Week 8: Electronics Production

Click to access the group assignment

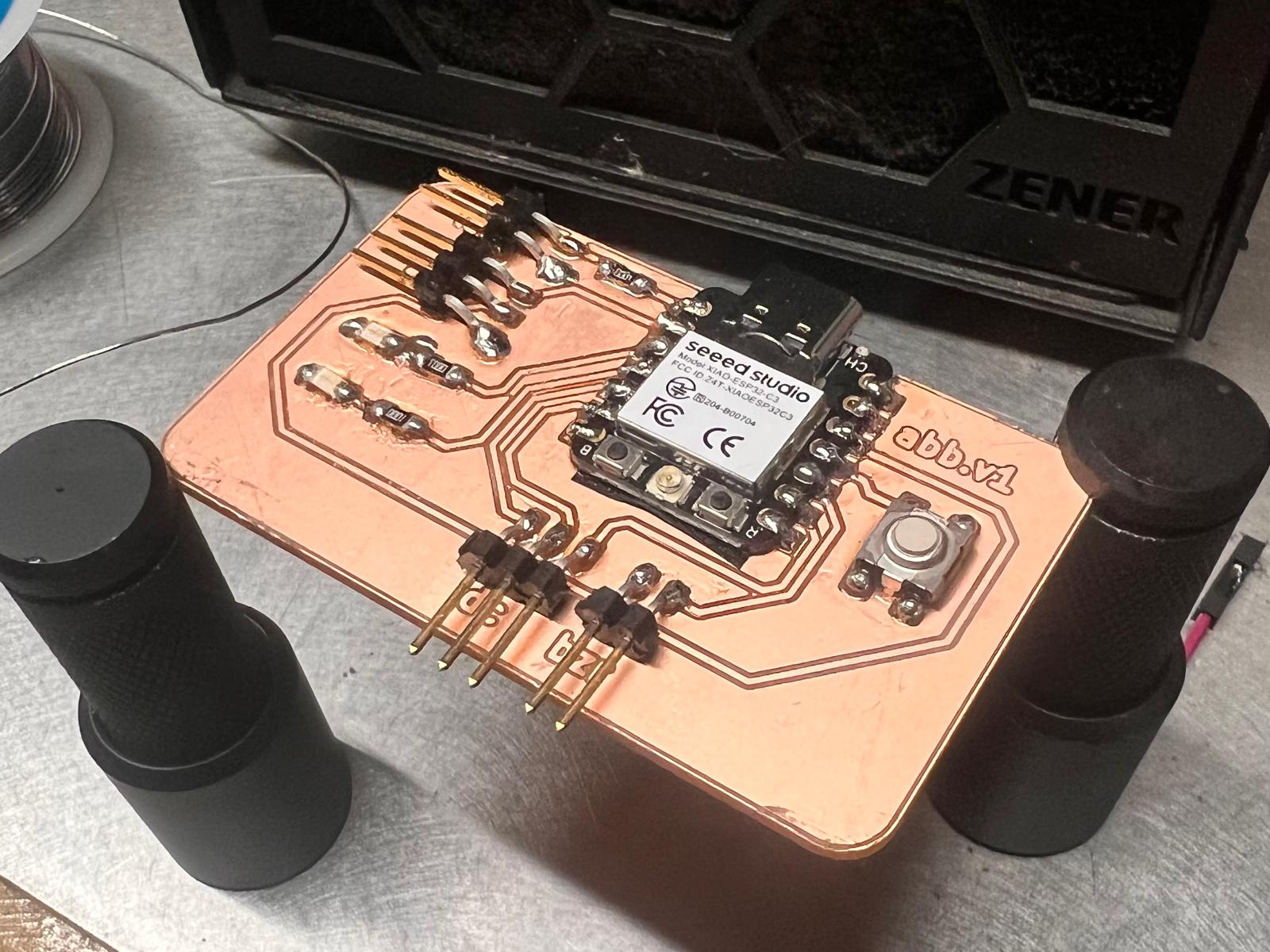

This week, I learned how to produce a custom PCB using a CNC milling machine. The process included file preparation, toolpath generation, probing, milling, and component soldering.

