Week 12

Moulding and Casting

Brief Overview

In this assignment, we're diving into the world of molding and casting materials. Each of us will review safety data sheets for materials like Instamold, Machine wax, EcoFlex, Moldsil, Hydrostone, and Epoxy Resin. Then, we'll compare test casts made with each material and explore the pros and cons of printing versus milling molds.

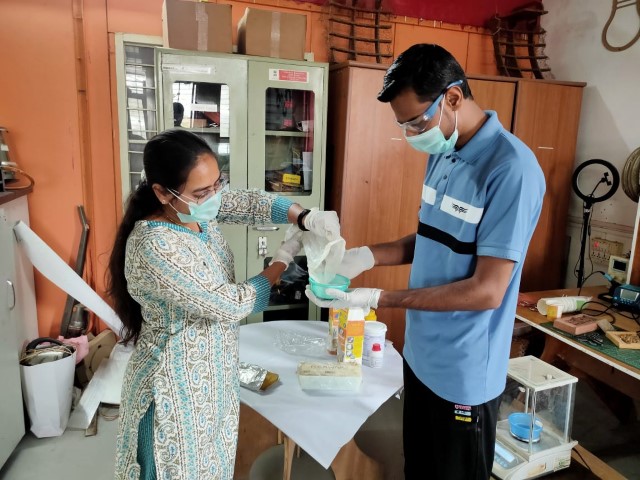

Heroshots

|

|

Group Assignment Page (Moulding and Casting)

In this assignment:-

1.Review the safety data sheets for each of your molding and casting materials

2.Make and compare test casts with each of them

3.Compare printing vs milling molds

In our group project at Vigyan Ashram, we're looking at safety data sheets for different materials, we've got quite the variety of materials here— Instamold, Machine wax, EcoFlex, Moldsil, Hydrostone, Epoxy Resin. Each of us will thoroughly studying its safety data sheet, and then sharing our findings with each other.

Molding and Casting materials

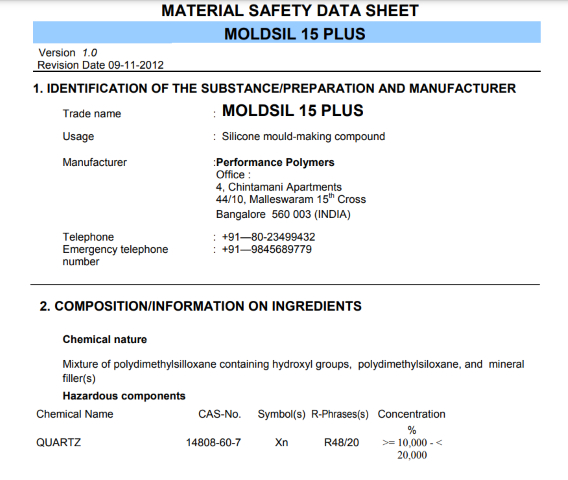

MOLDSIL-15 PLUS:

Moldsil-15 PLUS stands out as a superior grade condensation-curing Silicone RTV, meticulously crafted for molding applications. This exceptional product boasts a flowable consistency, coupled with remarkable mechanical strength. Its versatility shines through in its ability to cure at room temperature, yielding a flexible elastomer. Perfectly tailored for the intricate reproduction of artifacts, figures, and architectural elements, Moldsil-15 PLUS excels in capturing even the most delicate details.

Renowned for its precision, Moldsil-15 PLUS is a preferred choice across various artistic and industrial domains. From replicating prototypes and furniture to molding architectural pieces and sculptures, it delivers impeccable results every time.

Key Features:

- Flowable consistency with high-strength silicone rubber, ensuring exceptional detail reproduction.

- Robust mechanical properties, promising an extended service life.

- Outstanding elasticity and release properties facilitate effortless demolding.

- Superb chemical resistance, ensuring compatibility with a wide range of molding materials and longevity in performance.

DataSheet:

So I have started with choosing a Rear Auto Engine and Chassis, which I modfied and upgraded into a 4 wheels chassis and made a platform for my vehicle

|

|

Product Details

| Color: | White |

| Catalyst Type: | Condensation Cure |

| Grade Standard: | Industrial Grade |

| Packaging Size: | 20 Kg (Part A) and 1 Kg (Part B) |

| Curing Time: | 4 Hours |

| Hardness (Shore A): | 14 A |

| Brand: | MoldSil |

| Purity: | 99% |

| Set Contains: | Catalyst and Liquid Silicone Rubber |

| Form: | Liquid |

| Usage/Application: | For Making Flexible Molds |

Directions For Use

- Stir the base compound (Part A) vigorously before adding the catalyst.

- Mix 100 parts of Base compound with 5 parts of catalyst (Part B) provided.

- Stir vigorously for several minutes, scraping the sides and the bottom of the container to produce a homogeneous mix.

- De-aerate in a vacuum chamber in a container 4-5 times bigger than the content, till the bubbles from the mixture disappear.

- The mix is ready for use.

- For health and safety instructions, please refer to MSDS.

