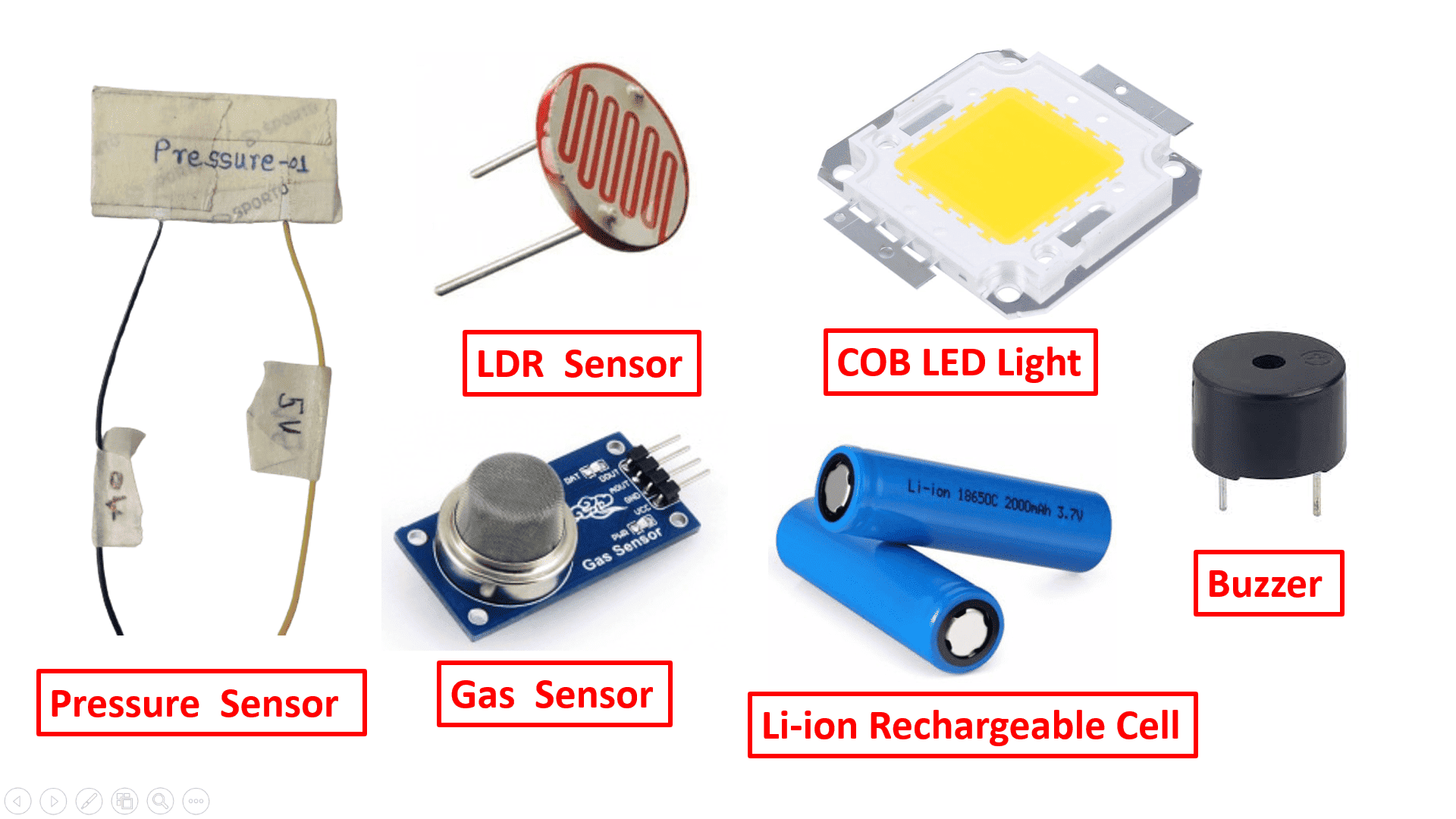

1. MQ135 Gas Sensor

In the ore secure helmet, I've integrated an MQ135 gas sensor to detect carbon dioxide (CO2), which is commonly found in mines and known as black damp. The MQ135 sensor operates on the principle of conductivity changes in its tin dioxide (SnO2) semiconductor when exposed to CO2 molecules. In the presence of CO2, the sensor's conductivity increases, altering the resistance across its electrodes. This change is measured and interpreted by the integrated ESP32 C3 microcontroller in real-time. When hazardous levels of CO2 are detected, the sensor triggers an alarm through a buzzer, alerting miners to take necessary precautions.

