2. Computer Aided design

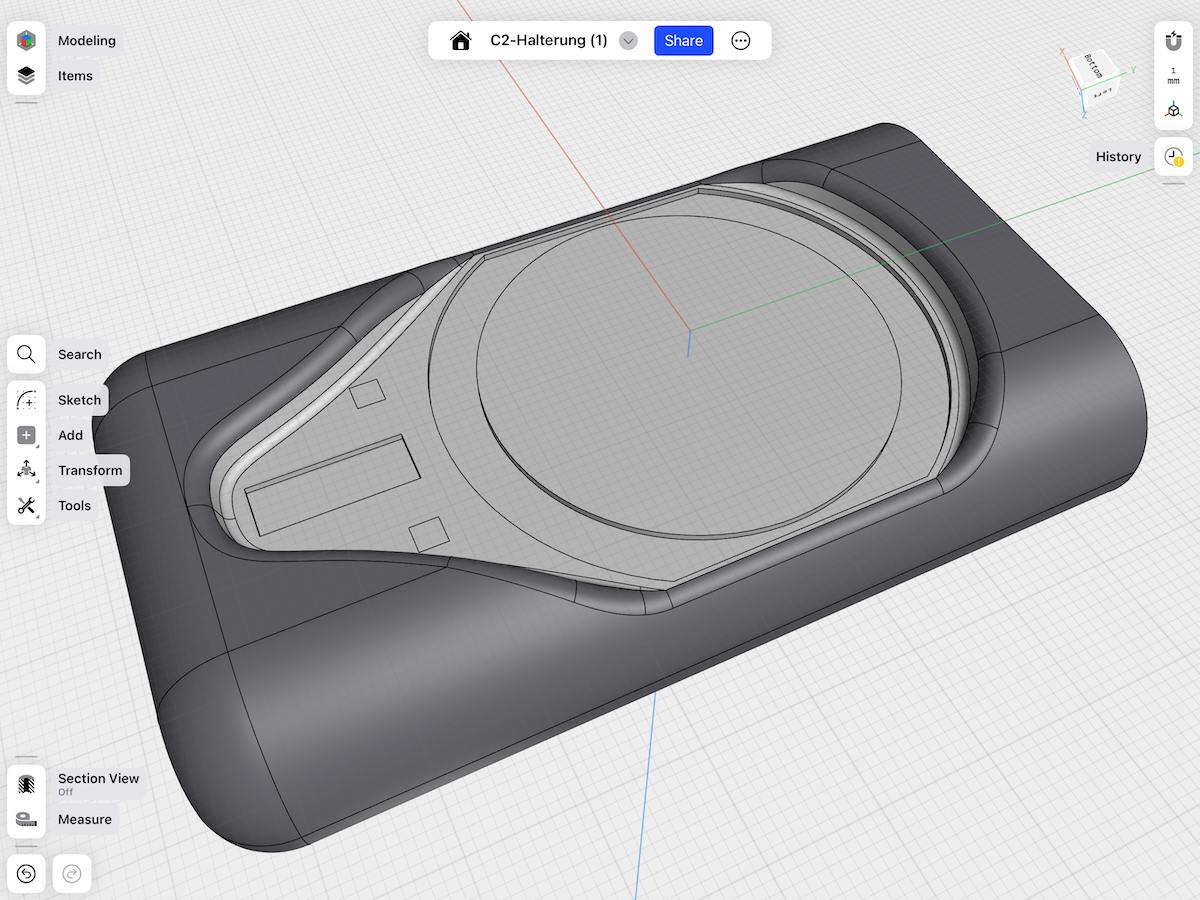

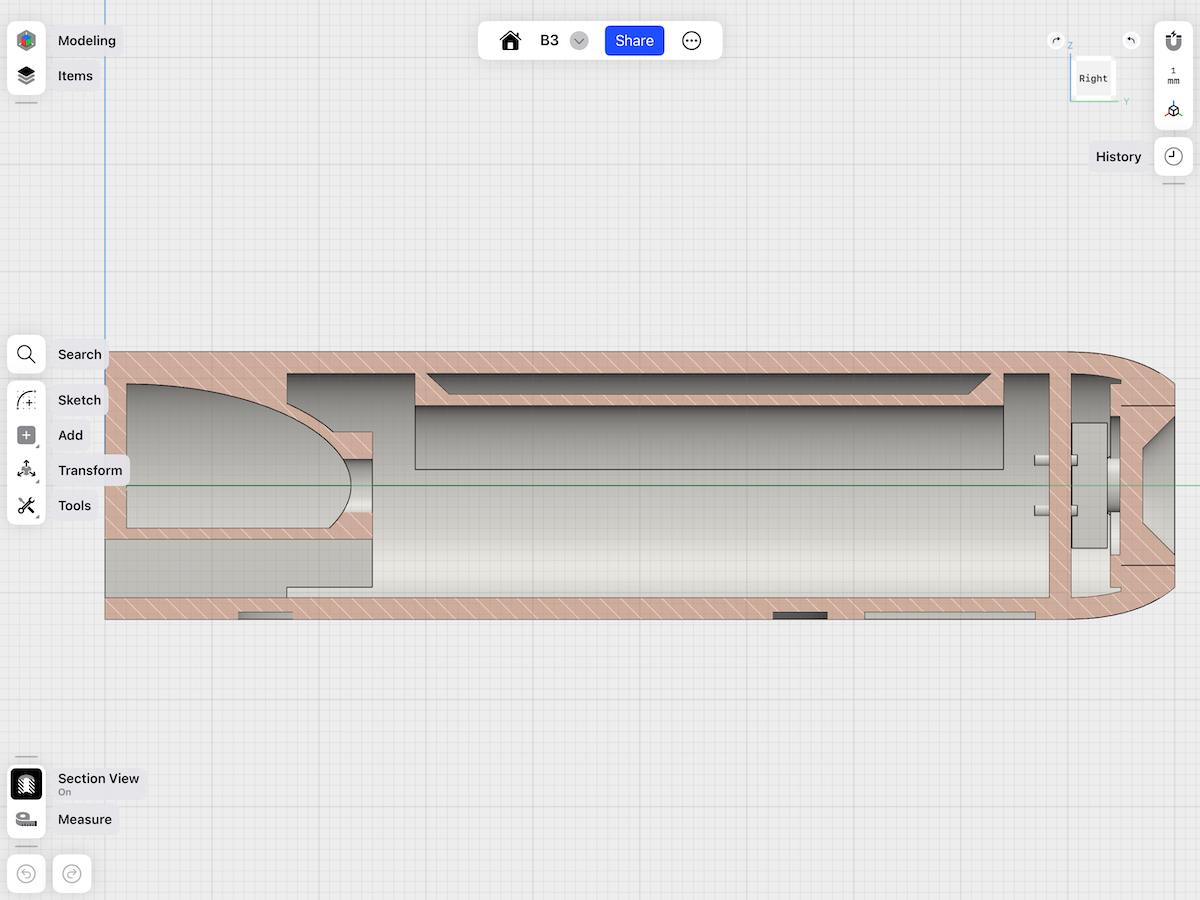

For the Cad Design Week I decided to continue with my Ludo project. The Ludo already exists as a proof of concept prototype, but it has one major problem. The lamp doesn't reliably align with the magnetic mount. It snaps into place, but is usually off by a few millimeters, which neglects the main functionality of automatically changing the color of the emitted light. This is the current state of the Luedo housing:

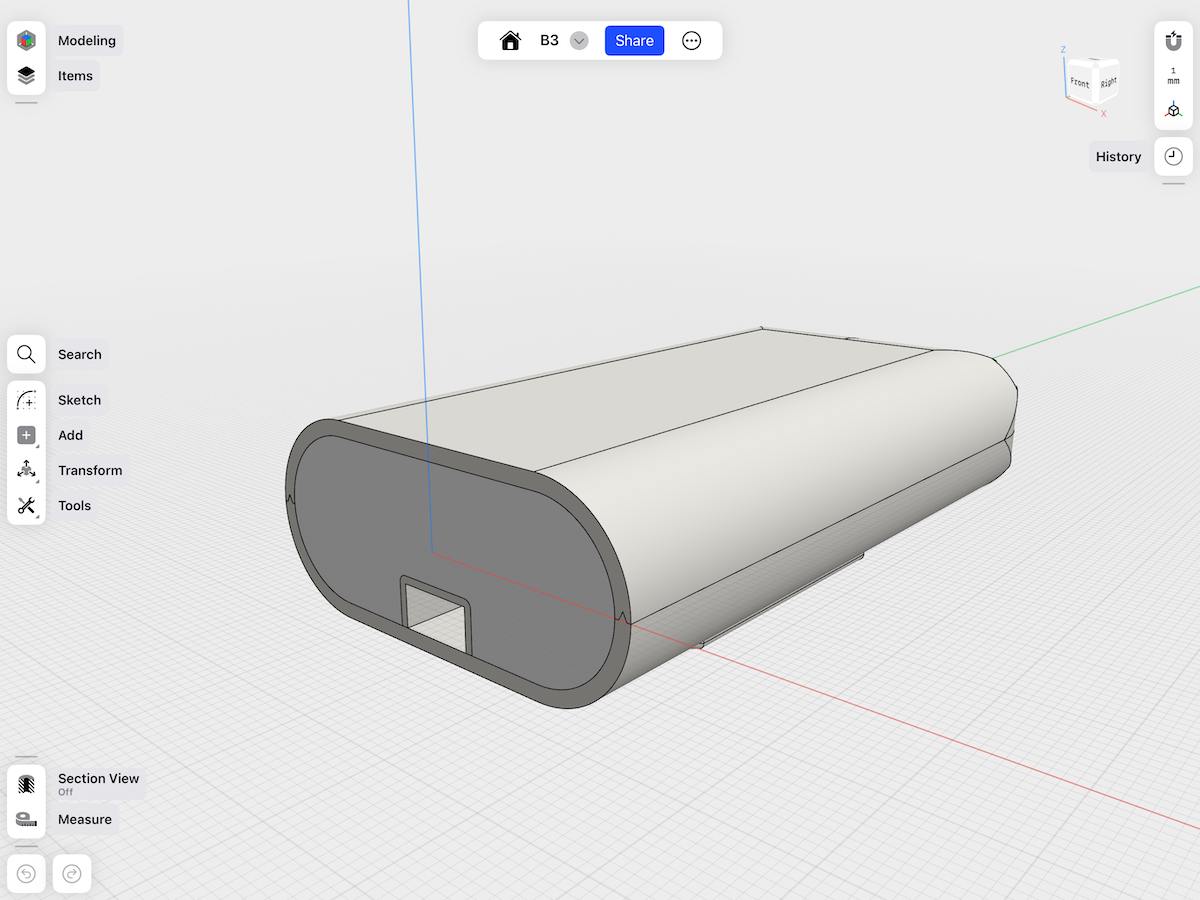

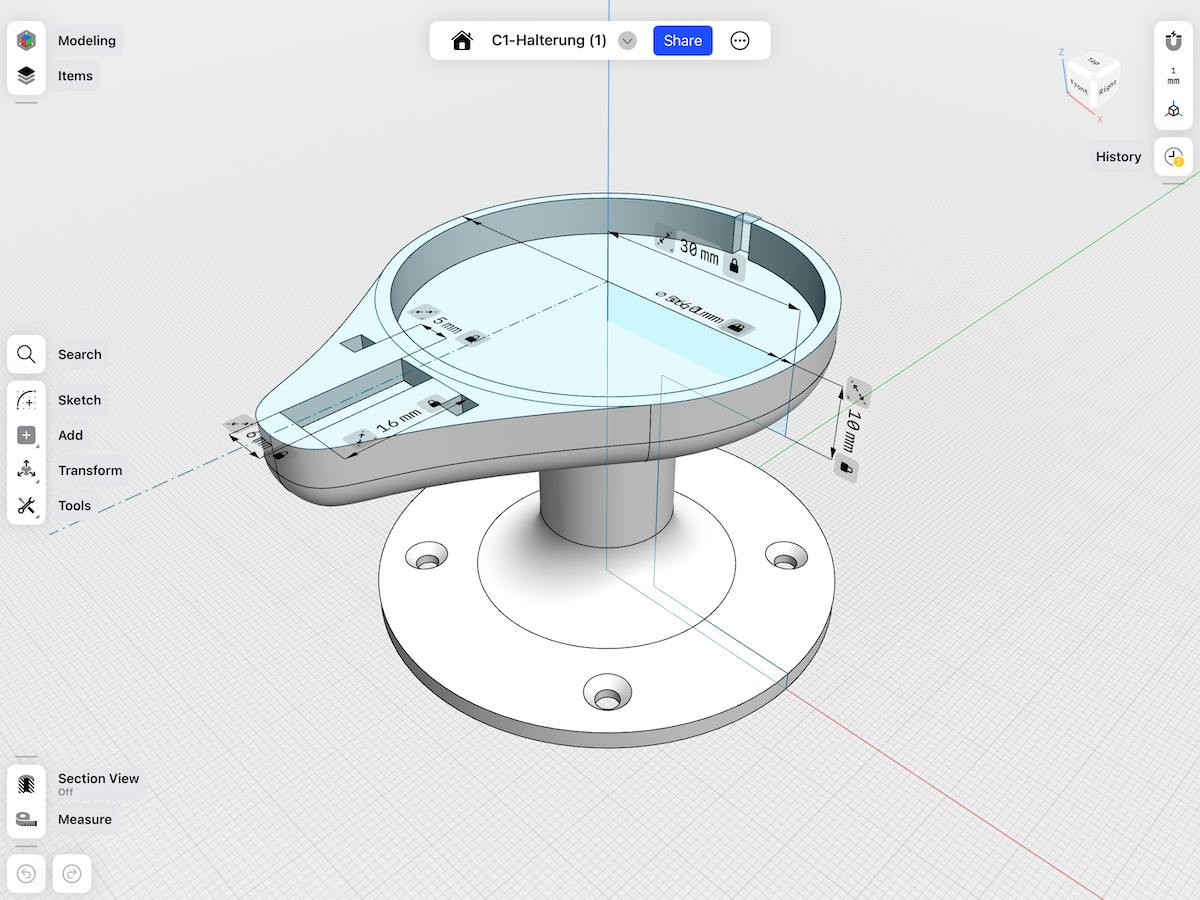

To improve the alignment, I had the idea to support the magnetic alignment with a mechanical component. That's why I redesigned the mount that will later be connected to the vehicle.

