week 18 Applications and Implications

Plan a final project masterpiece that integrates the range of units covered, answering:

What will it do?

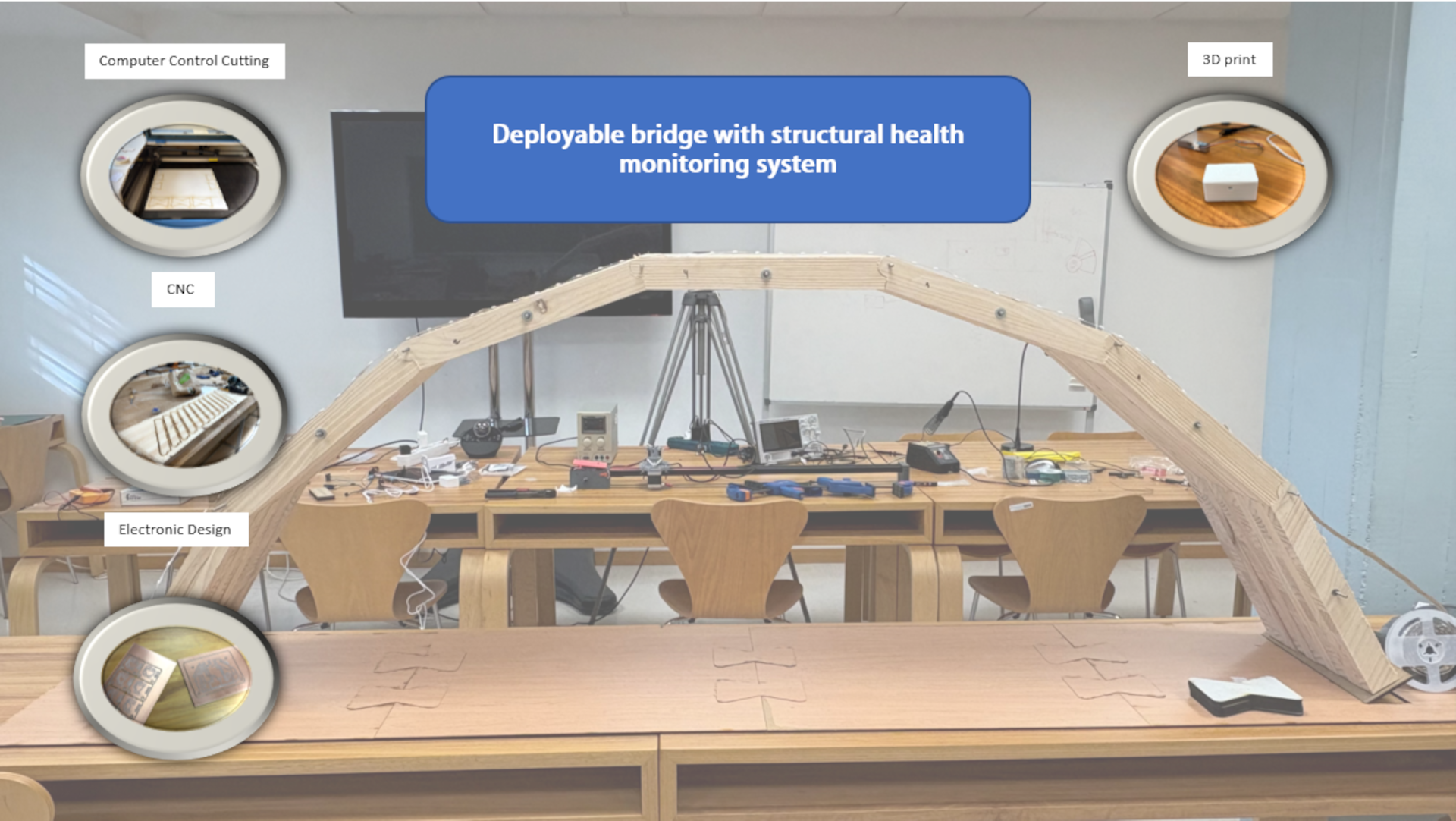

The project is a self-assembling wooden bridge equipped with a structural health monitoring (SHM) system. It will measure loads at critical joints using load cells, detect vibrations with accelerometers, monitor environmental conditions with humidity and temperature sensors, and display structural health status through LED lights. The LEDs will change color depending on the bridge’s condition, helping to visually communicate structural integrity in real time.