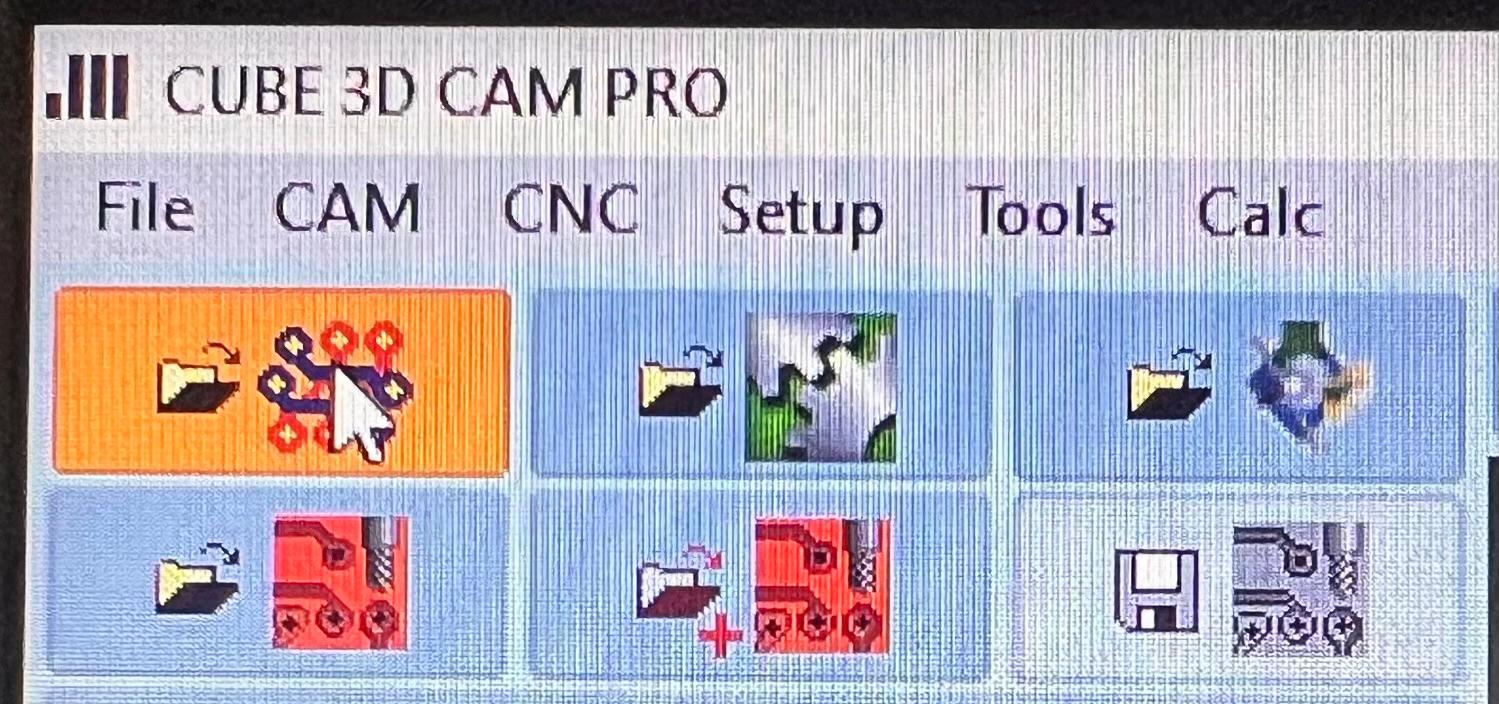

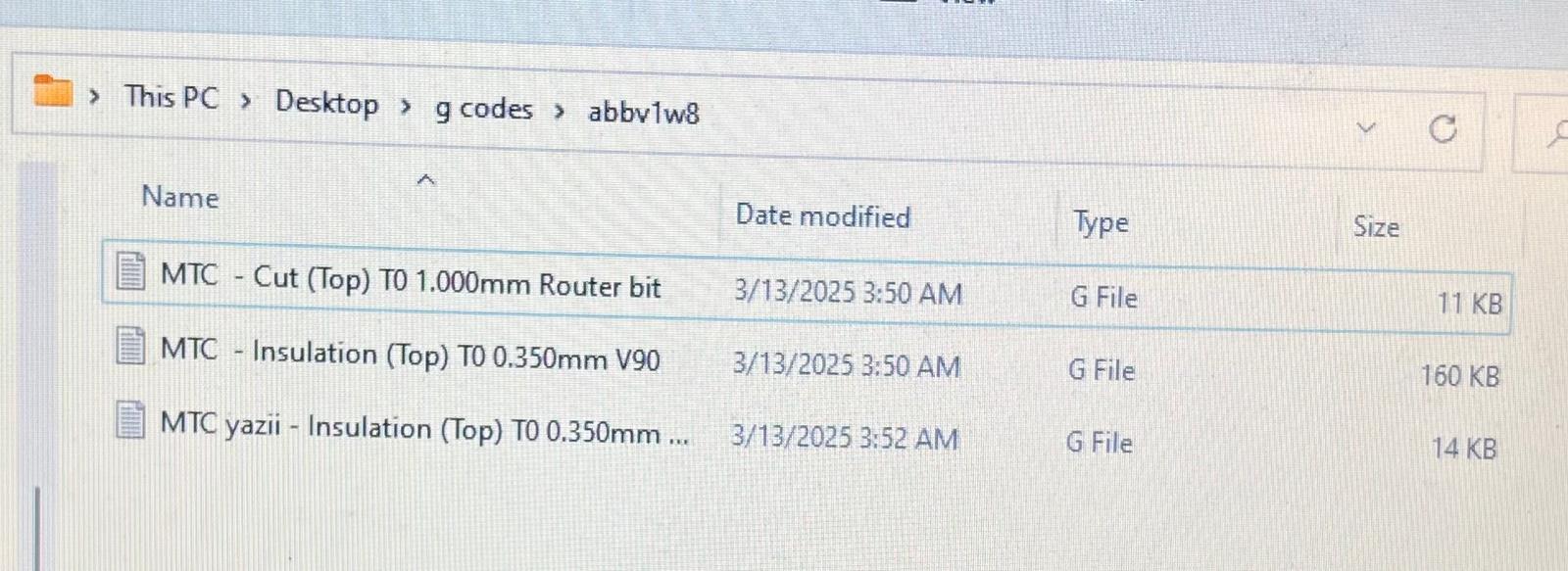

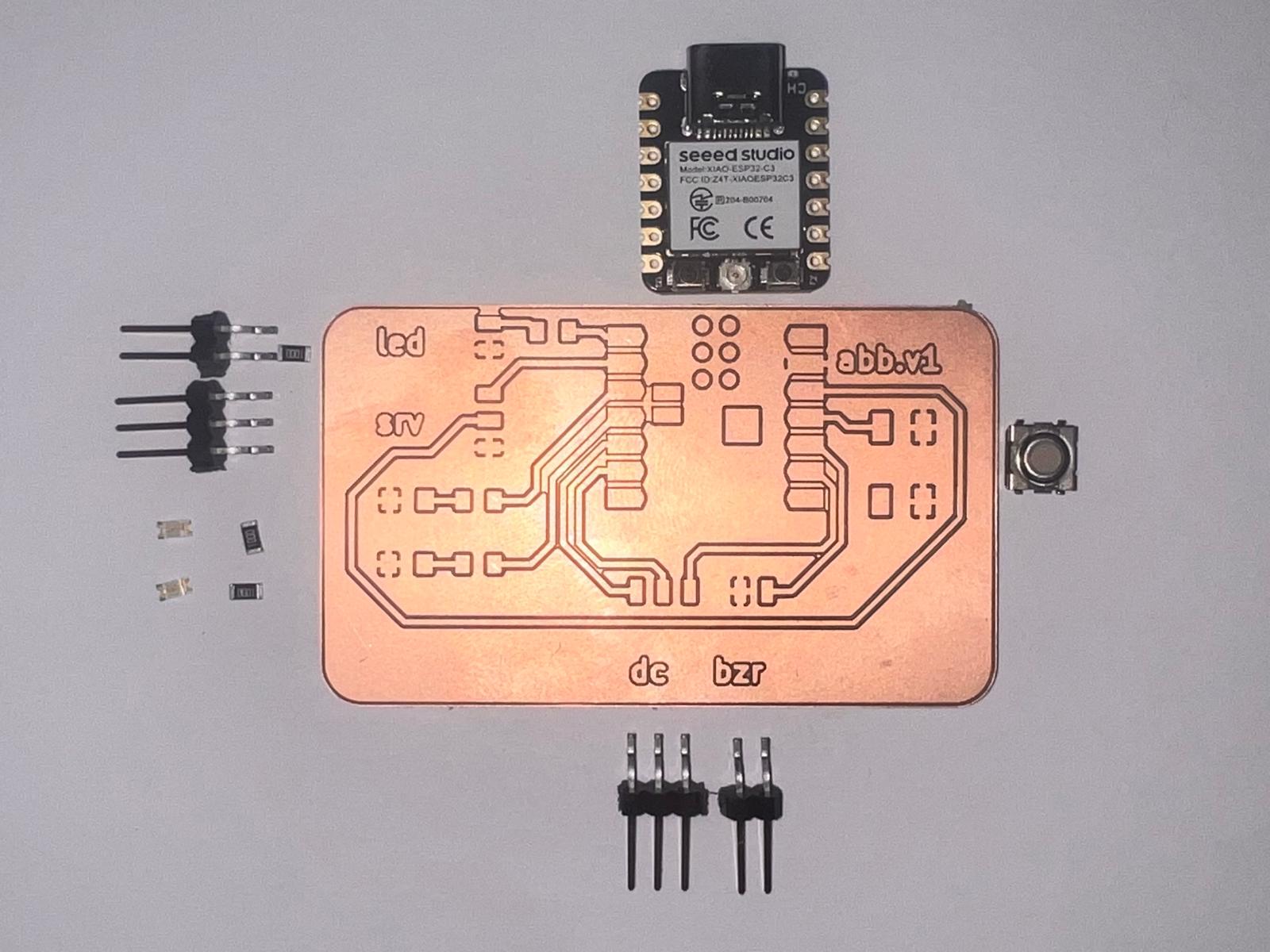

I started by importing my Gerber files into Cube 3D CAM Pro. This software allowed me to visualize the PCB design and generate G-code for the engraving and cutting operations.

After importing the Gerber files, I previewed the traces and outline. This helped me confirm the alignment, scaling, and overall board layout.

Generating Toolpaths in Cube 3D CAM Pro

- Engraving: V90 engraving bit (~0.1mm depth) for isolating traces

- Cutting: 1.0mm flat end mill (~1.8mm depth, multiple passes)

