Week 17. Applications and implications

Introduction

This week is dedicated to answering a series of questions about the final project. I have to say that as of today the project still has some things to be determined

What will it do?

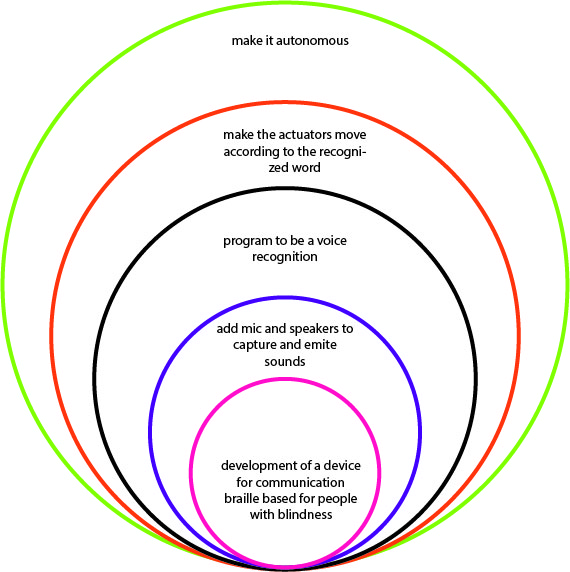

The main objective of this project is to create a low-cost automatic braille device. This device is designed for people with deafblindness as they may have communication, educational, social, etc. limitations.

This device will have braille cells that will act automatically. This will occur with a voice recognition system implemented in it. It will also have some keys as a stenographer that will allow through a loudspeaker to express themselves with people who have hearing impairment.

Who's done what beforehand?

There are devices called “refreshable braille lines” that allow people with blindness to communicate through another device, such as a smartphone, so that they can communicate through a mobile phone and an application. What I propose is to reduce costs since these devices cost around 3-6k$. These high costs are due to the use of cells such as the following image, whose individual cost amounts to $ 70 and the high number of cells makes it increase even more its price.

Researching about that I found the following link where Vijay, has managed to make a low cost cell, there I thought it was possible to make it cheaper, however he has not done, as far as I know, the integration of the complete equipment. And neither the voice recognition nor the communication part has been added.

What will you desing?

The structure, a logo, the electronic board that integrates the system, a transport system and, although it is designed, I will make a redesign of the cell because, although it is cheap, its dimensions make it somewhat costly to manufacture.

What materials and components will be used?

PLA for 3D printing, electronic components, resin for 3D printing, magnets, ferrite core, copper wire, more TBD.

How much will they cost? / Where will come from?

TBD.

What parts and systems will be made? What processes will be used?

Mostly 3D printing, programming, small-scale milling

What questions need to be answered?

Will I be able to implement everything? Will it work properly? Will I be able to scale the system in order to have the magnets available?

How will it be evaluated?

Although I intend to make it all work, my goal is to have it move according to sounds, so I may not get to complete the outermost spirals.

Conclusion and experiences

In addition, another problem I find is the language, to program it I am going to use Spanish or simple words in English, in order to make sure it works 100% since I am not an expert in this second language.