CNC creation program initialize...

My individual experience

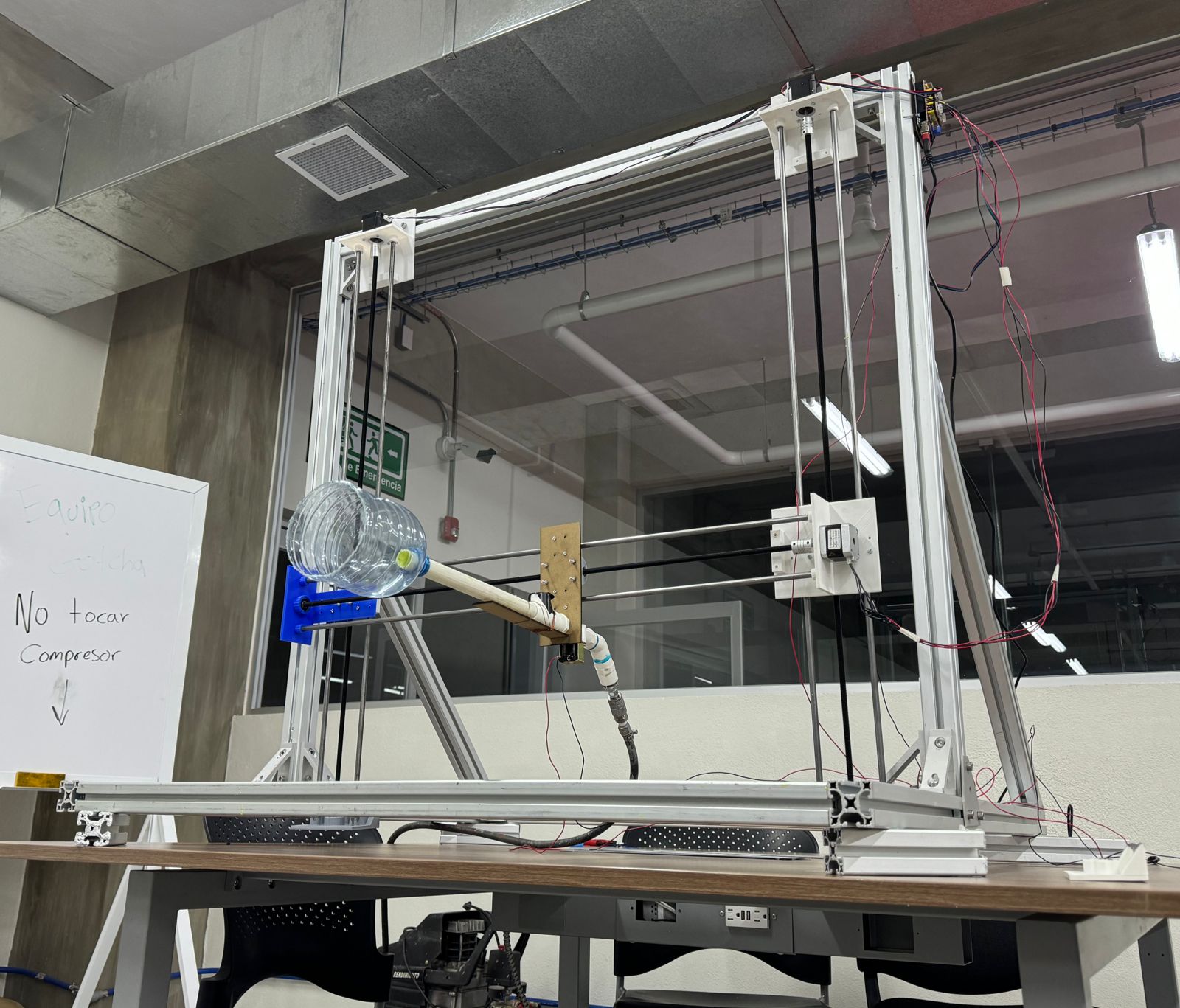

My team took on the construction of a CNC machine with a weird but interesting function, a paintball mechanism designed to create all sorts of artpieces through mechanic and electronic means.

