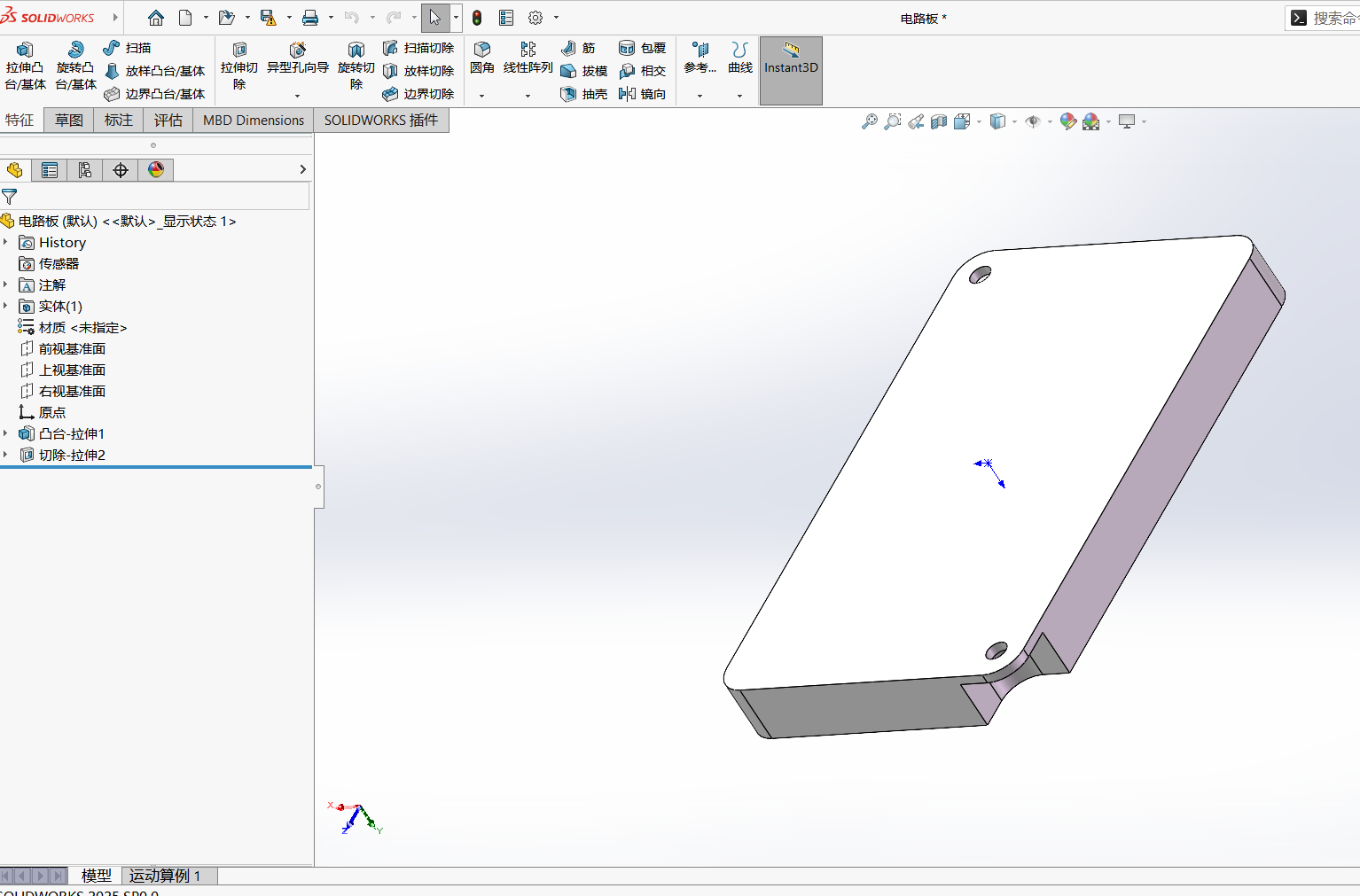

4. Fabrication and Iteration of Mechanical Parts (Led by Me)

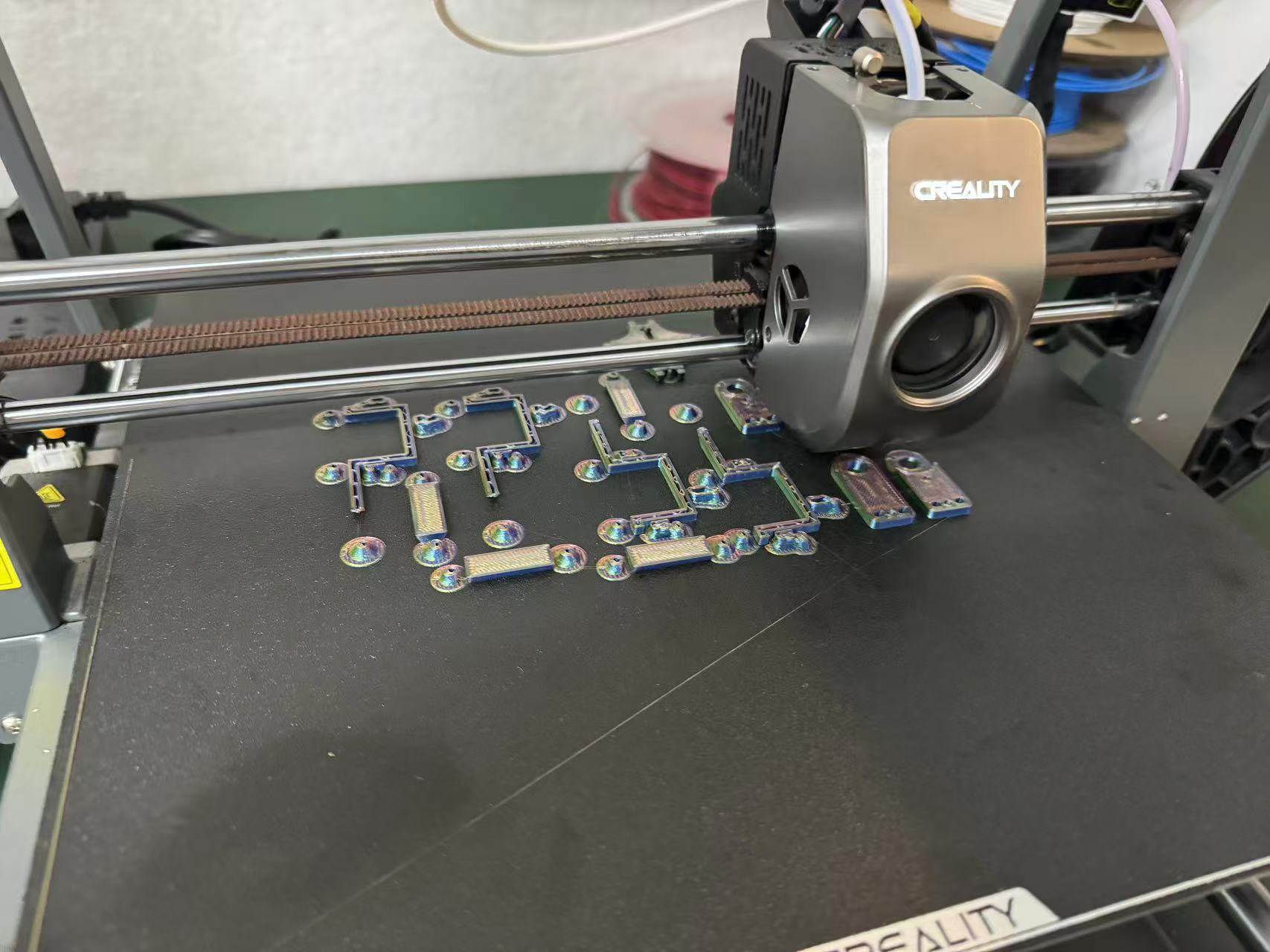

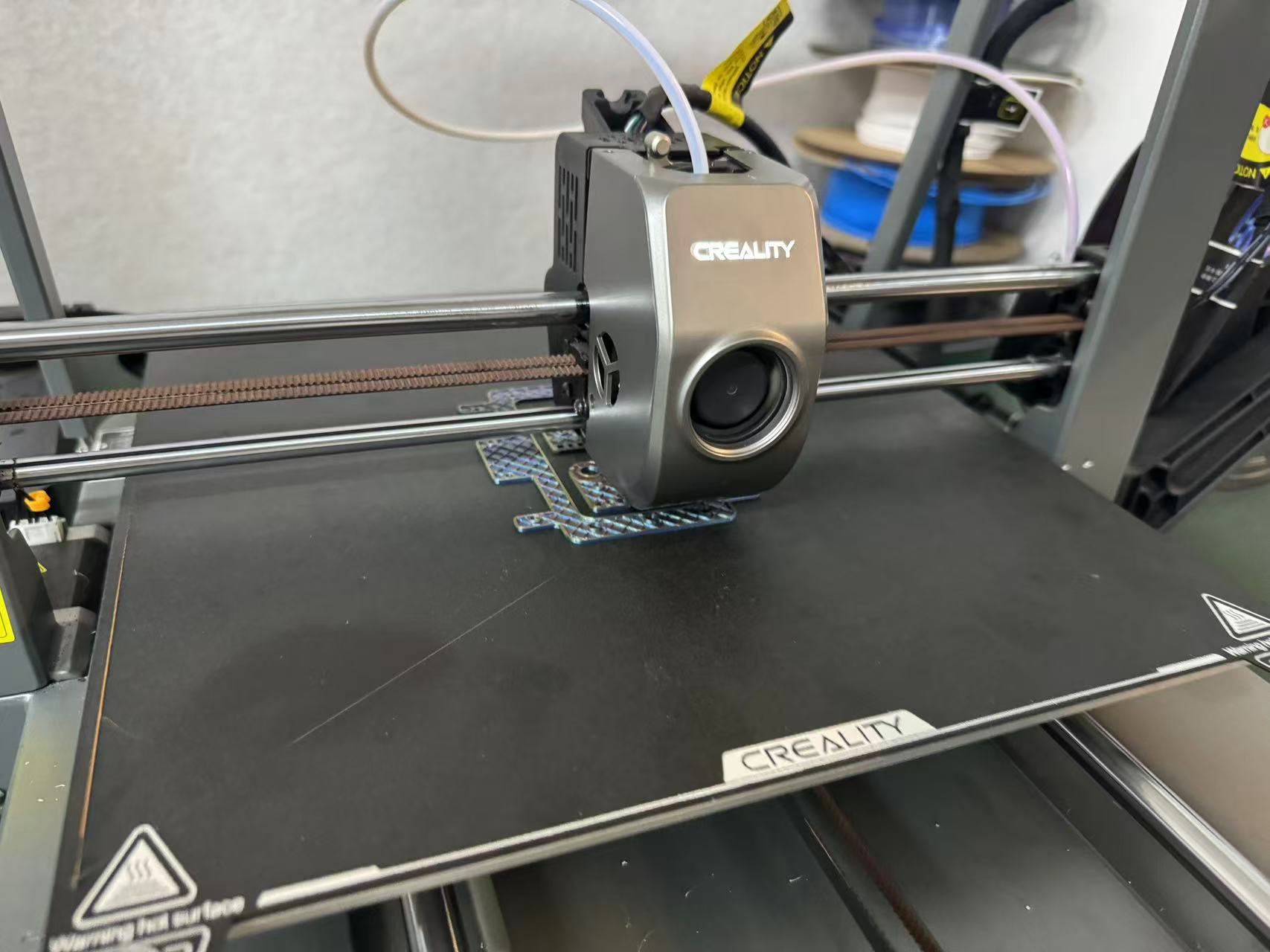

1. Initial Part Printing (FDM Printing)

I initially used the lab’s FDM 3D printer to print all parts, including:

- The central body shell

- Four legs (upper and lower segments)

- Servo mounting brackets

- Joint plates for the mechanical claws

However, during assembly testing, I encountered a serious issue: the dimensional tolerance of the FDM prints was too large, especially the servo mounting holes. The connection plates for the claws could either not fit at all or were too loose in the horizontal and vertical directions.

I tried the following adjustments:

- Modified hole dimensions in the model

- Reduced print speed to improve accuracy

- Switched to a finer nozzle

Despite these attempts, the print precision still failed to meet the requirements of the mechanical structure.

