Group Assignment

We made a CNC like machine that grabs tennis balls. You can check our project out here

Individual Contribution

This week I was responsible for:

- Documenting the whole process and collecting media

- Preparing the wires

Wires

Here is an overview

- 4-wire from ethernet cables for stepper motors

- 2-wire twisted for end stop

- 3-wire from ehternet cables

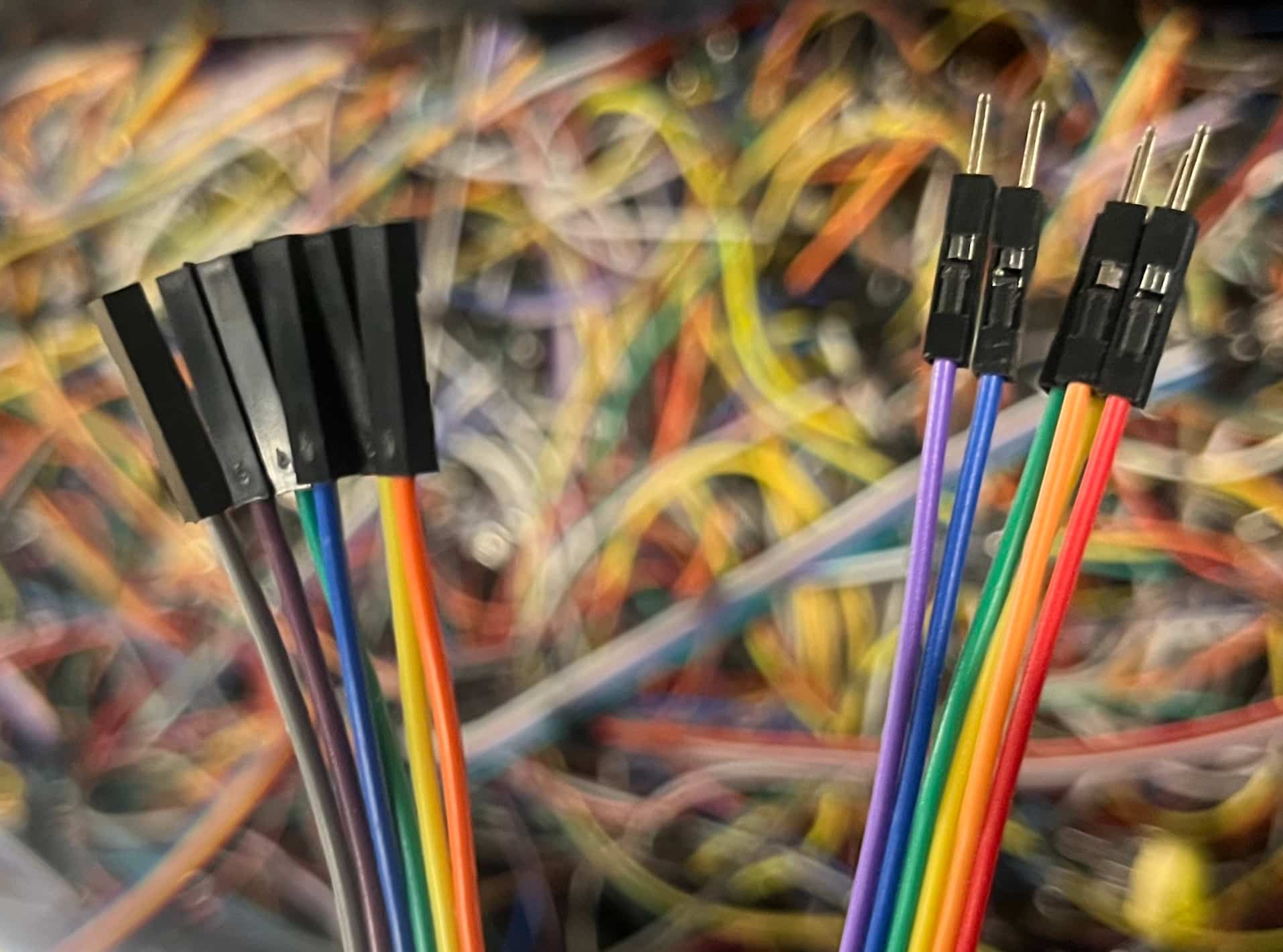

Normal Wire + Jumper Wire

I used female jumper wires on one end and connected the other end to the limit switch.

