3D printing and scanning

This week i worked on designing a 3d piece to print and scanning a small object in 3D>

THIS WEEK GROUP ASSIGNMENT(click the title)

Designing

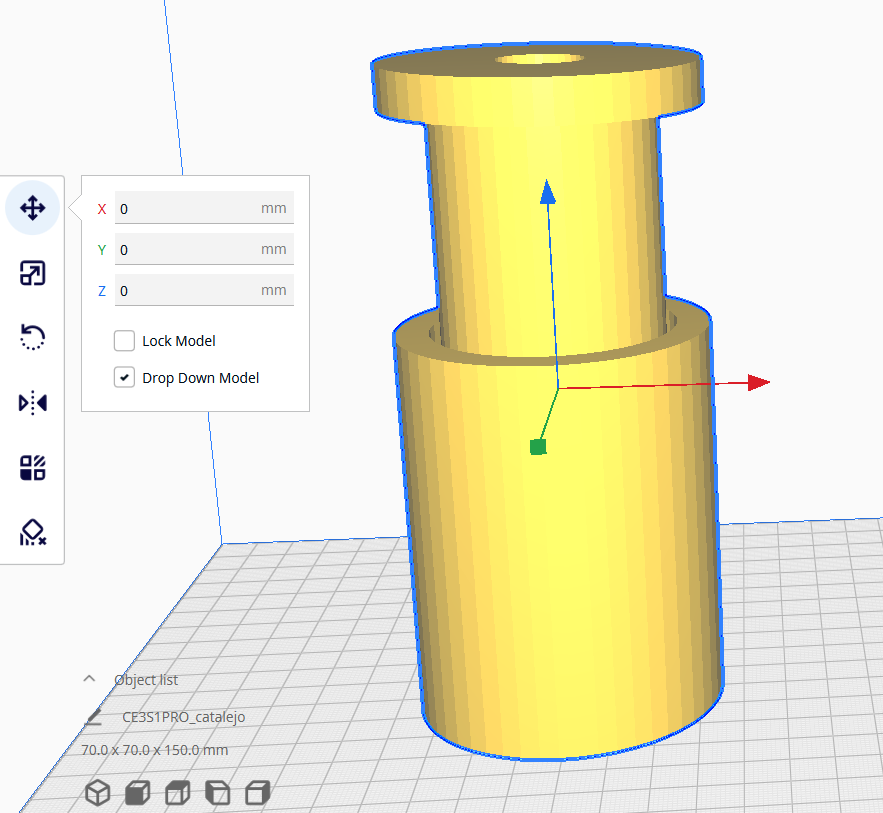

I designed the outer part of a small spyglass on solidworks

I made it so it couldnt be made in anything other than 3D print as it is 2 pieces that would require machining from below and above at the same time and also from the inside which is imposible.

Its imposible to carve in a cnc as in the design of the piece (you can find the file below), i made a part that collides with another

when you try to take them apart.

in the video below you can see what i did.

