17 - Applications and Implications, Project Development

Applications and Implications:

Propose a final project masterpiece that integrates the range of units covered.

17.1 Scope

My project aims to be a proof of concept for using non-optical compound parabolic concentrators as a method of cooking foods at the exit aperture.

Most parabolic concentrators used for solar heating or cooking currently available have a a satellite or trough shape reflecting and focusing light on to point above. A more comprehensive set of references can be found on my project page.

My design hopes to use the edge-ray that dictates all rays from the edges of a source to the edges of the target, all rays from the source’s interior will be directed to the target. This technique is used to intensify light in laser optics and in solar power generation.

Solar furnaces can reach incredibly high temperatures at their focal point exceeding 3500°C, so possible applications with correct isolation range from cooking food, firing ceramics and even smelting or sintering.

For the project I am going to present on the 12th of June, however, I am going to perform an experiment with a compound parabolic concentrator (CPC) made from a lightweight flexible reflective material (BoPET or Alu PET).

The experiment will be assessed on how long the coals or cooking plate can sustain a temperature above 120°C, or a pot of water boiling.

17.2 Design Process

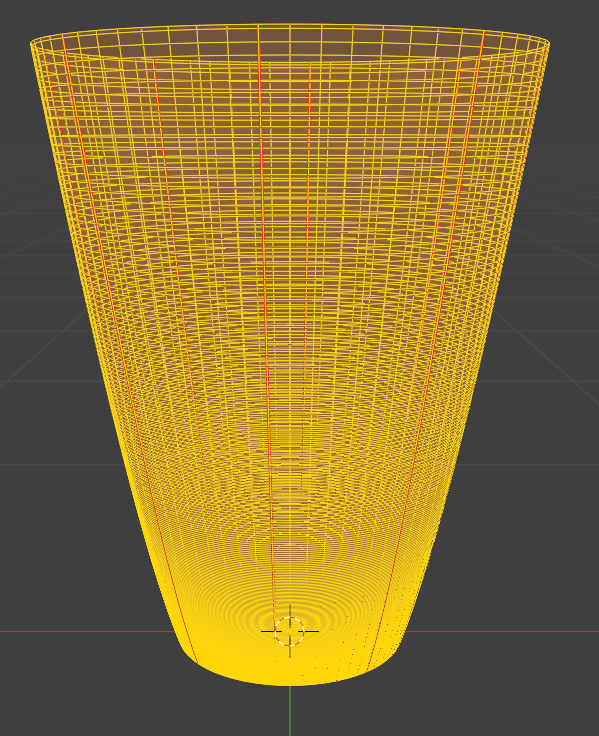

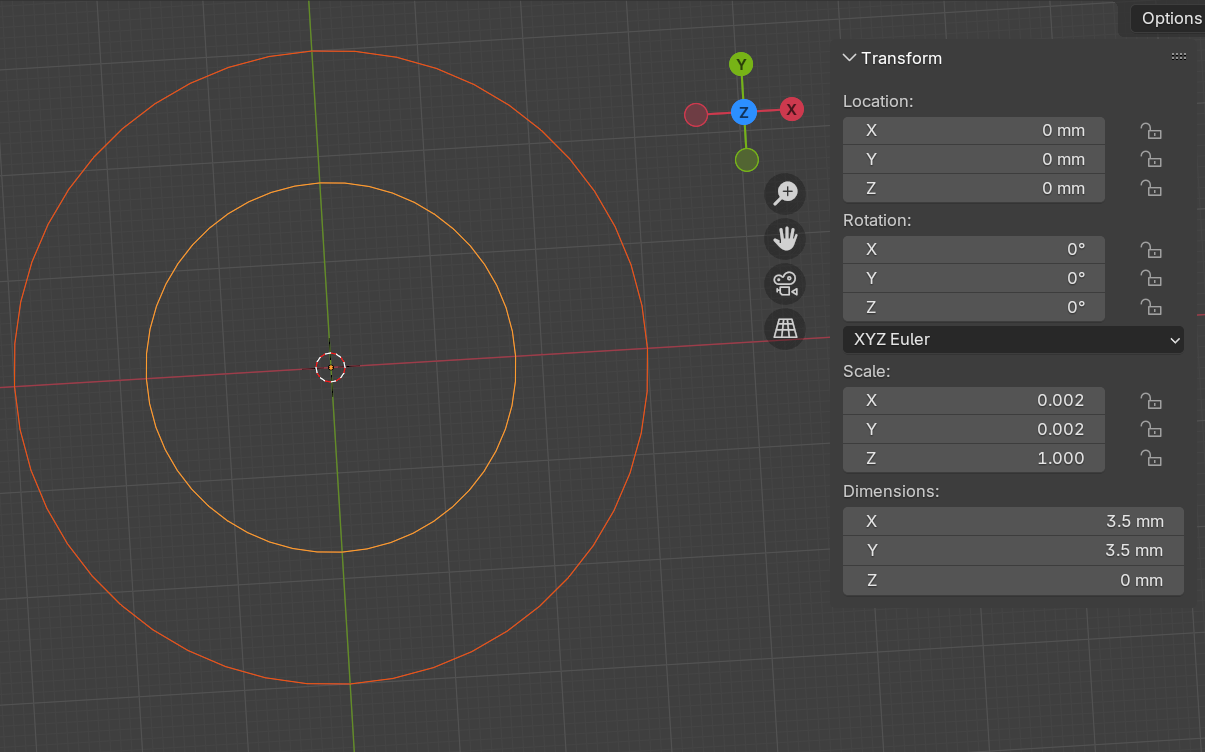

The parabola was created using a python script based on the edge ray principle

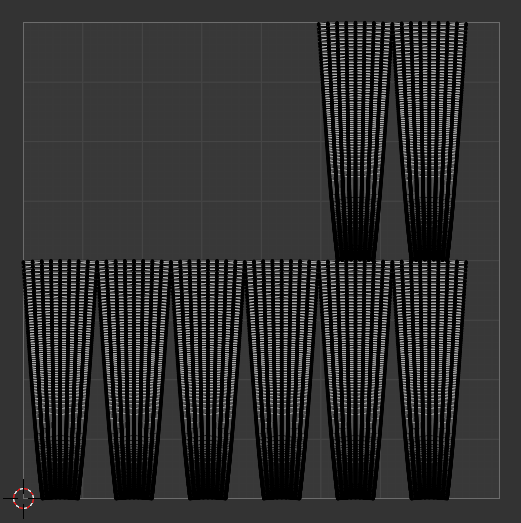

I then rotated it 360° with the “screw” modifier with 64 steps. This allowed me to mark equally distanced seams to unwrap the parabola into 8 pieces. This of course is only an approximation so that parabolic shape becomes more conic, but for this proof of concept I still hope to see the influence of solar concentration. These are then laser cut in cardboard with the RayJet400 to use as a template with the Mylar

Once the pieces have been cut and scotched together (the mylar tears easily so it is not adapted to sewing, hopefully the CPC doesn’t heat up too much so the adhesive fails or the nylon catches fire!), it is time to make the wire frame.

