Applications and Implications, Project Development

Individual assignment:

The assignment is to Propose a final project masterpiece that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What will I design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

The requirements that must meet my project are also given in the assignment

My project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design, and production, embedded microcontroller interfacing and programming, system integration, and packaging

Where possible, I should make rather than buy the parts of my project

Projects can be separate or joint, but need to show my mastery of the skills and be independently operable

1. What will it do?

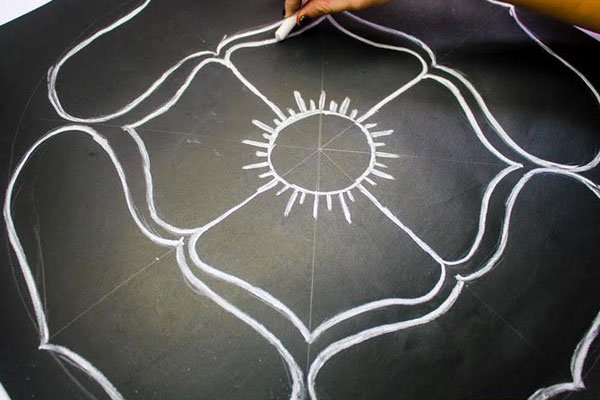

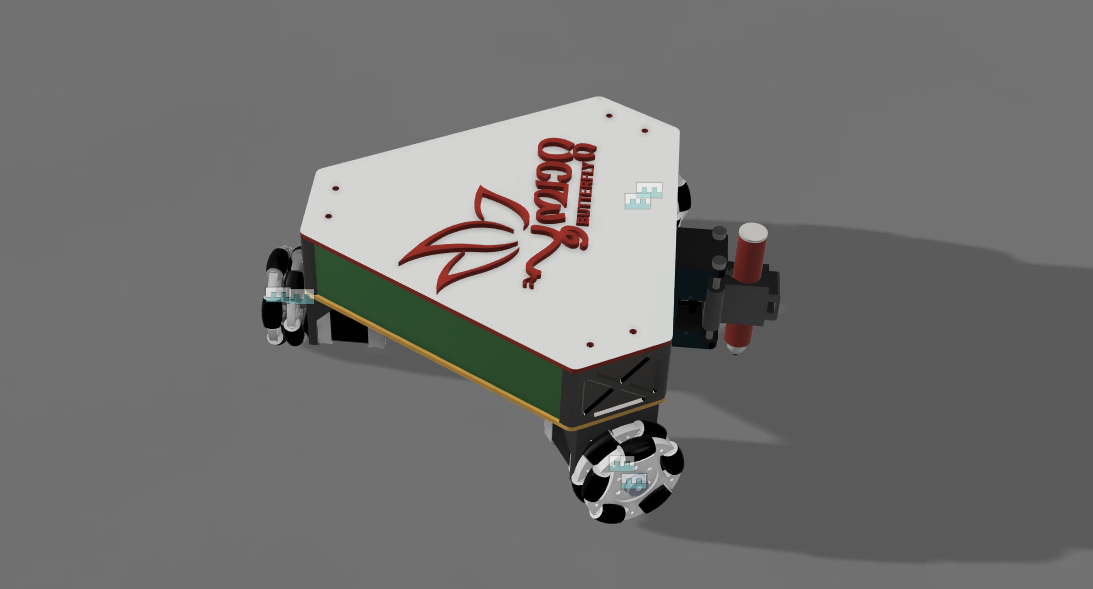

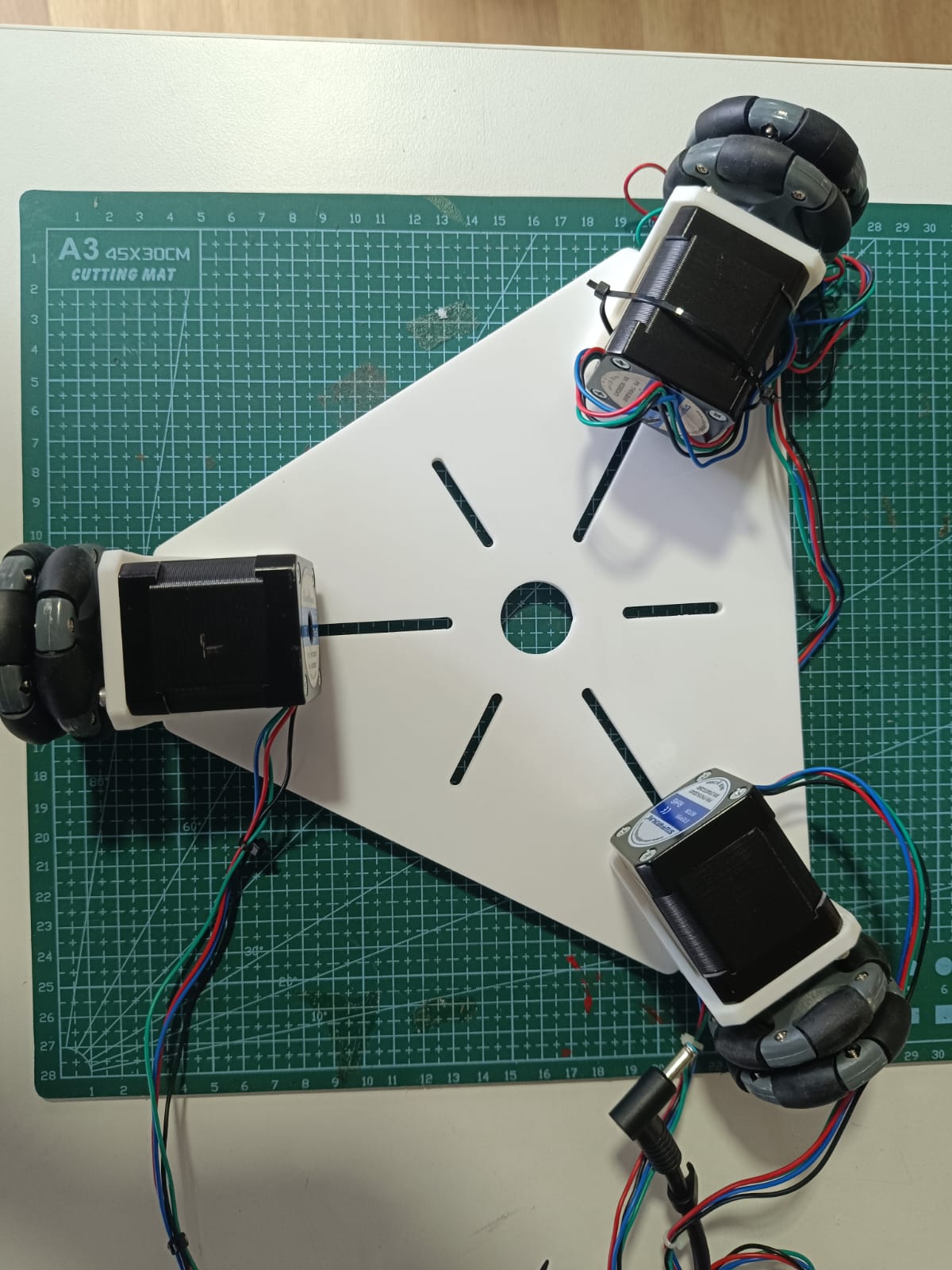

The project, named "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter," is a compact and efficient XY plotter. It is designed to draw intricate designs and images directly onto expansive canvases such as walls and floors. The plotter uses three omni-wheels, stepper motors, an ESP32 microcontroller, merging the precision of CNC technology with artistic creativity. This allows for high precision and detailed artworks on a larger scale. Moreover it draws design in floor…..Each year, our office takes part in the tradition of drawing a pookalam for Onam. However, creating these intricate floral designs on the floor is a challenging and time-consuming process. It takes around 5-6 hours to draw the pattern.

This inspired the creation of "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter," a cutting-edge tool designed to simplify and enhance this tradition.