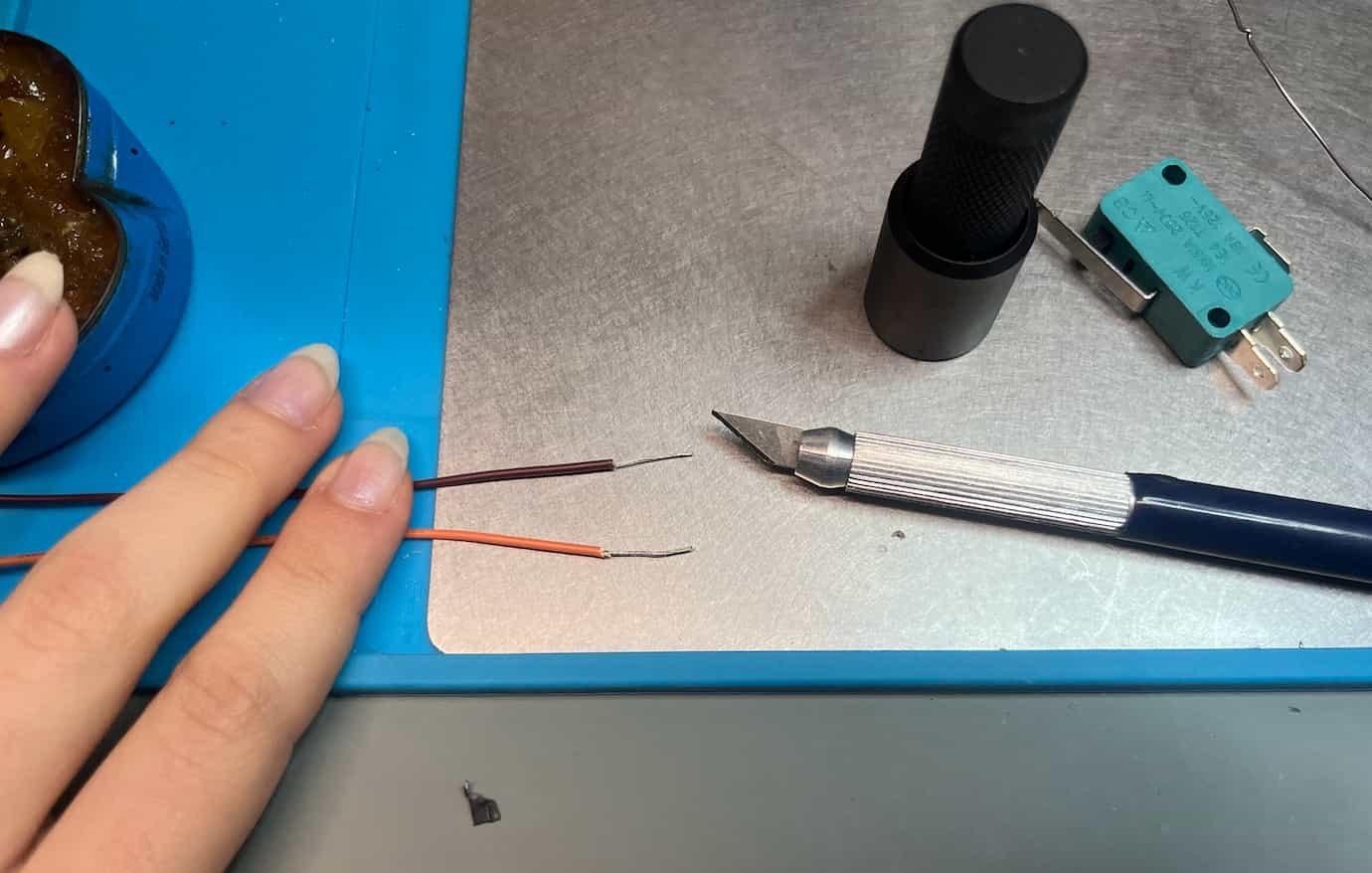

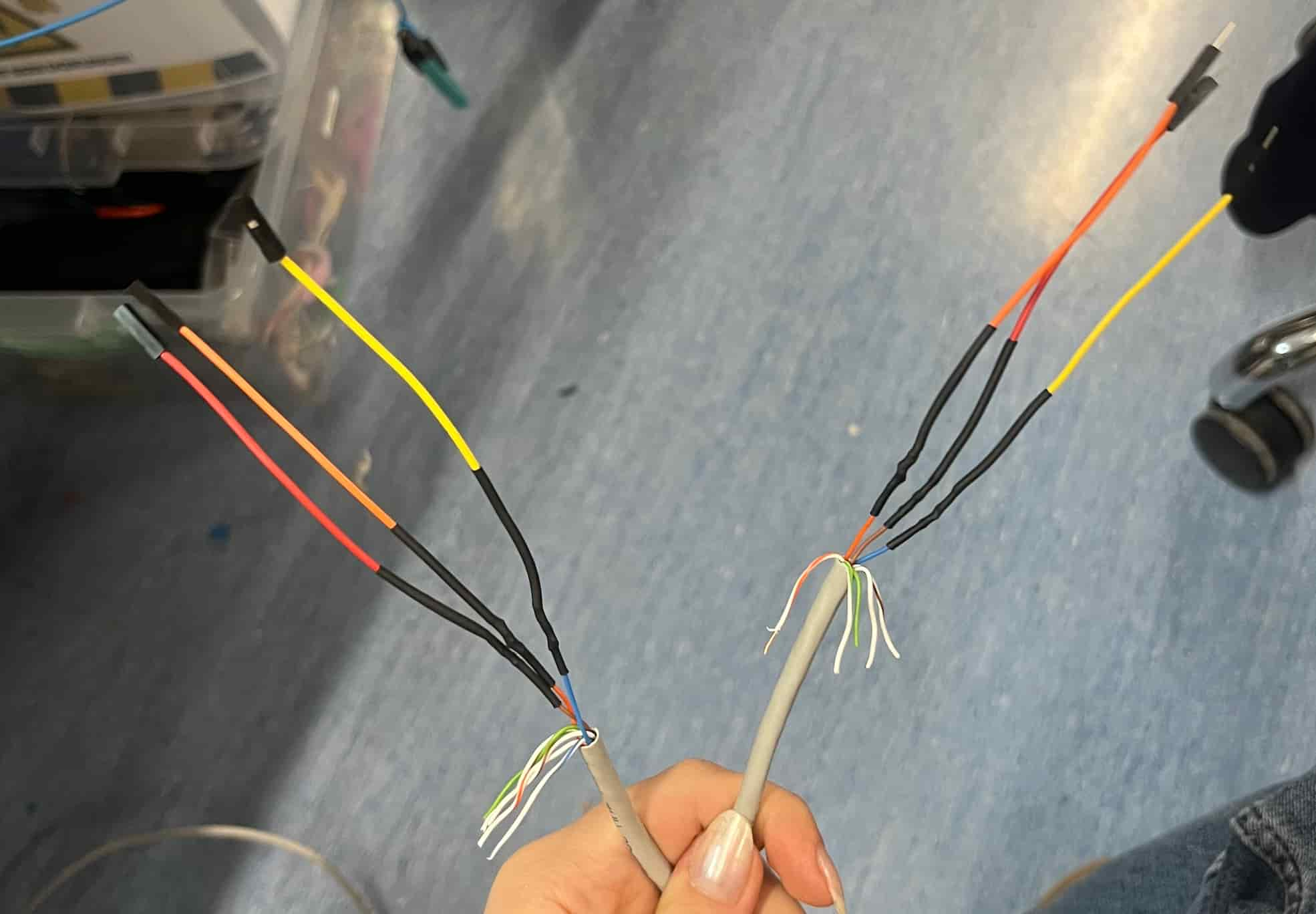

I cut the plastic off from the ends of both the normal(both ends) and the jumper wires. Normal wires:

Jumper wires:

And then I positioned the end of the jumper wire and the normal wire to be close and applied solder. I tried to make sure to always put a heat shrink on the wire before soldering the two together. There were times i forgot and i had to heat to area with soldering iron and gently pull the wires apart to put the heat shrink in.

Since the insulation is now out on the parts where I removed the plastic and soldered, I used heat shrinks. I applied heat with this machine:

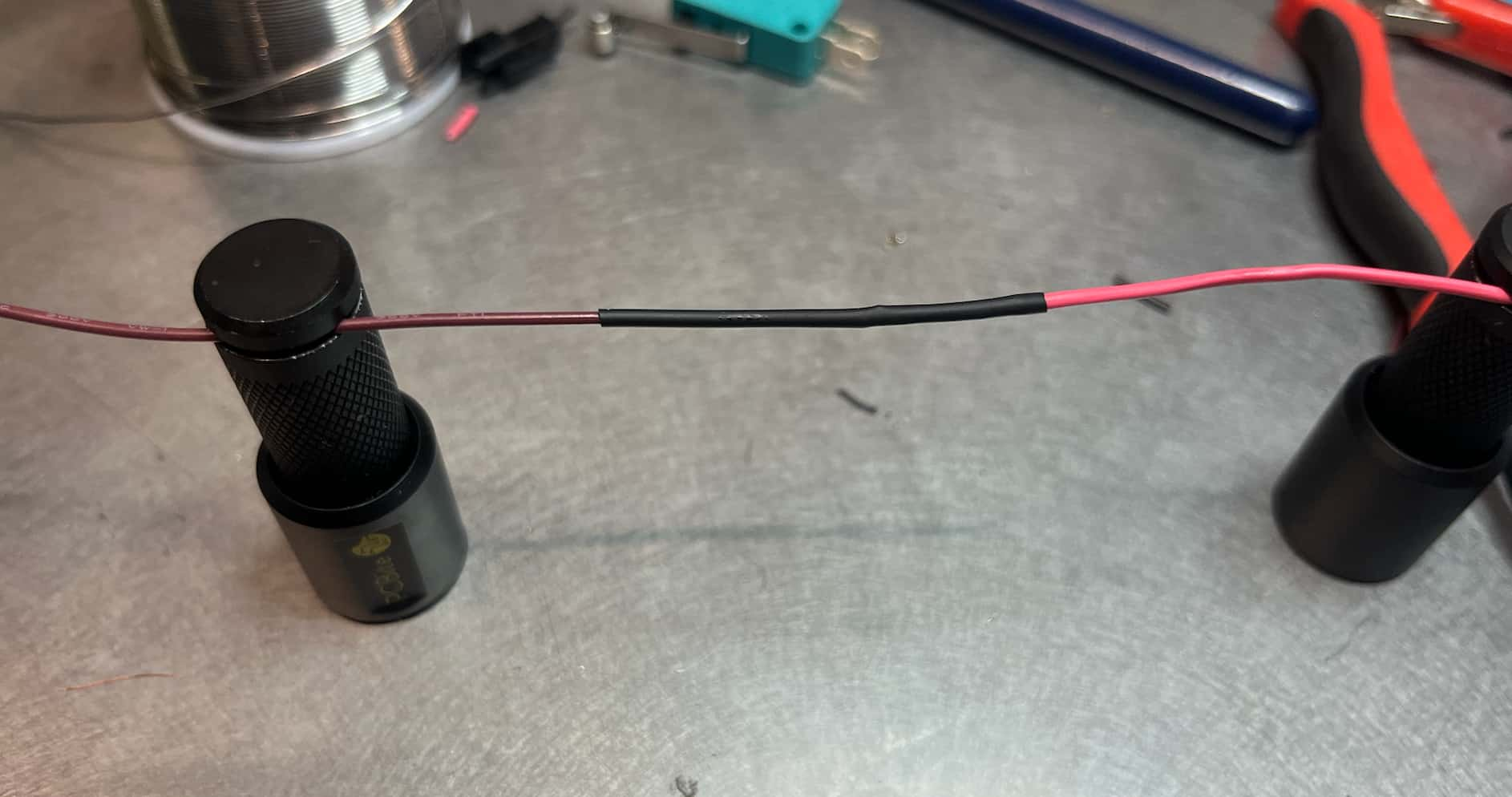

Here is the complete wire with the heat shrink:

Limit Switch

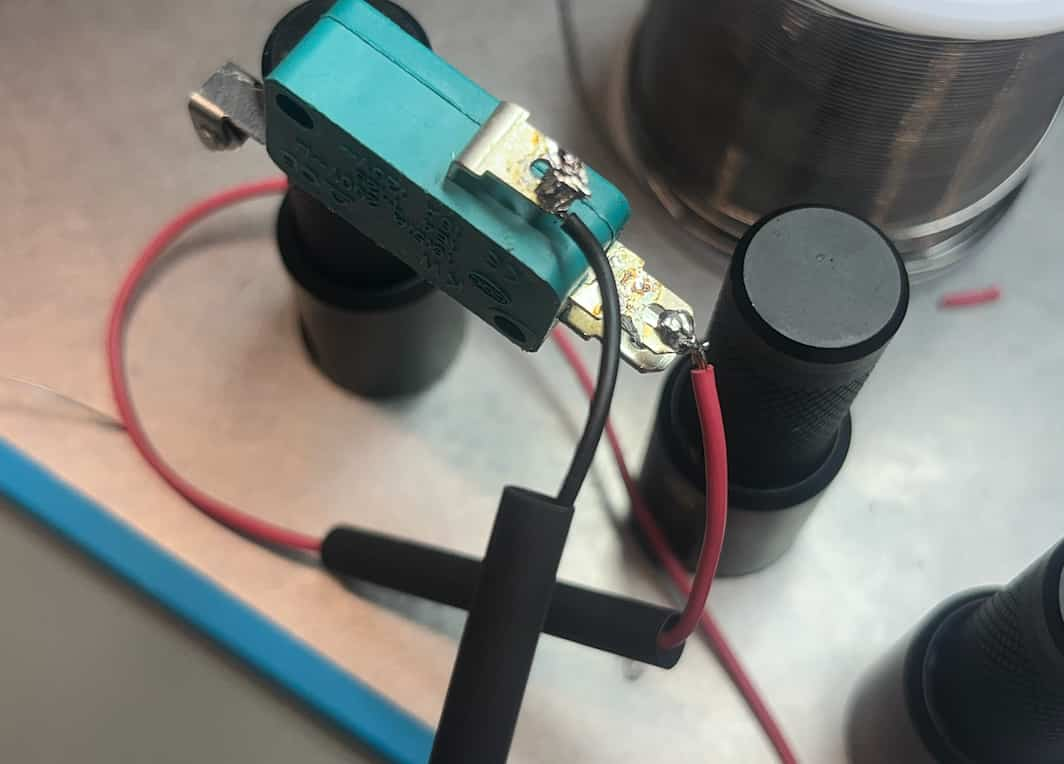

I grabbed the other ends of the two wires and first put on heat shrinks. I then wrapped the other ends of the wire to the limit switch and then soldered.

Using the same machine to apply heat, I shrinked the heat shrinks.