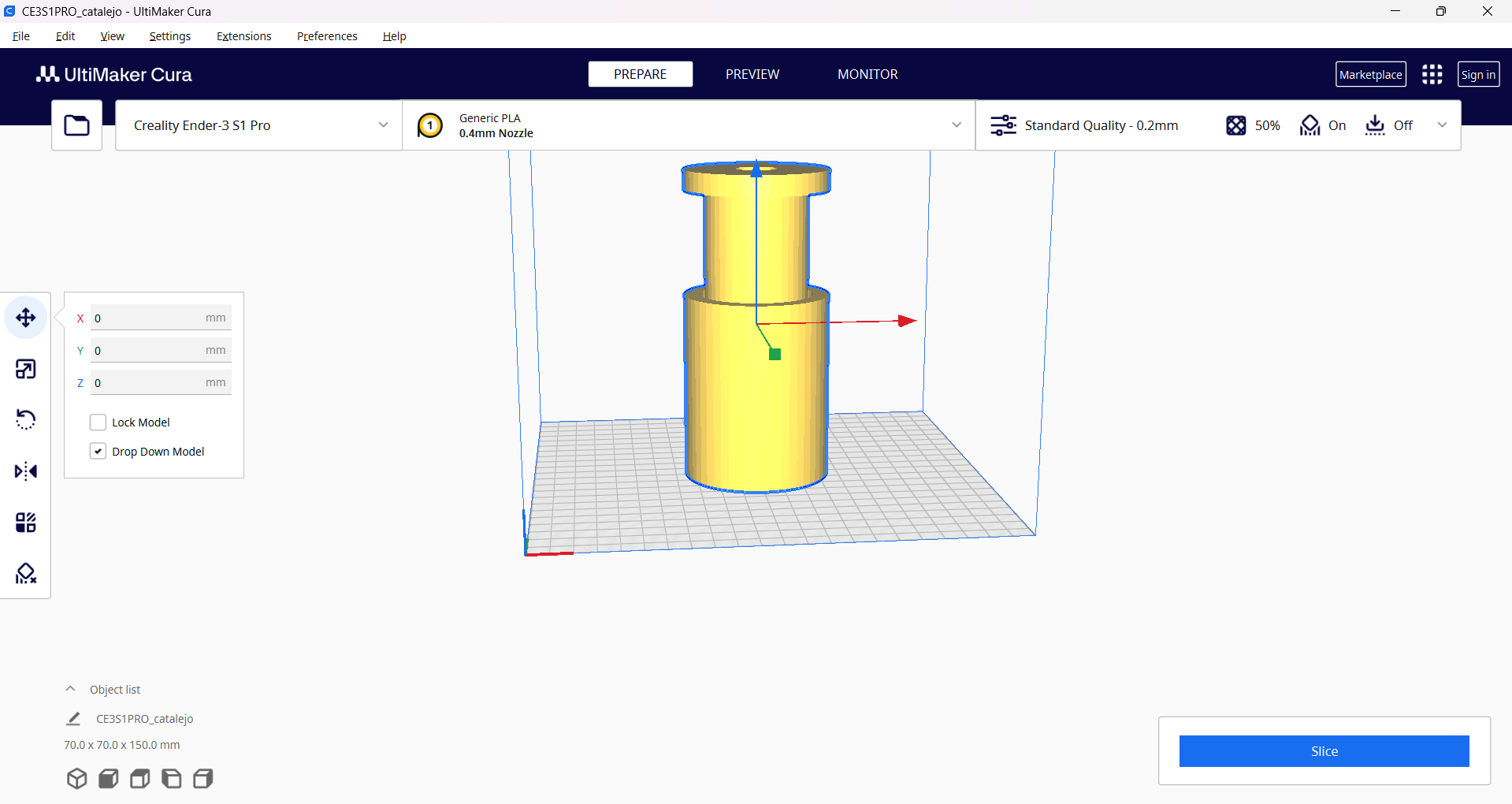

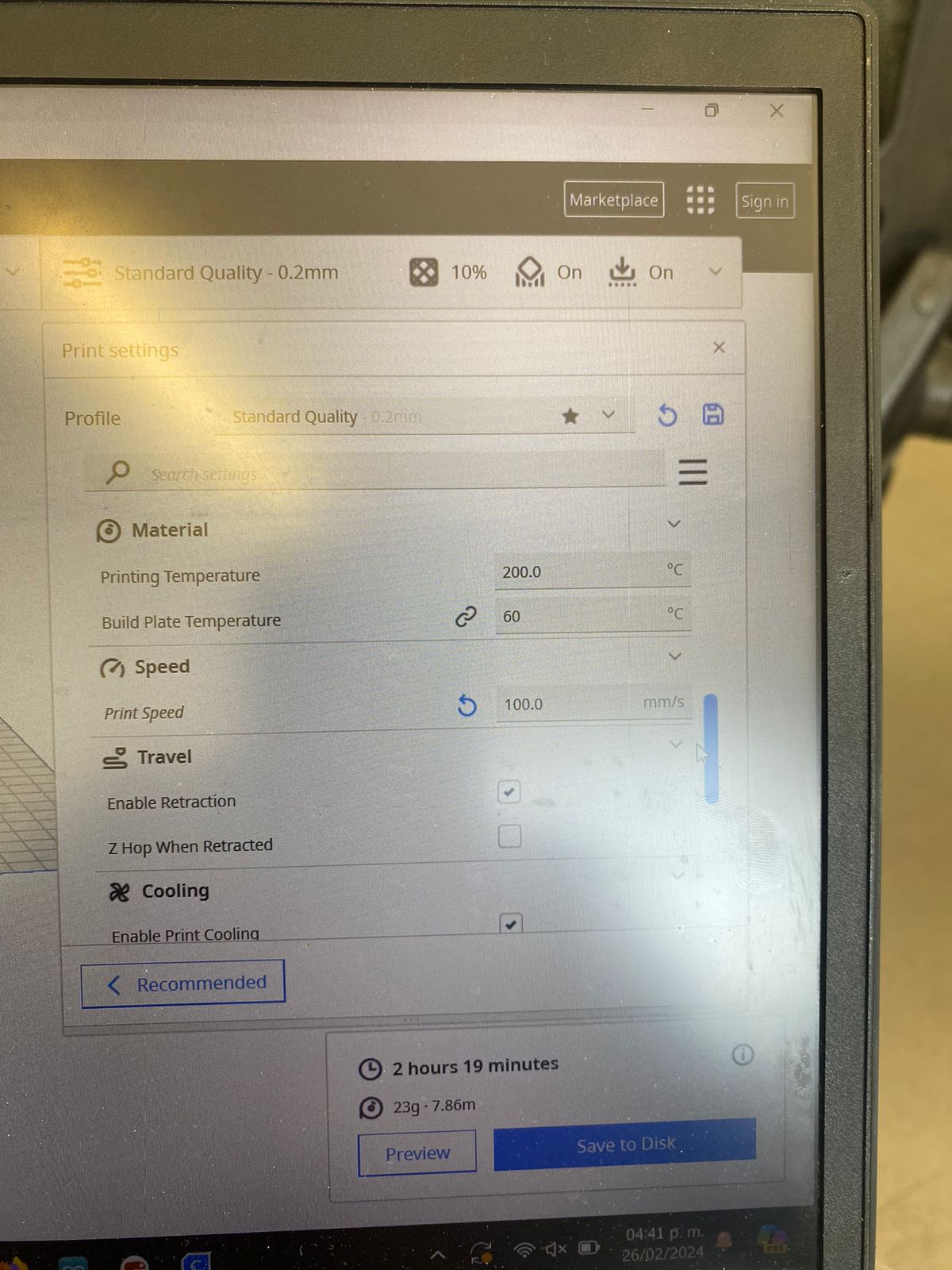

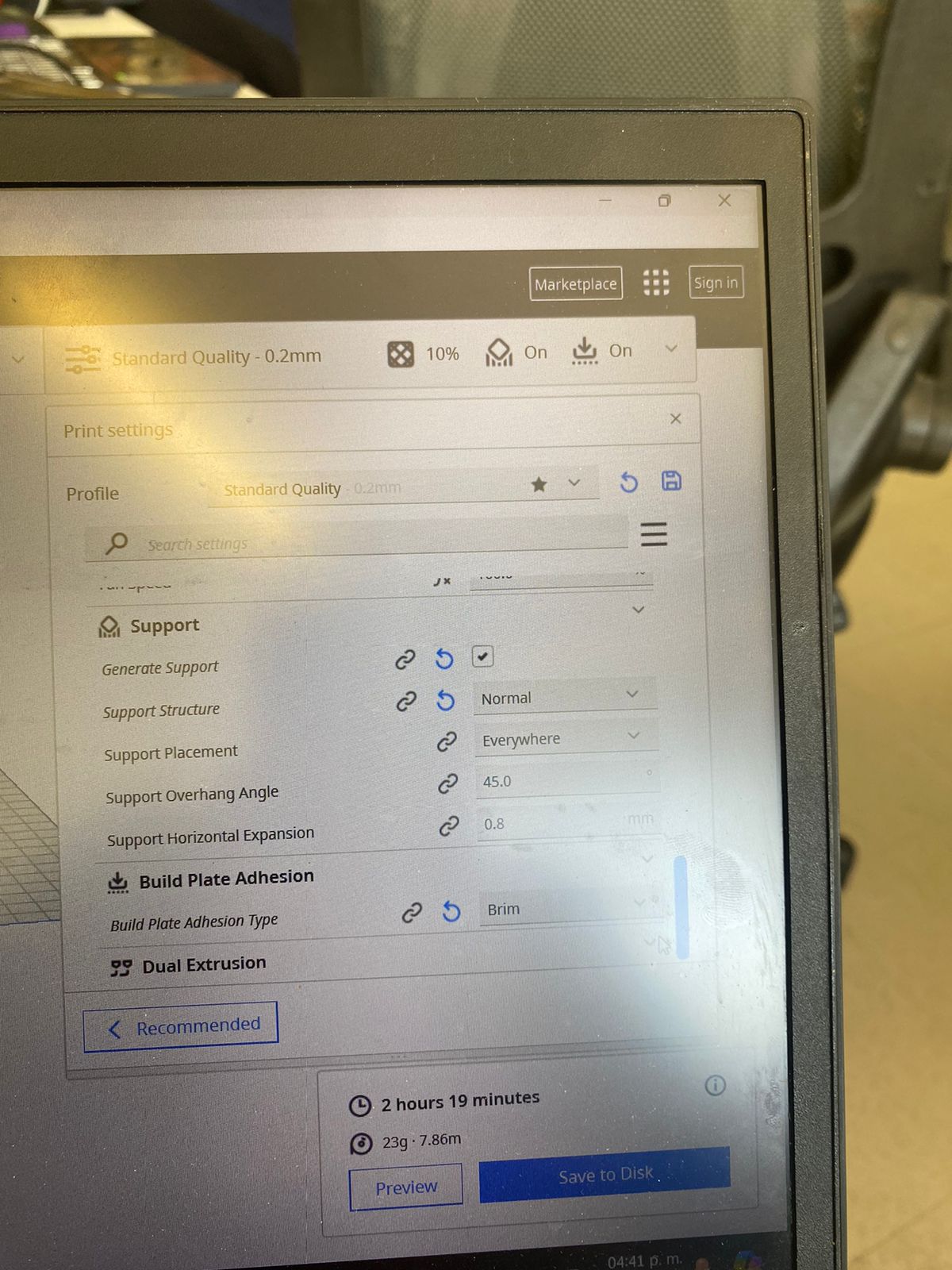

