Problem. Design and manufacture something without using the processes involved in previous weeks.

To do this, we decided to create an automated hot wire cutter.

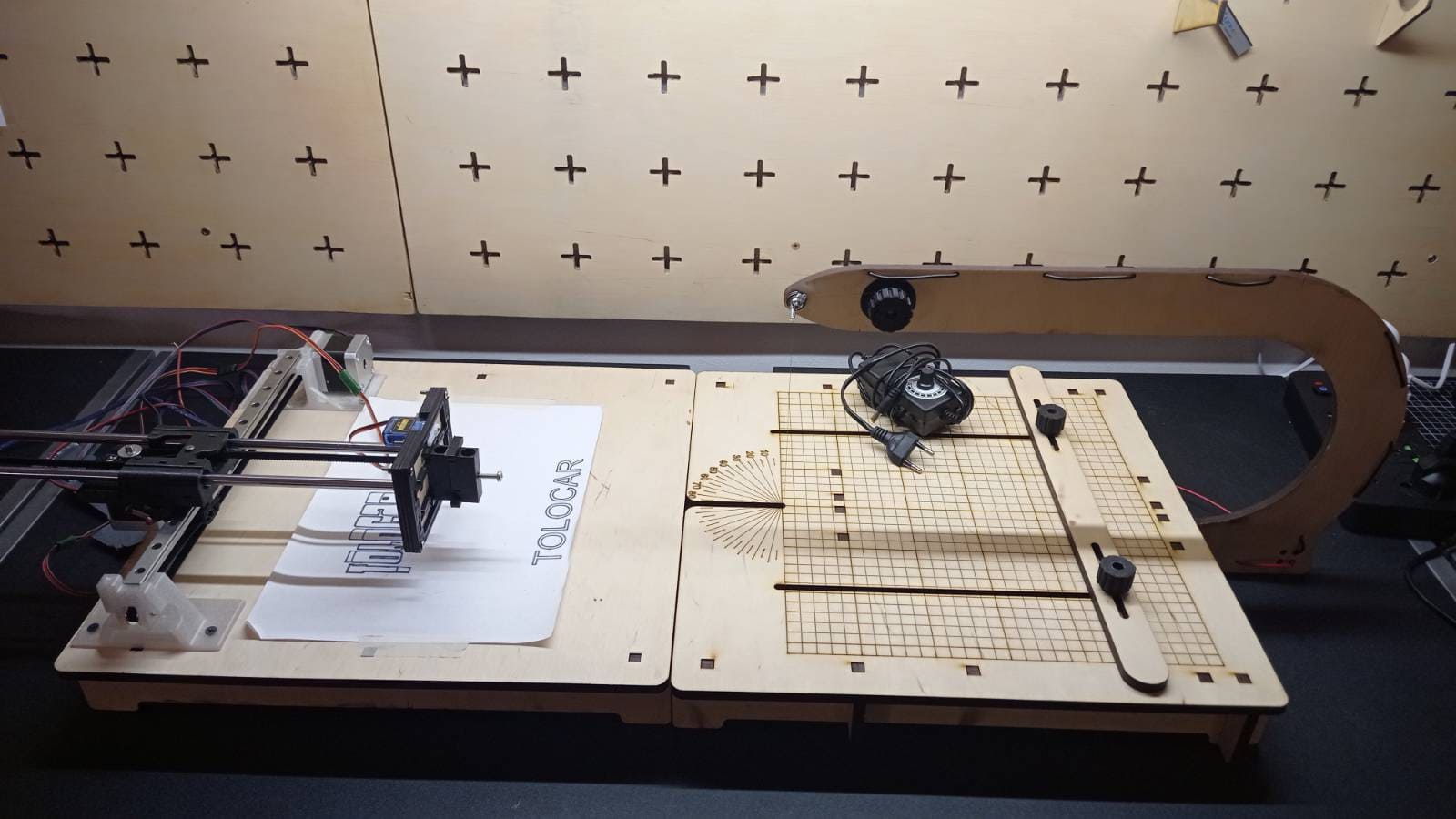

We had two separate machines made according to the models of open projects. pen-plotter hot-wire-cutter

We used a regular hot wire cutter and a pen plotter. In order to use them together, it was necessary to model a foam holder for the pen plotter, which will move the material along a given trajectory.

Therefore, we designed them in fusion 360. One part was cut out of plywood using an optical laser, and the other was printed on a 3D printer.

fusion file 3d print file dxf file

The next and most difficult step is communication between the plotter and the hot wire cutter.