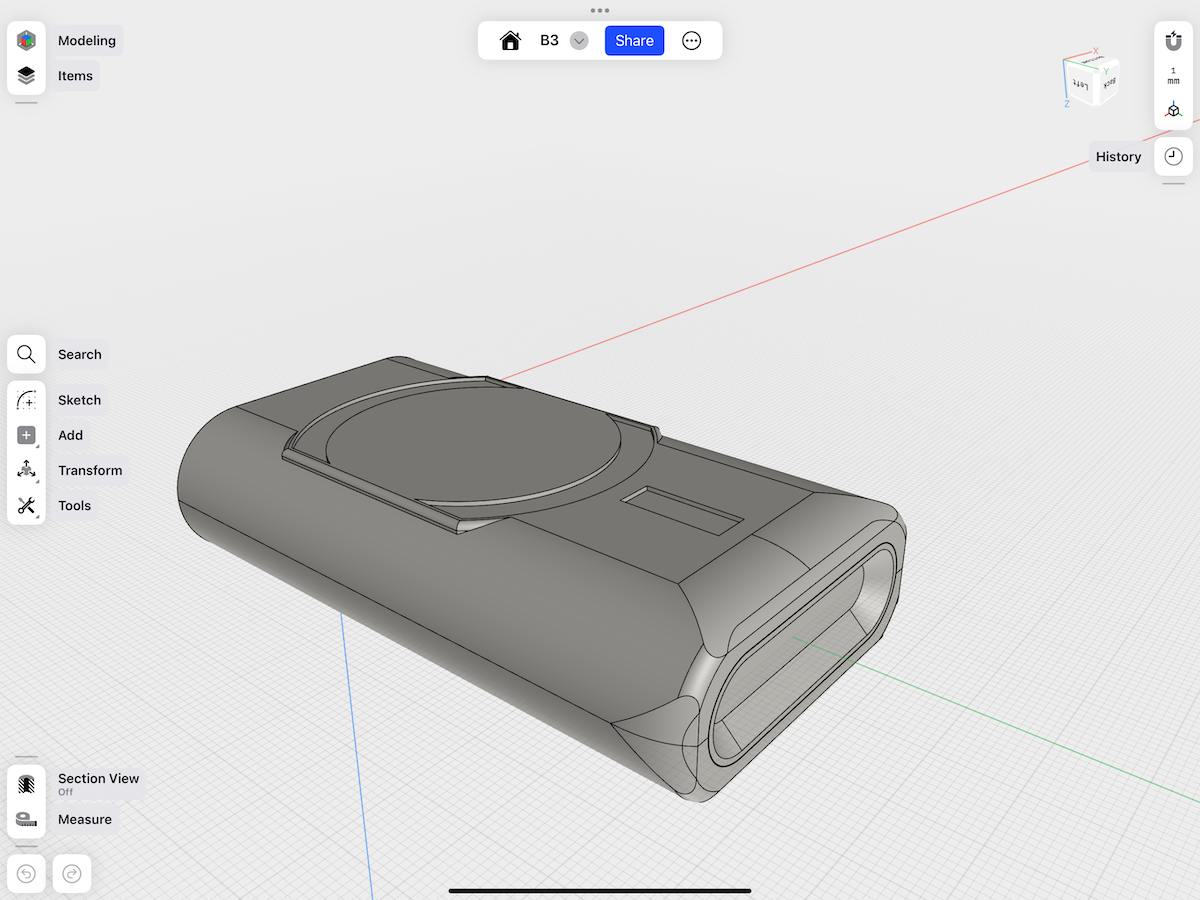

The new version of the mount has slopes on the sides to guide the lamp towards the magnet and ensure a fixed position. To model the improved mounting system, I decided to create a mockup of the lamp, which reduces the work to implement the system in the housing, which is quite complicated.