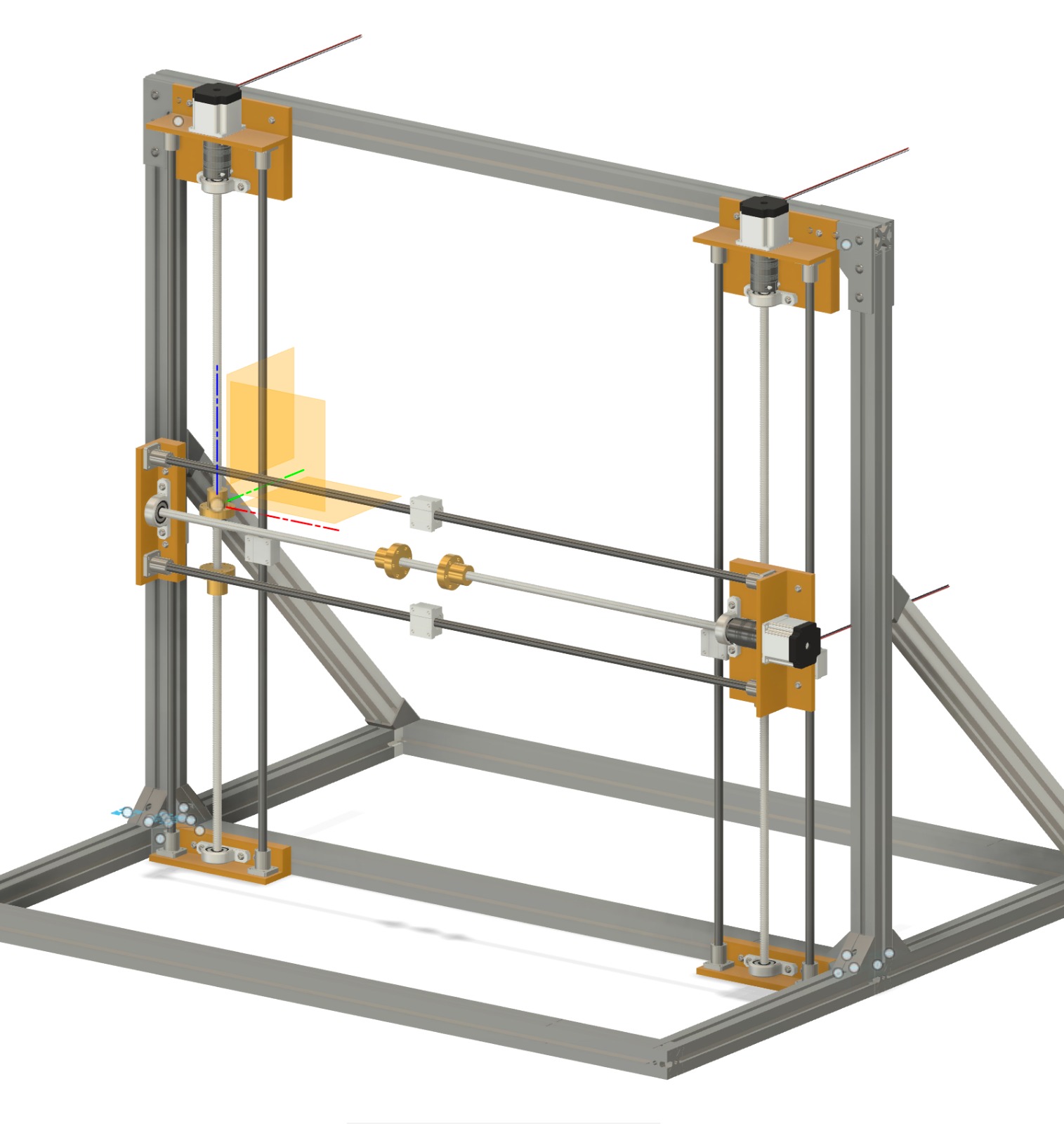

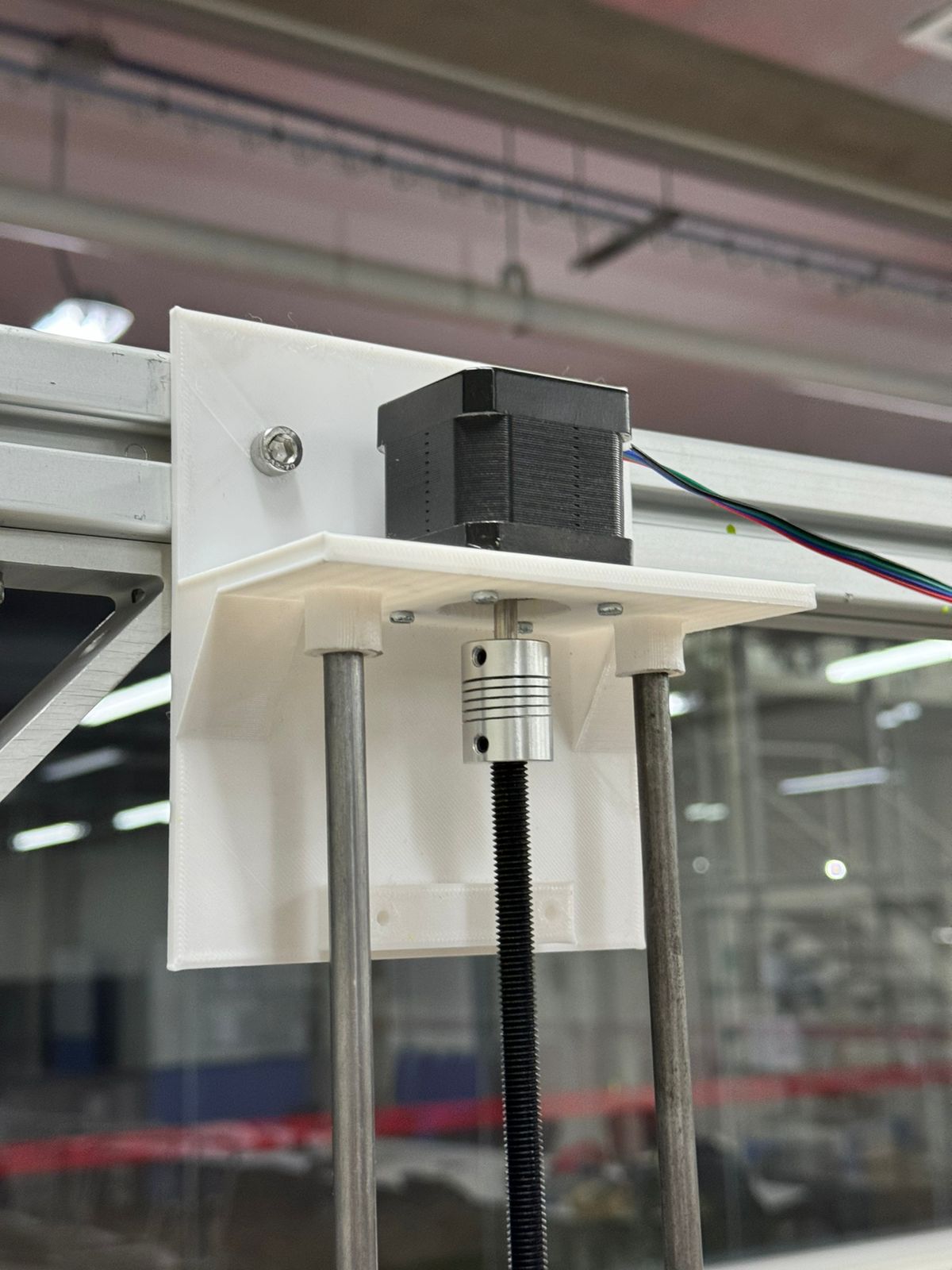

The machine was made usign aluminum profiles, screws (M3,M6,M8) with their respective washers and profile sliding pieces, 3 NEMA stepper motors and other tech wizardry that can be found in the group's site. My team was made up of 3 mechatronics students, 2 industrial design alumni, 1 programming systems schoolmate, 1 biomedics student, and a mechanics professor down at the IBERO Santa Fe in Mexico City. Quite the ensemble! The team shared many mutual interest and offered a variety of skills and schools of thought that allowed the realization of the project at hand.

But now, let's talk about my personal contributions to the team, as this is the individual part of the assignment.

The very first thing I actually contributed to the team was the idea, I thought it would've been a crazy suggestion, but the team seemed to like it very much and were quite enthusiastic of begin the designing process of the project.

