Week 17 Assignment

Applications and Implications

Propose a final project masterpiece that integrates the range of units covered, answering:

What will it do?

Who's done what beforehand?

What will you design?

What materials and components will be used?

Where will come from?

How much will they cost?

What parts and systems will be made?

What processes will be used?

What questions need to be answered?

How will it be evaluated?

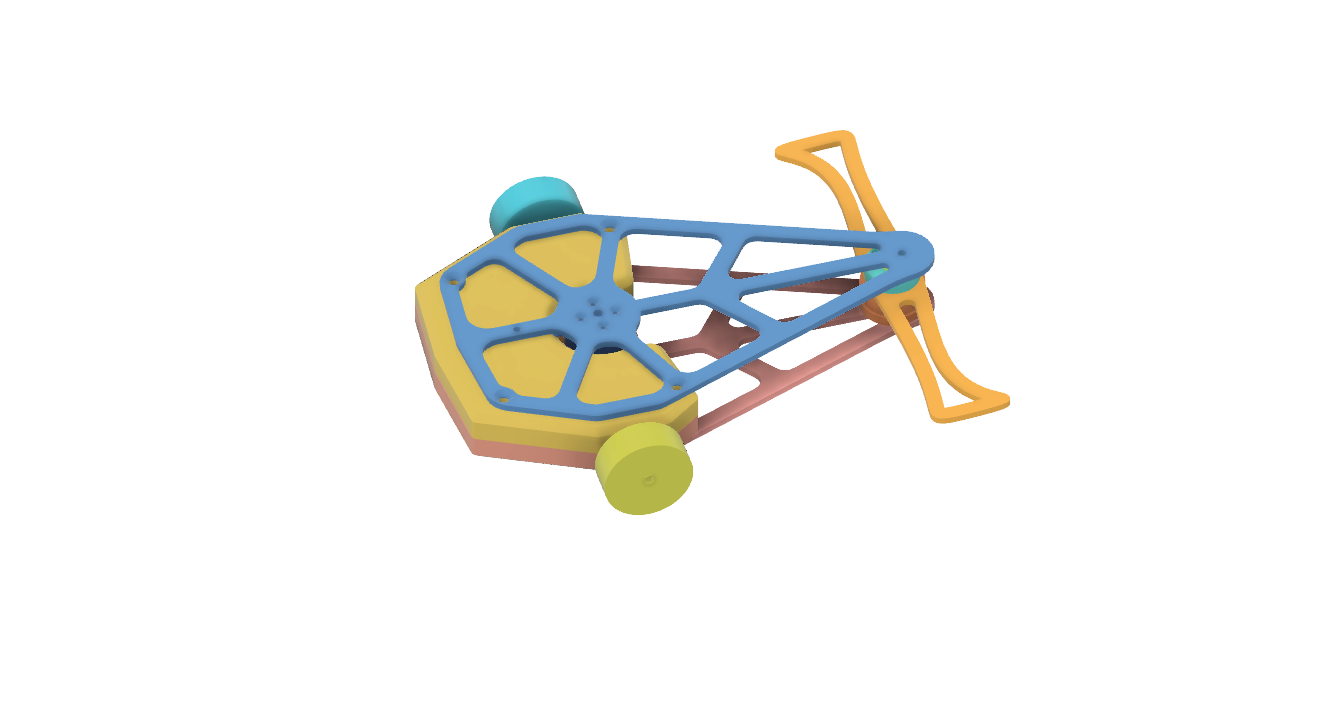

What Will SHREDZILA Do?

SHREDZILA is a beetle-weight battle bot designed for combat in robot fighting competitions. Its primary functions include:

- Combat Engagement: Equipped with a horizontal spinner weapon, SHREDZILA aims to engage and disable opponents by delivering powerful and precise strikes.

- Durability: The design and materials, such as the TPU shell, ensure it can withstand impacts and continue functioning throughout the battle.

- Mobility: With a robust drivetrain and carefully designed structure, SHREDZILA is capable of agile movements, allowing it to navigate the arena effectively and position itself strategically during combat.

- Inspiration: As a showcase piece built in a lab frequently visited by students, SHREDZILA aims to inspire and demonstrate the potential for designing and fabricating advanced battle bots, encouraging others to engage in similar projects and contribute to the development of a battle bot community in India, particularly in Kerala.

Who's Done What Beforehand?

