Week 7

Computer Controlled Machining

individual assignment

- make (design+mill+assemble) something big (~meter-scale)

- extra credit: don't use fasteners or glue

- extra credit: include curved surfaces

Group Assignment

- do your lab's safety training

- test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

Safety Training

Before using the CNC machine all users undergo safety training.

The most important part of the safety training is understanding that there can be a fire hazard, a risk of damage to the machine and a risk of injury to people so keeping an eye on the machine at all times is crucial.

- Always keep hands, bodyparts and clothing away from all moving parts

- Always use eye protection while the machine is running

- Use ear protection while the machine is running

- Use gloves while handling stock

- Do not leave the machine while it is running, always keep an eye on the machine

- Make sure the vacuum is turned on

- Do not use the machine if you are tired

- Do not use the machine if you are alone in the lab

During the training the users also learn how to use the machine:

- How to turn on and off the machine

- How to set up the machine

- How to use the software

Designing something big

For this assignment i designed something practical to solve a problem in my daily life.

Here in Iceland most homes are headed with hot water and this creates a rather annoying problem where you cannot have your bed in certaion orientations without there being a hole where you want to lay your head, as shown in the image below.

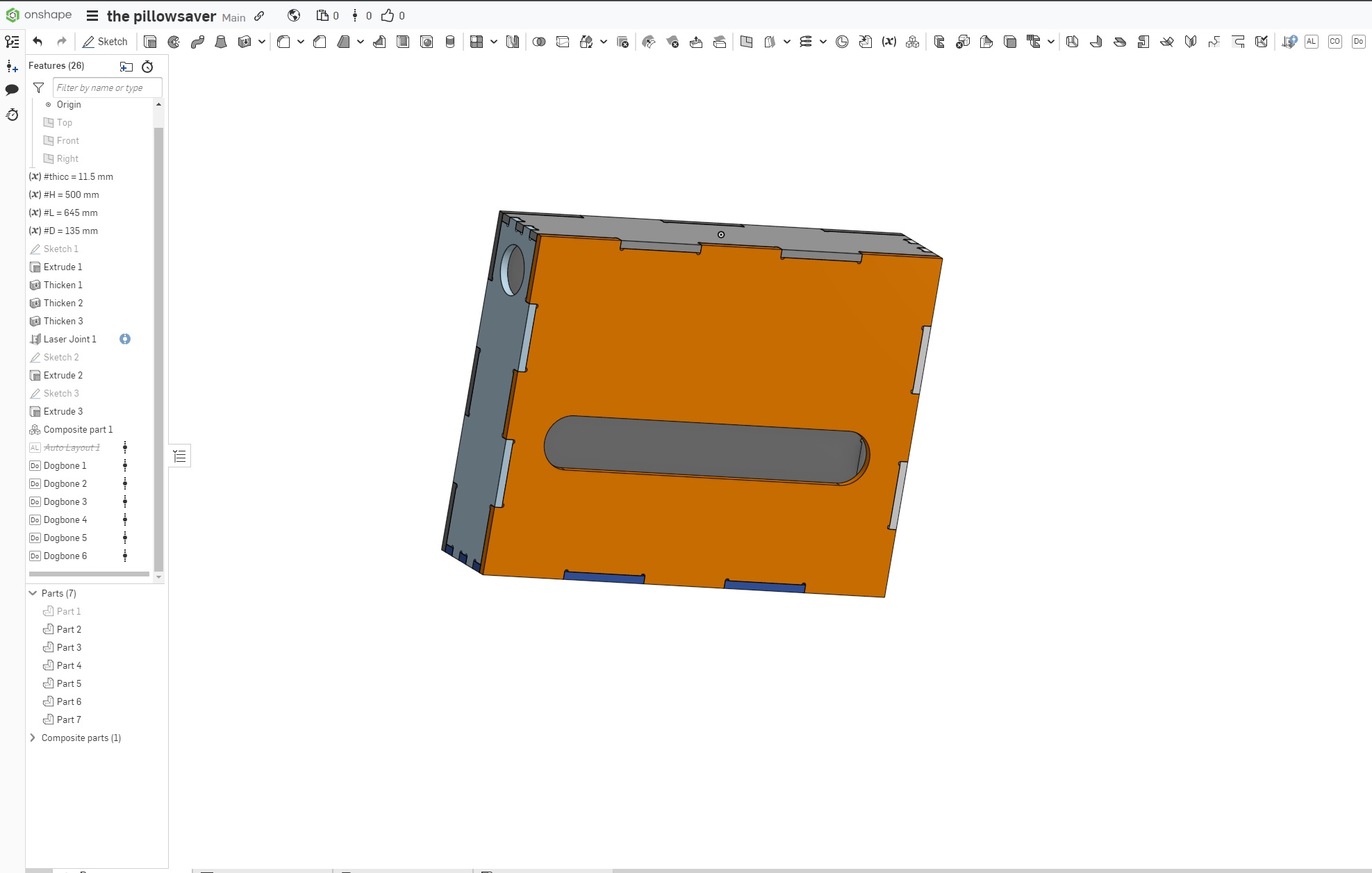

so i this box that fits perfectlu in the hole and i also designed it to make it possible to use the plug on the wall as well

