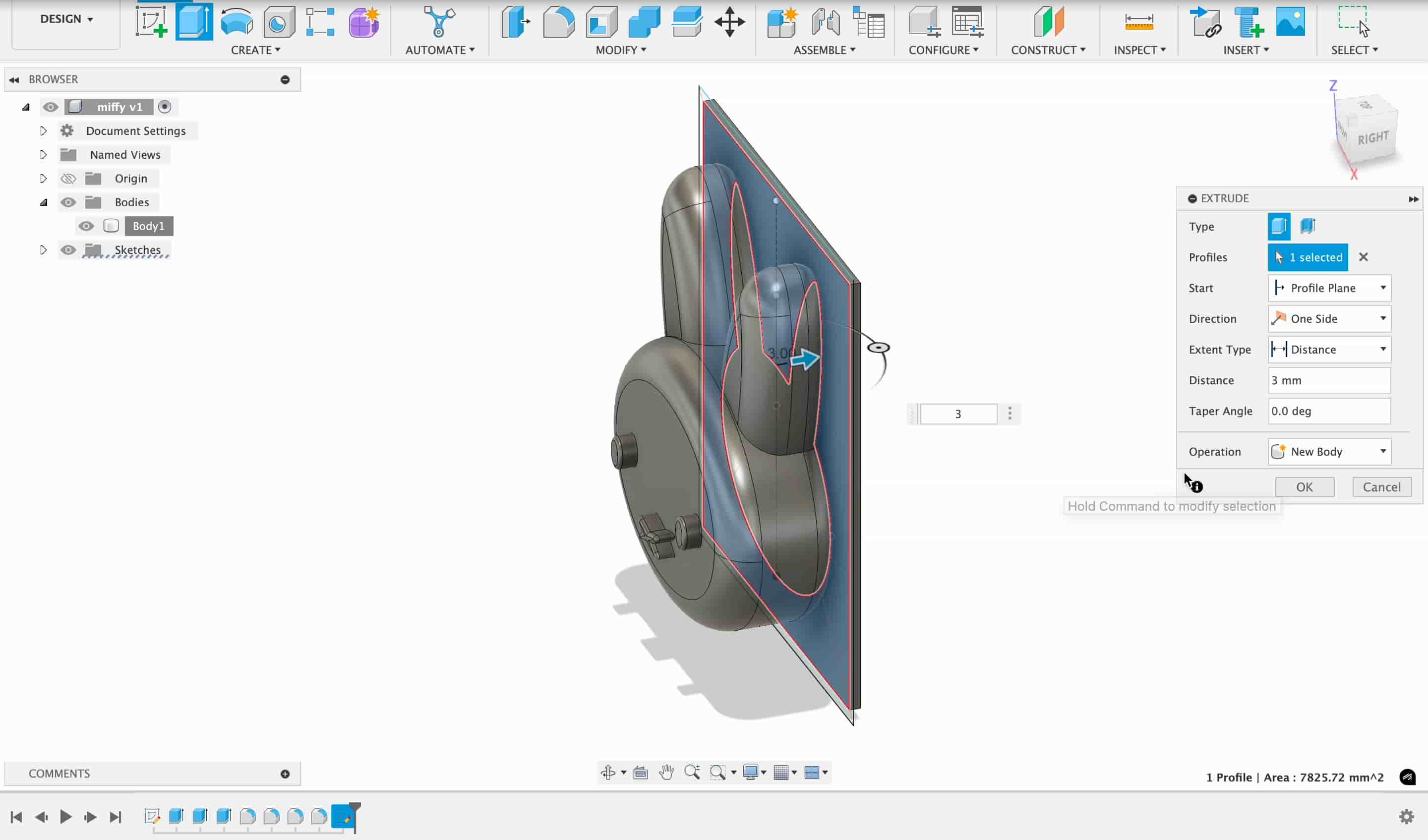

Fusion 360

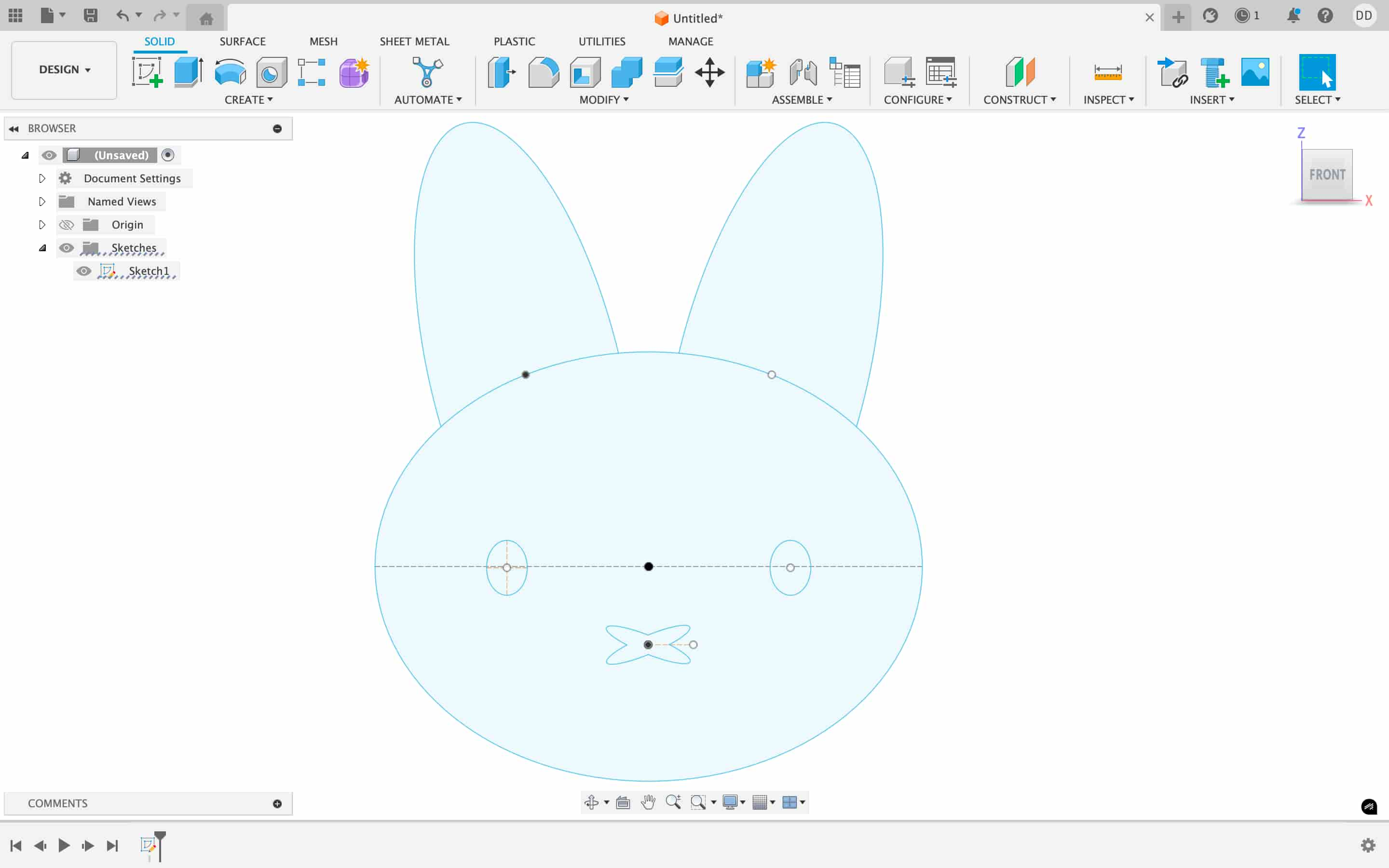

First I designed the mold. I drew a sketch of the shape I wanted. I used ellipse with different radius to create all the shapes. I created sketches only one on side and then used the symmetry tool to make it symmetrical for the other side.

