In this assignment I documented on -

Individual Assignment

Propose a final project masterpiece that integrates the range of units covered.

1) What will it do?

The helmet is designed to enhance the safety of miners by incorporating several key features:-

Gas Detection: It will detect hazardous gases (like methane, carbon monoxide) in the mining environment and alert the miner with an audible buzzer when dangerous levels are present.

Impact Detection: It will measure the intensity and location of impacts (e.g., from falling rocks) using a pressure sensor. This data can be useful for medical professionals to assess the severity and location of head injuries.

Lighting Control: It will automatically adjust the helmet’s LED light based on ambient light levels using an LDR sensor, ensuring miners have adequate lighting in dark areas without needing to manually switch lights on or off.

2) Who's done what beforehand?

Several advancements and projects have been made in the field of miner safety helmets:-

Gas Detection System: There are existing gas detection systems in mining helmets that alert miners to the presence of toxic gases. Companies like Drager and MineARC have developed such systems.

Impact Sensing: Helmets with impact detection capabilities have been developed, especially in sports and construction industries. For example, the Hovding airbag helmet for cyclists includes sensors to detect impacts.

Automated Lighting: Automatic lighting systems based on ambient light levels are commonly used in various applications, including helmets for construction workers.

3) What will you design?

I will design a smart mining helmet with the following features:

Integrated Gas Sensor and Buzzer: A gas sensor (MQ-135) will be interfaced with an ESP32-C3 microcontroller to monitor air quality and trigger a buzzer when hazardous gas levels are detected.