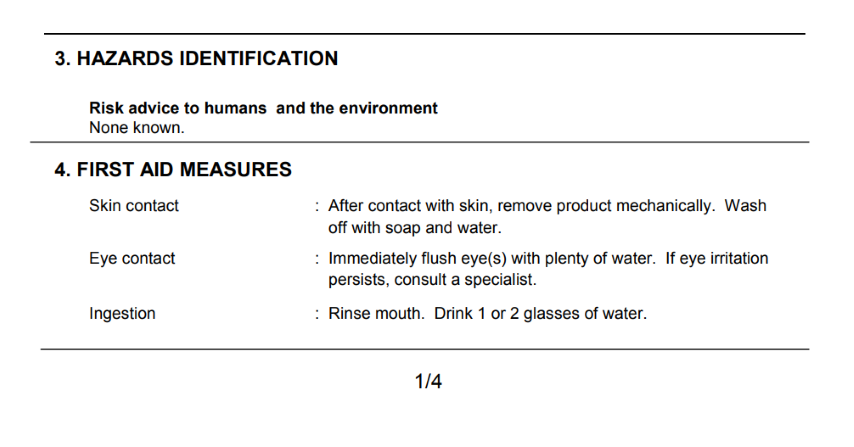

Instamold:

Instamold is a temporary mold making compound that mixes easily with water. Its proportion with water determines the mold strength and setting time:

- 1:1 ratio results in strong molds setting in 2-3 minutes.

- 1:2 ratio results in average strength molds setting in 5-8 minutes.

- 1:3 ratio results in weak molds setting in 10-12 minutes.

Properties:

- Safe for body casting.

- Compatible with pourable materials like plaster, wax, resin, and soap (<300°F).

- Made of natural materials.

Safety:

- May cause skin irritation or respiratory symptoms, take appropriate precautions.

Ecoflex Rubber:

Ecoflex rubber is a platinum-catalyzed silicone known for its ease of use. It is mixed in a 1A:1B ratio by weight or volume and cures at room temperature. It has low viscosity.

Safety:

- Wear safety gear including glasses, long sleeves, and vinyl gloves.

- Store at room temperature for optimal results; avoid hot environments.

- Use soon after acquisition as the product has a limited shelf life.

Epoxy Resin:

Epoxy resin is a versatile material commonly used for various casting and molding applications. Here's some information about its usage and properties:

Usage:

- Epoxy resin is suitable for casting small to medium-sized objects, including jewelry, art pieces, and prototypes.

- It can be mixed with pigments, dyes, or fillers to achieve desired colors and effects.

- Epoxy resin can be used with various molds, including silicone molds, to create intricate shapes and designs.

Properties:

- High strength and durability: Epoxy resin produces strong and resilient castings that can withstand handling and use.

- Excellent clarity: When properly mixed and cured, epoxy resin results in clear and transparent castings, making it suitable for encapsulating objects or creating resin art.

- Low viscosity: Some epoxy resins have low viscosity, allowing them to flow easily into mold cavities and capture fine details.

- Chemical resistance: Epoxy resin is resistant to many chemicals, ensuring the longevity of the castings.

Safety:

- Wear appropriate personal protective equipment, including gloves and safety glasses, when handling epoxy resin.

- Work in a well-ventilated area to minimize exposure to fumes.

- Follow the manufacturer's instructions for mixing ratios and curing times to ensure optimal results.

- Dispose of unused resin and cured waste according to local regulations.

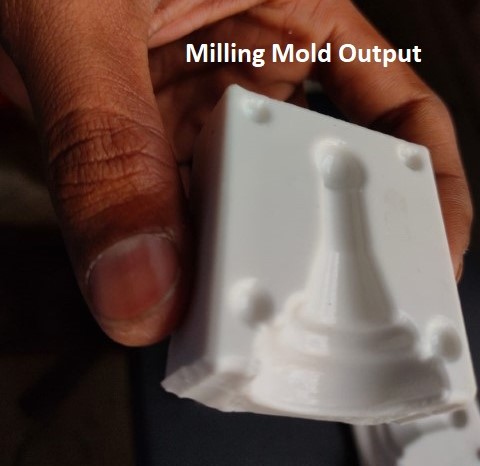

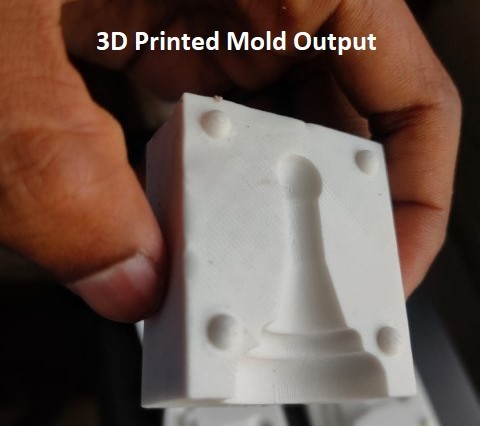

Comparing 3D Printing v/s Milling Mold

So we have tried to compare the mold prepared from 3D printer and Milling process.

|

|

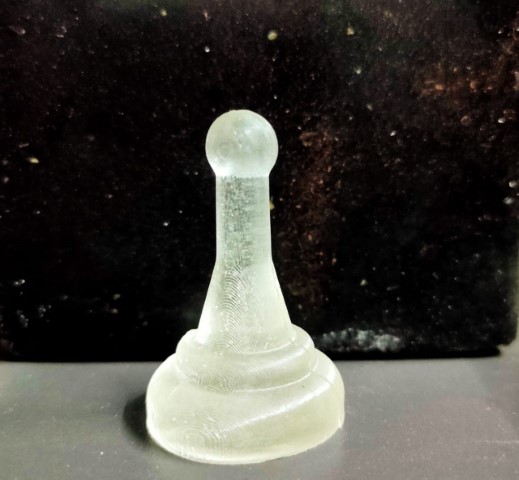

Final Cast Output

Milling Mold Output |

3D printing Mold Output |