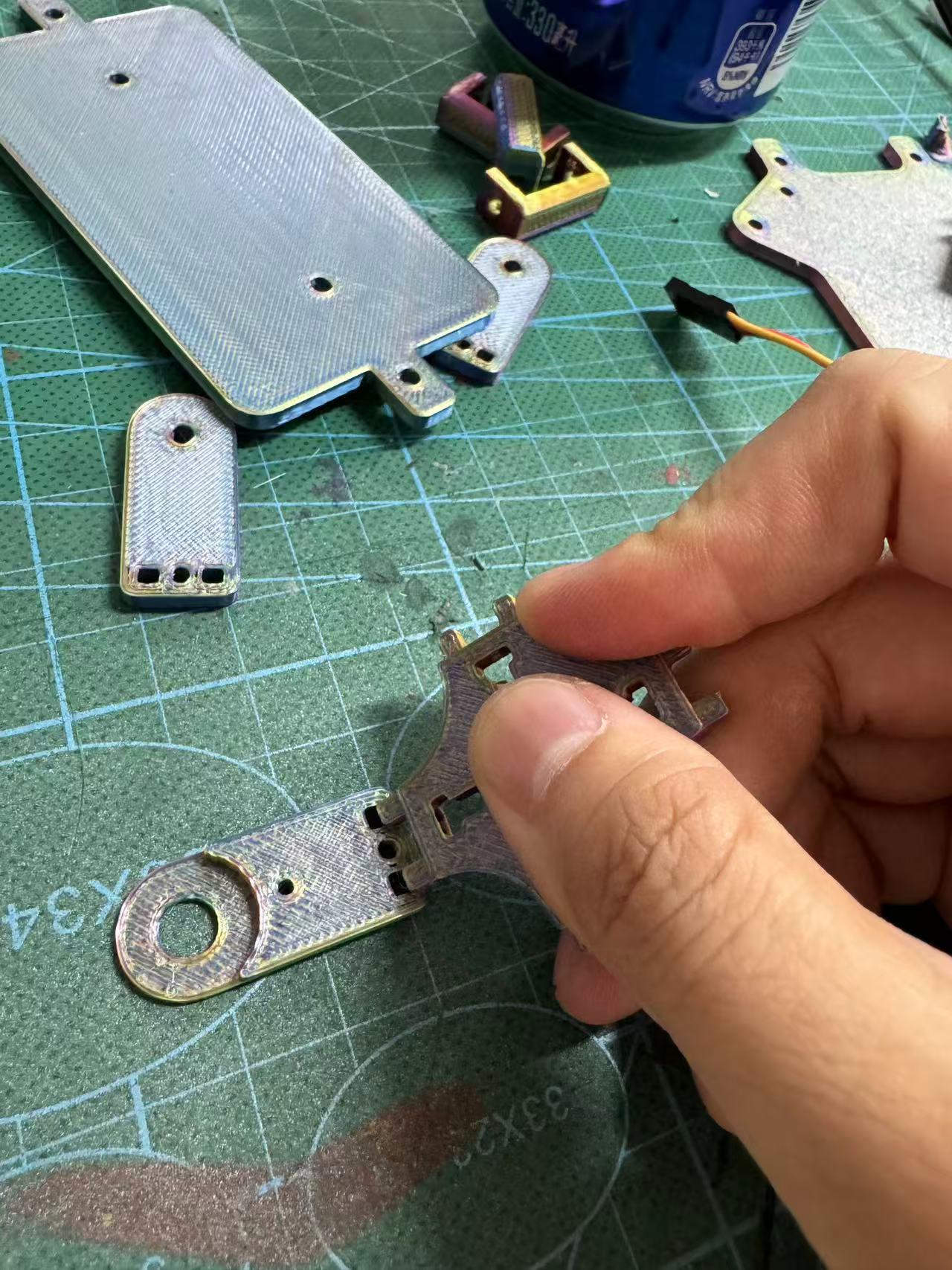

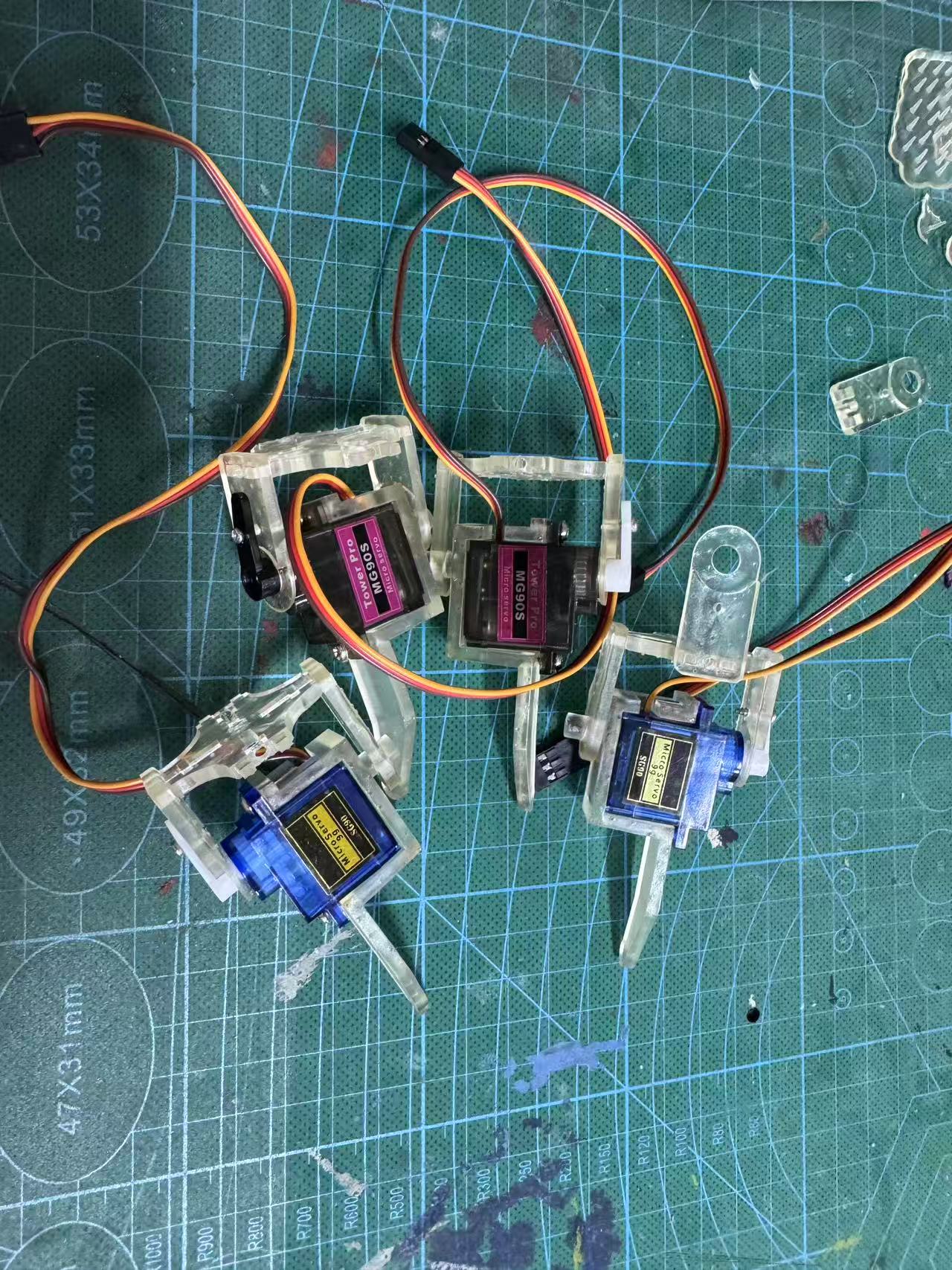

2. Precision Parts Switched to SLA Printing

Eventually, I switched all mechanical claw components—i.e., parts requiring high-precision fit with servos—to SLA resin printing. Details are as follows:

- Used an LCD-type SLA printer

- Material: standard gray photopolymer resin

- Layer height: 0.05 mm

- Print time: about 6 hours

- Post-processing: cleaned with IPA, then UV-cured

The results were very satisfying: extremely high print accuracy, perfect snap-fit, smooth surface with no layer lines, and tight, seamless assembly.