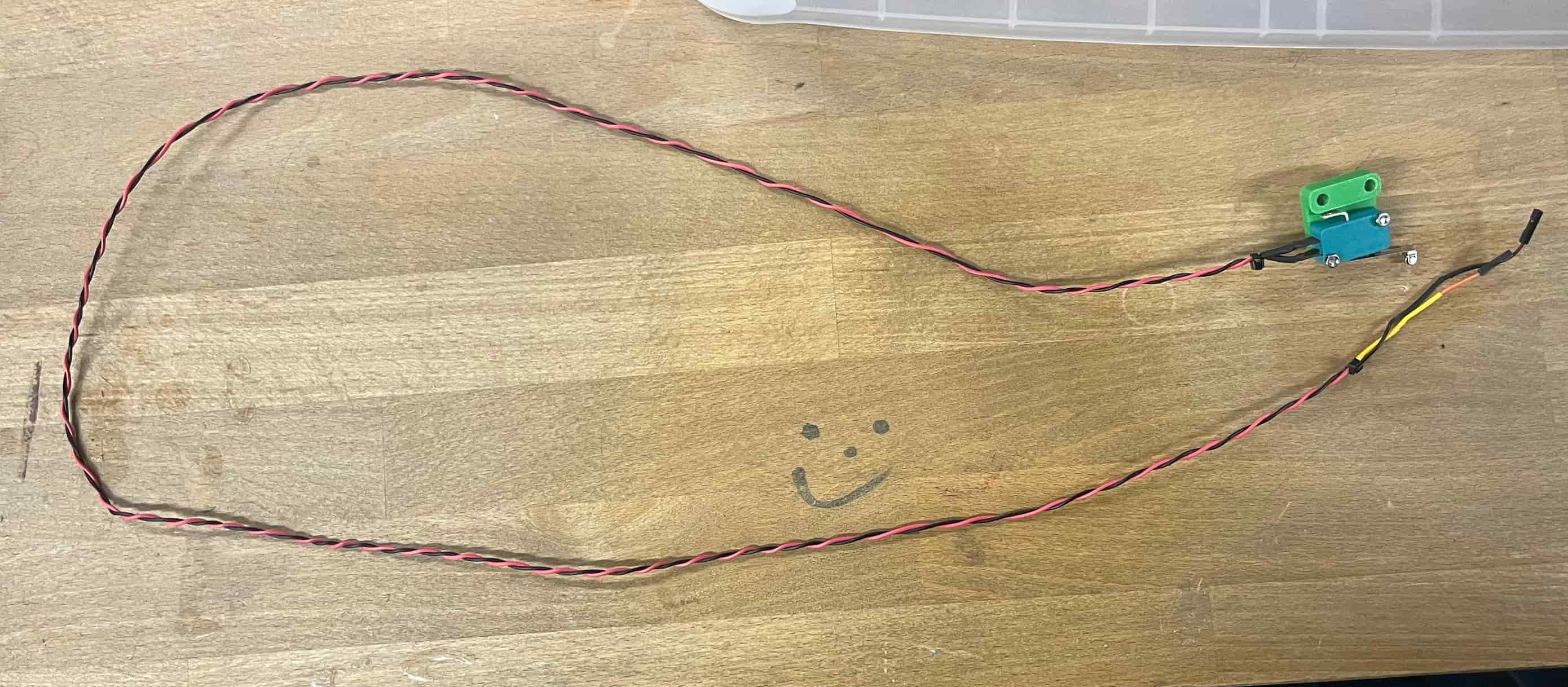

Final product:

Ethernet + Jumper Wire

This time I used jumper wires on both ends, male on one end and female on the other.

I cut the ethernet cable on both ends and seperated the wires. There are 8 wires in total and I needed to 3 of them for one cable and 4 of them for 4 cables.

I then followed the same steps of cutting, soldering, and shrinking the heat shrink

Conclusion

This week, I learned how to prepare, solder, and insulate custom cables for electronic connections. On the group side, I saw how CAD, electronics and physical assembly all come together in building a CNC-like machine.