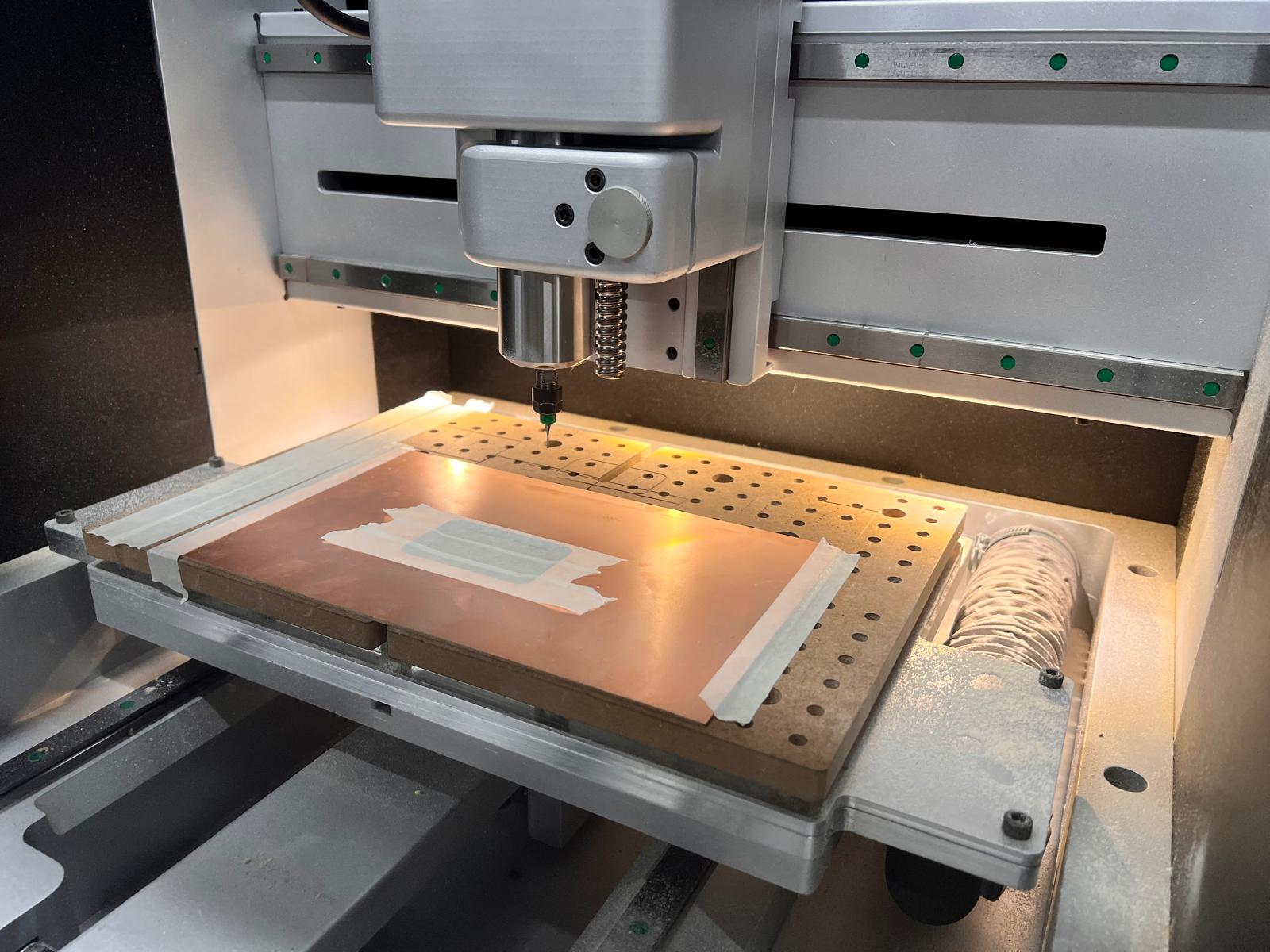

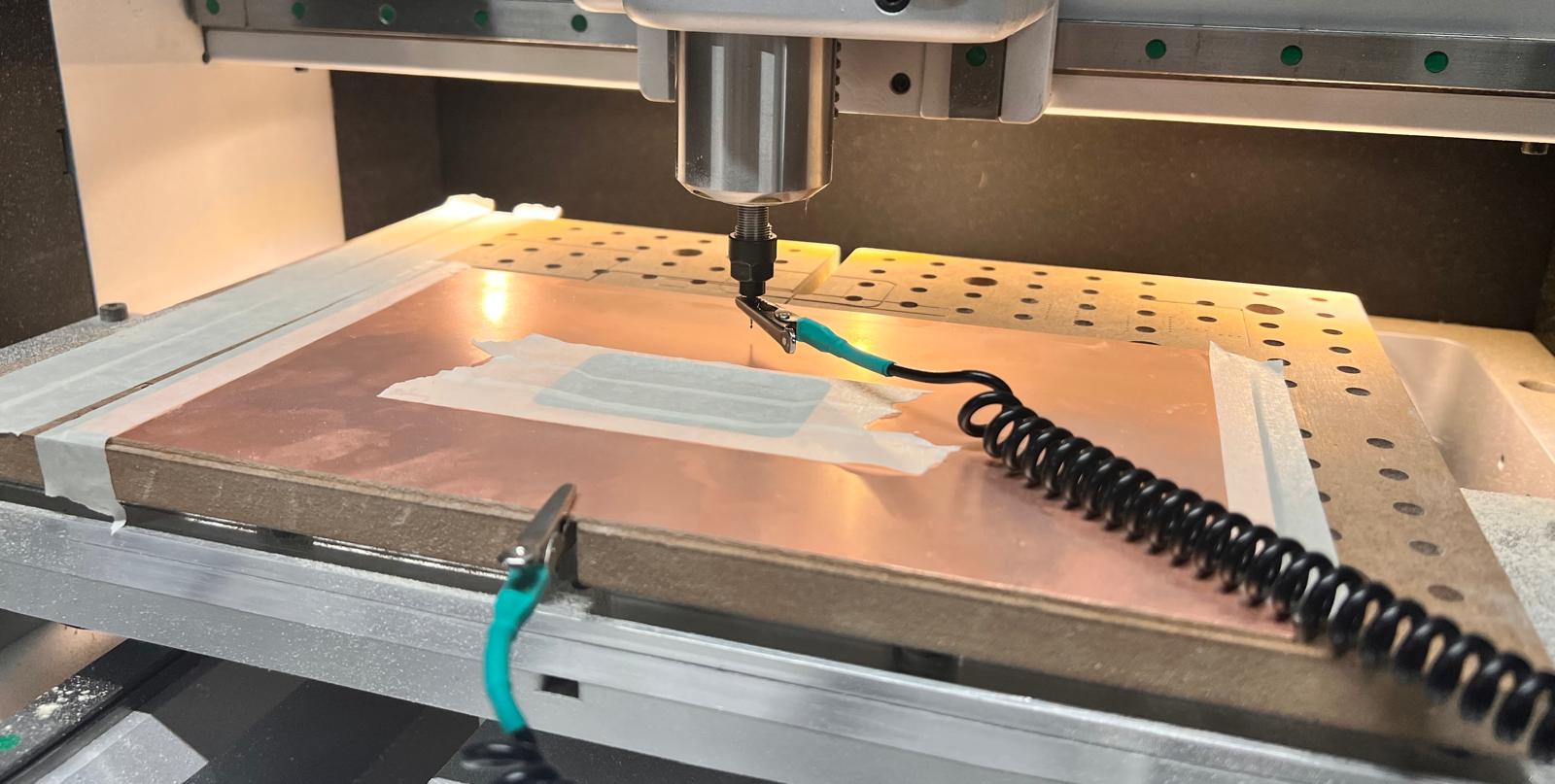

The copper-clad board was fixed with tape on a sacrificial layer.