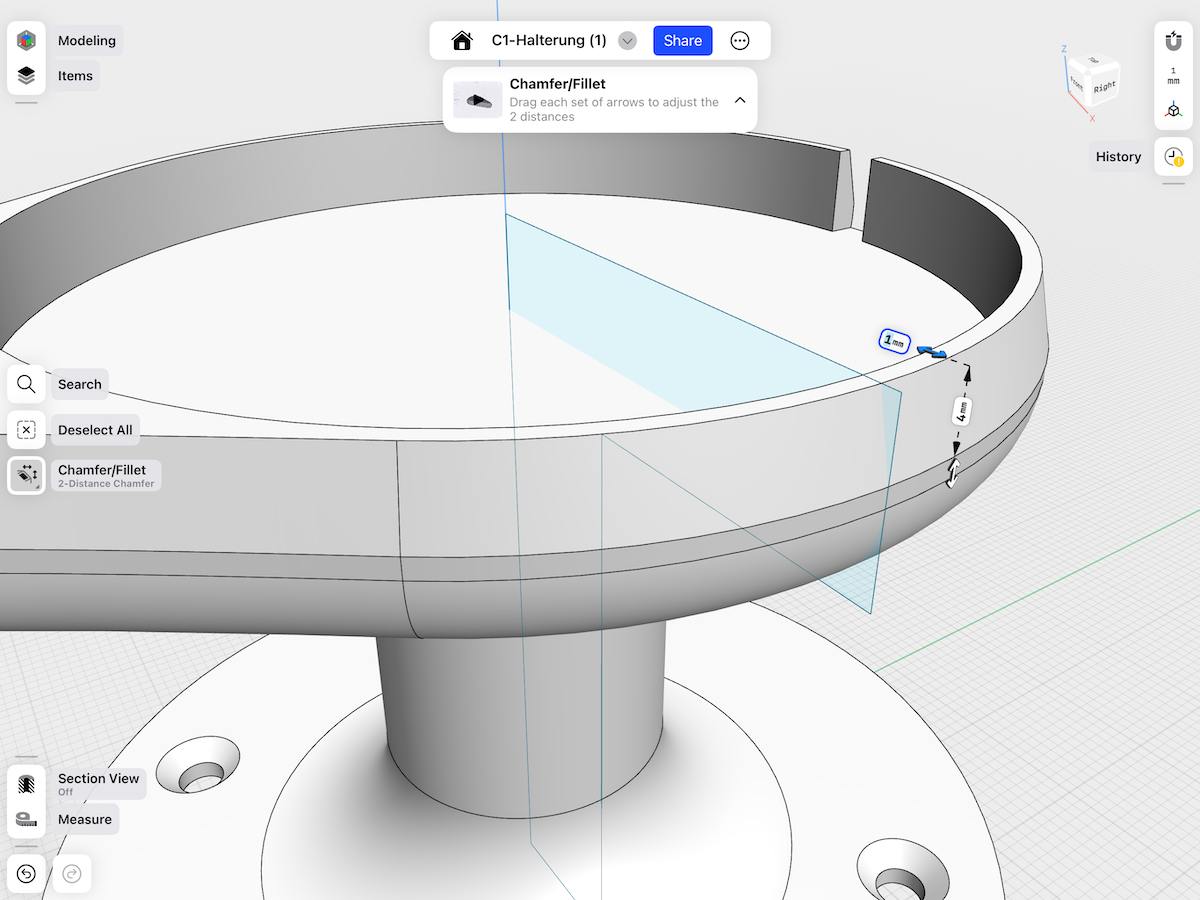

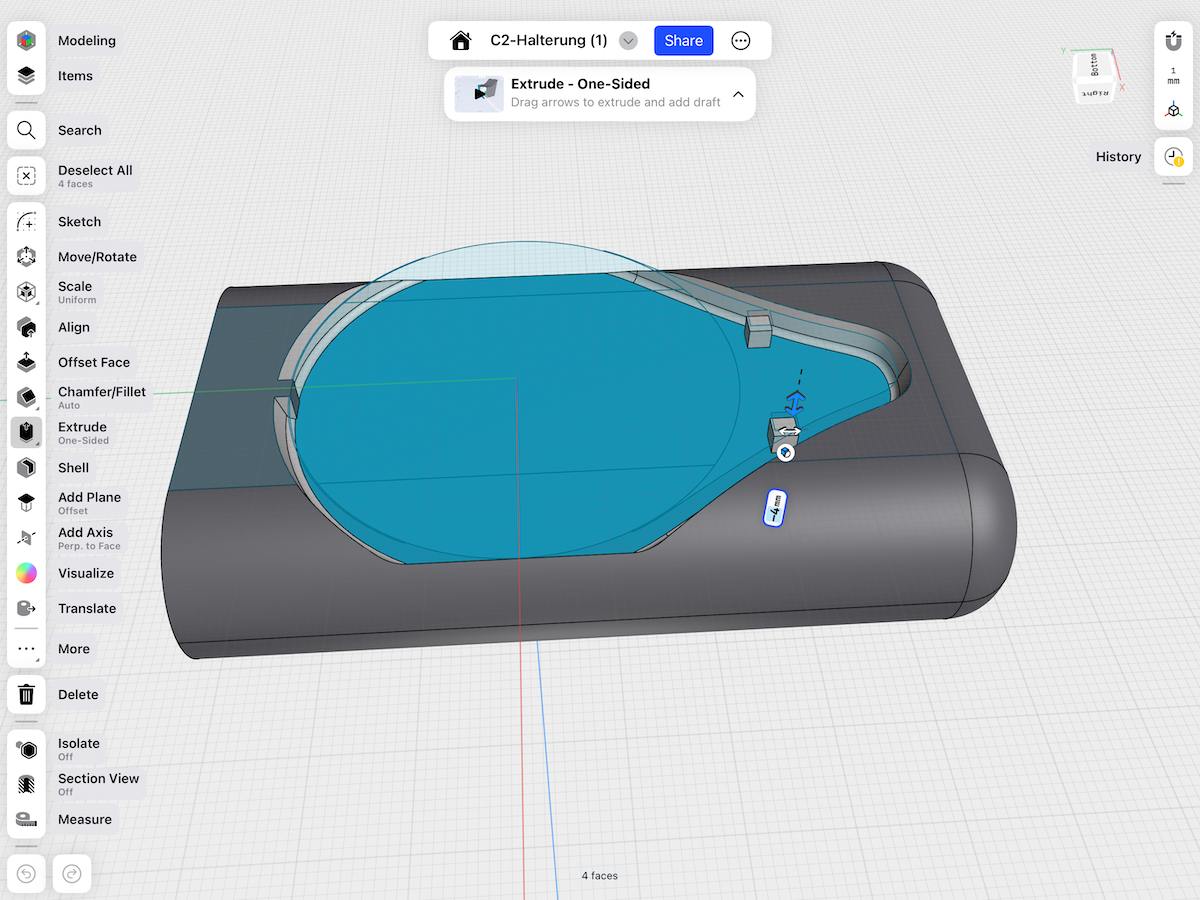

The housing includes two pieces of a metal ring to which the magnets form the charger/monitor snaps and a small alignment strip to lock the rotation. For the following mockup, I started with the existing mount and added some bevels and some radii.