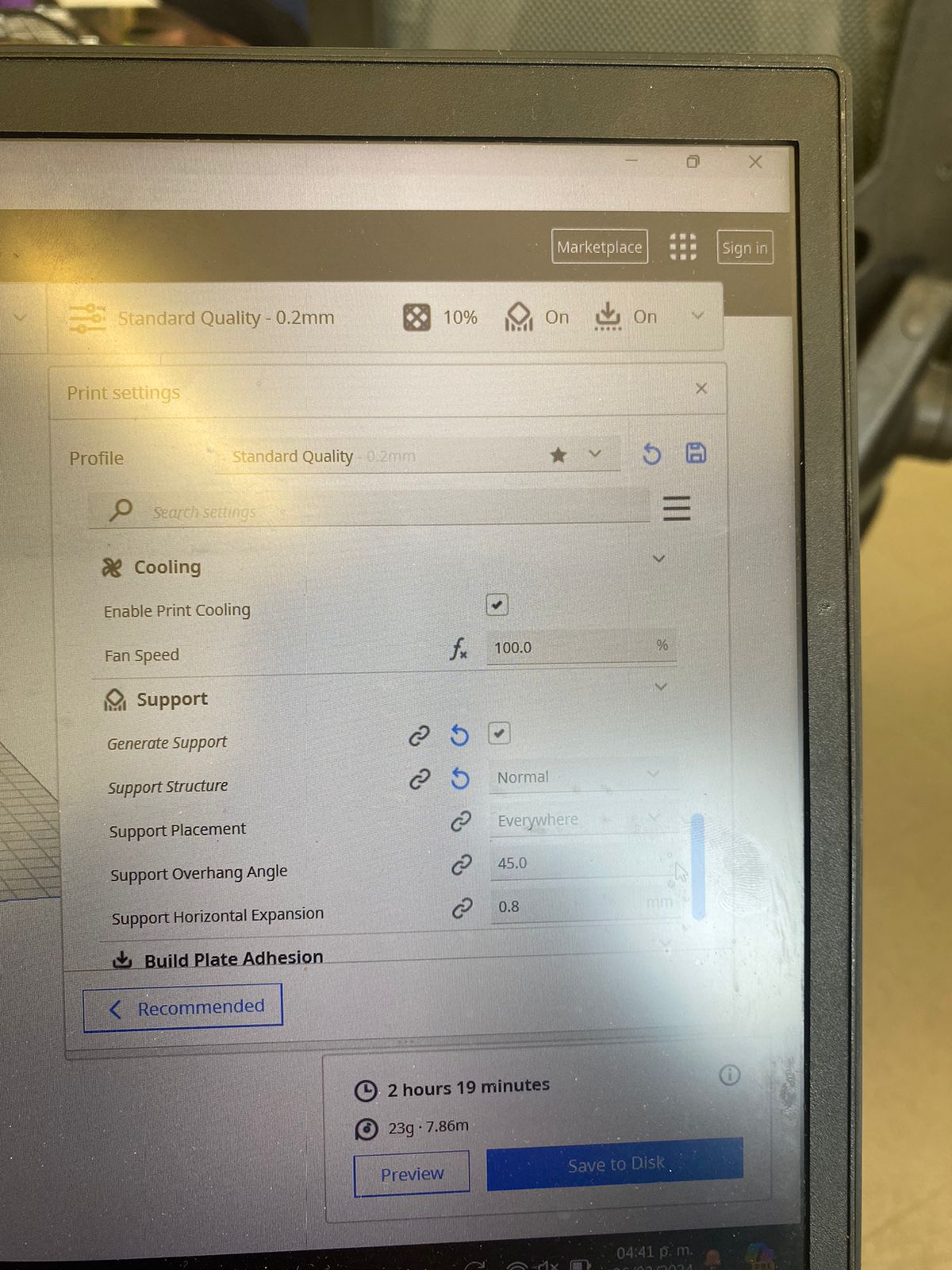

I exported the file of the object in stl format adn opened it on ultimaker cura

Ultimaker cura

It's an application designed for 3D printers, in which you can modify the printing parameters and then transform them into G code,