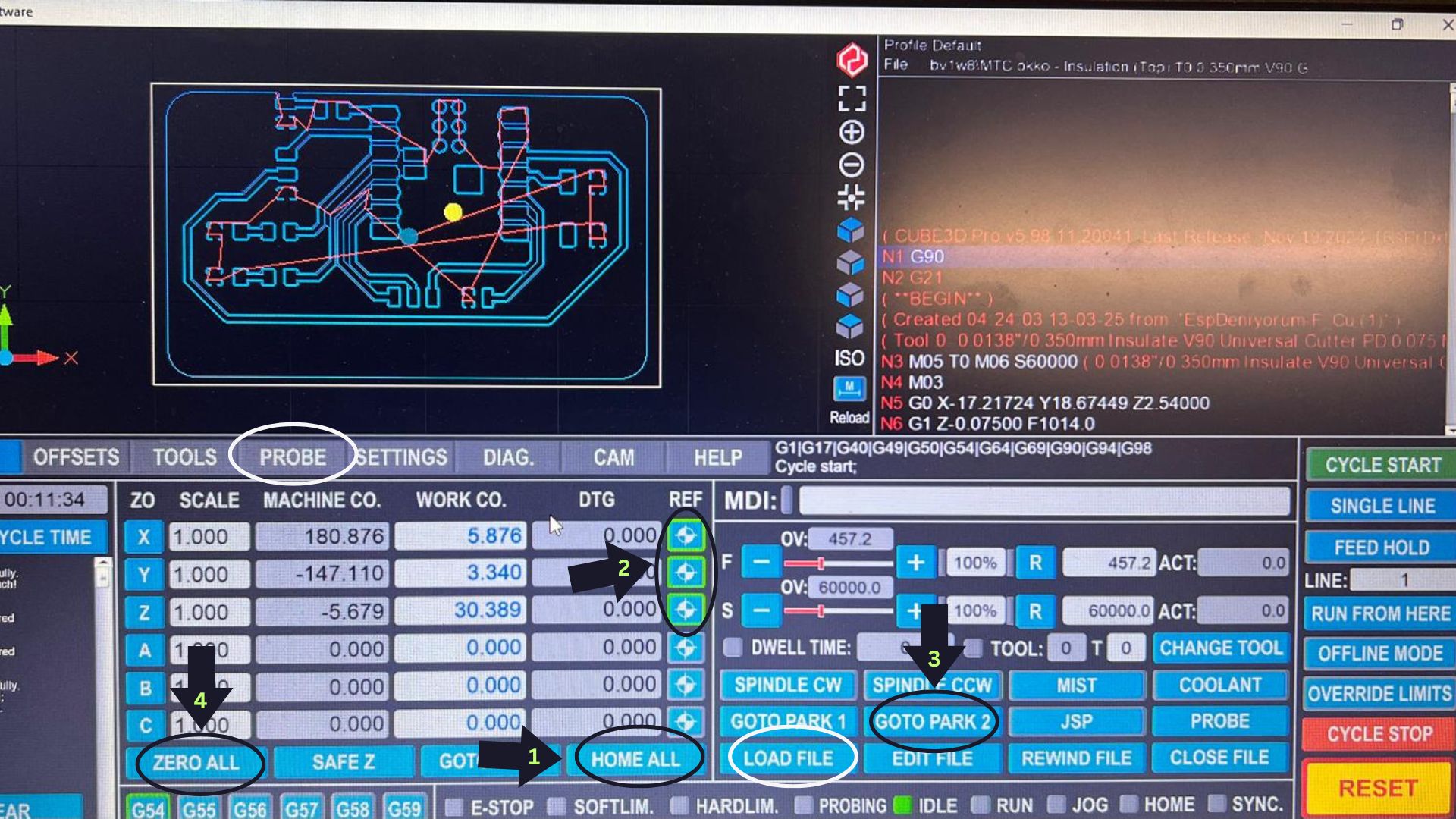

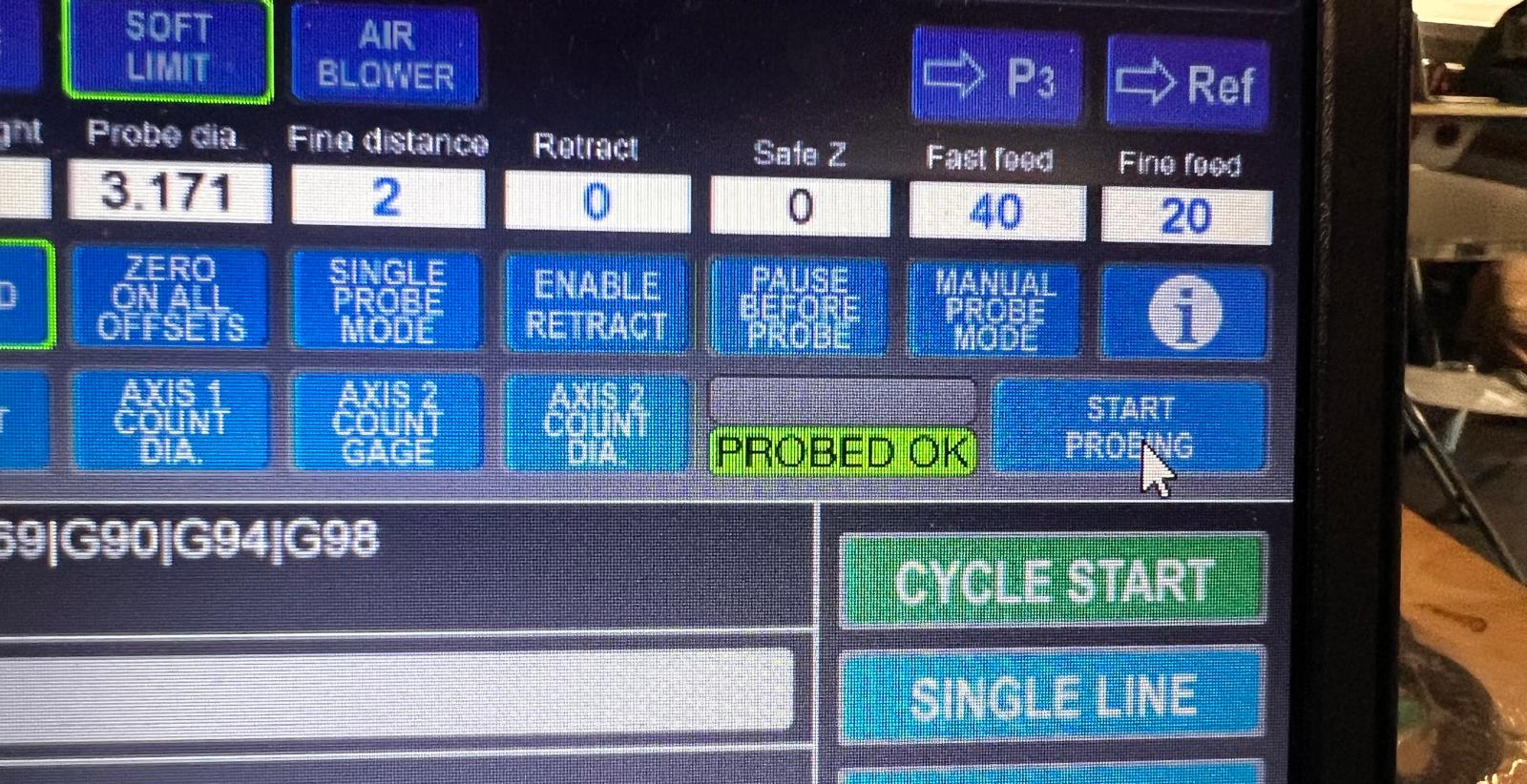

Machine Setup Sequence:

- Click HOME ALL

- Wait for all indicators to turn green

- Click GOTO PARK 2

- Click ZERO ALL

- Change the bit and begin probing

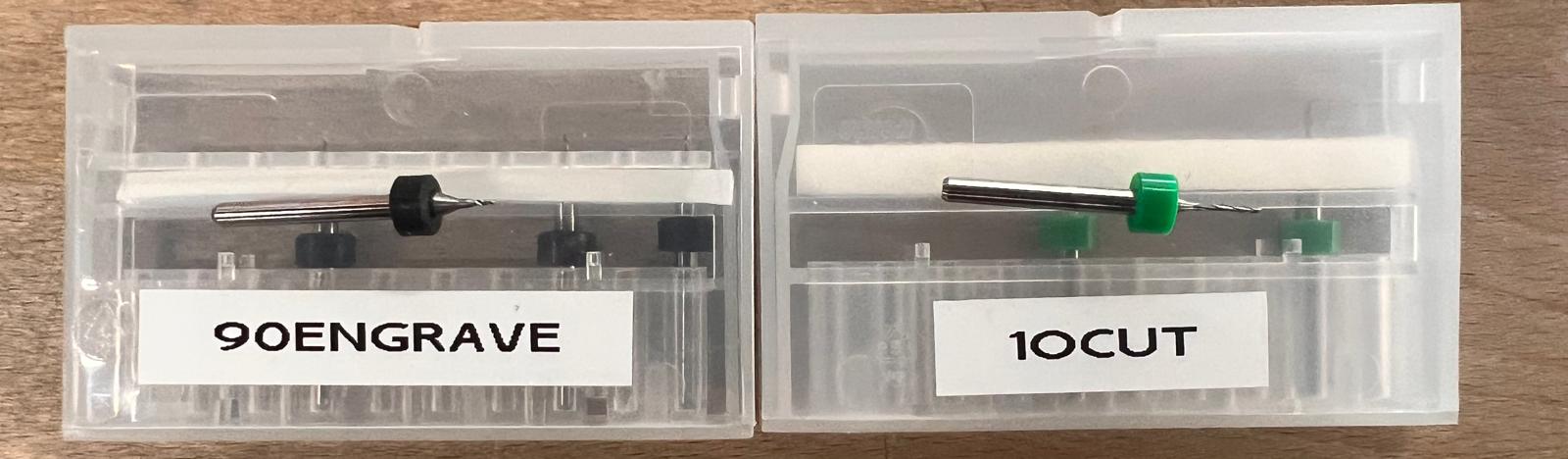

Bits used:

- V90 Engraving Bit

- 1.0mm End Mill

I used surface probing to determine the Z-offset of the copper board.

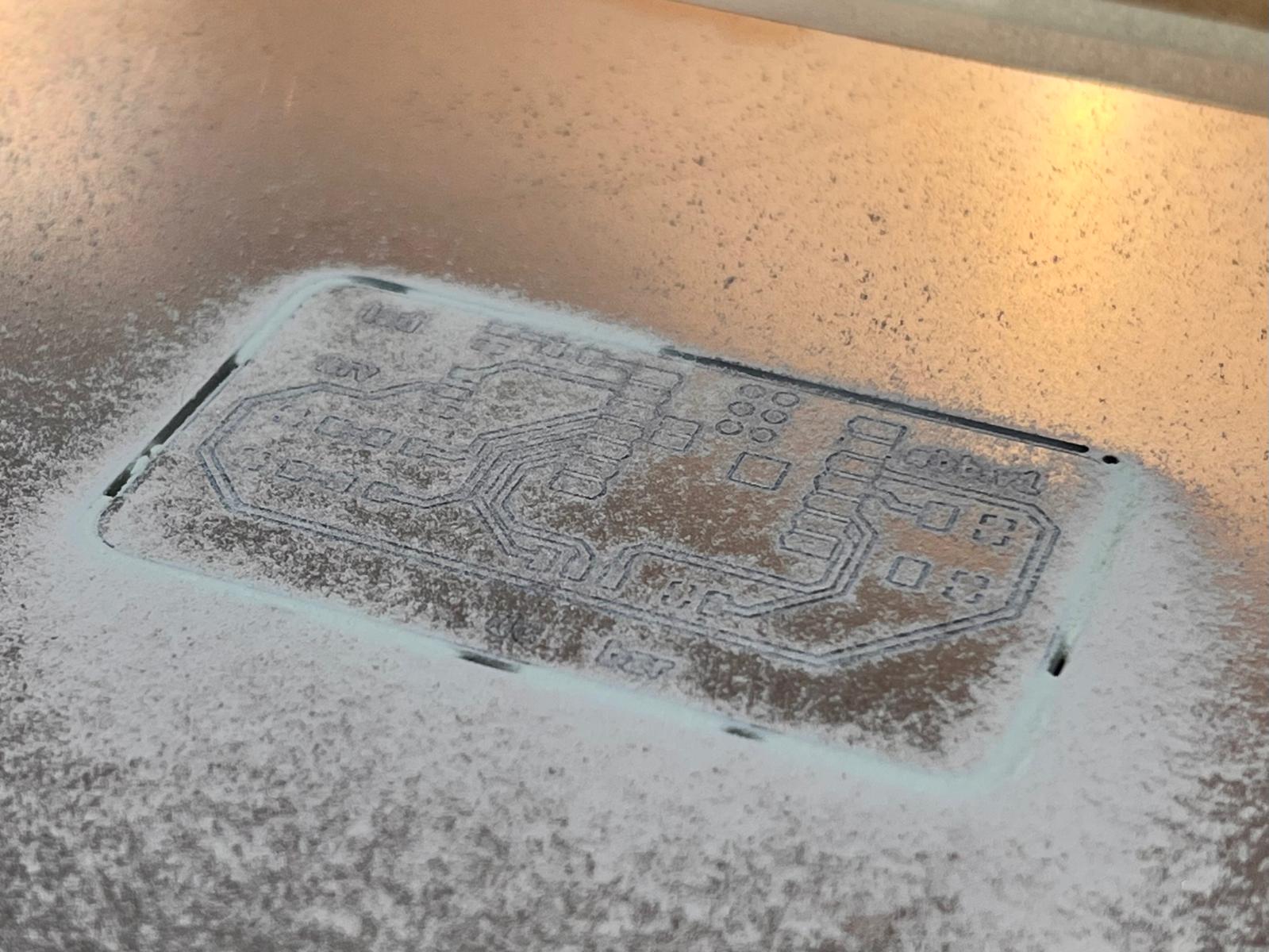

Started engraving traces with V90 bit.

Re-probed after switching to the 1.0mm bit.

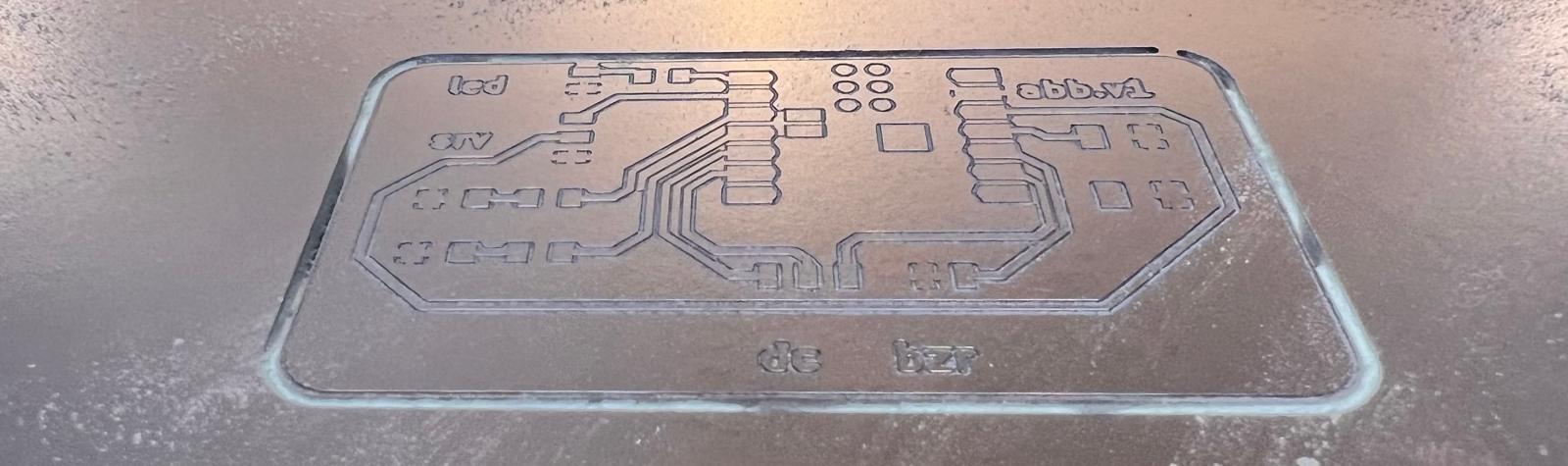

Traces and outline milled successfully.

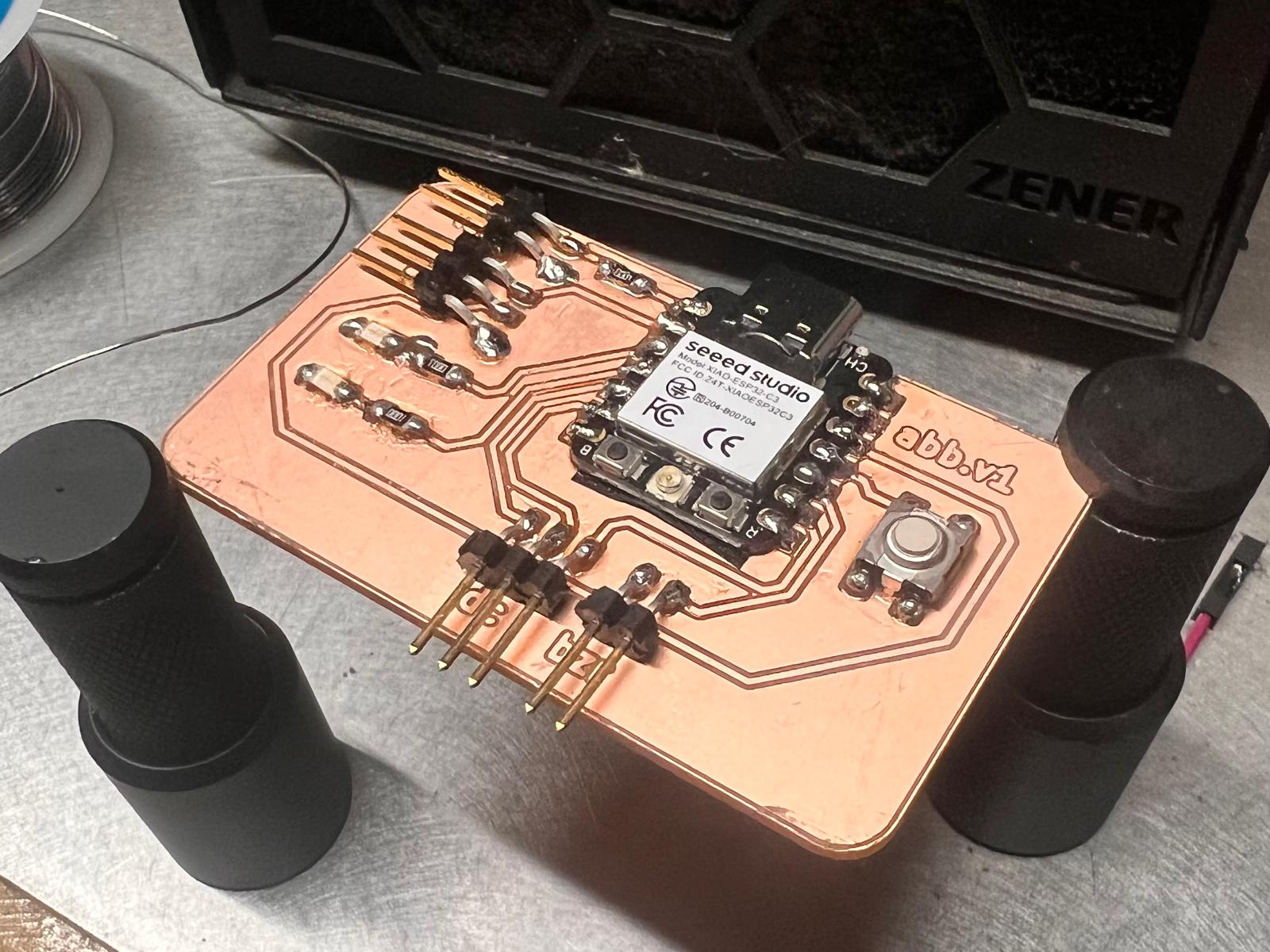

Cleaned PCB ready for component soldering.