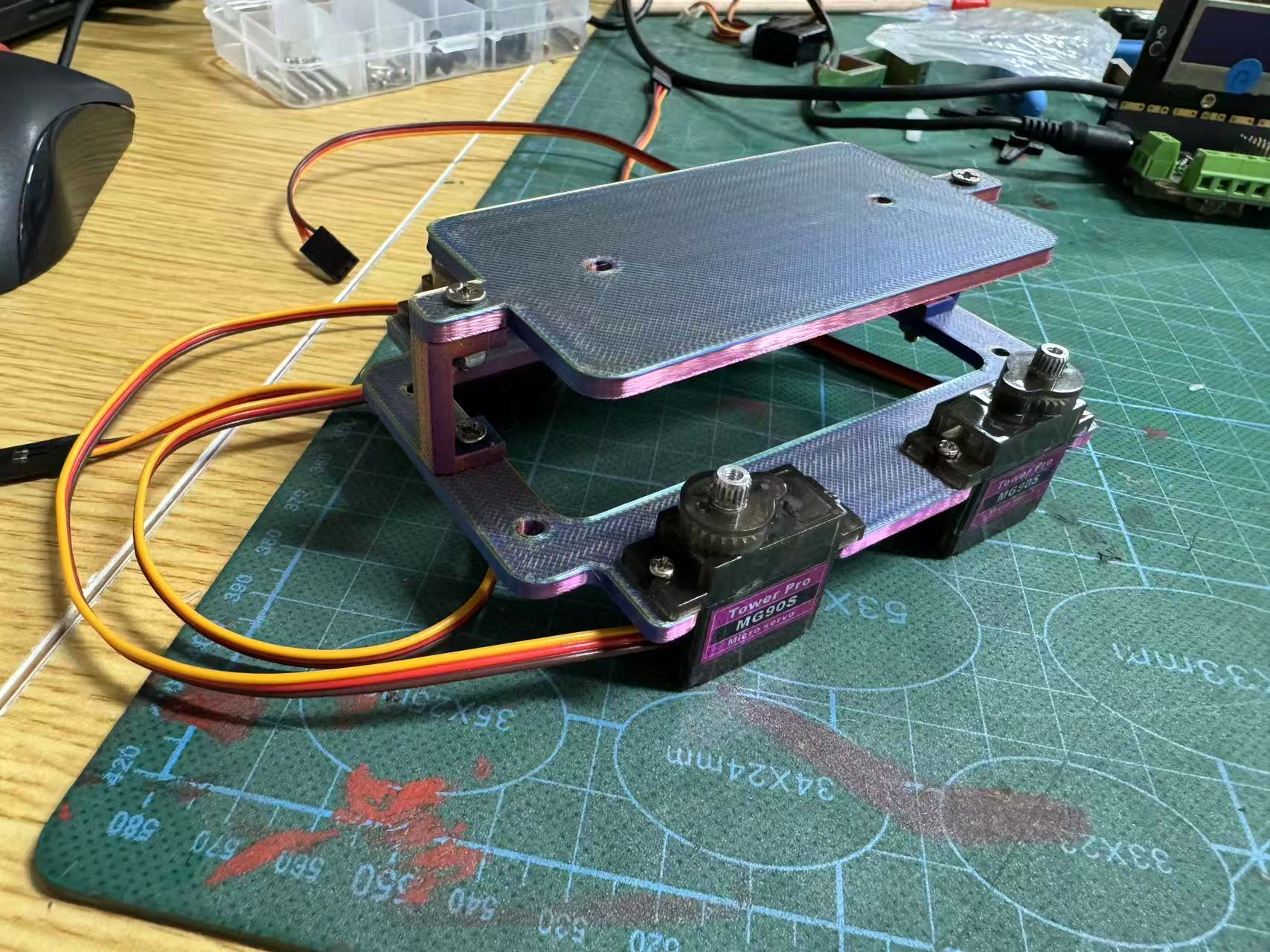

3. Central Structure and Leg Assembly

I completed the assembly of all parts and ensured the following:

- Each servo could be mounted easily and rotate within the required angle range

- Servo cables could be routed cleanly without affecting movement

- All four legs could stand stably in the initial pose, with a centered center of gravity

Part 2: Automation and Application

1. Control System Architecture Selection

After completing the structural assembly and standing stability test, I moved on to the second phase of the quadruped robot project: making the structure move and implementing basic motion logic through automated control.

1.1. Control Platform Selection and Rationale

For this phase, I chose the following setup:

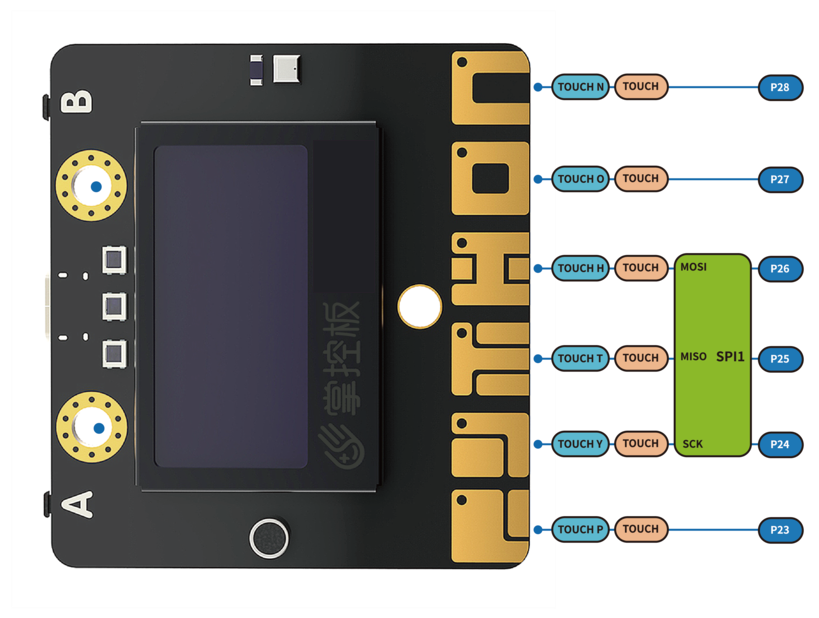

- Main controller: Handpy board

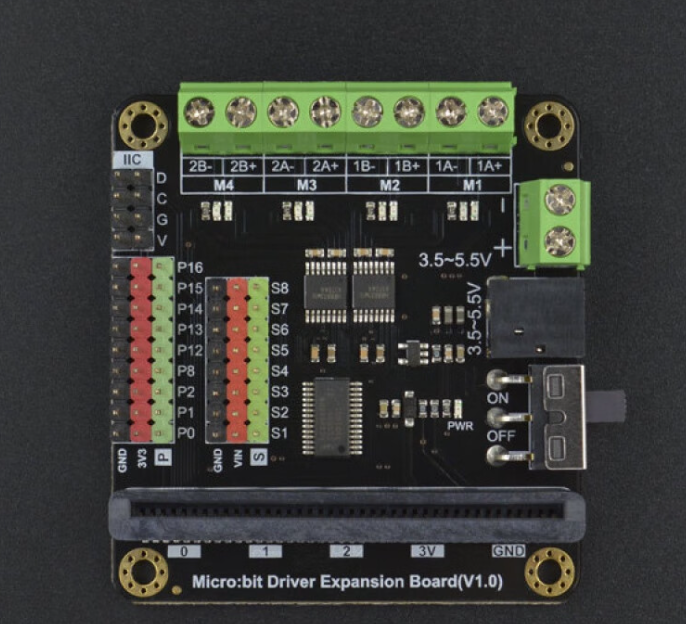

- Expansion board: DFRobot motor expansion board (based on PCA9685 chip)

- Servos: 8 x SG90

- Programming environment: Mind+ (Arduino mode, with

Microbit_Motor1control library support)

Reasons for selection:

- The Handpy board is widely used in education and comes with built-in Wi-Fi, making it convenient for future remote control applications.

- The DFRobot motor expansion board requires no manual I2C configuration—plug-and-play functionality.

- The Microbit_Motor1 library provides a simplified

servo(Sn, angle)command for servo control, making the logic easier to implement. - Mind+ supports both graphical and C++ dual-mode programming, which helps with program debugging and structured code management.

2. Servo Numbering and Body Mapping

The servo numbering scheme was defined during the structural design phase. The details are as follows (referencing the top-down structural diagram):

| Servo ID | Controlled Part | Function |

|---|---|---|

| S1 | Left front knee | Leg lift |

| S2 | Left front hip | Forward swing |

| S3 | Right front knee | Leg lift |

| S4 | Right front hip | Forward swing |

| S5 | Left rear knee | Leg lift |

| S6 | Left rear hip | Forward swing |

| S7 | Right rear knee | Leg lift |

| S8 | Right rear hip | Forward swing |

I adopted a layout in which even-numbered servos control knee joints (vertical lift) and odd-numbered servos control hip joints (horizontal swing). This mapping makes it easier to organize and program motion sequences.

3. Motion Logic Design Process

1. Initial Program Structure

I began by creating the following function structure:

DF_Initial_state(): Set all servos to 90° neutral positionDF_Standing(): Set legs into a crouched standing pose (preparation for gait)DF_Lying_down(): Simulate a lying/squatting postureDF_Move_forward_action_X(): Define four-frame forward walking sequence: A ~ D

These motion functions control each servo individually using esp.servo(Sn, angle).

2. Basic Gait Unit Design

Referring to diagonal gait patterns in real quadrupeds, I defined a full cycle as:

A → B → C → D → (loop)

| Frame | Core Motion Description |

|---|---|

| A | Lift left front + right rear leg → swing |

| B | Legs land and push forward |

| C | Lift right front + left rear leg → swing |

| D | Legs land and complete forward propulsion |

4. Code Implementation & Function Breakdown

1. DF_Initial_state(): Servo Initialization

void DF_Initial_state() {

esp.servo(S1, 90); // Left front knee

esp.servo(S2, 90); // Left front hip

esp.servo(S3, 90); // Right front knee

esp.servo(S4, 90); // Right front hip

esp.servo(S5, 90); // Left rear knee

esp.servo(S6, 90); // Left rear hip

esp.servo(S7, 90); // Right rear knee

esp.servo(S8, 90); // Right rear hip

}

Used for zeroing servo positions after power-on to avoid erratic behavior or self-triggering.