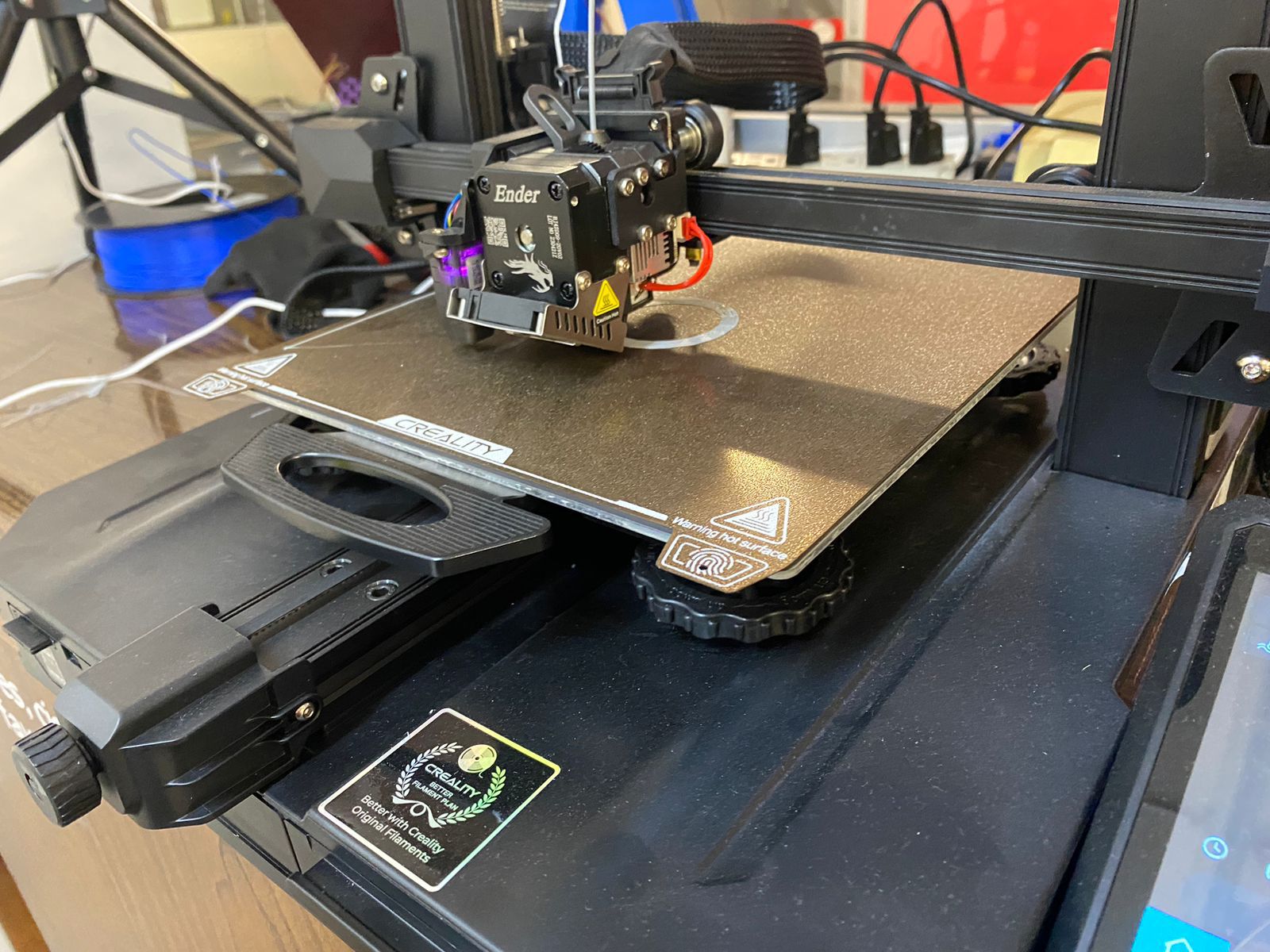

once opened we configured which printer we were going to use in our case the creality Ender-3 s1 pro. Once we have our printer we