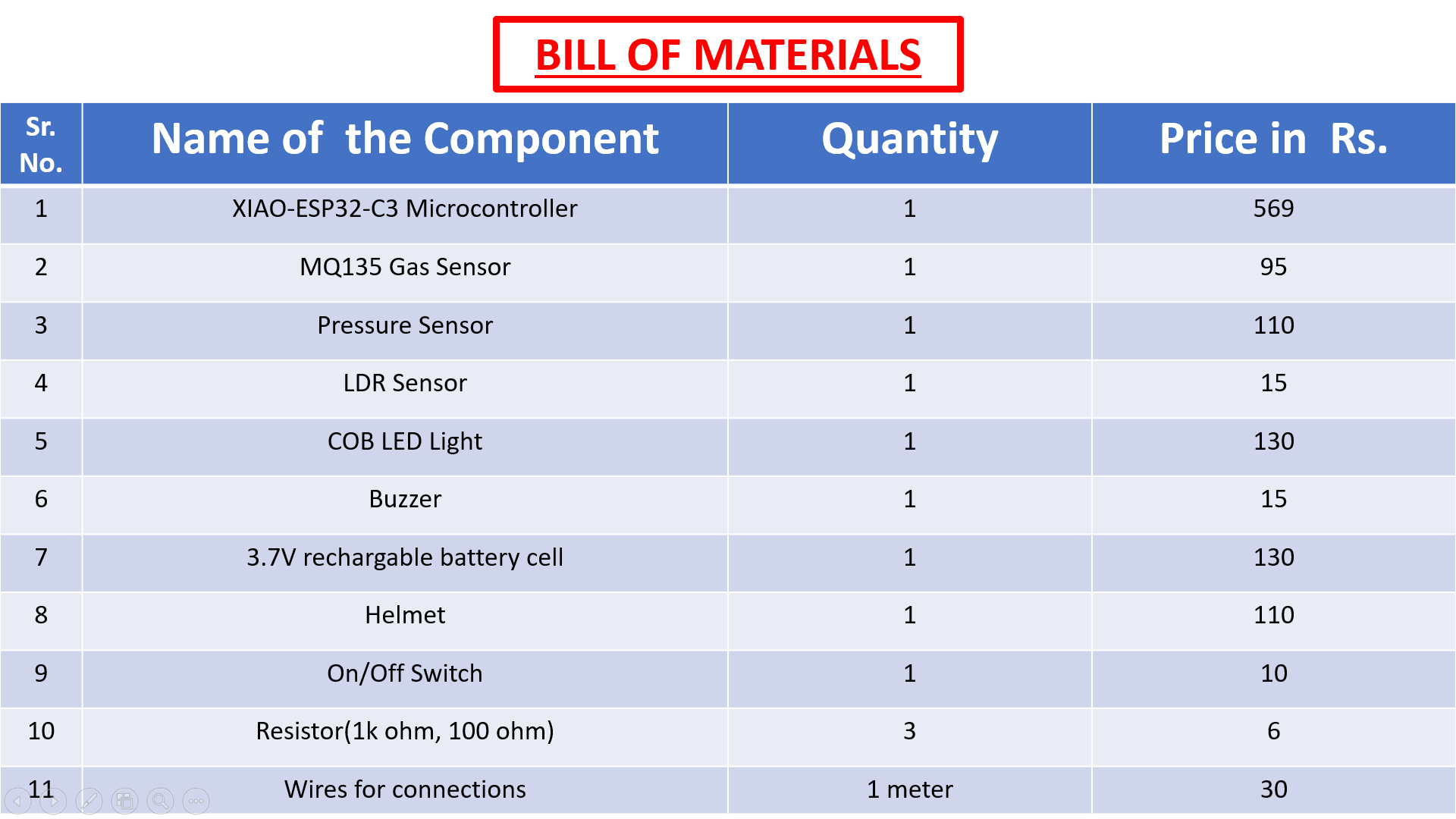

4) What materials and components will be used?

Here is the list of components and materials -

Components:-

1) Helemt

2) MQ135 Gas Sensor

3) Pressure Sensor

4) LDR Sensor

5) COB LED Light

6) Buzzer

7) 3.7V rechargable battery cell

8) On/Off Switch

9) Resistor(1k ohm, 100 ohm)

10) Wires for connections

11) XIAO-ESP32-C3 Microcontroller

Materials:-

1) Acrylic sheet(3mm) for PCB casing.

2) FR1 Material(2mm) for PCB Milling.

3) ABS Material for 3D printing.

5) Where will come from?

Components will be sourced from electronic suppliers such as Robu , Digi-Key, and local electronics stores. Enclosure materials can be sourced from local craft or hardware stores.

6) How much will they cost?

Overall cost of the project will be 1220 indian rupees approximately, it may vary depends on the electronics component values in various regions.

7) What parts and systems will be made?

For the smart mining helmet, several parts and systems will be developed. The helmet will feature a gas detection system comprising a gas sensor and buzzer to alert miners of hazardous gases, an impact detection system using a pressure sensor to log impact data for medical assessments, and an automated lighting system with an LDR sensor and LED for optimal illumination based on ambient light. These components will be integrated with an ESP32-C3 microcontroller, which will process sensor data and control the systems. The helmet will also include a rechargeable battery pack for power. The design will ensure sensor accuracy, durability, and miner safety, with thorough testing in simulated mining conditions.

8) What processes will be used?

Process Used:-

1) PCB Milling

2) Laser Cutting

3) 3D printing

4) Vinyl Cutting

9) What questions need to be answered?

1. How accurately does the gas sensor detect hazardous gases?

2. Can the pressure sensor reliably detect impacts on the helmet?

3. How long will the battery last on a single charge?

4. Can the helmet withstand harsh mining conditions?

5. Is the buzzer loud enough to alert miners in noisy environments?

10) How will it be evaluated?

The helmet will be evaluated based on the following criteria:-

Functionality:- Ensure that each sensor works as intended. The gas sensor should accurately detect hazardous gases and trigger the buzzer. The pressure sensor should detect impacts and log data correctly. The LDR sensor should control the LED light based on ambient light levels.

Durability:- Test the helmet under simulated mining conditions to ensure it can withstand harsh environments, including impacts and exposure to various gases.

Usability:- Gather feedback from miners using the helmet in a real or simulated mining environment. Ensure that the alerts (buzzer and LED light) are effective and that the helmet is comfortable to wear.

Safety:- Ensure that the helmet meets safety standards and regulations for mining equipment, providing reliable protection to the wearer.