The problem is that, typically, the working surface of a plotter is located beneath its guide rail. However, we needed to move it to the side. The most difficult task was to take into account the trajectory of the string cutter. After all, in certain places of the model, it can affect its quality. Therefore, it is important that the G-code correctly describes the entry/exit points and sequence of string movement.

The entire process from creating a model to its manufacture is described below.

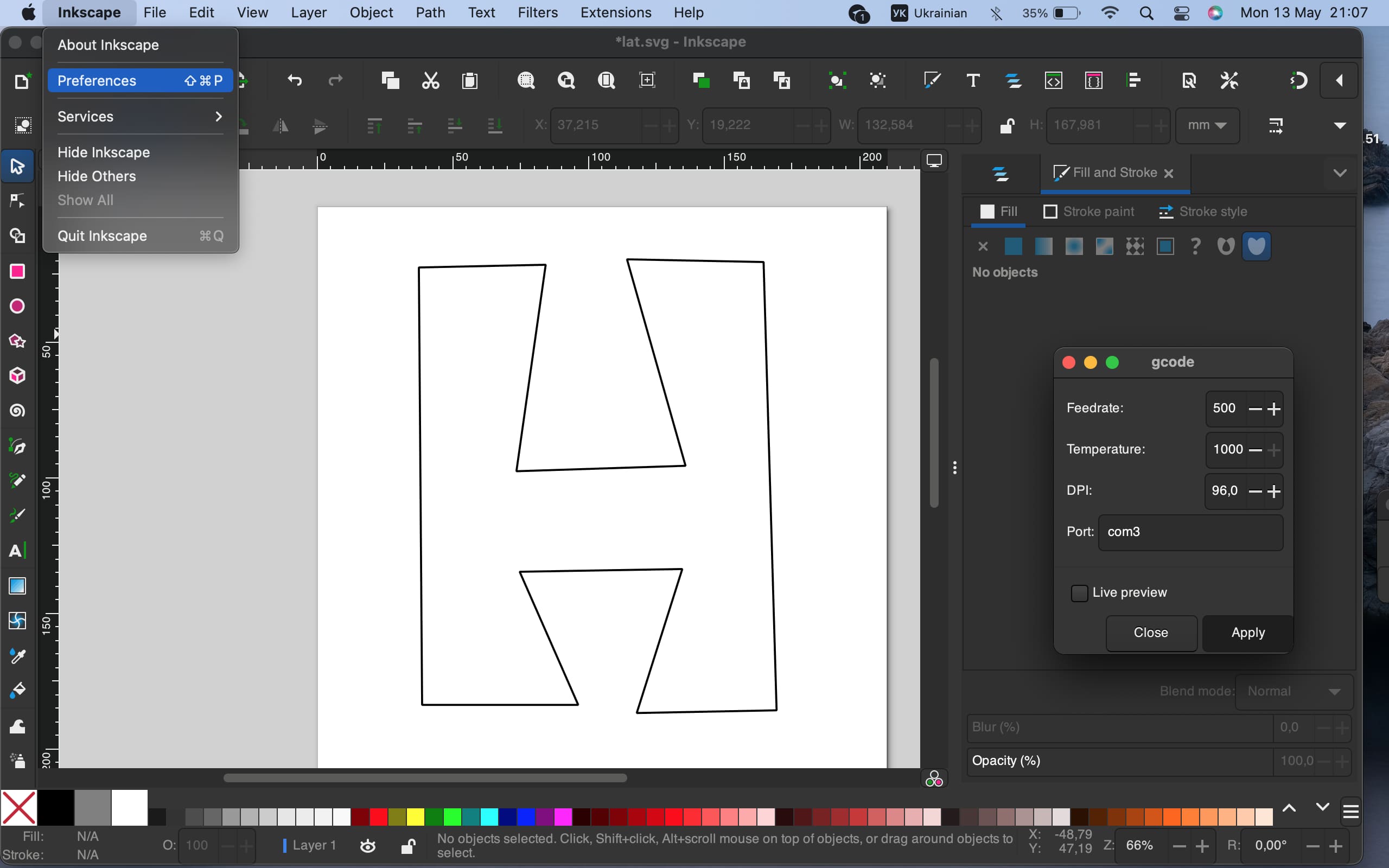

1. Create a vector design in Inkscape.

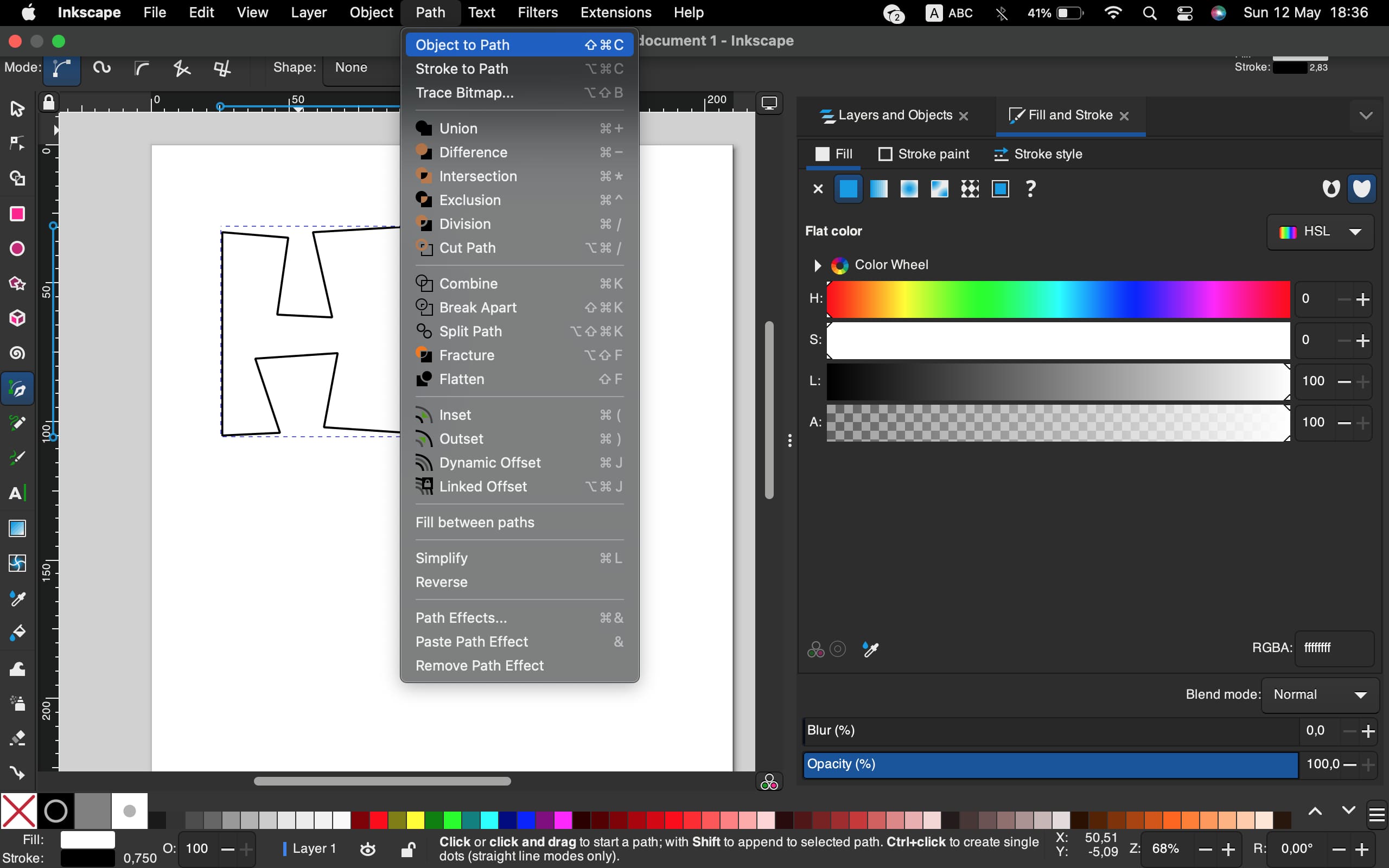

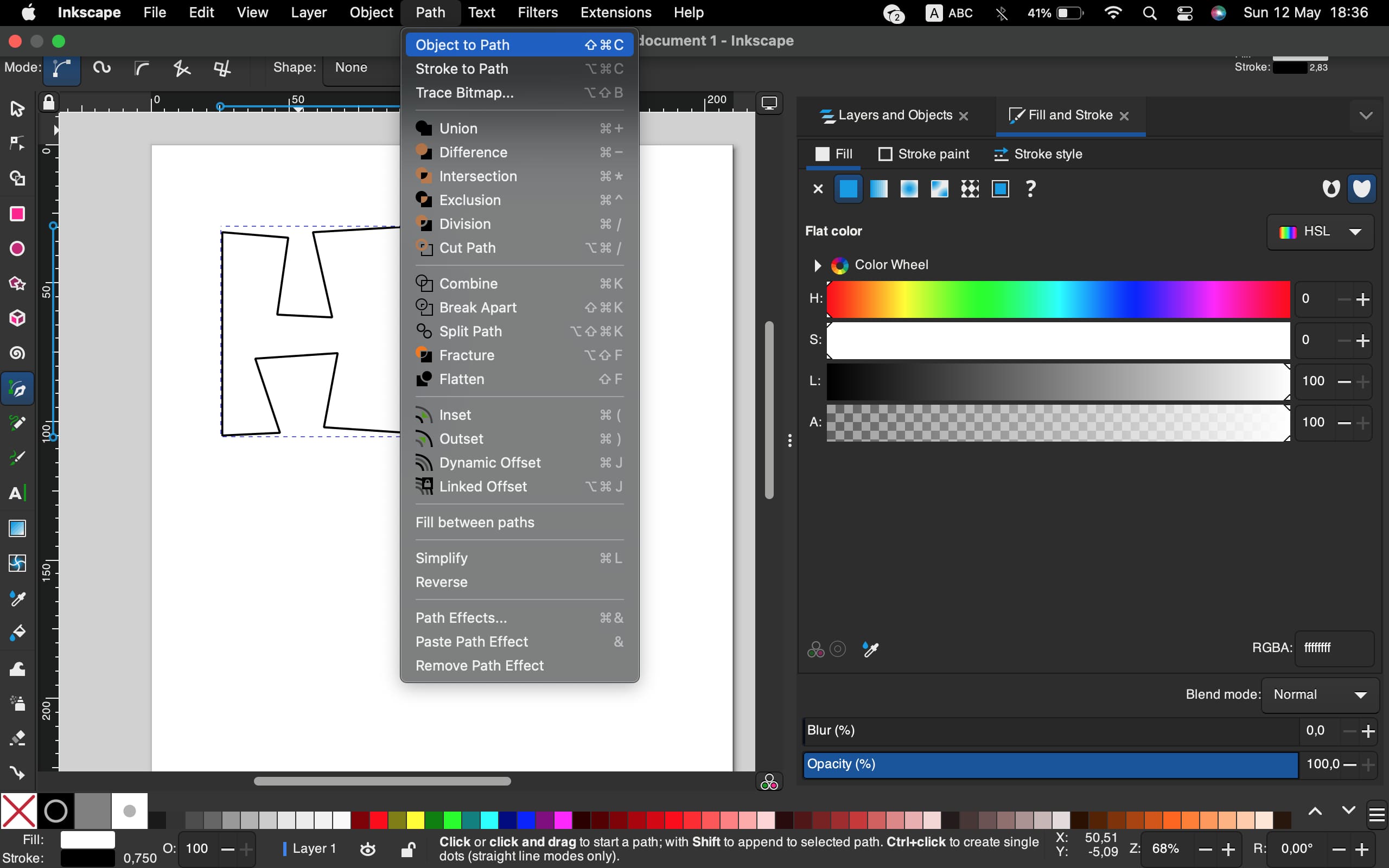

2. The design must have a closed circuit

When the design is ready, go to the Path tab and select the Object to Path function there.