2. DF_Standing(): Ready Posture

esp.servo(S1, 135);

esp.servo(S2, 135);

esp.servo(S3, 45);

esp.servo(S4, 45);

Forms a balanced, crouched stance for starting the next leg movement.

3. DF_Lying_down(): Crouch Simulation

esp.servo(S1, 90);

esp.servo(S2, 135);

Used to demonstrate controlled resting action and test servo angle limits.

4. Gait Core Motion Frames

[A] Lift left front + right rear → swing

esp.servo(S1, 105);

esp.servo(S2, 165);

esp.servo(S7, 15);

esp.servo(S8, 165);

[B] Legs land → push forward

esp.servo(S1, 135);

esp.servo(S2, 105);

esp.servo(S7, 45);

esp.servo(S8, 105);

[C] Lift right front + left rear → swing

esp.servo(S3, 15);

esp.servo(S4, 15);

esp.servo(S5, 105);

esp.servo(S6, 15);

[D] Legs land → push forward

esp.servo(S3, 45);

esp.servo(S4, 45);

esp.servo(S5, 135);

esp.servo(S6, 75);

5. Main Function Execution Flow

void setup() {

DF_Initial_state();

delay(2000);

DF_Standing();

delay(300);

DF_Lying_down();

delay(300);

DF_Standing();

delay(300);

for (int index = 0; index < 5; index++) {

DF_Move_forward_action_A();

delay(300);

DF_Move_forward_action_B();

delay(300);

DF_Move_forward_action_C();

delay(300);

DF_Move_forward_action_D();

delay(300);

}

}

Execution logic:

Initialize → Stand → Lie down → Stand again → Perform 5 full gait cycles → Stop

This sequence demonstrates the robot's full functional flow from power-on to movement, useful for both testing and presentation.

6. Debugging and Troubleshooting

After completing the program logic design and structural assembly, I conducted multiple rounds of debugging. The main goals were:

- Ensure each servo performs as expected

- Enable stable execution of basic gaits

- Ensure system runs without overheating, jitter, or misalignment

I recorded and resolved multiple real issues through a layered diagnosis approach:

1. Unresponsive Servos or Angle Errors

Symptoms: S7 and S8 showed no movement during Action A.

Troubleshooting:

- Servos tested OK via channel swap

- Loose connector found

- No PWM output detected on D7

Solutions: Changed slot, reconnected firmly, labeled channels

2. Unbalanced Movement, Tilting or Skewed Trajectory

Symptoms: Robot leaned forward and deviated to the left

Troubleshooting:

- S1/S3 angle mismatch

- Loose servo bracket on left front leg

- S2 too far forward (165°), causing imbalance

Solutions: Symmetrical angle table, replaced parts with SLA, reinforced servo mounting

3. Overheating and Buzzing Servos

Symptoms: S2/S8 heated up and buzzed after 2 minutes

Troubleshooting:

- Long duration holding under load

- No angle overflow

- New servos showed same problem

Solutions: Limit angles, add buffer frames, use MG90S in future, extend delay()

4. Jerky or Irregular Movements

Symptoms: Frames switched before motion completion

Troubleshooting:

- Delay(300) insufficient for some moves

- Large angle jumps observed (e.g., 45° → 135°)

Solutions: Increased delay to 350ms, added intermediate angles, suggest using millis()

5. Glitchy or Unstable Control Logic

Symptoms: Random desynchronization or jitter, restored after reboot

Troubleshooting:

- Voltage drop from 5V to 4.3V under load

- Shared power line between board and servos

Solutions: Separate power supplies, added 1000uF capacitor, recommend independent DC supply

Debugging Summary

I developed a reliable debugging workflow:

- Classify problem types based on symptoms

- Diagnose layer-by-layer: software → angles → mechanics → power

- Maintain logs of servo behaviors, angles, and timing

- Record fixes for repeatability and future improvement

Ultimately, I realized that a stable robotic motion system is built on precise mechanics, reliable power delivery, and synchronized timing—not just correct code.

Quadruped_SG90_Robot_stl.rar