Who’s done what beforehand?

Previous research has explored SHM systems in full-scale bridges using professional-grade sensors and complex data acquisition systems. Projects in academia and industry have used load cells and accelerometers to monitor stress and vibrations, while deployable structures have been developed in robotics and emergency engineering. However, few have integrated all these elements—self-assembly, low-cost sensing, environmental monitoring, and real-time visual feedback—in a small-scale timber prototype. This project fills that gap by combining these concepts with open-source tools and modular construction techniques.

What sources will you use?

Academic literature on SHM, timber structures, and deployable systems. Datasheets and application notes of sensors and microcontrollers. Open-source hardware.Documentation from FabAcademy.

What will you design?

The structure will consist of an arch that is assembled by many little blocks, I have to design the blocks and the joints between them. Also the supports need to be designed with specific consideraions to properly traspase the tension to the floor.

I have to design a part that direction the vertical load to the cell load to bending.

On the electronic topic I have to design the pcb’s. This means using kicad design the components, tracks the pcb will have.

Finally I need to design the system integration. Which consist of 3d printed boxes to rpotect electronics.

What materials and components will be used?

Timber beams and dowels for the bridge structure Load cells (e.g., 50 kg strain gauge type) ADXL345 accelerometers Humidity and temperature sensor (e.g., DHT22 or SHT31) Xiao ESP32C3 microcontroller Custom PCB LEDs and resistors Wires, headers, and mounting hardware 3D-printed or CNC-fabricated parts

Where will come from?

Custom parts fabricated in the fablab. material is bought on local commerce like Leroy Merlin. electronics, as it is more specific, will be bought on online stroes like amazon, cetronic

How much will they cost?

| Material | Amount | Cost per unit € | Total € |

|---|---|---|---|

| Spanish Pinus sylvestris wooden boards of 240x40x28 mm | 3 | 35.99 | 107.97 |

| threaded steel rod | 6 | 1.09 | 6.54 |

| Single-sided white laminated plywood | 2 | 31.85 | 63.7 |

| MDF board | 1 | 11.99 | 11.99 |

| Load Cells | 6 | 1.5 | 9 |

| acceleromter | 1 | 3 | 3 |

| Moister sensor DIY | 1 | ~0 | ~0 |

| Led lights White PCB, 5m 30 IP30 WS2812B | 1 | 3.38 | 3.38 |

| humidity sensor htp11 | 1 | 2.41 | 2.41 |

| copper board | 2 | 1 | 2 |

| copper board | 1 | 1 | 1 |

| PinHeader_01x04_P2.54mm_Horizontal_SMD | 9 | 0,59 | 5,31 |

| Ribbon cable | 10 m | 10,30 | 10,03 |

| R_1206 0 Ohm RC1206FR-070RL | 1 | 0,09 | 0,09 |

| XIAO-ESP32C3 | 1 | 4,39 | 4,39 |

| PinHeader_02x03_P2.54mm_Vertical_SMD | 6 | 0,55 | 3,3 |

| PinHeader_01x03_P2.54mm_H_SMD | 6 | 3,04 | 18,24 |

What parts and systems will be made?

Bridge modules with embedded joints A sensor mounting system A custom PCB for data handling Firmware for sensor reading and LED control A user interface through visual LED cues Possibly a web interface for sensor monitoring

What processes will be used?

Woodworking (cutting, drilling, assembly) - CNC and lasser cutting 3D printing Soldering and PCB assembly Microcontroller programming (Arduino/C++) Data collection and basic signal processing Structural testing (static and dynamic loads)

What questions need to be answered?

How accurate and reliable are the sensors in this configuration? Can the modular joints handle the necessary loads without failure? What thresholds define safe vs. critical conditions in the bridge? How responsive and clear is the LED-based feedback? How scalable is the design for future applications?

How will it be evaluated?

The functionality and stability of the self-assembling structure The successful integration and accuracy of the sensor system The clarity and responsiveness of the visual feedback (LEDs) Testing under different loading conditions and environmental changes The completeness of documentation and reproducibility of the system

Project development

Prepare drafts of your final project summary slide (presentation.png, 1920x1080) and video clip (presentation.mp4, 1080p HTML5, < ~minute, < ~25 MB), put them in your root directory, and check that they are linked in the final presentation schedule

Slide test