Individuals like Tombstone and Robert Cowan from the famous show BattleBots have pioneered similar concepts and designs:

- Tombstone: Known for its devastating horizontal spinner weapon, Tombstone has demonstrated the effectiveness of this design in BattleBots competitions, inspiring many enthusiasts to explore similar concepts.

- Robert Cowan: As a competitor and builder in BattleBots, Robert Cowan has contributed to the advancement of combat robot technology with his innovative designs and engineering solutions.

Design Plan: SHREDZILA

For SHREDZILA, I will design most of the mechanical parts from scratch, ensuring that they are optimized for performance and manufacturability. I will prioritize using parts that are easily accessible in India, considering factors such as availability, cost, and quality. By designing mechanical components in-house, I can tailor them to the specific requirements of SHREDZILA, optimizing performance and reliability.

While mechanical parts will be custom-designed, I will also incorporate off-the-shelf components where feasible, particularly for electronic modules. Given the complexity and specialized nature of electronic components, I will focus on designing custom electronic modules to control SHREDZILA's functionality and performance. However, I will ensure compatibility with commonly available electronic components and modules to facilitate repairs and replacements.

This approach will not only streamline the design and manufacturing process but also ensure that SHREDZILA can be easily maintained and repaired, even in environments with limited access to specialized parts and resources.

What materials and components will be used?Where will they come from?How much will they cost?

SHREDZILA Electronics Bill of Materials (BOM)

| Item | Quantity | Description | Price (Estimate) | Source |

|---|---|---|---|---|

| Switch | 2 | Toggle Switch (SMD) | ₹5 | fablab |

| ESP32 Module | 1 | Microcontroller Development Board | ₹230 | fablab |

| Resistors (1208 package, as required) | Resistors for ESP32 Minimum Circuit | ₹2 | fablab | |

| 5v Voltage Regulator | 1 | LM7805 Voltage Regulator | ₹12 | fablab |

| Diode (1N4007) | 1 | Diode (1N4007) | ₹5 | fablab |

| Electrolytic Capacitor (100uF, 25V) | 1 | Electrolytic Capacitor (100uF, 25V) | ₹5 | fablab |

| Ceramic Capacitors (0.1uF) | 1 | Ceramic Capacitors (0.1uF) | ₹5 | fablab |

| Resistor (220 ohms) | 1 | Resistor (220 ohms) | ₹.50 | fablab |

| 3.3v Voltage Regulator | 1 | LM317 Voltage Regulator | ₹20 | fablab |

| Resistors (220 ohms, 1k ohm) | Resistors for LM317 Circuit | ₹.50 | fablab | |

| Electrolytic Capacitor (10uF, 25V) | 1 | Electrolytic Capacitor (10uF, 25V) | ₹5 | fablab |

| Ceramic Capacitors (0.1uF) | 1 | Ceramic Capacitors (0.1uF) | ₹3 | fablab |

| LED for Power Indicator | 1 | SMD LED (1208 package) | ₹1.5 | fablab |

| 20A ESC | 1 | Electronic Speed Controller (ESC) - 20A | ₹400 | fablab |

| 40A ESC | 1 | Electronic Speed Controller (ESC) - 40A | ₹1000 | fablab |

| 2212 BLDC Motor | 2 | Brushless DC Motor - 2212 | ₹450 | fablab |

| 3S LiPo Battery | 1 | Lithium Polymer Battery - 3S, 30C | ₹1800 | fablab |

| 3-Pin 2.54mm Male Berg Strip | 1 | 3-Pin Male Berg Strip (2.54mm pitch) | ₹5 | fablab |

| Terminal Connectors | 1 | Terminal Connectors (as required) | ₹5 | fablab |

SHREDZILA Bill of Materials (Mechanical)

| Item | Quantity | Description | Price (Estimate) | Source |

|---|---|---|---|---|

| Screws | ||||

| 6mm CSK Screws (12mm length) | 8 | Countersunk screws | fablab | |

| 3mm Screws (12mm length) | 4 | Standard screws | fablab | |

| 3mm Screws (40mm length) | 6 | Standard screws | fablab | |

| 3mm Lock Nuts | 6 | Locking nuts | fablab | |

| 6mm Hex Standoff (12mm length) | 6 | Hexagonal standoffs | fablab | |

| 6mm Button Head Screws (15mm length) | 2 | Button head screws | fablab | |

| 3mm CSK Screws (12mm length) | 4 | Countersunk screws | fablab | |

| 3mm Screws (25mm length) | 2 | Standard screws | fablab | |

| Stock Materials | ||||

| 6063 Aluminum Plate (225mm x 365mm x 5mm) | 2 | Aluminum plate | fablab | |

| HCHCR Plate (375mm x 125mm x 5mm) | 1 | High carbon high chromium plate | ₹600 | Local hardware store |

| Additional Components | ||||

| TPU Filament (1kg) | 1 | Flexible filament for 3D printing | fablab | |

| Drawn Cup Needle Roller Bearing, HK1212 | 3 | Needle roller bearings | ₹150 | Local hardware store |

| Planetary Gear DC Motor 12V | 1 | 12V DC motor with planetary gears | ₹1200 | online marketplaces robu.in |

What parts and systems will be made?