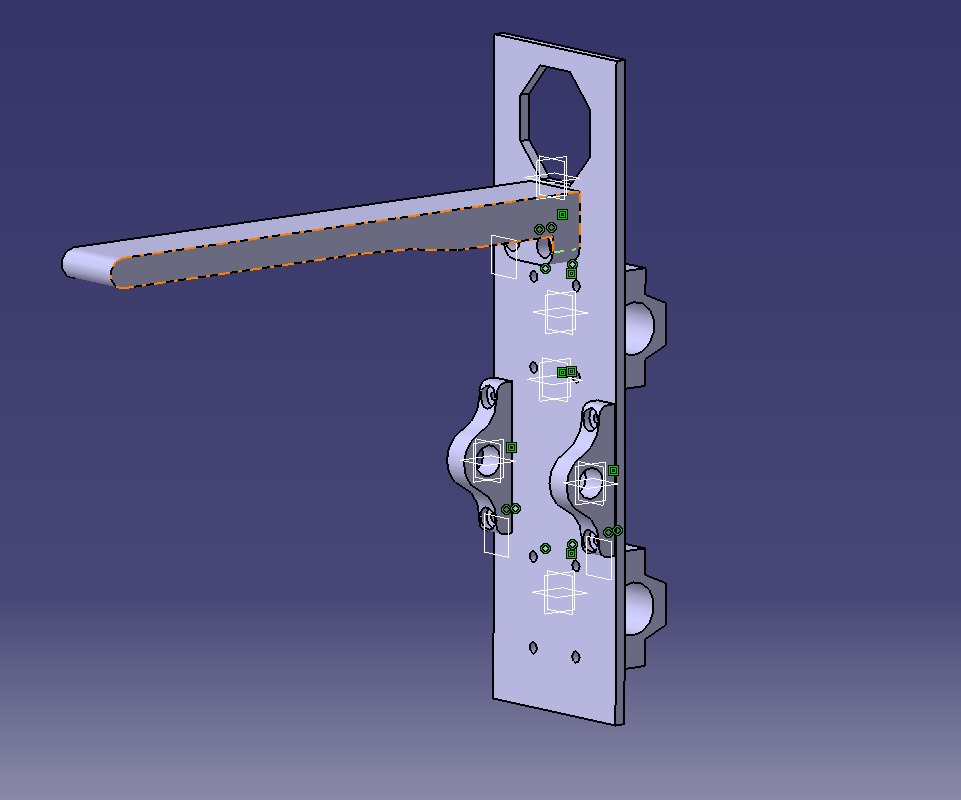

After getting the concept in paper, or actually in a whiteboard. I began helping with the design process of the project, creating the central mounting joint and its accessories that allowed the paintball dispenser to be properly mounted. Also, I aided in the design of the axis bearing pieces that are held in the bottom, top and middle of the machine's structure.

Now, the next part is going to refer with the term of "we" as obviously, teamwork makes the dream work! This stage was done by almost the entire team, so it should be counted as a contribution made by everyone.