Designe file svg

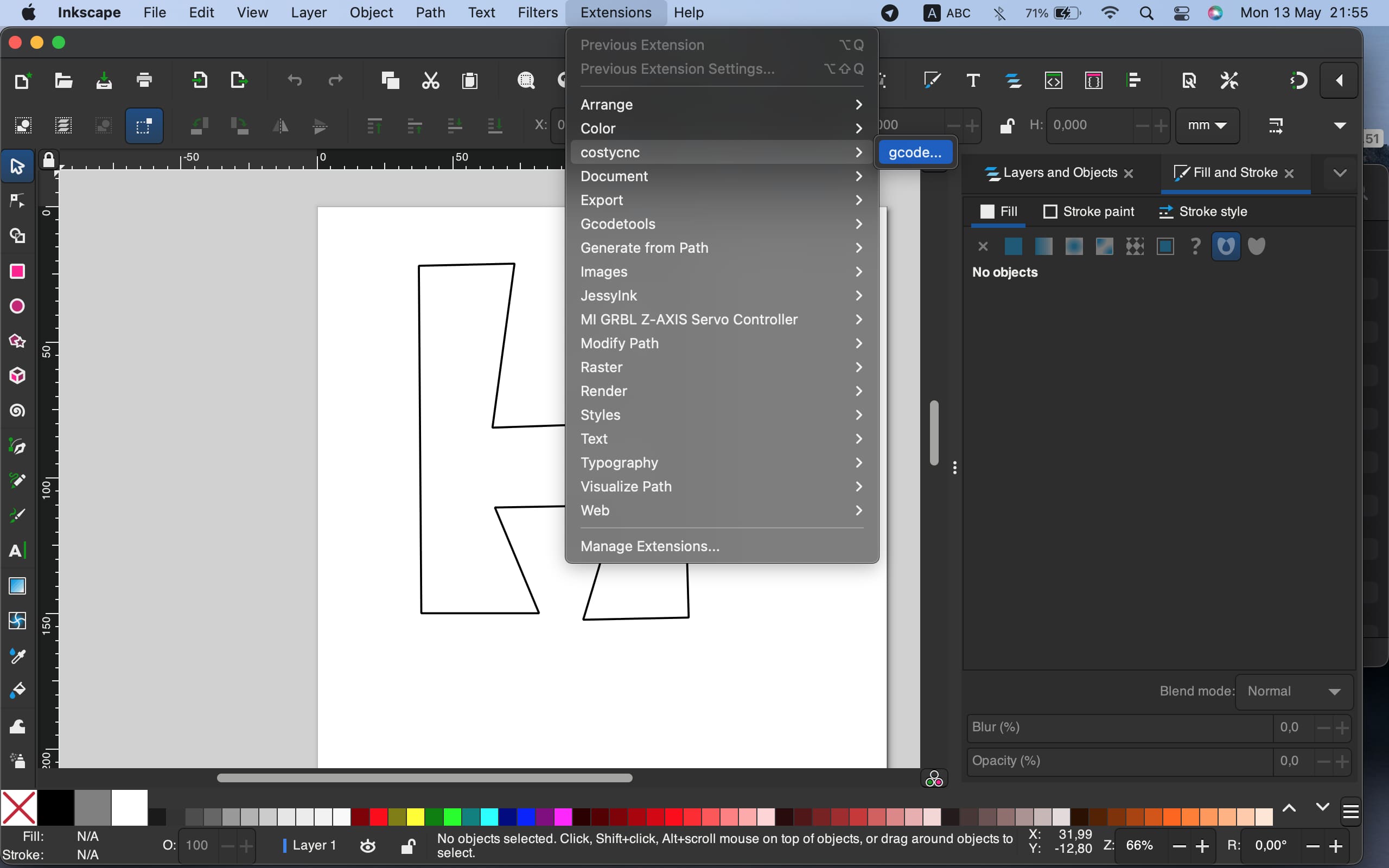

The next step is to convert the image into gcode. To do this, you need to install a special plugin "costycnc", which can be downloaded from the link.

To install it, you need to go to the Preferences tab and find the directory where the files for the extensiol tab are installed.

You need to unpack the downloaded file into this folder.