For SHREDZILA, I opted for a combination of materials and fabrication techniques tailored to maximize performance and durability. The shell, crafted from TPU, promises resilience and impact absorption, crucial for surviving intense battles. Aluminum was the natural choice for the arms, providing the necessary strength and structural integrity to support the entire robot. As for the weapon assembly, I spared no expense, opting for HCHCR steel cut with precision water jet technology to ensure razor-sharp accuracy and formidable striking power. Despite facing challenges sourcing components locally, I took matters into my own hands, designing and fabricating a bespoke BLDC planetary gear mechanism to elevate SHREDZILA's capabilities to new heights. This meticulous approach underscores my commitment to engineering excellence and sets SHREDZILA apart as a true force to be reckoned with in the arena.

What processes will be used?

Manufacturing Processes for SHREDZILA

- 3D Printing: Shell

- CNC Milling: Aluminum Arms

- Water Jet Cutting: Weapon Assembly

- PCB Milling: Electronic Components

- Assembly: All Parts

Each manufacturing process plays a crucial role in crafting SHREDZILA:

- 3D Printing: The TPU material is meticulously 3D printed layer by layer to create the resilient outer shell of SHREDZILA. This process ensures both flexibility and durability, essential for withstanding the rigors of combat.

- CNC Milling: Precision-machined aluminum arms are crafted using CNC milling machines, ensuring accuracy and uniformity. These arms provide structural support to SHREDZILA, enhancing its stability and performance in battle.

- Water Jet Cutting: The weapon assembly, made from HCHCR steel, undergoes water jet cutting to achieve intricate shapes and sharp edges. This process is essential for creating a formidable offensive weapon capable of delivering devastating blows to opponents.

- PCB Milling: Custom electronic components, including circuit boards for control systems, are fabricated using PCB milling techniques. This ensures precision and reliability in the assembly of electronic systems, critical for SHREDZILA's functionality.

- Assembly: Finally, all parts of SHREDZILA are meticulously assembled, with attention to detail and quality control measures. This ensures optimal functionality and performance in combat situations, making SHREDZILA a formidable competitor in robowars.

By employing these specialized manufacturing processes, SHREDZILA is crafted to be a formidable competitor, combining strength, agility, and cutting-edge technology for dominance in the arena.

.jpeg)

What questions need to be answered?

1.will the pully will hold at high speeds and inartia and angular mommentam

2.communication between ps2 and esp32

3.will it withstand the vibration

How will it be evaluated?

The evaluation of SHREDZILA will focus on the following criteria:

- Combat Performance: SHREDZILA's agility, maneuverability, and effectiveness in battle.

- Crushing Ability: The robot's capability to crush soda cans and waste materials, demonstrating its strength and power.

- 3D Printing Quality: Assessment of the durability, flexibility, and craftsmanship of the 3D-printed components, particularly the TPU shell.

- Overall Presentation: Evaluation of SHREDZILA's aesthetics, build quality, and attention to detail.

By evaluating SHREDZILA based on these criteria, we can assess its performance in combat, its ability to showcase fab lab capabilities, and its overall impact as a symbol of innovation and excellence.