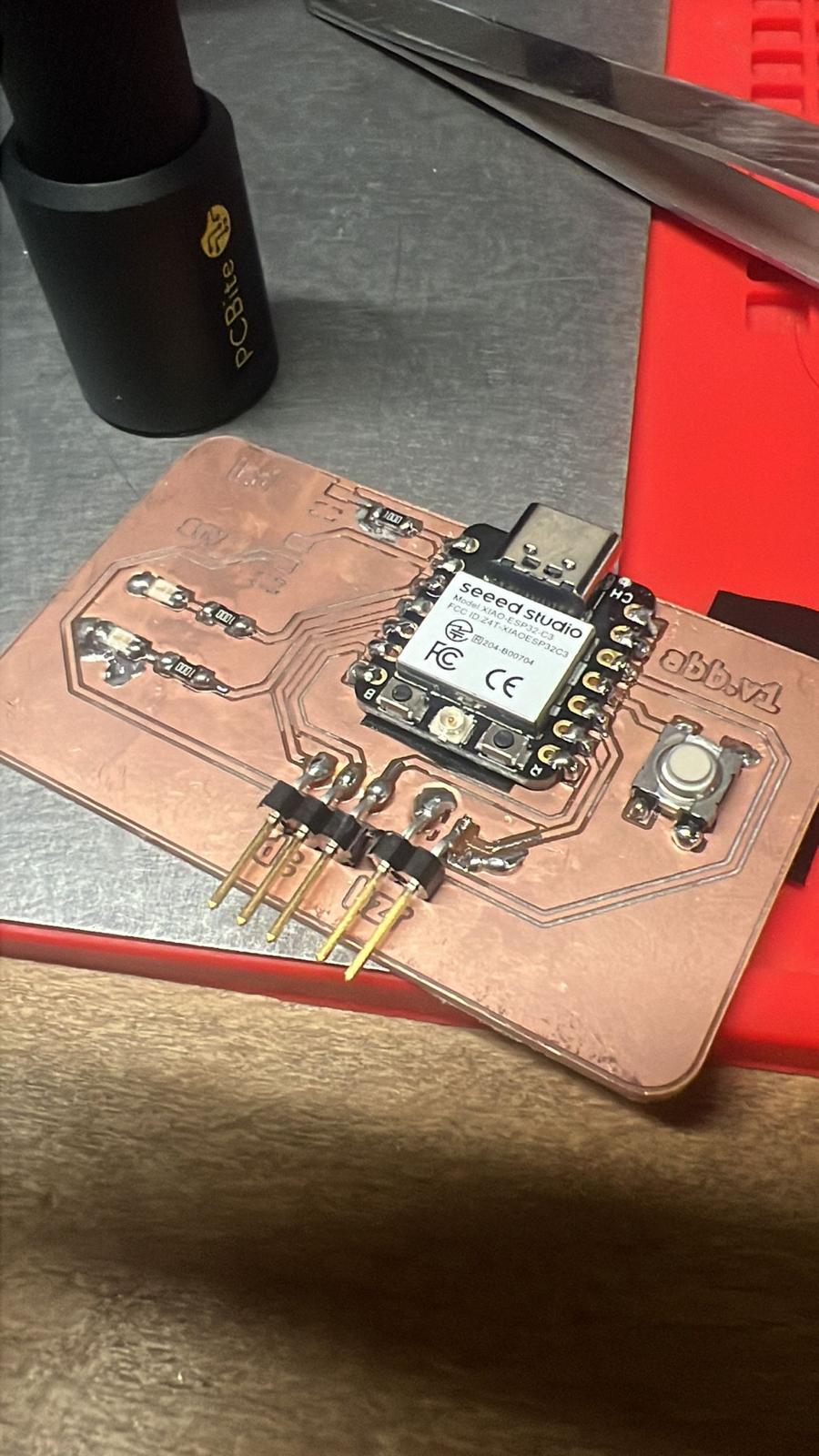

First soldering attempt had some issues.

Successfully fixed the solder joints in a second pass.

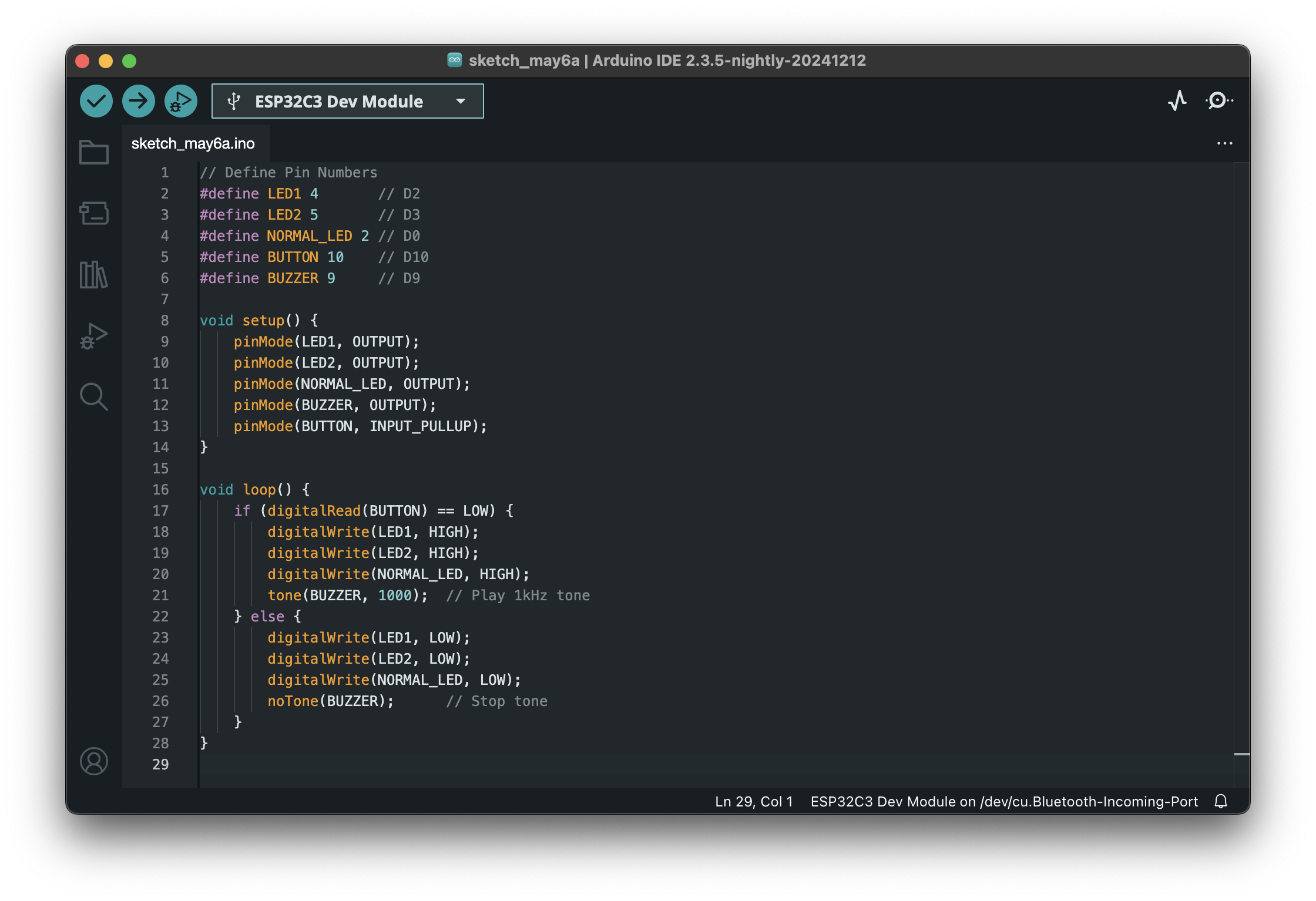

Testing the Board Functionality

Uploaded code with Arduino IDE to test LEDs and buzzer via button input.

Code

#define LED1 4

#define LED2 5

#define BUTTON 10

#define BUZZER 9

void setup() {

pinMode(LED1, OUTPUT);

pinMode(LED2, OUTPUT);

pinMode(BUZZER, OUTPUT);

pinMode(BUTTON, INPUT_PULLUP);

}

void loop() {

if (digitalRead(BUTTON) == LOW) {

digitalWrite(LED1, HIGH);

digitalWrite(LED2, HIGH);

tone(BUZZER, 1000);

} else {

digitalWrite(LED1, LOW);

digitalWrite(LED2, LOW);

noTone(BUZZER);

}

}Summary

- LEDs light up when button is pressed

- Buzzer makes sound at 1000 Hz

- Button uses internal pull-up and is responsive

Final video

Hero Shot