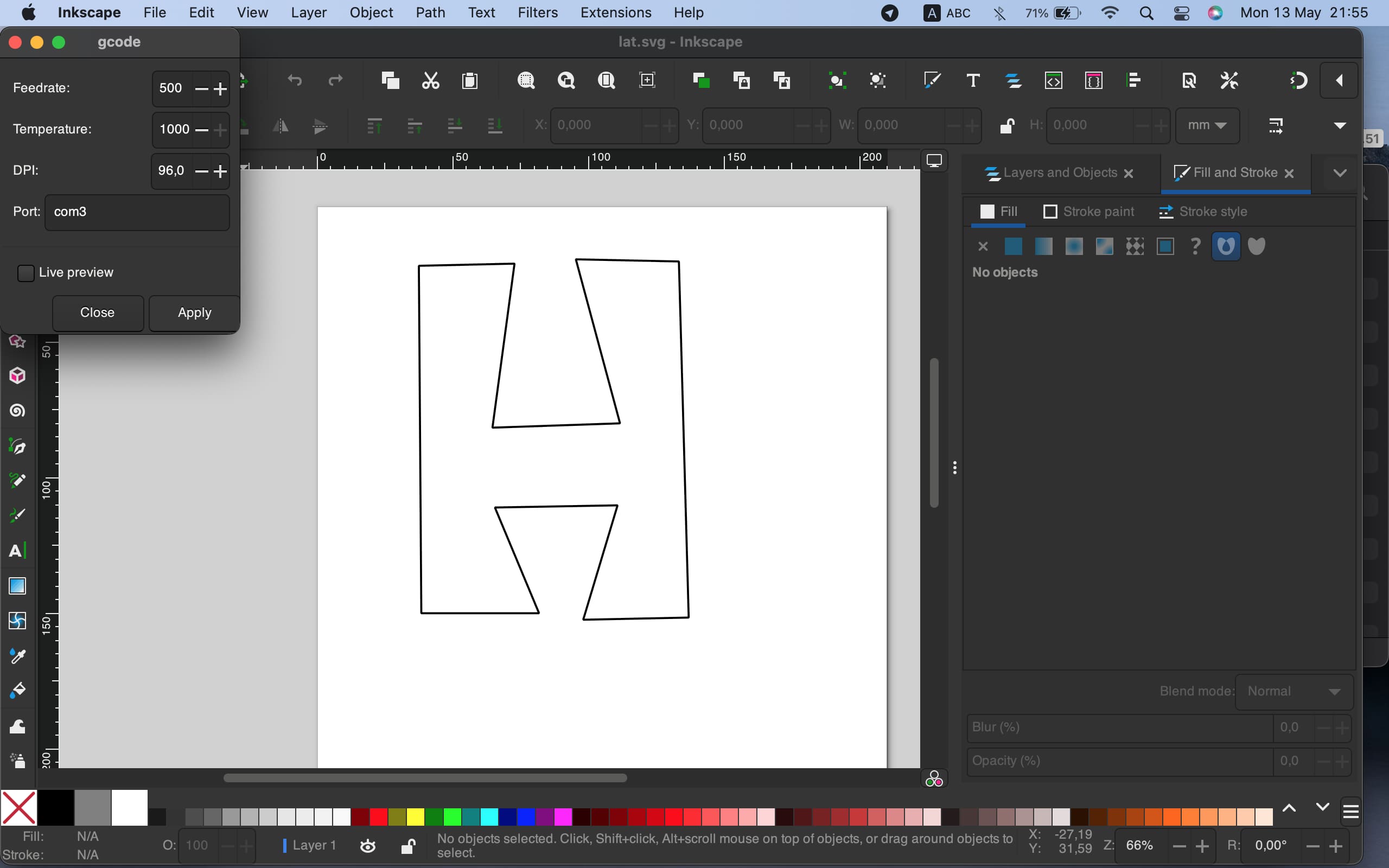

Go to the extension tab and select the costycnc - gcode plugin.