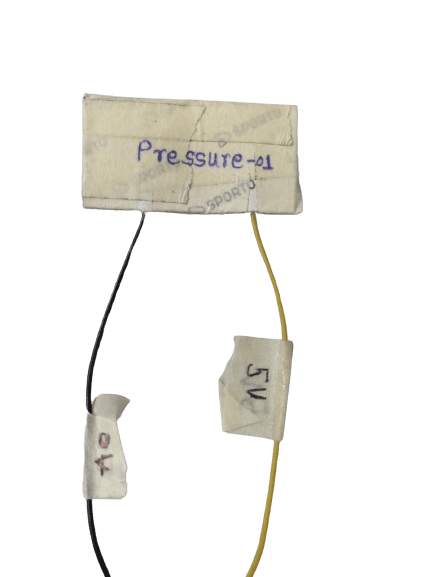

2. Pressure sensor

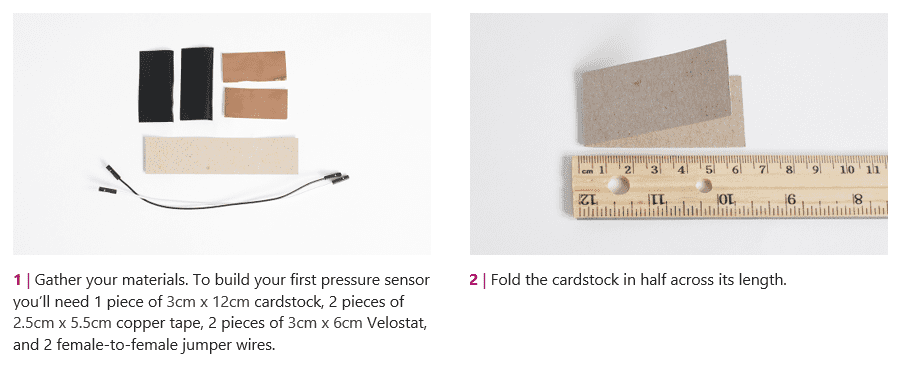

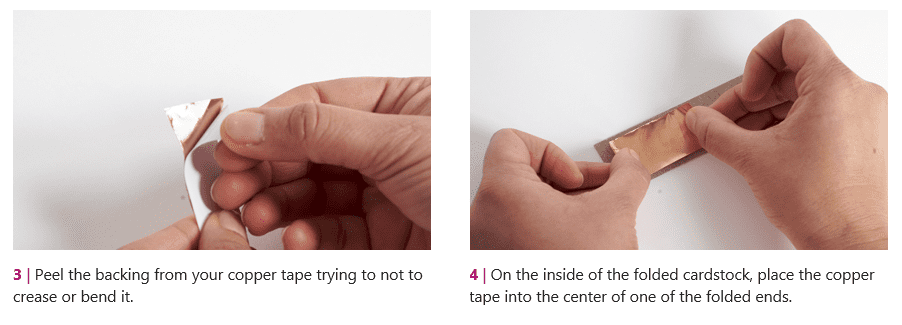

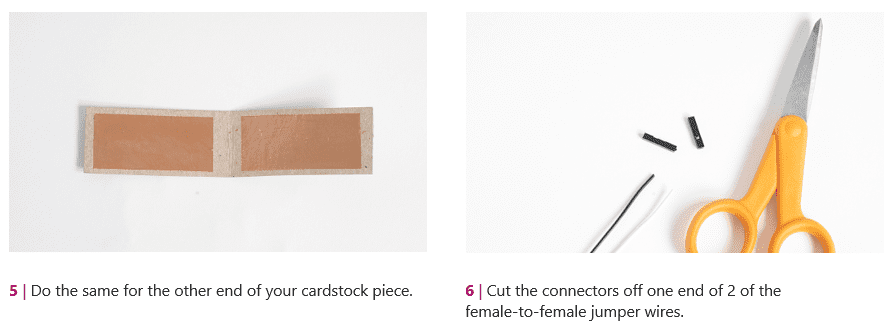

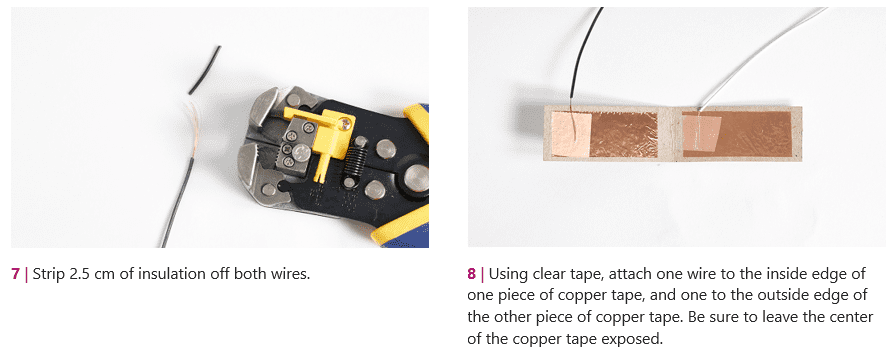

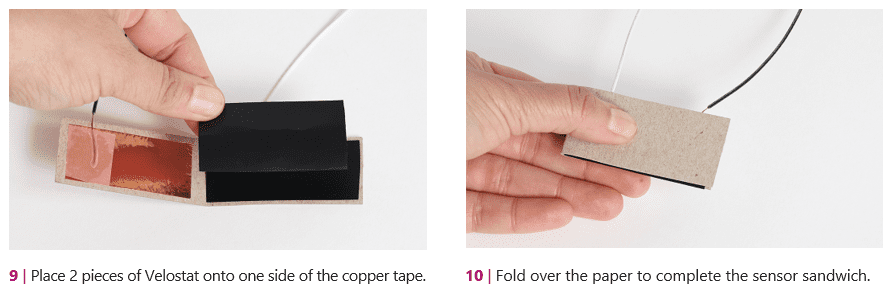

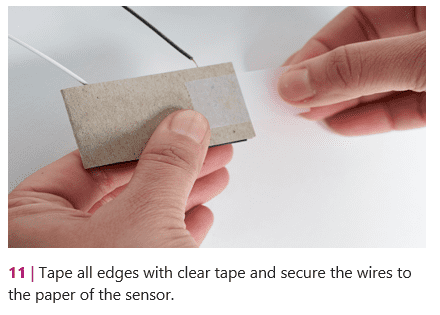

I've used Velostat to make the pressure sensor in the ore secure helmet. Velostat is a conductive material that changes its resistance when pressure is applied. When rocks hit the helmet, the pressure causes the Velostat's resistance to change. This change is measured by the helmet's microcontroller, which then provides information about the intensity of the impact. This helps doctors assess the location and severity of head injuries, enhancing miner safety.

I refer the following steps to build a pressure sensor using velostat-

LDR Sensor

I've integrated an LDR (Light Dependent Resistor) sensor in the ore secure helmet to control the LED lighting automatically. The LDR sensor works by detecting the ambient light intensity and changing its resistance accordingly. When light levels are low, the LDR's resistance increases, which is detected by the helmet's microcontroller. The microcontroller then turns on the helmet's LED lights to provide better visibility. Conversely, when light levels are high, the LDR's resistance decreases, signaling the microcontroller to turn off the LEDs. This automatic adjustment ensures that miners always have appropriate lighting, enhancing safety and convenience in varying light conditions inside the mines.

Buzzer

I've integrated a buzzer into the ore secure helmet specifically linked to the MQ135 gas sensor. When the gas sensor detects hazardous levels of carbon dioxide (CO2) in the mine, the helmet's microcontroller triggers the buzzer to emit a loud alarm. This immediate audible alert notifies miners of the presence of dangerous gases, prompting them to take necessary precautions to ensure their safety. This feature plays a critical role in enhancing miner safety by providing timely warnings of hazardous conditions within the mining environment.