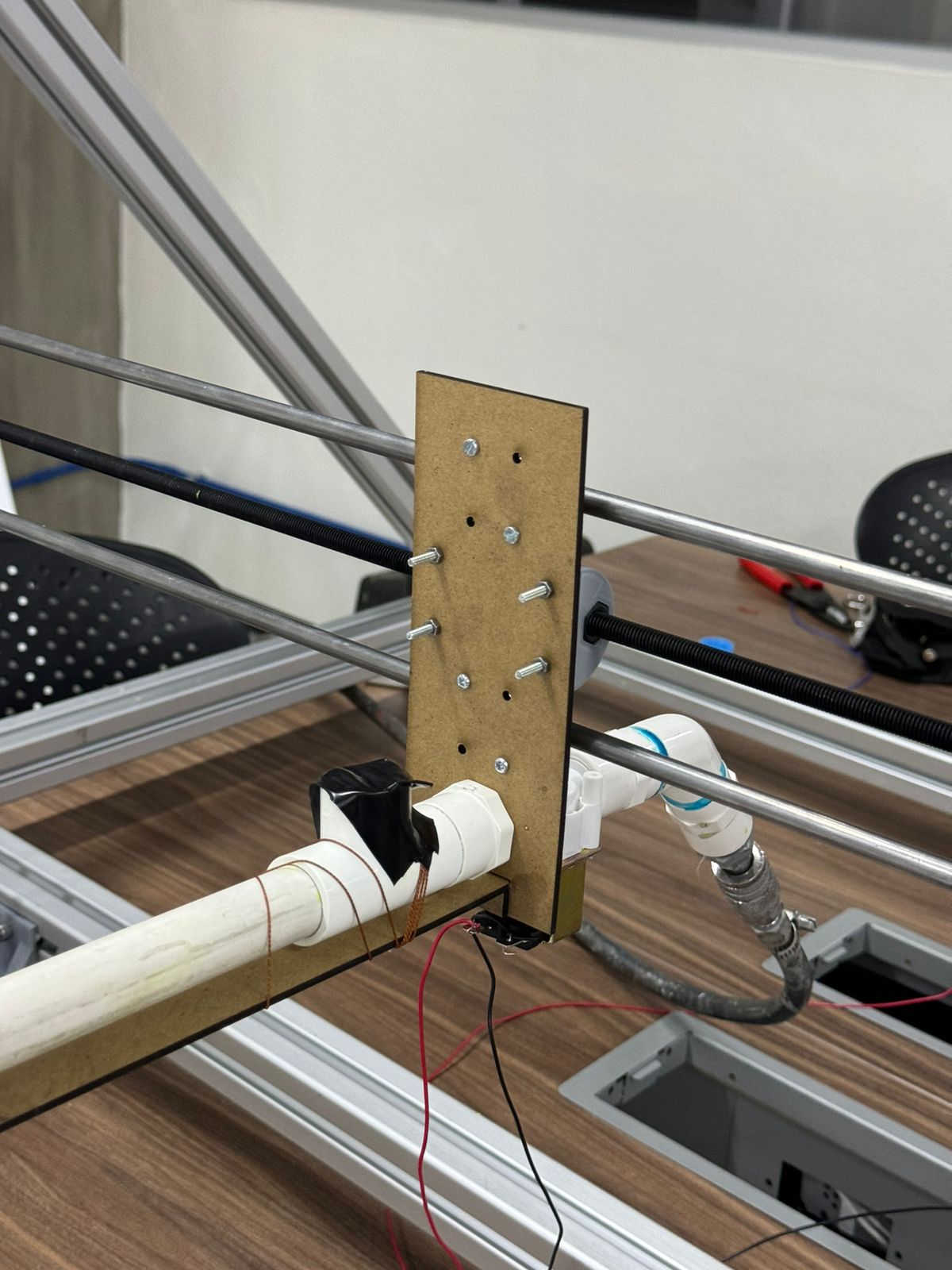

Assembling the machine was indeed a challenge, but with determination and careful planning, my team and I managed to conquer it. Ensuring we had all the necessary components laid out before us was crucial to avoid any unnecessary interruptions during the build process. We meticulously checked for Allen keys, screwdrivers, joints, screws, washers, cables, electronics, and every other tiny part, sparing ourselves the hassle of last-minute runs to the store or waiting impatiently for online deliveries.

Once we had everything in place, it was time to tackle the aluminum profiles. Some of these profiles were longer than required, so a quick trip to the metal cutting band saw machine was in order to trim them down to the proper dimensions. With that hurdle cleared, we moved on to assembling the basic structure using M6 screws, washers, and sliding pieces, carefully constructing the foundation that would support the weight of our CNC paintball dispenser.

As the machine took shape, we proceeded to install the stepper motors and bearings, securing them in place with the same trusty M6 screws and sliding pieces. These components were the backbone of our machine, allowing for precise movement and control of the paintball tool along each axis. The next thing that found it's way into the agenda was the testing, we fired a few paintball rounds with varying pressure measurements to see the most effective one, as well as the positioning, which is important to determine the projectile's trayectory.

Of course, with a machine of this size (1m x 1m x 1m), space considerations were paramount. We had to carefully plan where to place it to minimize any inconvenience. Additionally, we discovered the optimal tank pressure for firing the paintball contents ranged from 70 to 90 psi, prompting us to recommend a compressor for custom use.

In the end, seeing our CNC paintball dispenser in action was immensely satisfying. It was a testament to our teamwork, problem-solving skills, and dedication to bringing our ideas to life. And as we admired our creation, we knew that the journey was just as rewarding as the destination.

Here is a little video of the testing rounds we did at the end.

Files

- For file searching you should check out the group's website.