Click apply on the window. First you need to select the image

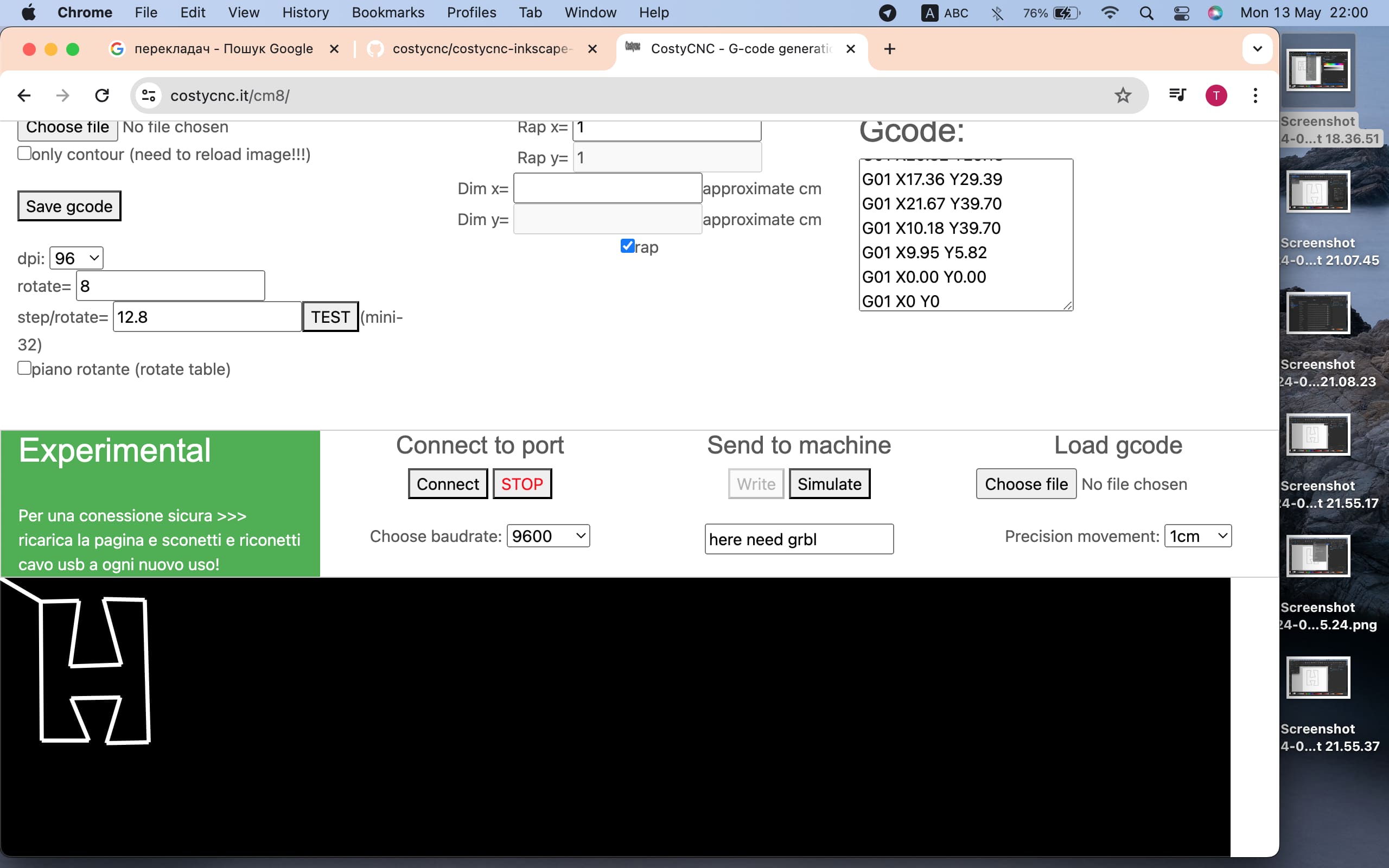

Copy the generated code and paste it into the appropriate box on the site. When the image is displayed in the window below. Press the save gcode button