2. Who's done what beforehand?

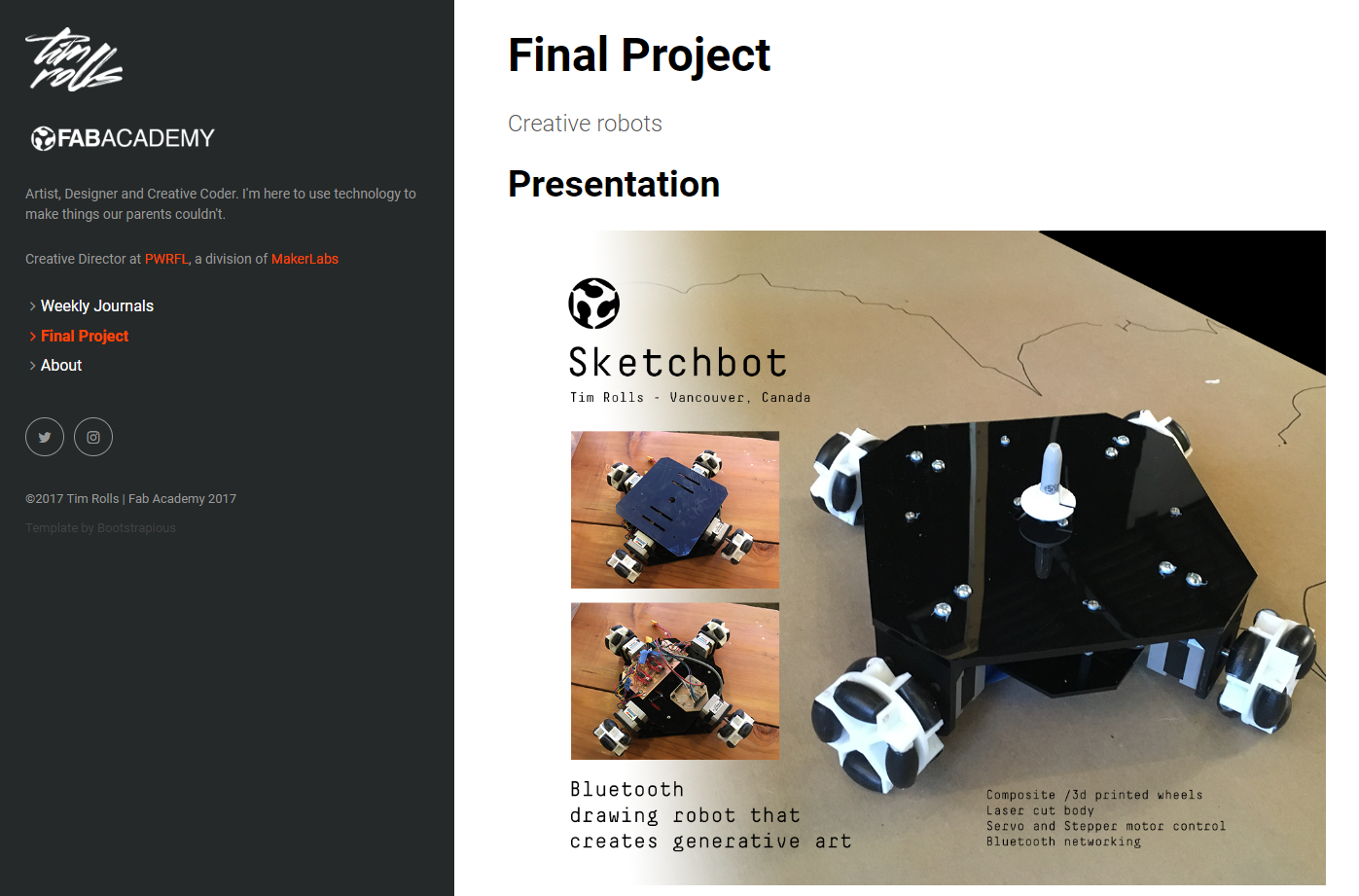

Tim Rolls, a Fab Academy graduate in 2017, created a sketchbot with four wheels and a larger design. In contrast, I aimed to reduce the machine's size and increase its accuracy.

3. What will you design?

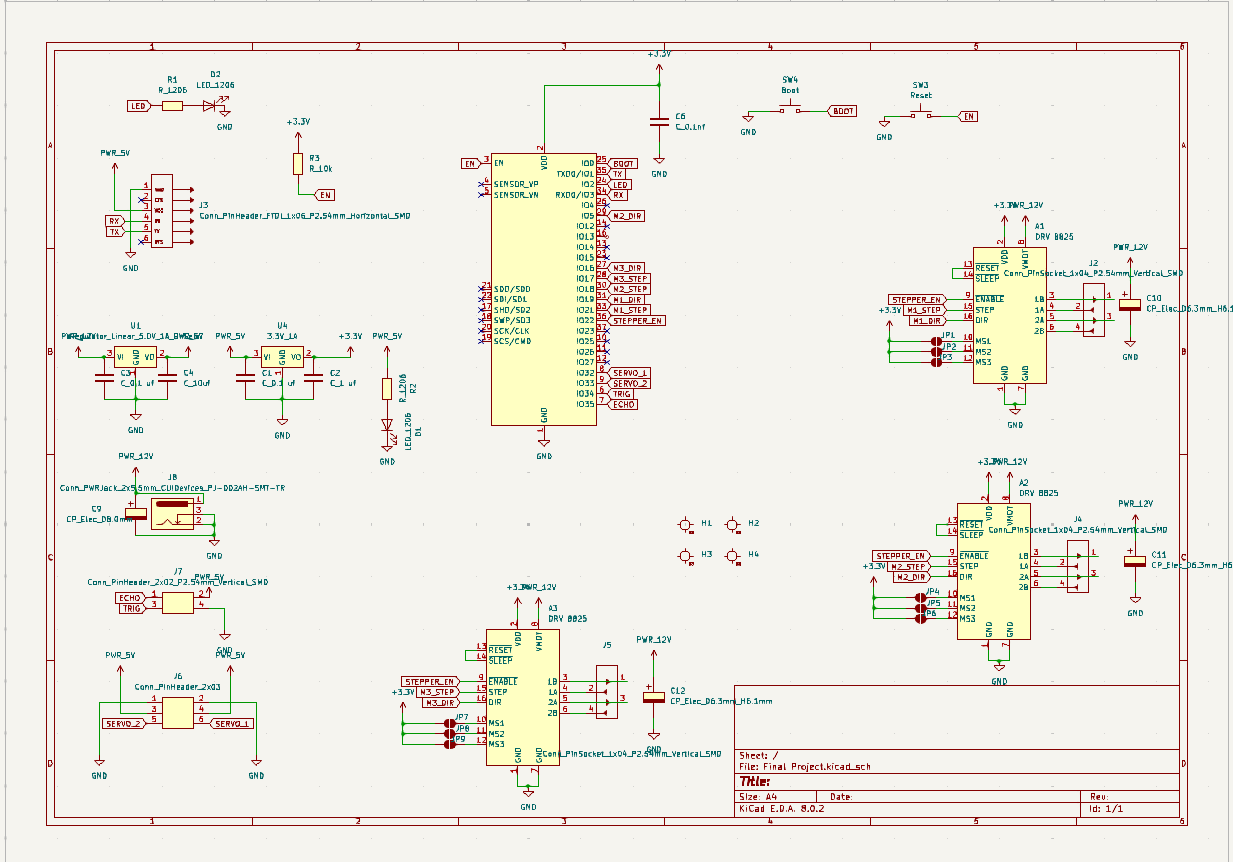

The project involves designing several components, including the main body of the plotter, motor brackets, wheel couplings, pen holder, and the PCB in KiCAD. These designs are essential for creating the precise and versatile plotting capabilities of the device.