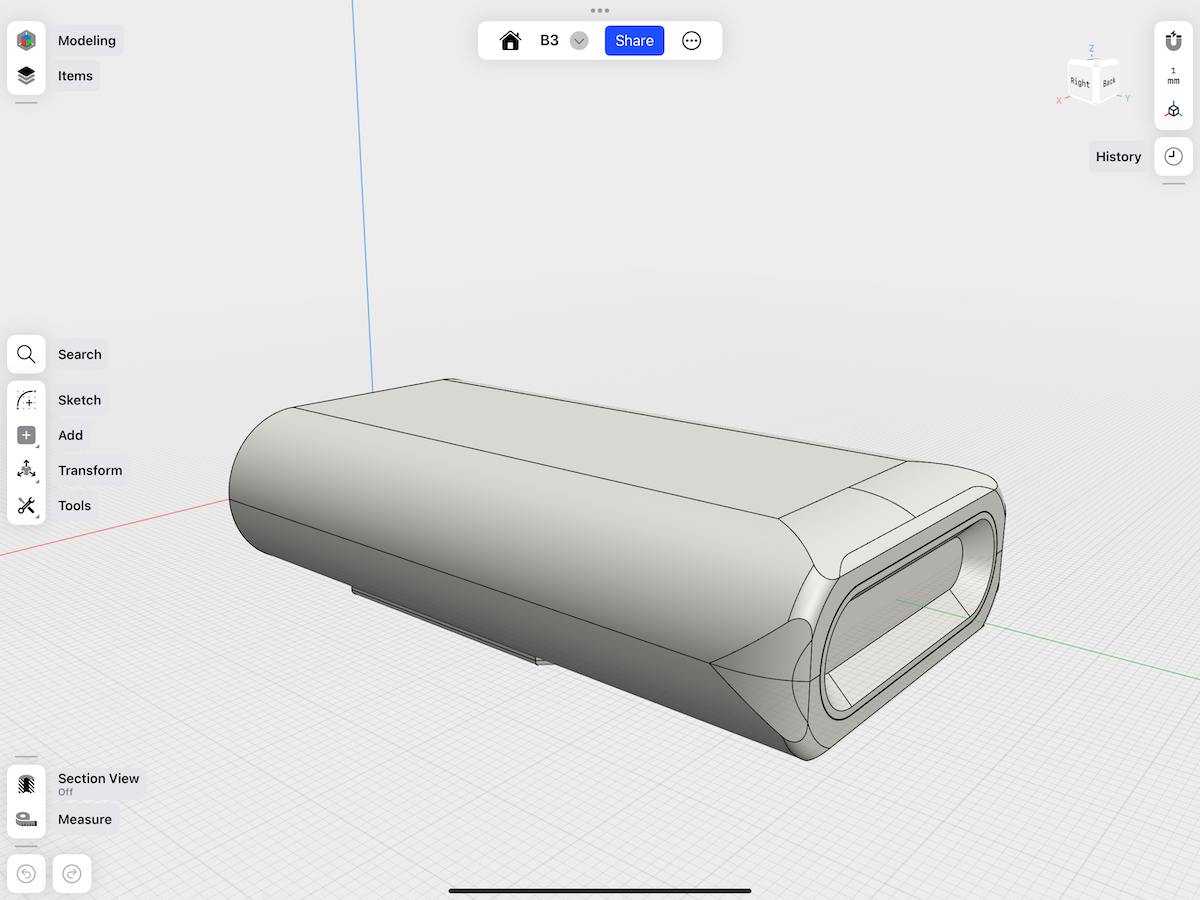

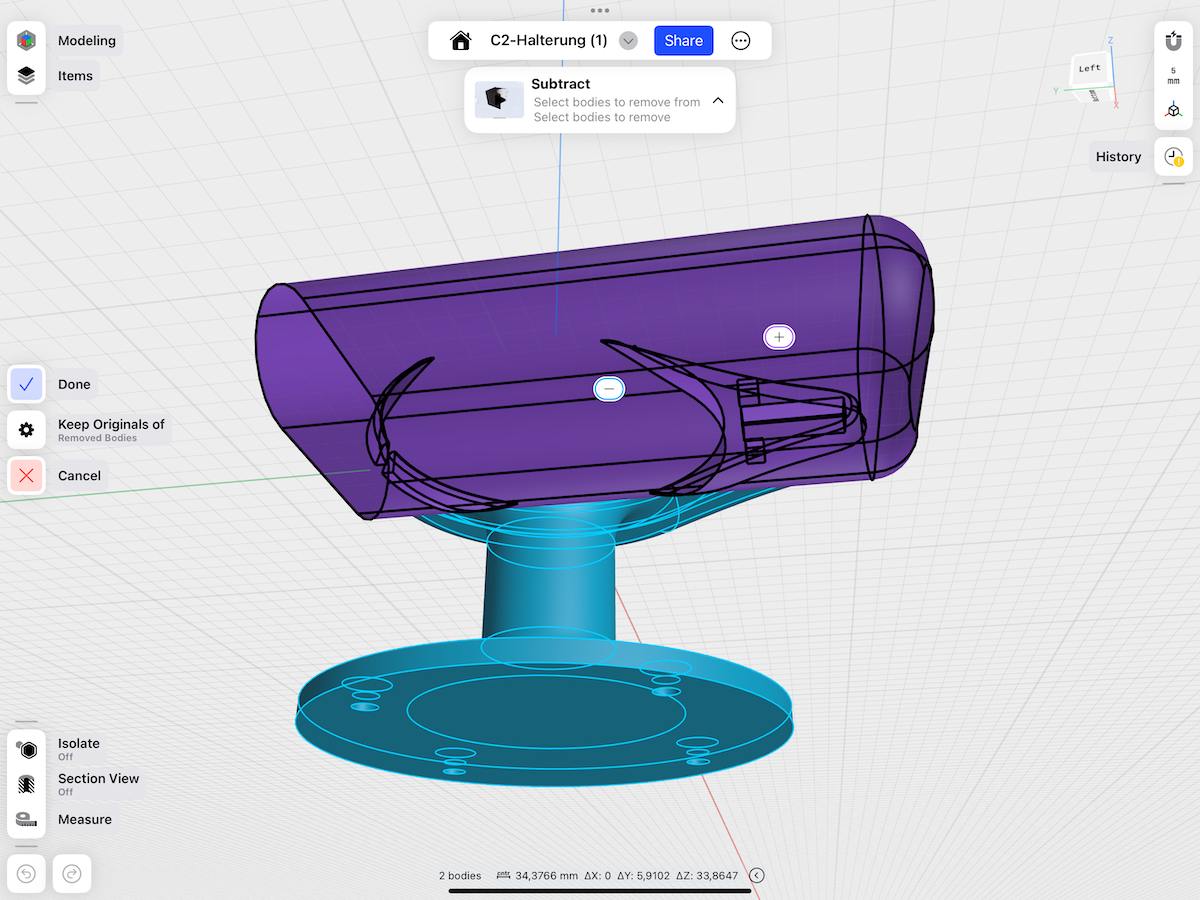

After completing the mount, I subtracted the mount from the purple pebble shape to create a mechanical prototype that could later be printed during 3D Printing Week.

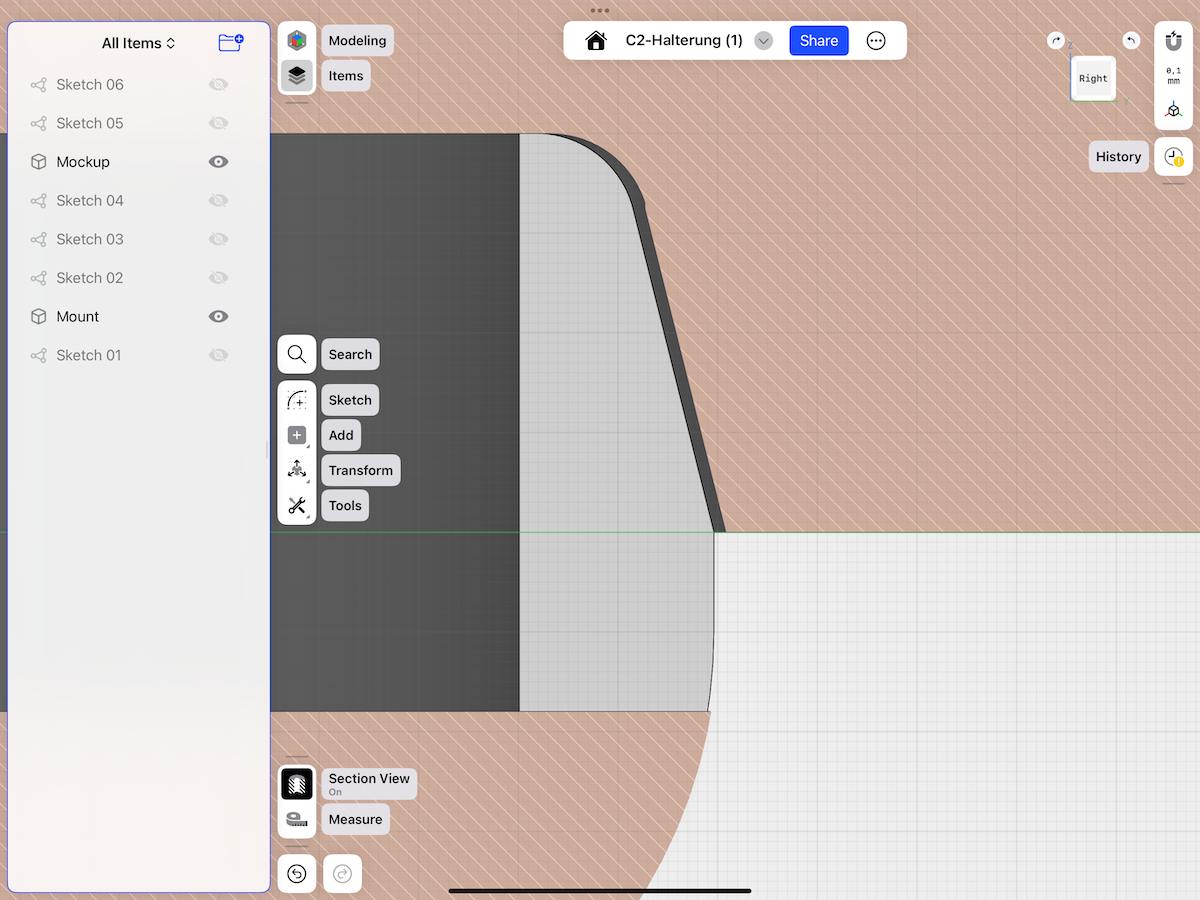

After subtracting the shapes from each other, I had to do some cleaning up in the model.

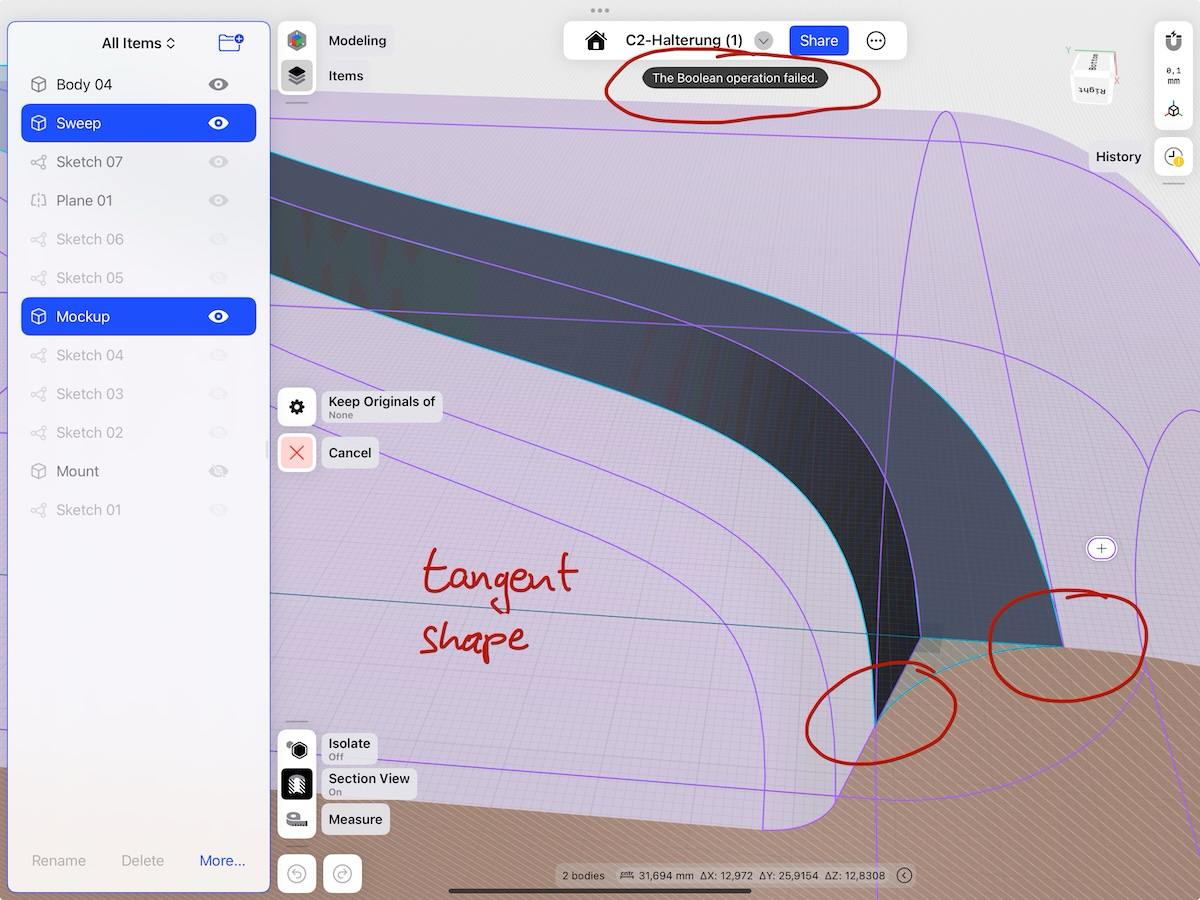

Many times I have failed to subtract the Boolean operation because I was trying to manually sweep a fillet on an edge. The idea was to redefine the shape of the fillet as an asymmetric shape to improve the alignment capabilities of the shape. After getting the errors, I decided to just go with a normal fillet.

I added 0.1mm of clearance on each side, giving me a total of 0.2mm to move the mount.

The 'final' resulting shape not only has the advantage of more secure alignment, but it also increases the magnetic surface area, resulting in better magnetic adhesion. The downside of the redesigned mounting system is that it reduces the internal volume of the lamp itself. Another disadvantage is the not so streamlined design of the outer shell, which already annoys me. This can be seen in detail when the part is printed.