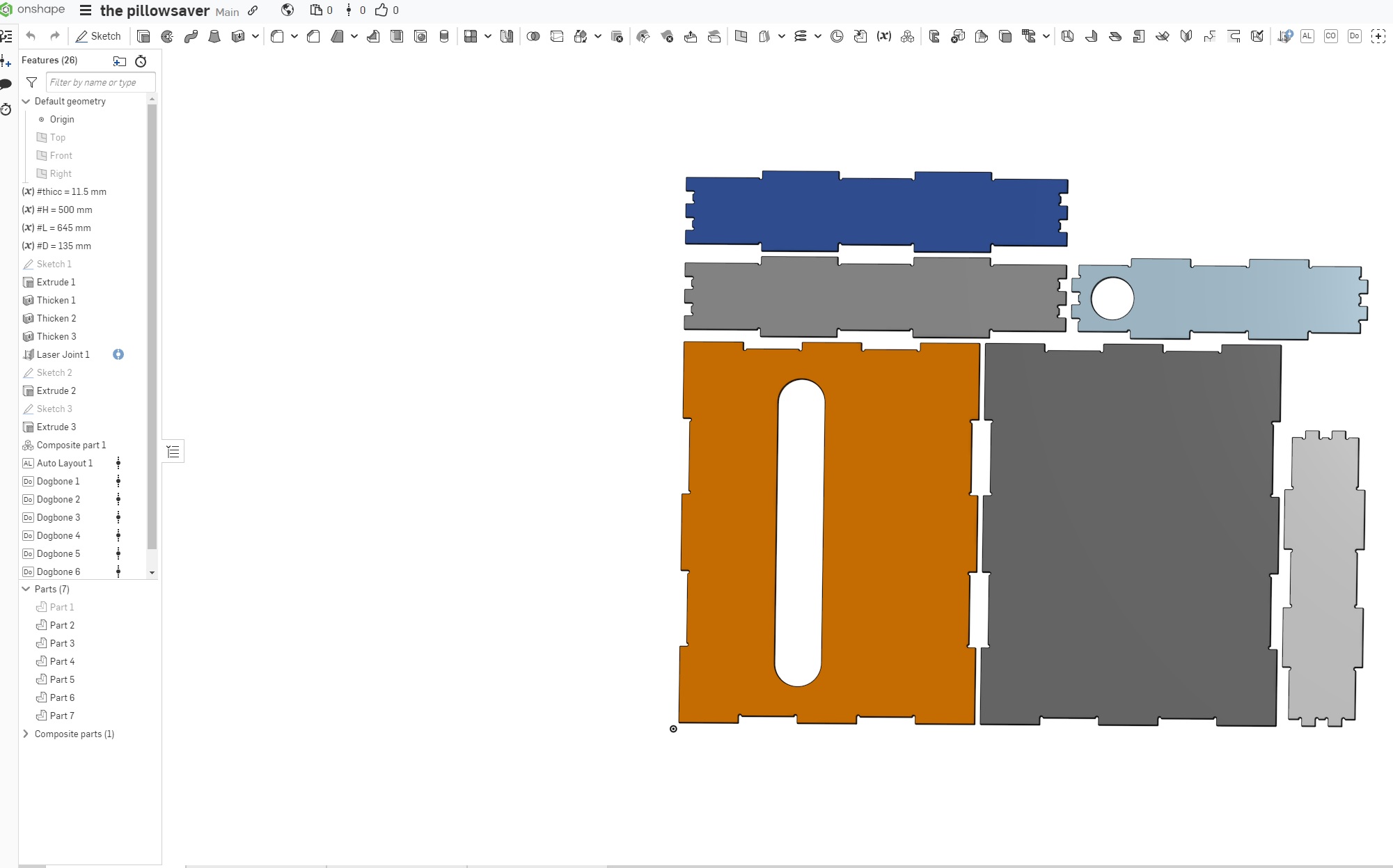

using a custom tool in onshape called "auto layout" I was able to lay the box flat with the press of a button and then usin g another tool for making dogbones I found Here to add dogbones as I found it way easier than ding it in Vcarve.

this design worked really well, ther were no issues milling it and the joints fit really snug and are pretty much imposible to seperate with out a prying tool and

the box could also be assemled in a few differnt configurations

I then added some components so I could move the wallplug behind the bed to the side of the box so I could still acces power.