Mechanical Design

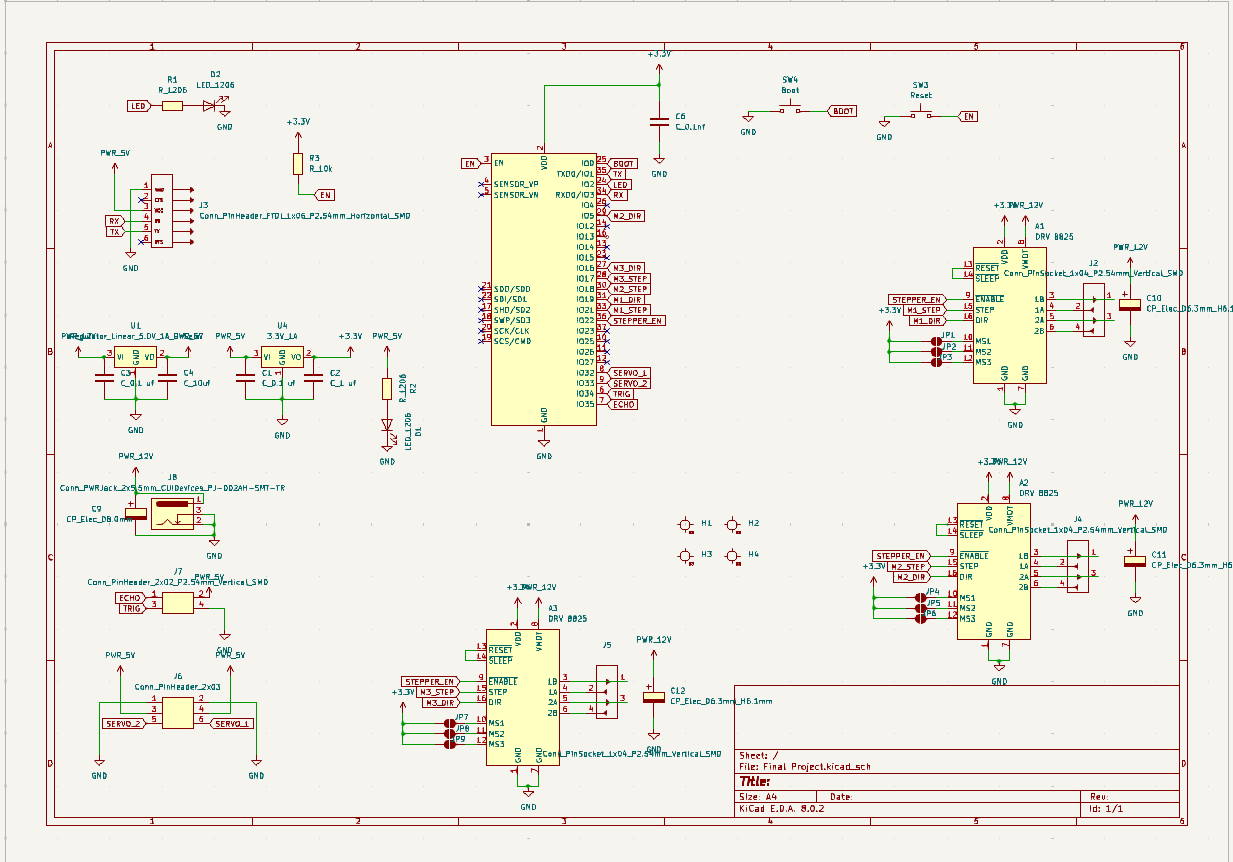

Electronics design: Designing and integrating the necessary electronic components.