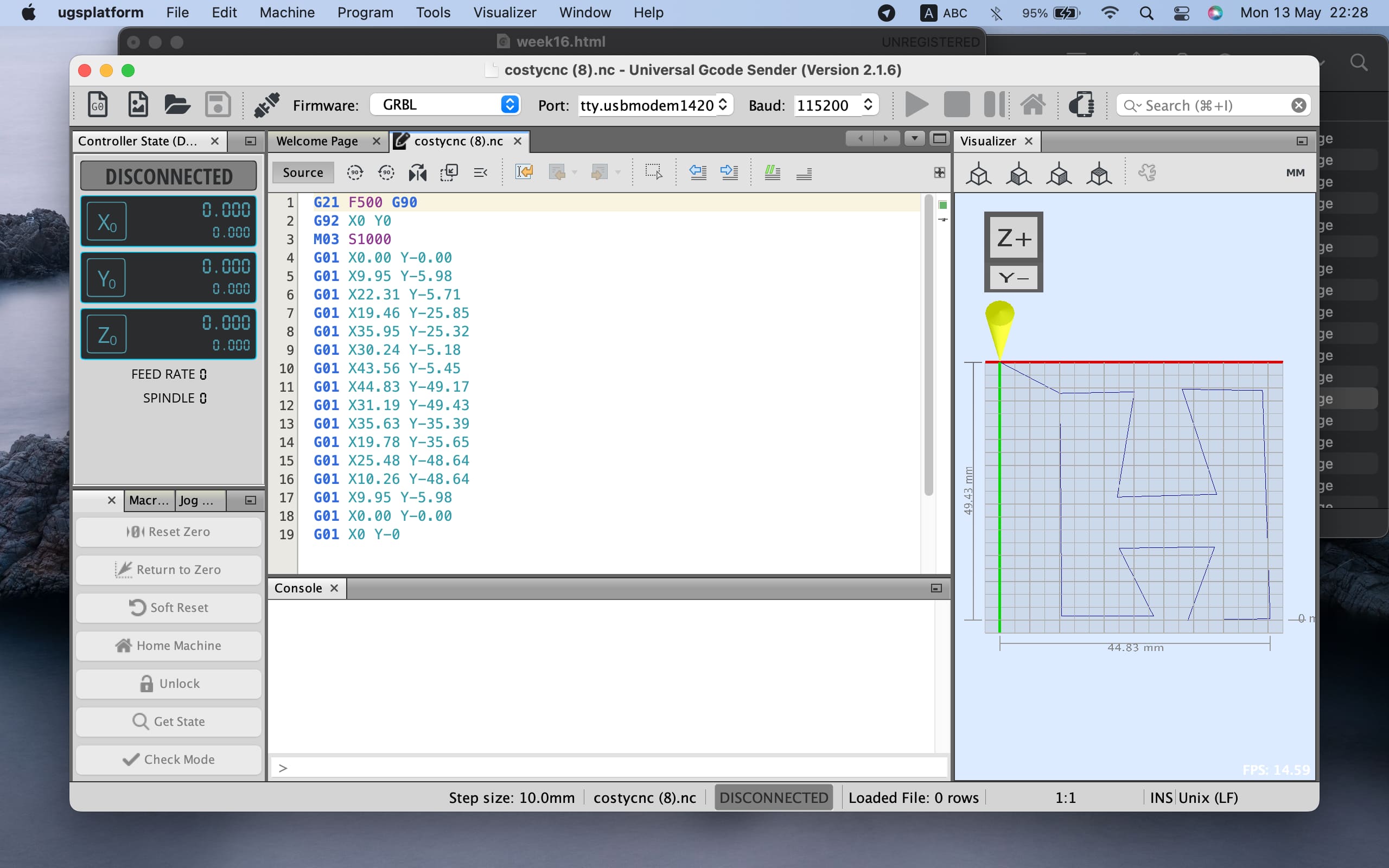

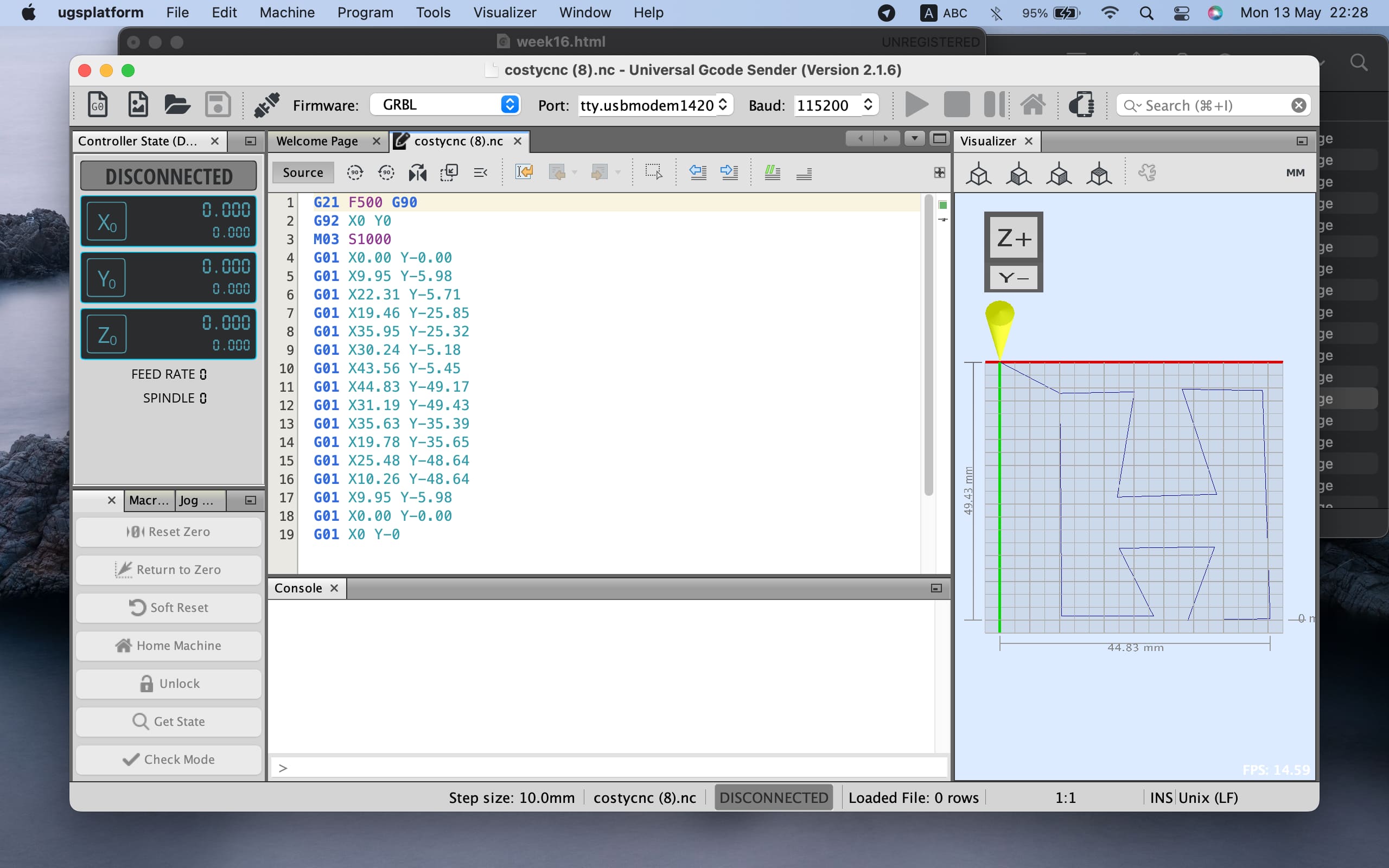

Open the saved file in Universal gcode Sender. After connecting the program to the plotter, you can cut the planned design

There are two disadvantages that should be noted. Plotter and string cutter usually work in different coordinate planes. Therefore, it is necessary to use all points along the Y axis with negative values

And the second drawback - when converting an image to gcode, the size of the image decreases

Ahe first time it was not possible to choose the correct size of the model

My personal contribution includes creating additional components for the model, as well as finding a solution for software integration.