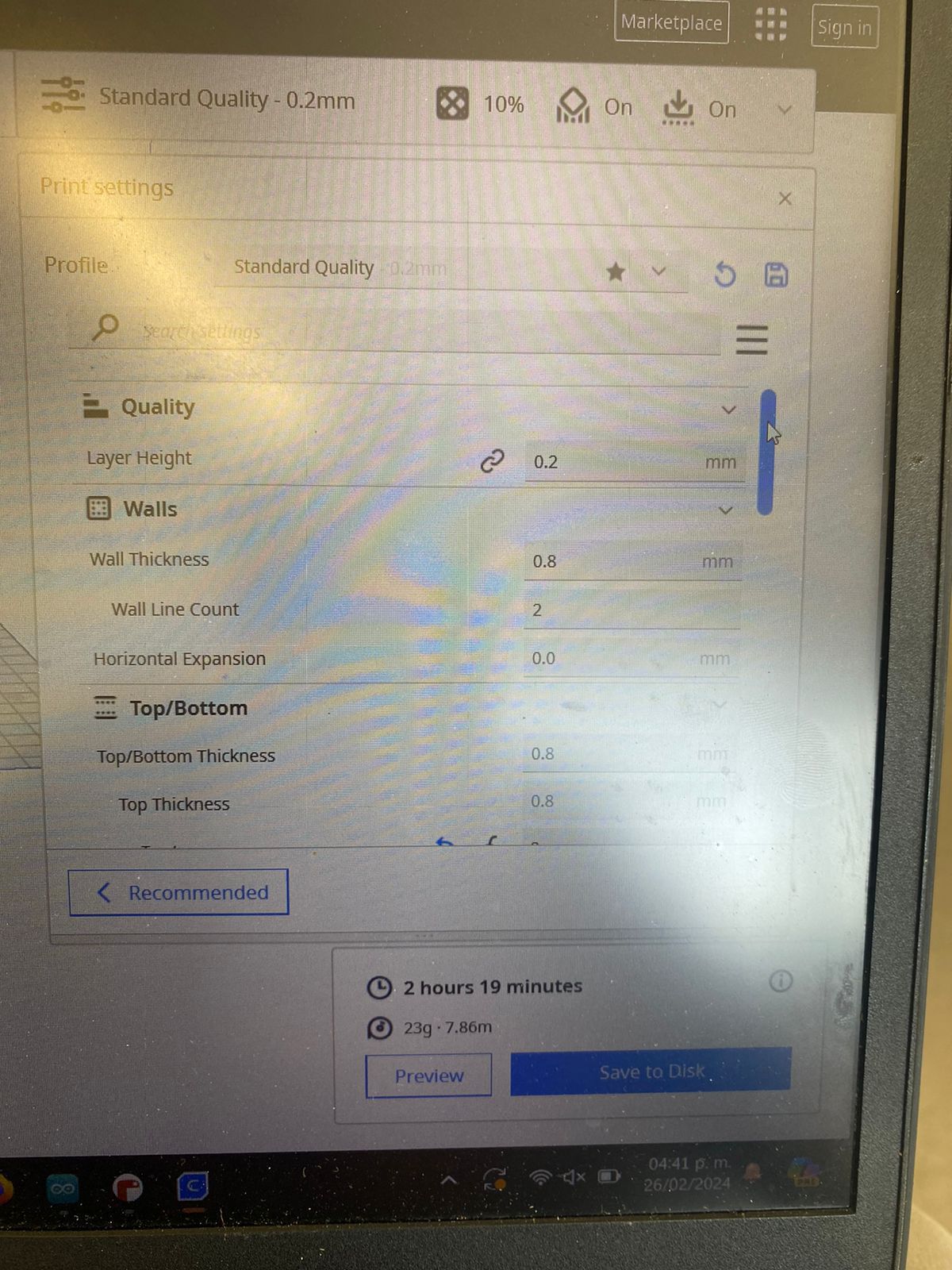

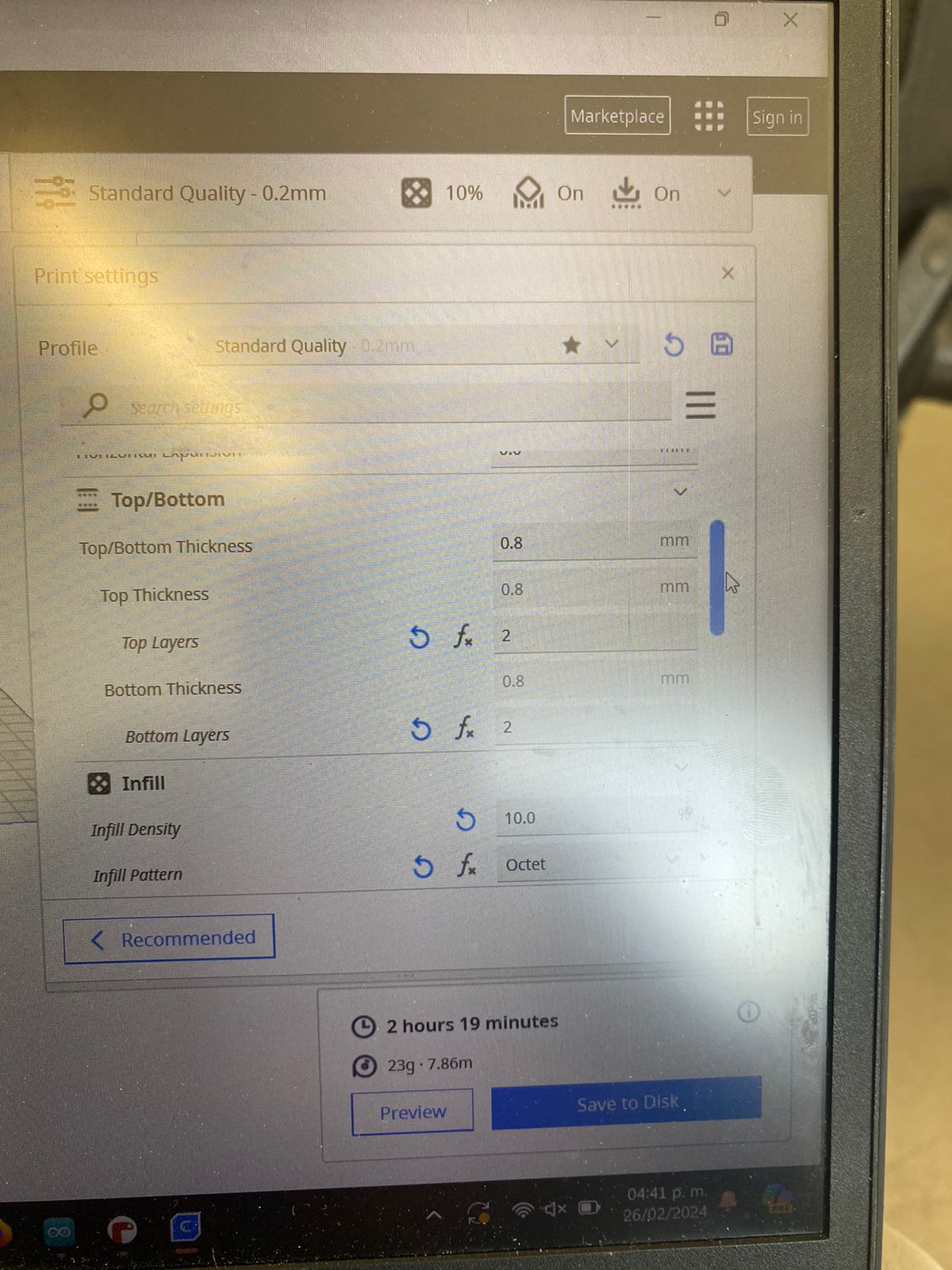

upload the file and select the piece and use the buttons on the left side of the screen to move the piece in a suitable printing position.

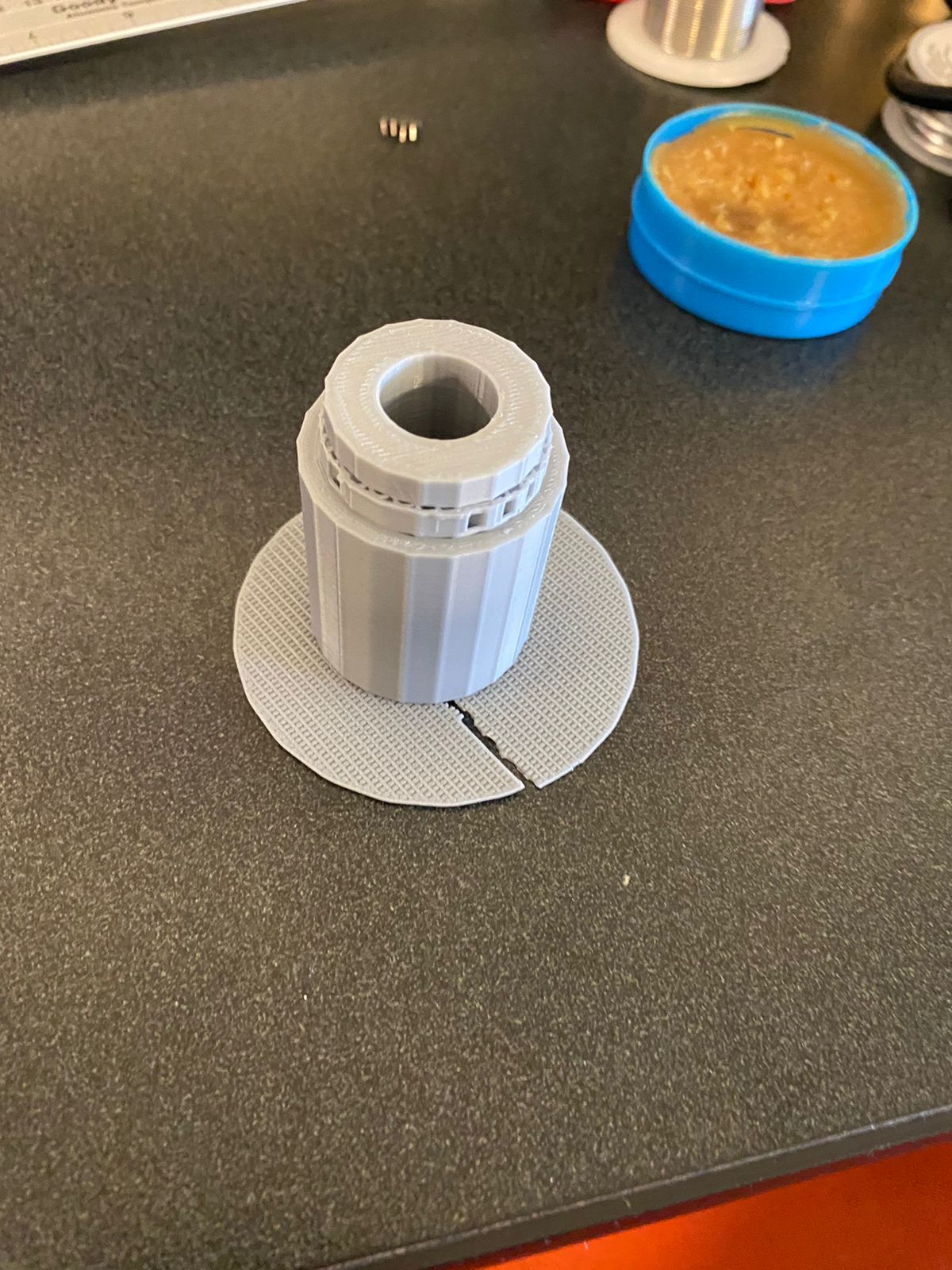

for my object i had to add an raft adhesion plate and normal supports as it had many 90 degree angles. once i had it all setup I saved it to my sd disk and took it to the printer, it took around 3 hours to print and takiing the supports off was a little bit dificult.