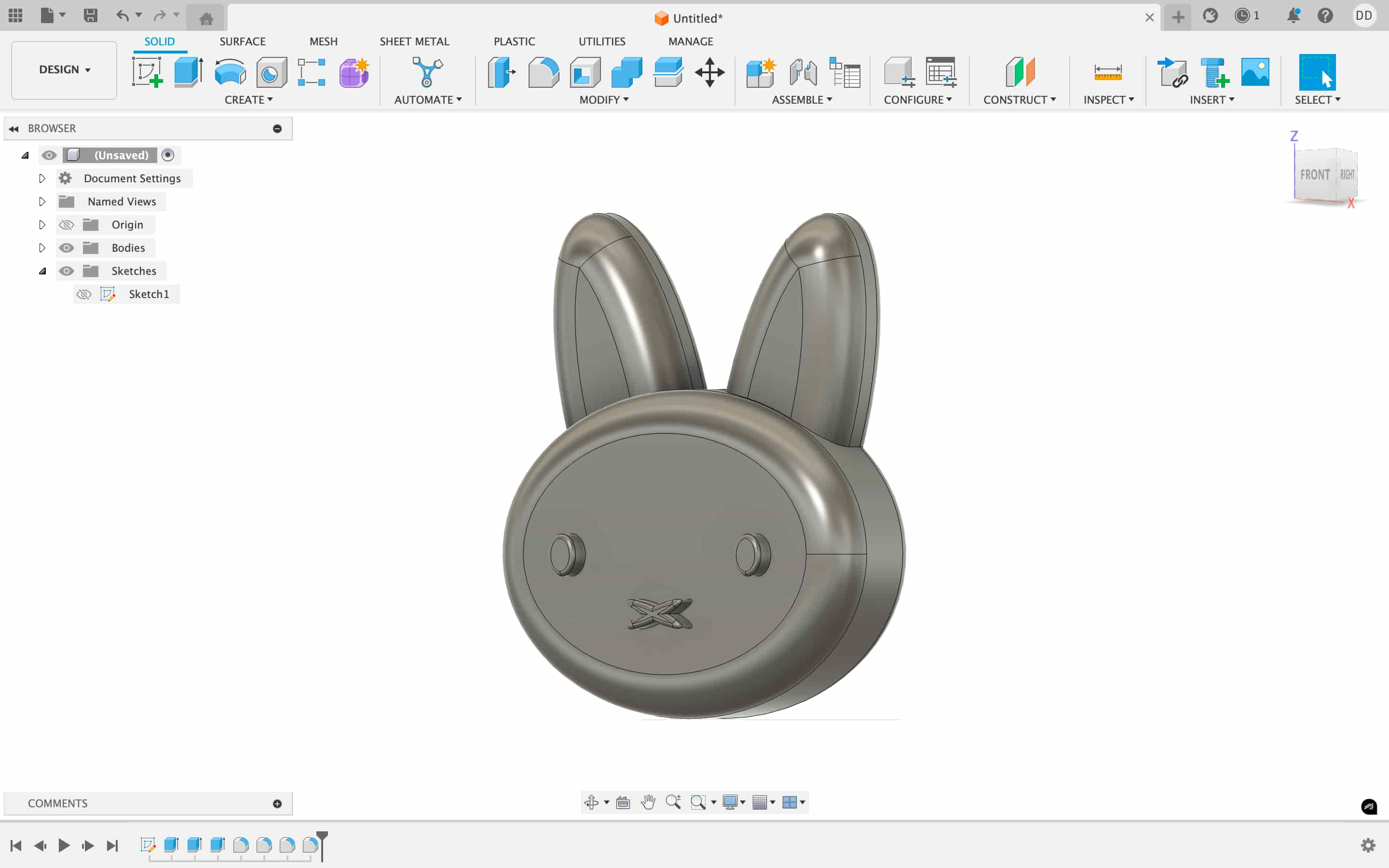

I used extrude to make the shape 3D. Here are the measurements for extrude:

- 35 for the face

- 20 for ears

- 30 for head

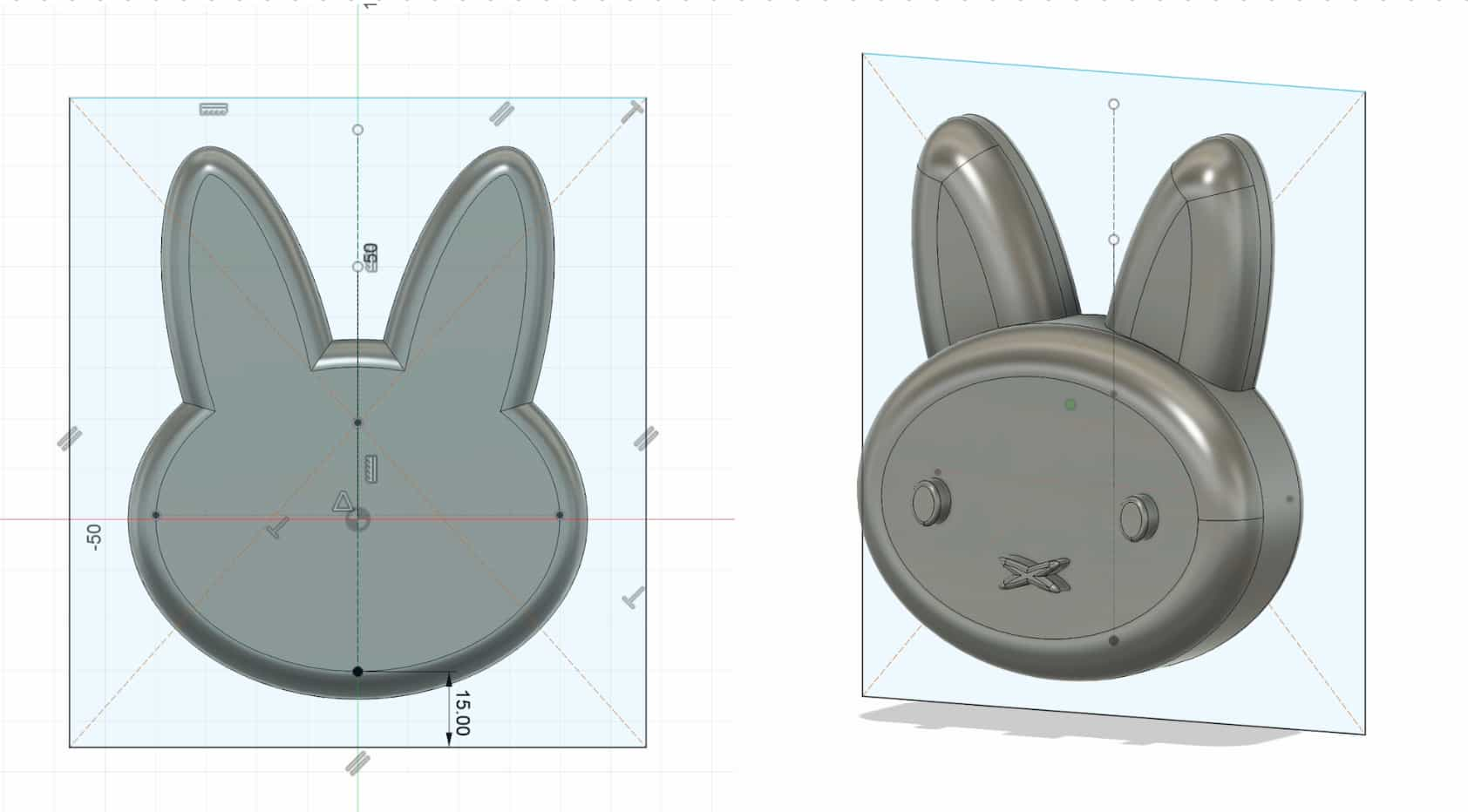

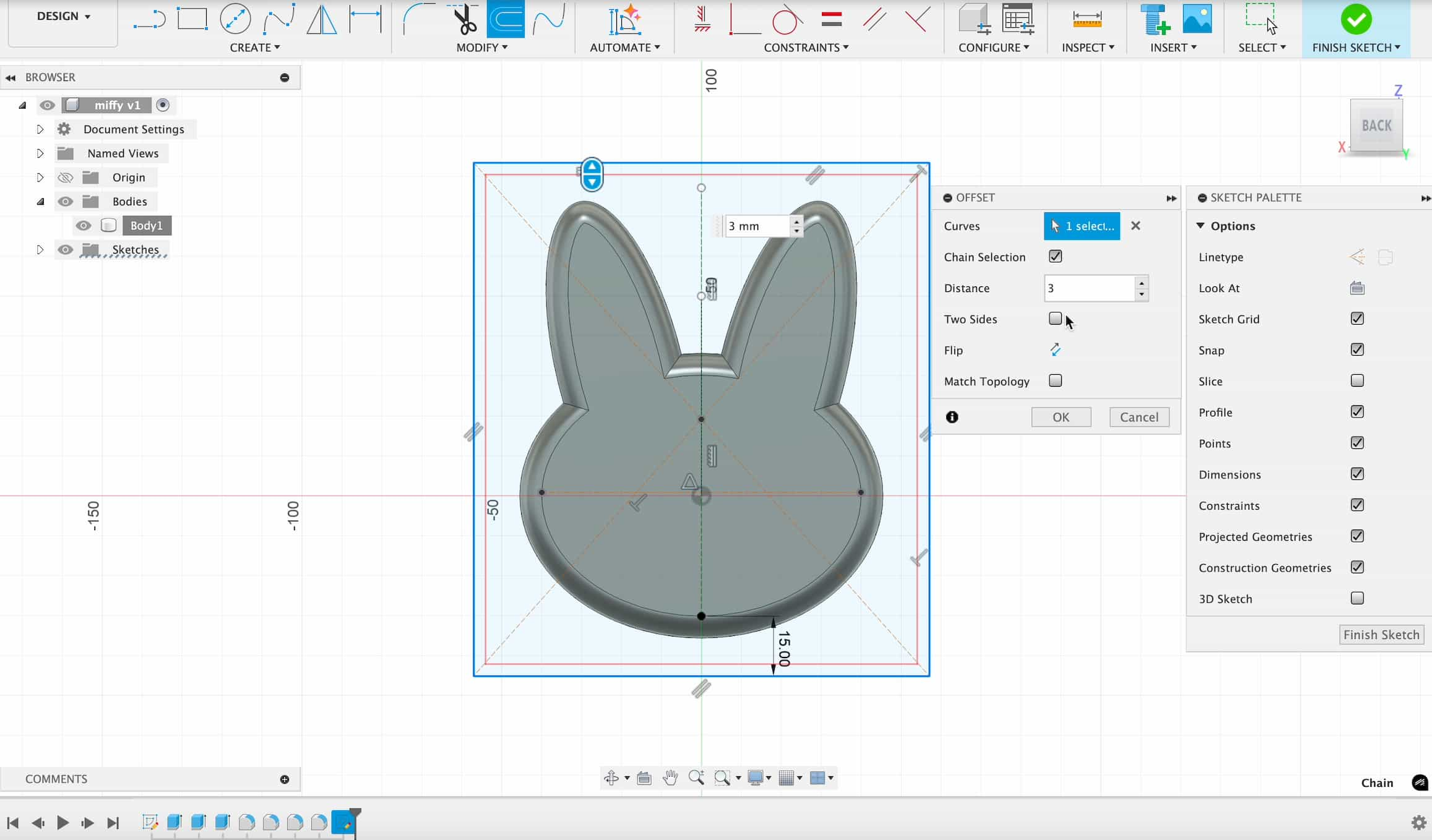

To create the mold shape I started out by creating a new skech at the back of the head. I drew a rectangle and adjusted shape.

I used fillet 3mm to create an inner rectangle.

I selected the inner rectangle and used extrude -> join to make the bottom of the rectangle.

I selected the outer rectangle and used extrude again.