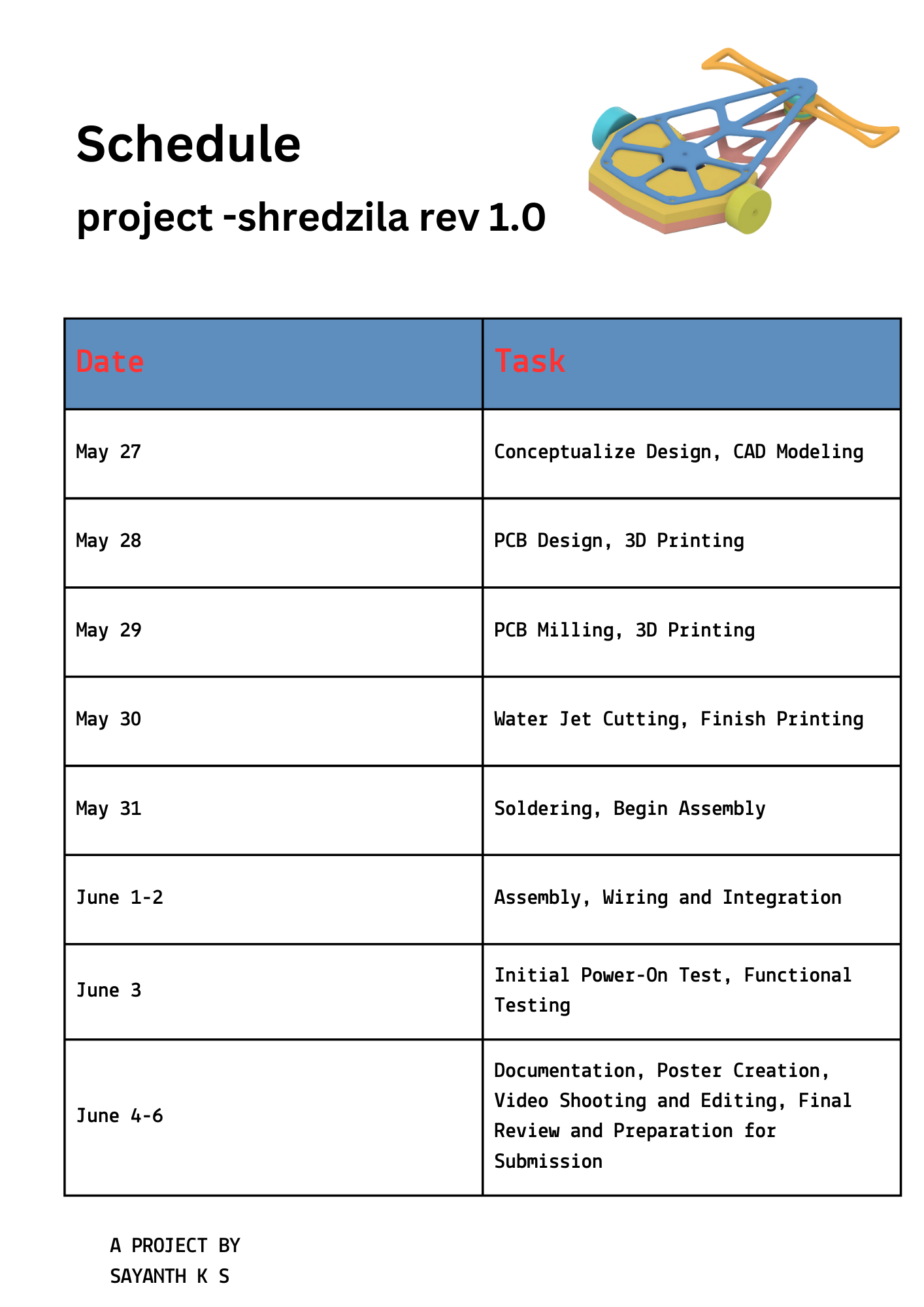

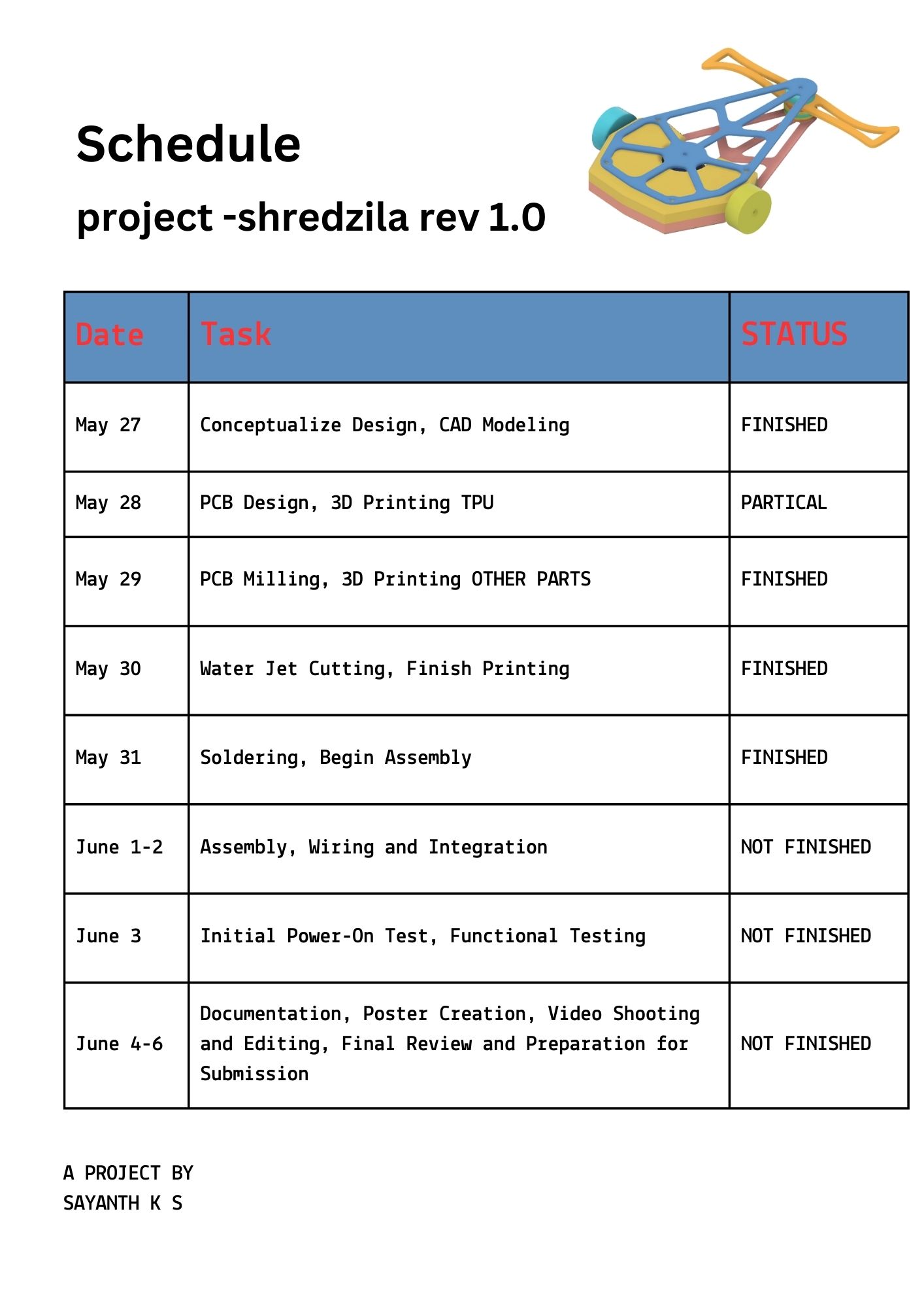

what will happen when?

PROJECT DEVELOPMENT

what tasks have been completed

- Machined water jet parts.

- 3D printed TPU parts.

- Modified and tested BLDC planetary gear motor.

- Started work on ESP32 and PS2 controller communication.

.jpeg)

what tasks remain?

- Machine the pulley shaft using CNC lathe.

- Mill a stand for the showcase.

- Design and mill the PCB.

- Write firmware for the project.

- Test motor torque and ensure it meets requirements.

- Resolve issues with PS2 controller communication.

- Match the rotational inertia of the weapon and the driver pulley.

- Determine how to tension the belt properly.

- Address concerns about switching on the battery from outside.

what's working?

- Motor modifications and testing.

- i implemented the ps2 communication to a level and it is working

- Machined and 3D printed parts like the shell and pully

what's not?

- Difficulty in achieving desired motor behavior.

- Ensuring proper communication between ESP32 and PS2 controller.

- Matching rotational inertia of the weapon and the motor , tensioning the belt for the weapon system correctly.

what questions need to be resolved?

- How to achieve smoother motor operation without twitching.

- how to finish the PS2 controller integration.

- Methods for matching rotational inertia and tensioning the belt.

what will happen when?

- Complete machining of the pulley shaft using CNC lathe.

- Finish designing and milling the PCB.

- Write and test the firmware for the project.

- Resolve communication issues with the PS2 controller.

- Address concerns related to matching rotational inertia and tensioning the belt.

what have you learned?

- Maximum PWM values can cause motor twitching; optimal values are crucial.only pwm of 1600us can be safely used when the motor is started instantly rather then slow ramp up

- this was due to the fact one motor was 1000kv and only that motor had this problem and i solved it by slowly testing the duty cycle one by one till the twitching was eliminated

- Sandblasting aluminum provides a good finish but can be prone to scratching.

- High infill percentages in 3D printing PLA can mimic materials like PETG for specific parts like pulleys .