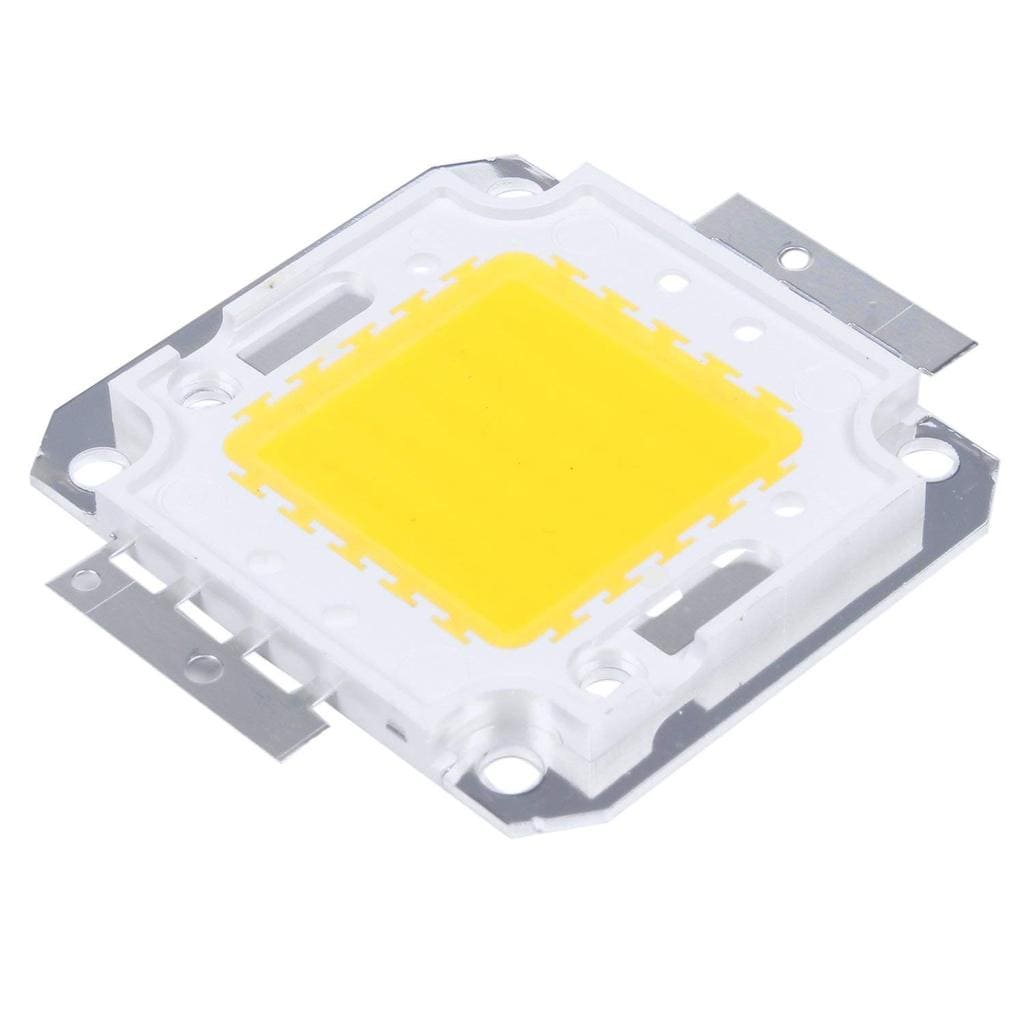

COB LED Light

A COB (Chip-on-Board) LED light is a compact, high-intensity light source that can be integrated into the ore secure helmet for enhanced illumination. COB LEDs are known for their brightness and energy efficiency, making them suitable for applications where strong, focused lighting is needed in confined spaces like mines. These lights can be controlled by the LDR sensor in the helmet, automatically adjusting based on ambient light conditions to provide optimal visibility for miners. Integrating COB LED lights ensures miners have adequate lighting to work safely and effectively in challenging mining environments.

3.7V rechargeable battery cell

I'm using a 3.7V rechargeable battery cell in the ore secure helmet. This type of battery is commonly found in portable electronics and uses lithium-ion technology, known for its energy density and rechargeability. It powers all the critical components of the helmet, such as sensors, microcontrollers, LED lights, and the buzzer. This setup allows the helmet to be lightweight yet reliable, providing sufficient power for continuous operation in mining environments.