.png)

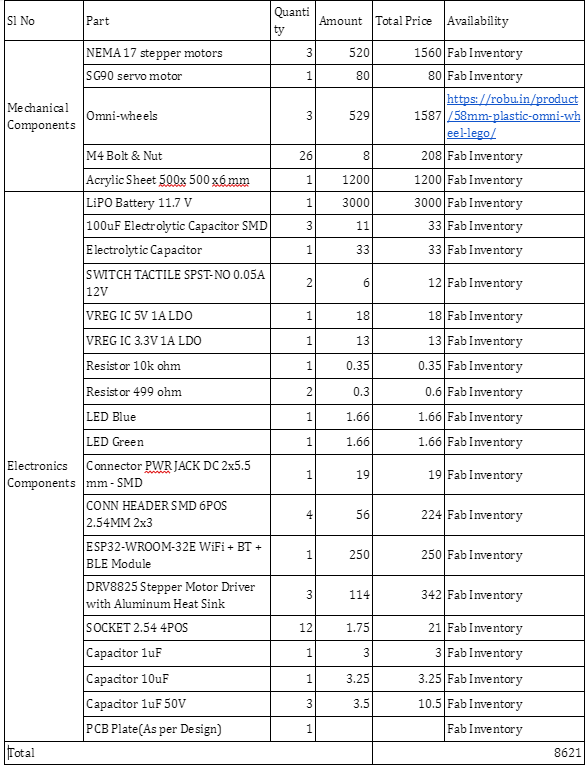

4. What materials and components will be used?

Materials and components used include:

5. Where will they come from?

Components like the omni-wheels were ordered from Robu.in, while the rest of the components were sourced from inventory.

6. How much will they cost?

As per todays BoM it will cost more than Rs.8000 cost may vary and it will include it on the final project documentation

7. What parts and systems will be made?

Parts and systems to be made include the main body, motor brackets, wheel couplings, pen holder, and the electronics including the microcontroller board and main electronics board. Additionally, integrating software with hardware and thorough system testing are essential parts of the project.

Main Parts

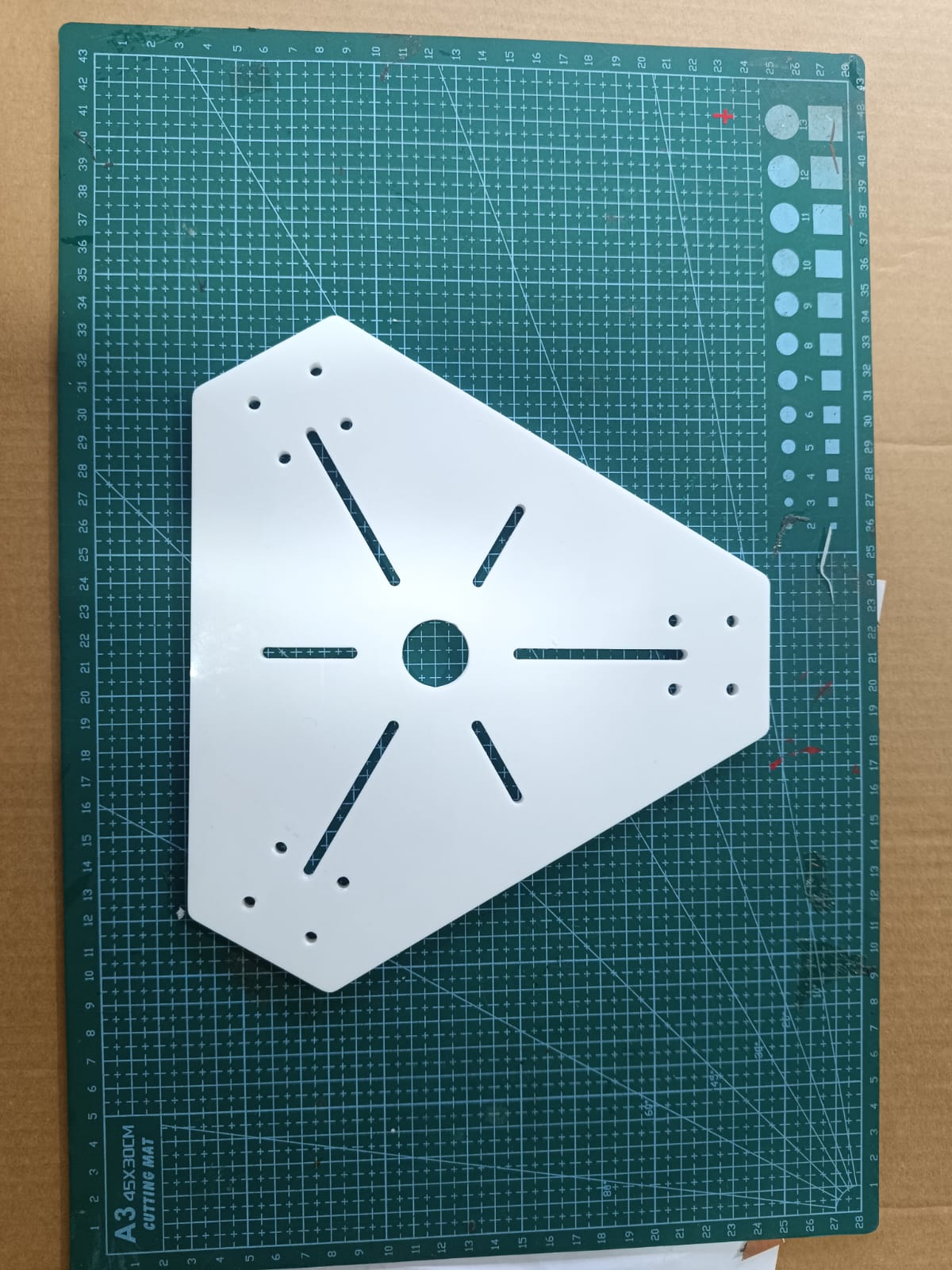

1.Acrylic Body: For strong base i am using 6mm acrylic sheets that is routed using Zund . Top body is also designed with 3mm acrylic