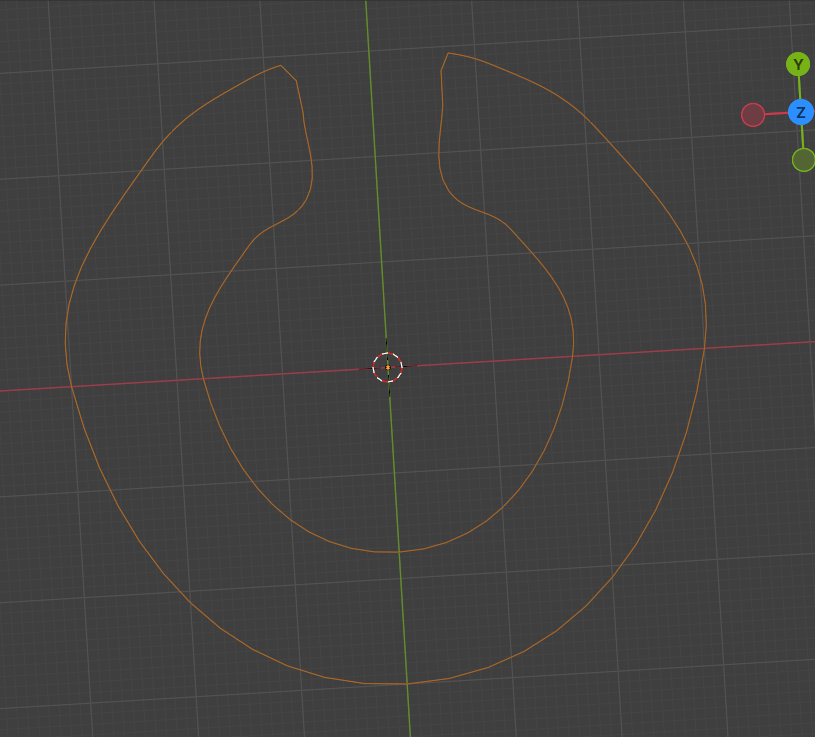

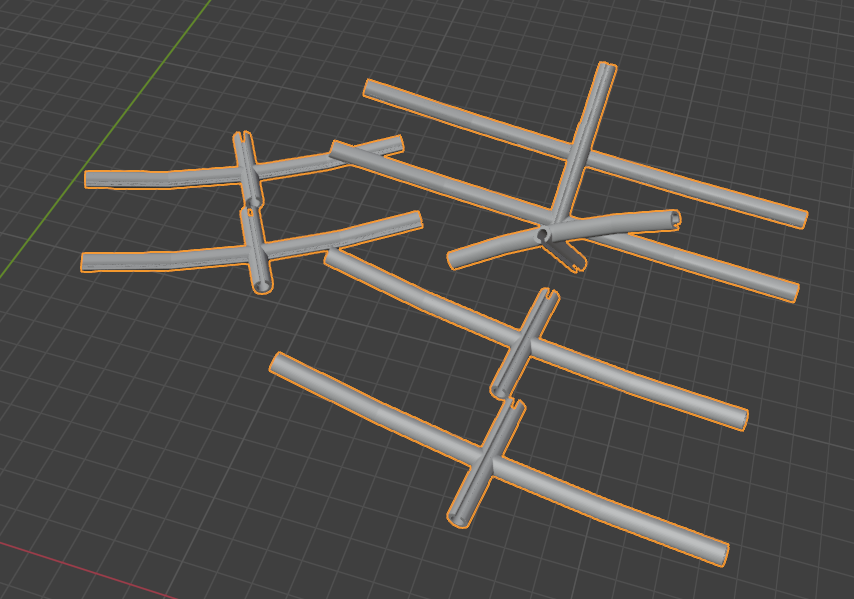

The wire frame is made from taking edge cuts at various heights and then bevelling a teardropish shape around the curve.

The meshes are cleaned up at 0, 33, 66 and 99 cm to make horizontal and vertical connections to guide the 3mm wire frame into position and hold the parabolic form.

To attach the frame to MYLAR fabric I used rivets, cutting a hole and then reinforcing it with metal rivets as you can see in the photos below. There were 4 rivets for each of the 8 edges, so 32 rivets in total. A big thank you to Cindy for her help and handywork.

A rugged case houses the PCB and the electronic components. The electronics measure the temperature of rocks or the exterior of the cooking pot. Once the temperature exceeds 90 degrees, it sends a message via Arduino Cloud to inform the user that it is at cooking temperature.

However, for the experiment I'll have to be present to make sure it doesn't set on fire, or at least be there to capture it on film !

The parabola starts to take shape, and it can be stored or used as a shower curtain too!

| Component | Amount | Price | Cost | |

|---|---|---|---|---|

| Mylar | 2 m2 | 12 euros for 6 m2 | 12 euros | |

| PLA | 20 euros | 0 taken from Lab | ||

| Lava Rocks | 10-12 kg | 3kg 9 euros | 37 euros | |

| Cork | 0.5 m2 | 20 euro / m2 | 0 taken from Lab | |

| 3mm wire | 0 taken from Lab | |||

| 32 metal rivets | 0 taken from Dani (thanks) | |||

| Xiao ESP32s3 | 5.82 euros | 0 taken from Lab | https://es.rs-online.com/web/p/placas-y-kits-compatibles-con-arduino/2500966?gb=s | |

| PCB copper board | 0 taken from Lab | |||

| RGB LCD Screen |

17.3 Design Issues

The CPC is designed to focus light at the exit aperture. So in the current design the CPC is directly in contact with the cooking surface. This raises problems using BoPET or ALU PET materials as they typically fail around 250-260°C. Should the current design attain such temperature, it will at least make a nice art school project!

It would open the door to using a more robust approach to build the CPC typically from thin steel, brass or aluminium sheets kirigami’d into shape, or a solid permanent structure made from “earthen” materials and a reflective surface added to the internal wall to be used for community cooking.

The current design lacks insulation, a more robust even permanent structure would allow for insulation to be used for the oven.

Should the temperature be too low, I will consider adding a Fresnel lens at the the exit aperture, which would allow the CPC to be placed at a height above the cooking surface, and reduce the risk of it setting alight, but perhaps increase the risk of damage at the cooking surface. These had some interesting results.