Individual Assignment

My final Fab Academy project is "Ore Secure Helmet." I've developed an ore secure helmet designed to prevent accidents in mining due to hazardous gases and rock collisions. This helmet features several integrated sensors and components to enhance miner safety. It includes an MQ135 gas sensor that detects hazardous gases like carbon dioxide (CO2) and triggers a buzzer alarm to alert miners when dangerous levels are present. Additionally, the helmet uses a Velostat pressure sensor to measure the intensity of impacts from small rocks, providing valuable data to help doctors assess potential head injuries. An LDR sensor is incorporated to control COB LED lights based on ambient light intensity, ensuring miners always have optimal lighting conditions. All these sensors are interfaced with an ESP32 C3 microcontroller, which processes the data and manages the helmet's functions. The helmet is powered by a 3.7V rechargeable lithium-ion battery, ensuring it remains lightweight and portable while providing continuous operation in demanding mining environments. This combination of advanced features significantly enhances miner safety by providing timely warnings and protecting against potential injuries.

As per the essential requirements for the final project, it should consist of processes/ systems:

1) 2D and 3D design

2) additive and subtractive fabrication processes

3) electronics design and production

4) microcontroller interfacing and programming

5) system integration and packaging

This week we need to work on the final project and document the progress of the work.

What tasks have been completed?

1) PCB design and soldering are completed. All the electronic peripherals used in the project were tested with programming using a developed PCB board.

2) All the elecctronic components such as MQ135 gas sensor, LDR sensor, COB LED light, buzzer, etc. are purchased.

3) A safety helmet used during thee minning is purchased.

4) 2D and 3D modeling of different parts and the project assembly are done.

5) 3D printing and laser cutting for COB LED light casing and PCB casing is done.

What tasks remain?

1) Final integration of all devices with the microcontroller board and programming remains.

2) Final assembly and testing is remain.

3) Integration of all the components with 3.7V battery is remain.

4) Integration of whole system with app is remain.

What has worked? What hasn't?

1) The final project PCB board of XIAO-ESP32-C3 microcontroller is working very well.

2) LDR sensor gives accurate values and based on that COB LED light working very well.

3) Pressure sensor also gives proper impact measurement.

4) Whole system is working on 3.7V battery.

5) All the 3D printed and laser cut parts fit correctly on the helmet.

1) Still not getting the actual measurement of Gas sensor.

2) Based on gas sensor measurement, buzzer calibration is still not correct.

What questions need to be resolved?

1) Routing of connections for the wearable device is a challenging task. Still, I am confused about the route. All the connections need to be hidden.

2) COB LED light consume more power and heat up very fast.

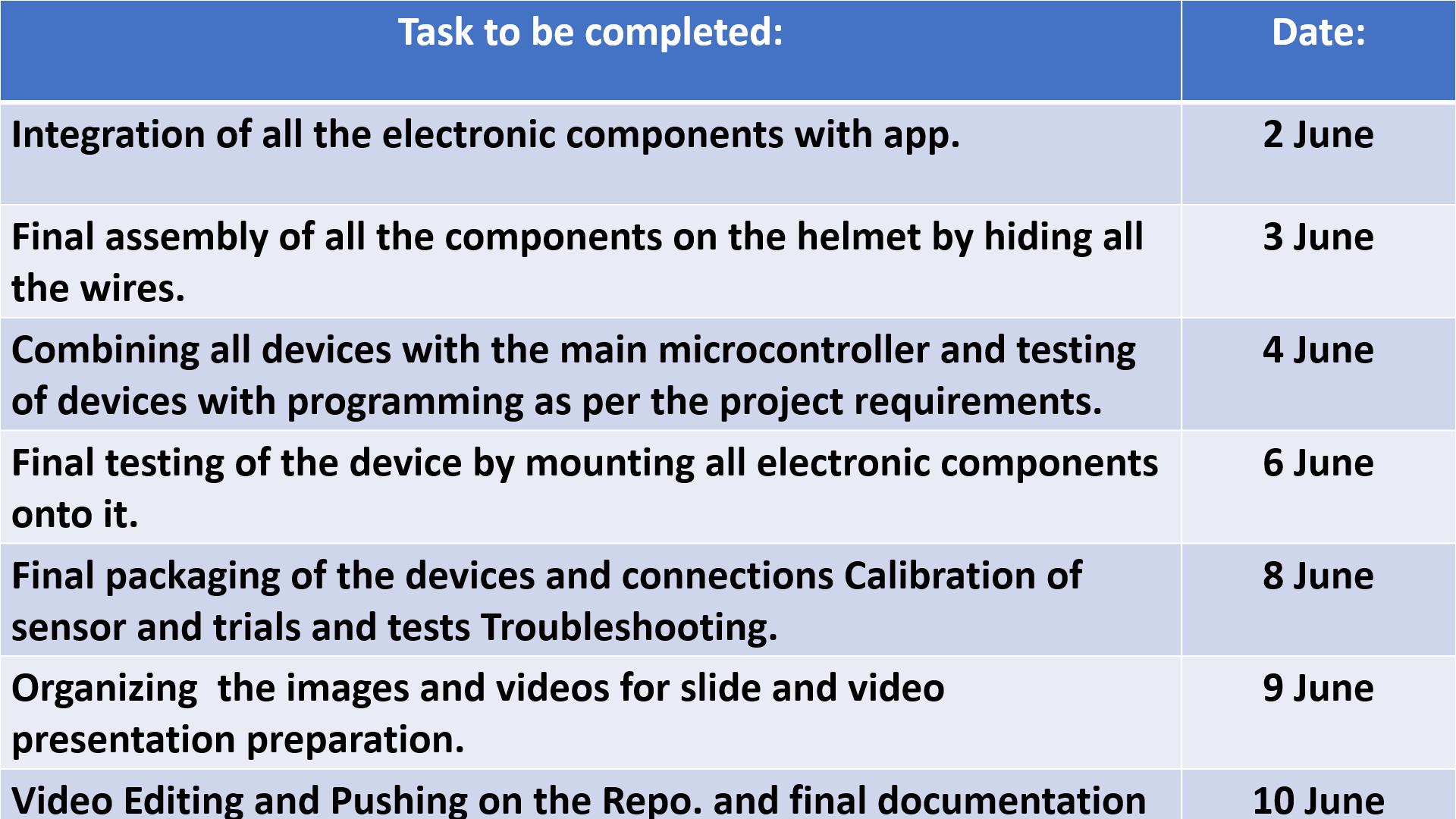

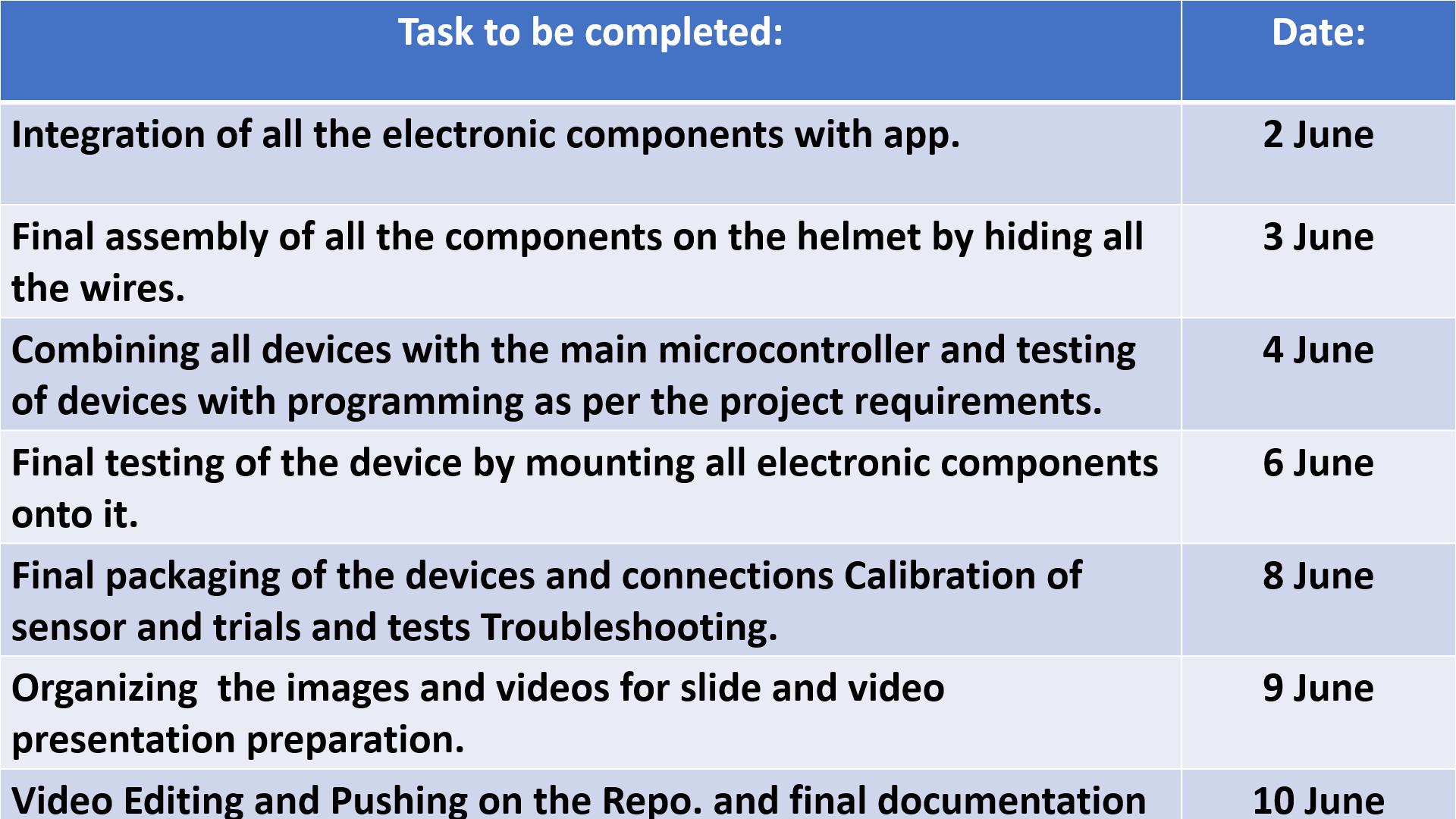

What will happen when?

What have you learned?

The final project for my ore secure helmet and the Fab Academy course have been incredible learning experiences for me. From the very beginning with GITLAB and web development for documentation, I learned the importance of documenting every step of the process. While I wasn’t initially fond of using mobile cameras, the lectures encouraged me to capture and document my work meticulously.

As a mechatronics engineering student, I already had knowledge in solid modeling, laser cutting, 3D printing, and electronics. This course helped me revise these concepts and learn many new things. Starting from basic soldering to designing PCBs, the course has significantly boosted my confidence. I still need to improve my soldering skills for PCB boards and will seek help from colleagues for soldering ICs, but designing the final project board was a major achievement. I carefully designed my final project board to ensure it worked well. My prior experience with 3D printing and laser cutting was enhanced through machine characterization, which was a great learning experience.

During the molding and casting week, I made a smiley emoji and learned about different materials like metals and polymers. It was both educational and enjoyable. I also learned to handle a CNC router machine during the computer-controlled machining week, which was a valuable skill. In the wildcard week, I learned to use an embroidery machine, which was a wonderful and awaited experience.

For my ore secure helmet project, I developed a helmet designed to prevent accidents in mining due to hazardous gases and rock collisions. The helmet features an MQ135 gas sensor that detects carbon dioxide (CO2), known as black damp, which triggers a buzzer to alert miners of dangerous gas levels. I also used a Velostat pressure sensor to measure the intensity of impacts from rock collisions, helping doctors assess potential head injuries. An LDR sensor controls COB LED lights based on ambient light, ensuring optimal visibility for miners. All these sensors are connected to an ESP32 C3 microcontroller, which processes the data and manages the helmet's functions. The helmet is powered by a 3.7V rechargeable lithium-ion battery, ensuring it remains lightweight and portable while providing continuous operation in demanding mining environments. This combination of advanced features significantly enhances miner safety by providing timely warnings and protecting against potential injuries.

This course has taught me to prepare a detailed plan from idea generation to final prototyping, including dissemination to the target audience, along with IPR, marketing plans, business models, and financing. I have developed a deep appreciation for electronics and hope to create something impactful for society in rural areas.

Thank you, Prof. Neil sir and all the Fab Academy team, my instructor Dr. Kiran Wakchaure sir and Mr. Suhas Labade sir.