.png)

.jpeg)

.png)

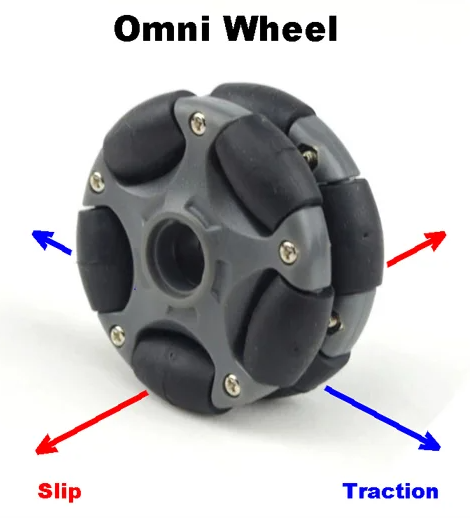

2.Omni Wheels

Omni wheels feature small rollers embedded around their circumference. Each of the rollers is placed perpendicular to the direction in which the omni wheels turn. Here are the top five benefits of omni wheels.

360-Degree Movement

They are known as “omni wheels” because they are capable of turning and moving in 360 degrees. They don’t actually swivel, nor do they turn

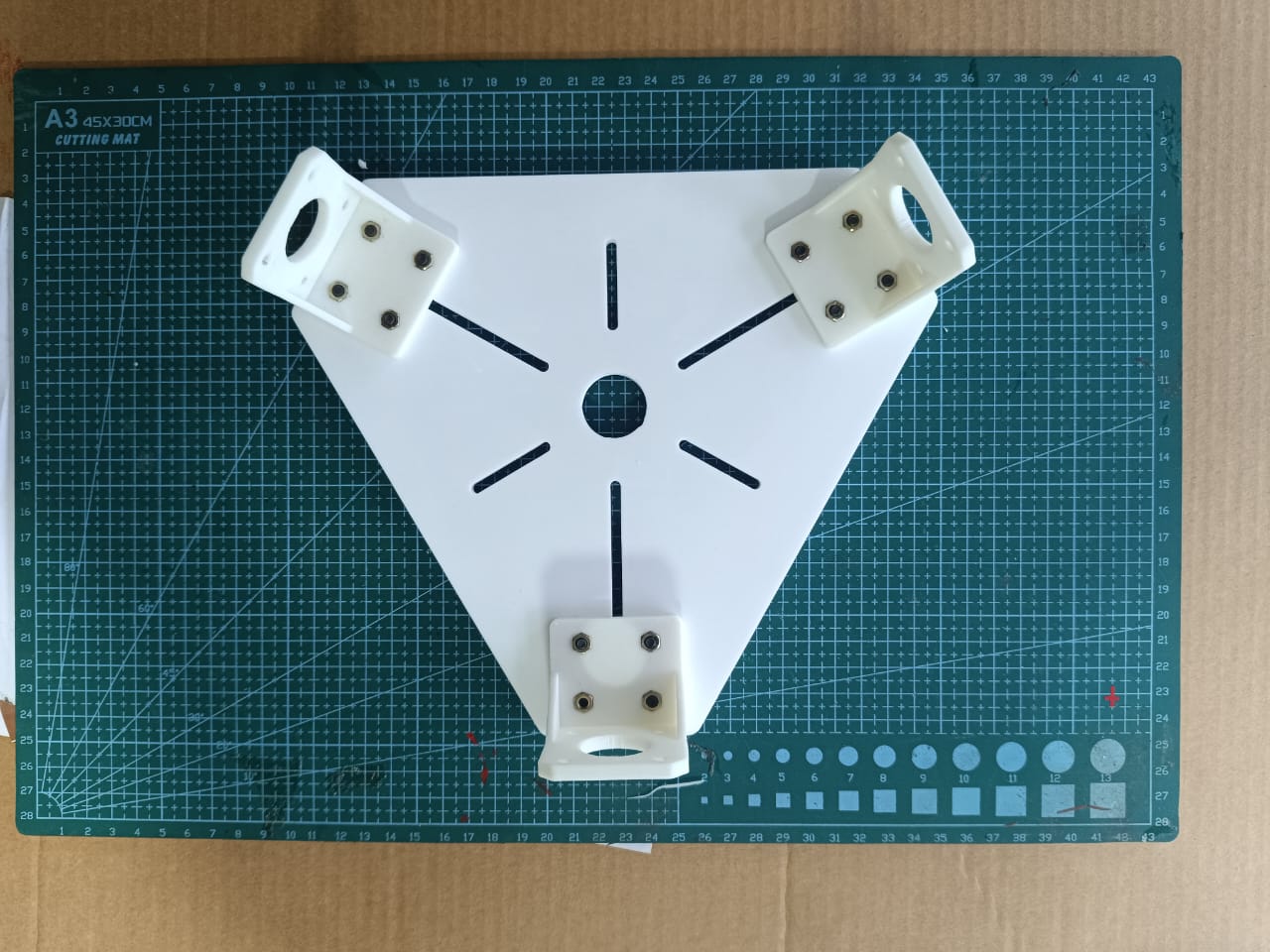

3.Motor Mounts

3D printed Motor Mounts: Customized Motor mount for NEMA 17 Motors that help connect the wheels

Systems

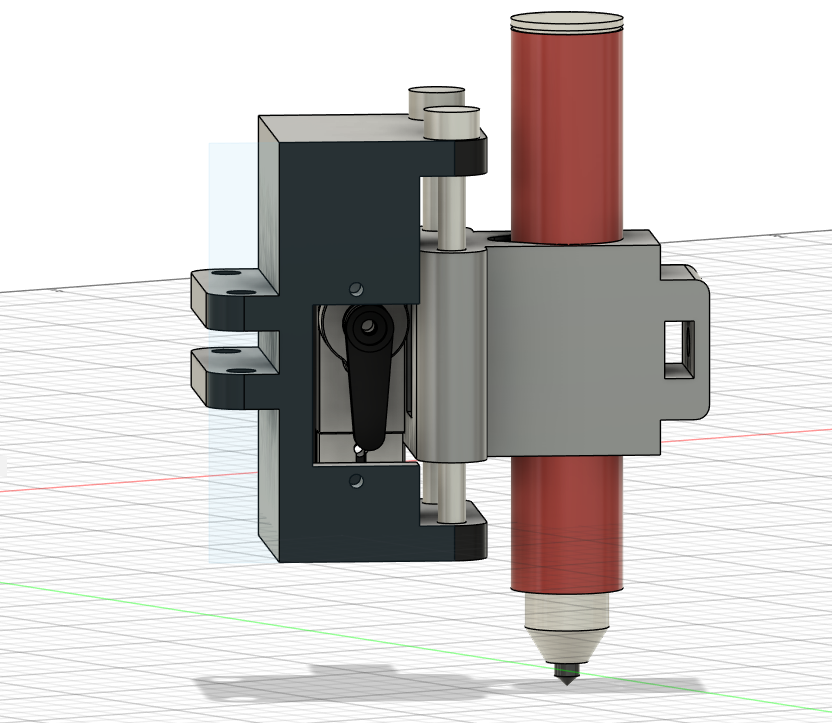

1.Servo Pen Lift

The penlift mechanism in the "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter" is designed to precisely control the vertical movement of the pen, allowing it to lift and lower as needed for accurate plotting. This mechanism utilizes a servo motor mounted on a custom-designed bracket attached to the plotter's main body. The servo motor, controlled by the ESP32 microcontroller, receives commands to adjust the pen's position based on the G-code instructions.

2.User interface system for input.

The Infinity Plotter is a Frontend Application, developed using the Next.js framework. The application facilitates seamless communication with connected CNC (Computer Numerical Control) machines through the WebSerial API. This interface aims to offer a user-friendly experience for monitoring and controlling CNC operations directly from a web browser.

8. What processes will be used?

processes involved include:

- CAD design using Fusion 360

- Manufacturing body parts using Zund and Laser Cutting Machines

- 3D printing for motor mounts

- PCB milling and soldering

- System integration and testing

9. What questions need to be answered?

Questions to be addressed include ensuring the software is correctly interfaced with the hardware, verifying the system's functionality through testing, and determining the plotter's performance in creating detailed designs on various canvases.

- How accurately can the software interface with the hardware?

- What is the precision level of the stepper motors in the plotter?

- How effectively does the penlift mechanism operate in practice?

- Can the system consistently produce detailed and high-quality designs?

- How easy is it to calibrate the plotter for different canvas sizes and types?

- How does the plotter perform under continuous use for extended periods?

10. How will it be evaluated?

Success Criteria:

The project will be evaluated through thorough testing using the electronics board, ensuring all components are integrated and compatible, and assessing the system's ability to create detailed and precise designs. Additionally, documentation and final presentation will provide insights into the project's success.

- The design should be aesthetically pleasing and user-friendly.

- The project should utilize the knowledge and skills acquired during the FAB Academy effectively.

Final Evaluation:

The project will be considered successful if it meets the above criteria and demonstrates reliable performance using the available materials and processes.

Future Scope

The "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter" has significant potential for future developments and applications, particularly in construction and road signage. By implementing a draw pan mechanism, the plotter can be adapted for precise and efficient marking on floors at construction sites. This can greatly enhance the accuracy and speed of layout work, ensuring that designs are adhered to with minimal errors. The plotter's ability to create detailed and complex patterns can be utilized to mark positions for walls, electrical outlets, plumbing lines, and other critical construction elements directly on the construction floor.