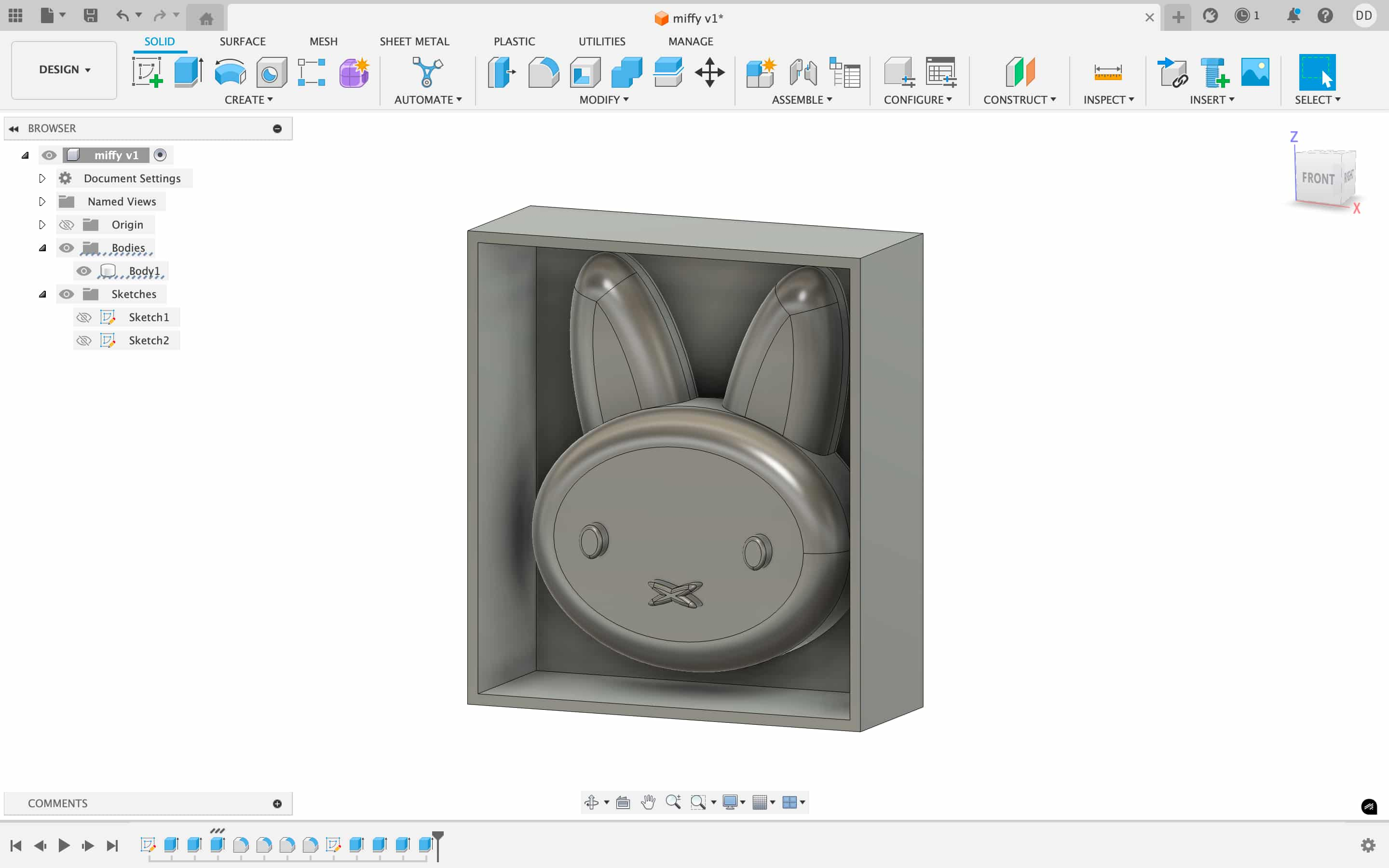

Mold

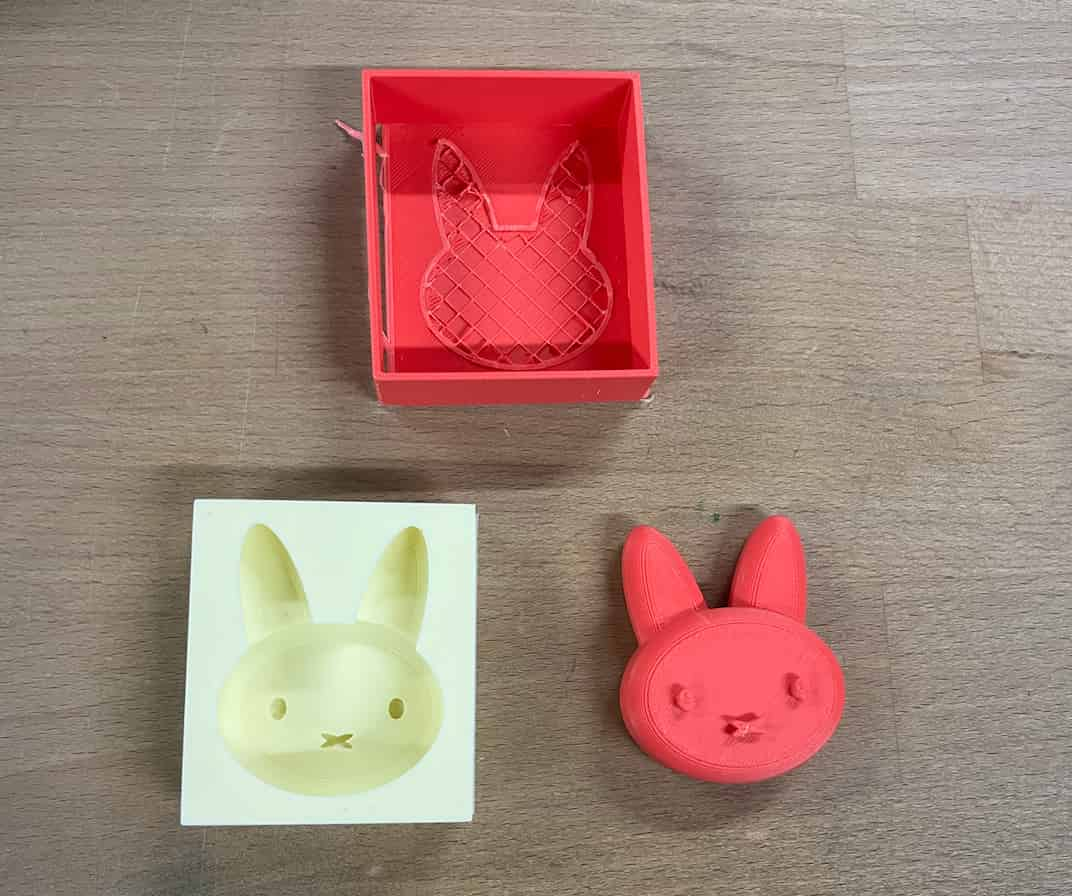