Finally i took it to print and didnt have to change any specs on the printer since i already did it from cura

hero shot

Scanning

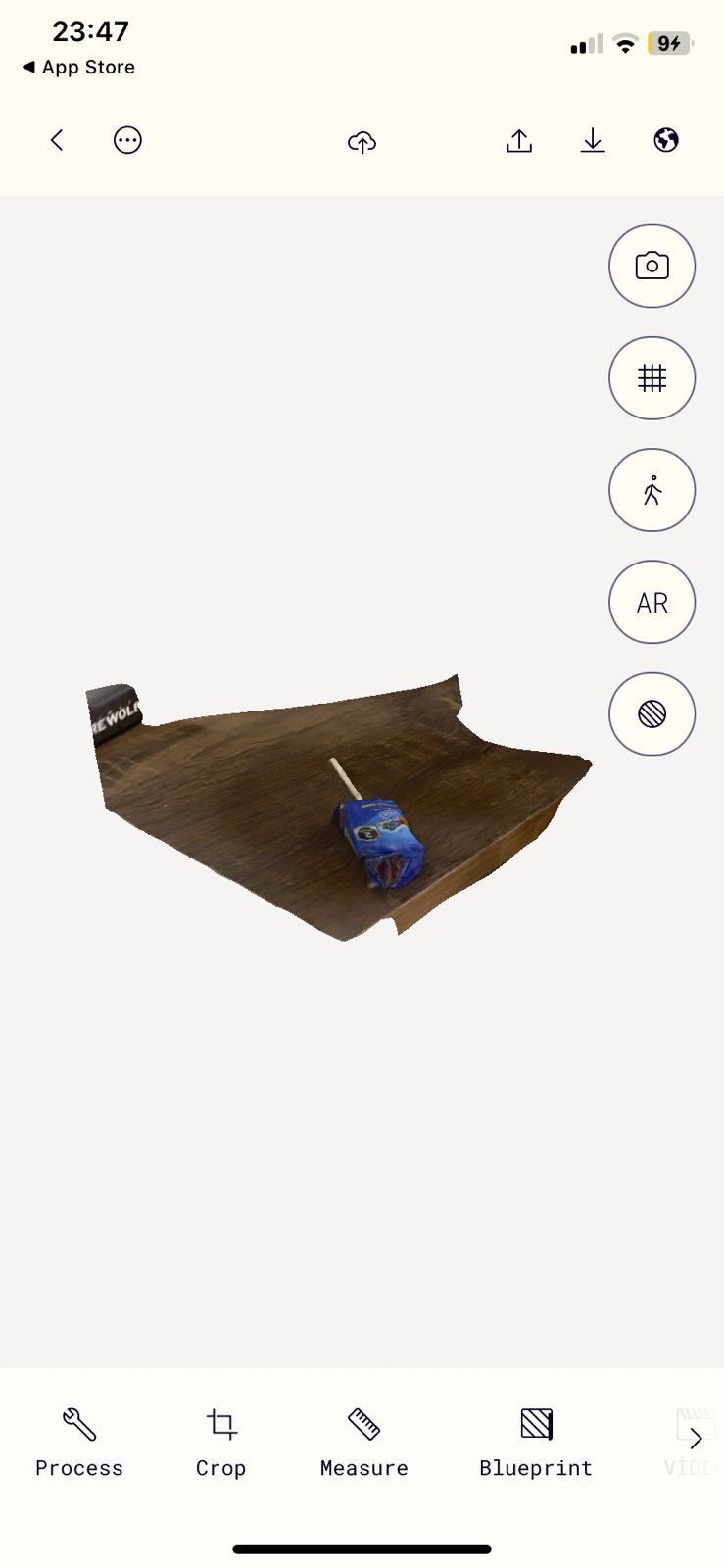

To scan i used polycam which is an app that takes photos of and object and you have to go moving around so that it gets better results at recreating it in 3d

I scanned a lolipop that I had on my desk and took 36 photos of it with polycam

to do the scan first i opened polycam and it opened my camera and i started taking picrures of the object from various different angles

without moving the object.

It is important that the object wouldnt move as the app would recreate the object more acuratelly, having taked all the

pictures i wanted i pressed the done button and the app started loading teh 3d model

And at the end when it finished loading it looked pretty well and actually identified a little bit more than i wanted as it took pieces of my tabble and

a game i had hanging around.

i cant include the 3d scanned archive since it weight almost 90 Mb but i included the solid part and ultimaker file for the print.

conclusion

i learned that the material has to hot to be adhesive adn every materail has its own parameter for printing and the print tends to go wrong if you dont use the parameter or a adhesion plate