Furthermore, the plotter can be adapted to plot signs on roads. This involves creating a robust and weather-resistant version of the plotter capable of handling outdoor conditions. The plotter can be equipped with specialized nozzles for different types of road marking paints and materials. This adaptation will enable the plotter to draw lane markings, pedestrian crossings, traffic symbols, and other essential road signs with high precision. The automation of road sign plotting will increase the efficiency of road maintenance crews, reduce labor costs, and enhance the quality and consistency of road markings.

The future scope also includes integrating advanced technologies such as GPS for precise positioning, IoT for real-time monitoring and control, and AI for optimizing the plotting paths and improving the accuracy of complex designs. Additionally, expanding the software capabilities to include more sophisticated design tools and user-friendly interfaces will make the plotter more accessible to a broader range of users and applications.

By leveraging these advancements, the "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter" can become an indispensable tool in the construction and road maintenance industries, providing high precision, efficiency, and versatility in a variety of marking and plotting tasks.

Incorporation of Various Design and Production Elements

- 2D and 3D Design: CAD design in Fusion 360.

- Additive and Subtractive Fabrication Processes: 3D printing, laser cutting, and milling.

- Electronics Design and Production: Designing and producing microcontroller and main electronics boards.

- Embedded Microcontroller Interfacing and Programming: Using ESP32 for control and G-code interpretation.

- System Integration and Packaging: Assembling all components, integrating software and hardware, and thorough testing.

PROJECT DEVELOPMENT

What tasks have been completed, and what tasks remain?

Completed Tasks:

Design

Completed the design of the project .

Electronics design

%201.png)

Manufacturing

Completed the manufacturing of Base body and Motor Mounts

I have completed the base design in my wildcard week

I have 3D Printed the motor mount & wheel base for the plotter

Remaining Tasks:

- Fabrication and testing of the PCB

- Fabrication of the outer case.

- User Interface Building

- Final programming adjustments and testing.

What's working? What's not?

Working: The mechanical parts is assembled properly

Not Working: The Penlift mechanism isspring loaded and iam using an M3 bolt , It need to change to a polished 3 mm rod

9. What questions need to be answered?

- How can the software be correctly interfaced with the hardware to ensure seamless operation?

- How reliable is the Bluetooth communication between the microcontroller and external devices?

- How can the integration of the G-code interpreter be optimized for better plotting accuracy?

- What improvements can be made to the current design to enhance the overall reliability and user experience of the plotter?

When will it be completed?

The project will be completed three days before the presentation date, the 10th. This means the target completion date is the 7th.

| Date | Activity | Status | Remarks |

| 18 May 2024 | Main Body Design | Completed | Scheduled to Zund |

| 20 May 2024 | Motor Bracket Design | Completed | Scheduled to 3D printing |

| 21 May 2024 | Wheel Coupling | Completed | Done By Milling |

| 22 May 2024 | Assembly of Wheels | Completed | |

| 23 May 2024 | Assembly of main Body | Completed | |

| 24 May 2024 | Testing with CNC shield | Pending | |

| 27 May 2024 | Electronics Design Micro Controller Board | Pending | |

| 27 May 2024 | Electronics Design Main Board | Pending | |

| 28 May 2024 | Pen Holder Design | Pending | 3D Printing |

| 29 May 2024 | Electronics Production | Pending | |

| 30 May 2024 | Soldering | Pending | |

| 31 May 2024 | Soldering | Pending | |

| 1 June 2024 | Software checking, Interfacing | Pending | |

| 2 June 2024 | Testing using board | Pending | |

| 3-5 June | Total System Integration | Pending | |

| 5-7 June | Documentation | Pending | |

| 10 June 2024 | Final Presentation | Pending |

What You Have Learned from This Project

From working on the "പൂമ്പാറ്റ: The Butterfly - Infinity Plotter" project, I have gained a wealth of knowledge and experience across several domains of engineering and design. Firstly, I have deepened my understanding of CAD design and the importance of precision in creating functional components. Using Fusion 360 to design the plotter's parts has taught me the intricacies of translating conceptual designs into tangible, manufacturable components.

I have also enhanced my skills in both additive and subtractive fabrication processes. The project involved extensive use of 3D printing and laser cutting, providing me with practical experience in these techniques and an appreciation for their applications and limitations. Additionally, the process of milling and soldering PCBs has improved my proficiency in electronics manufacturing and assembly.

Working with the ESP32 microcontroller and integrating it with stepper motors and a servo for the penlift mechanism has expanded my knowledge of embedded systems. I have learned how to interface hardware with software effectively, using G-code interpretation for precise control of the plotter's movements. This has also improved my programming skills, particularly in the context of embedded systems and real-time control.

System integration and testing were crucial parts of the project, teaching me the importance of thorough testing and debugging to ensure all components work seamlessly together. This experience has underscored the value of iterative testing and the need for meticulous attention to detail.

Additionally, the project has highlighted the importance of effective project management, from sourcing materials and managing costs to coordinating various aspects of the design and manufacturing process. It has reinforced the significance of planning, time management, and adaptability in handling unforeseen challenges.

This project has been a comprehensive learning experience, providing me with practical skills and knowledge that are applicable to a wide range of engineering and design challenges.