Here is the mold 3D printed:

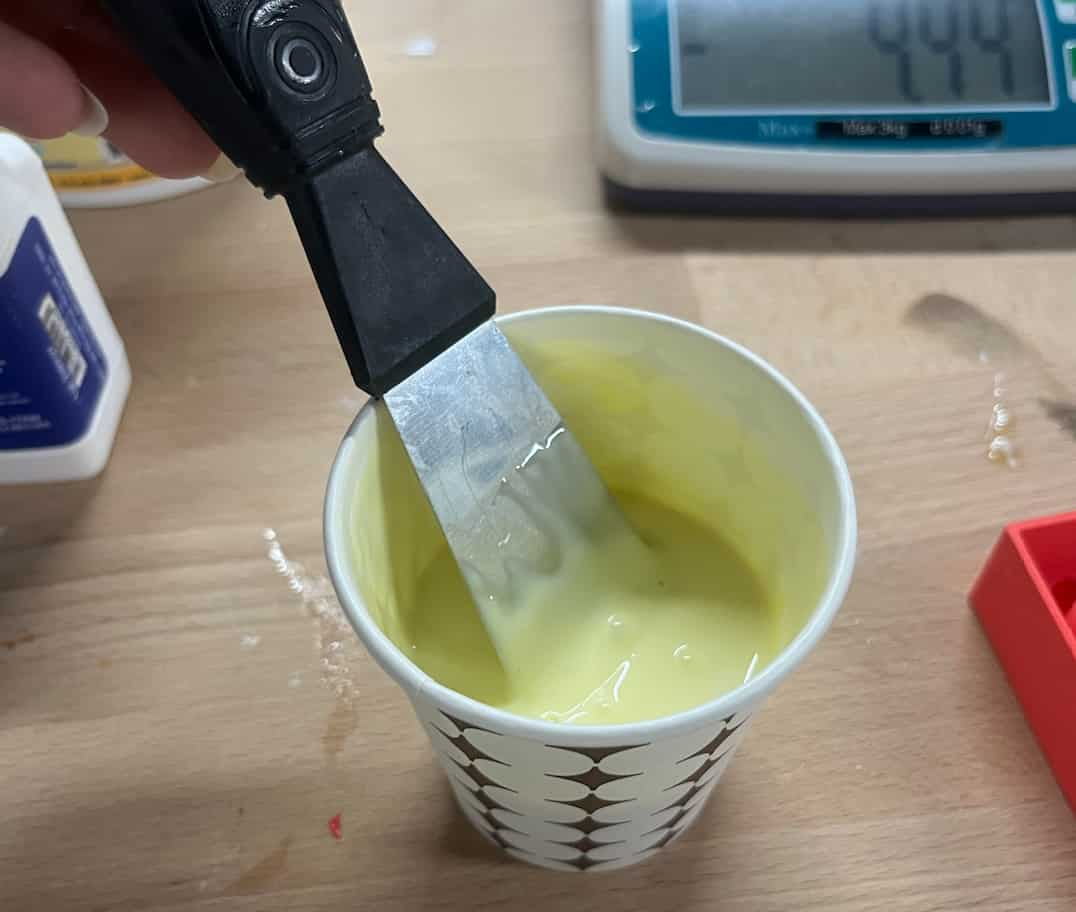

The materials I used:

The ratio of the two (A and B) should be 100A : 10B. I measured as shown:

Mixed very well:

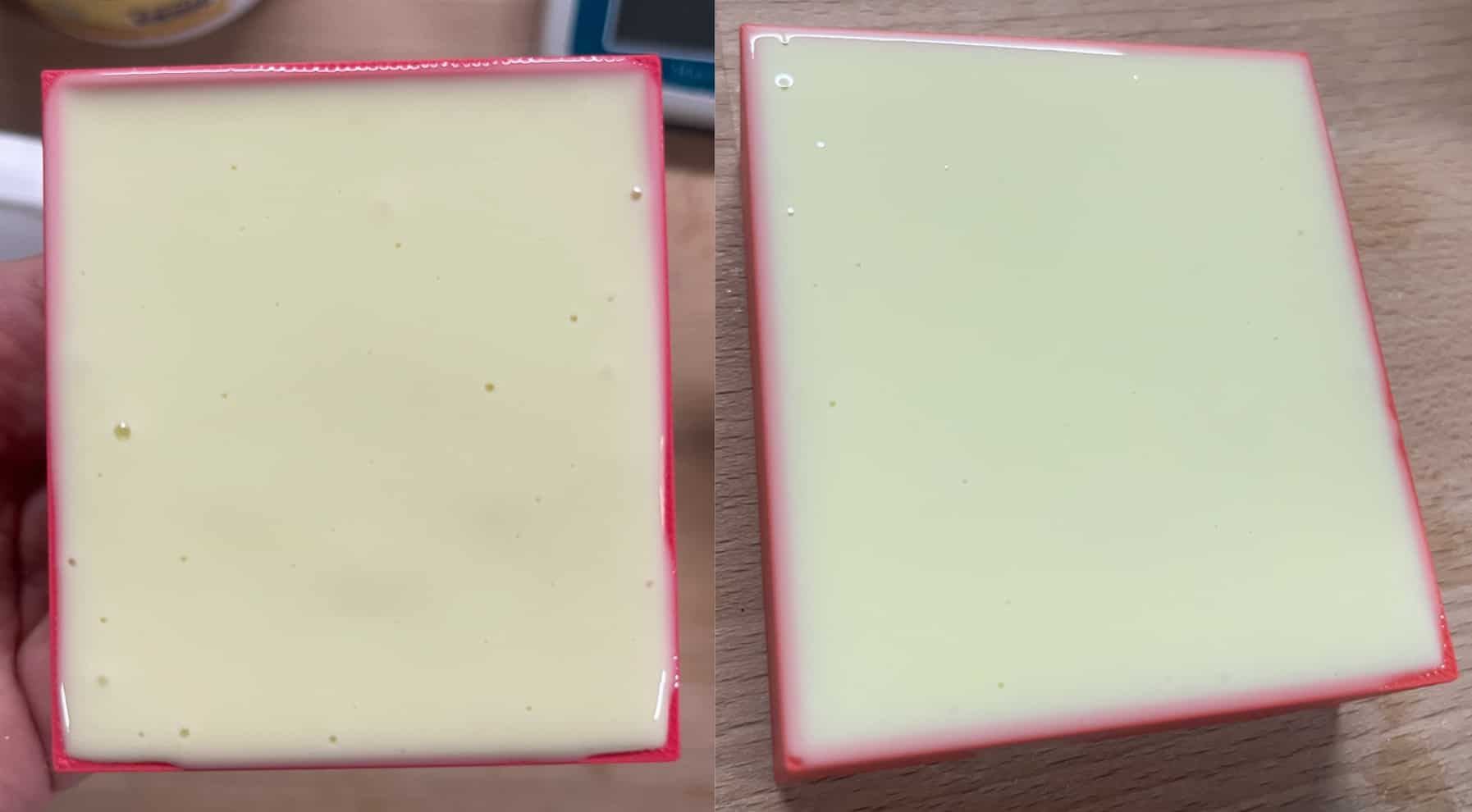

I popped the small bubbles that came on the surface. Here is the before and after:

Once the mold had dried, I broke the 3D print to get it out.

Resin

I then mixed the A and B for resin. The ratio was 1:1 this time.

I also added some purple dye and poured the resin into my mold

Final Product:

Files

Here are the files: