Wildcard Week

Tasks for this week

Design and produce something with a digital process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce

Idea

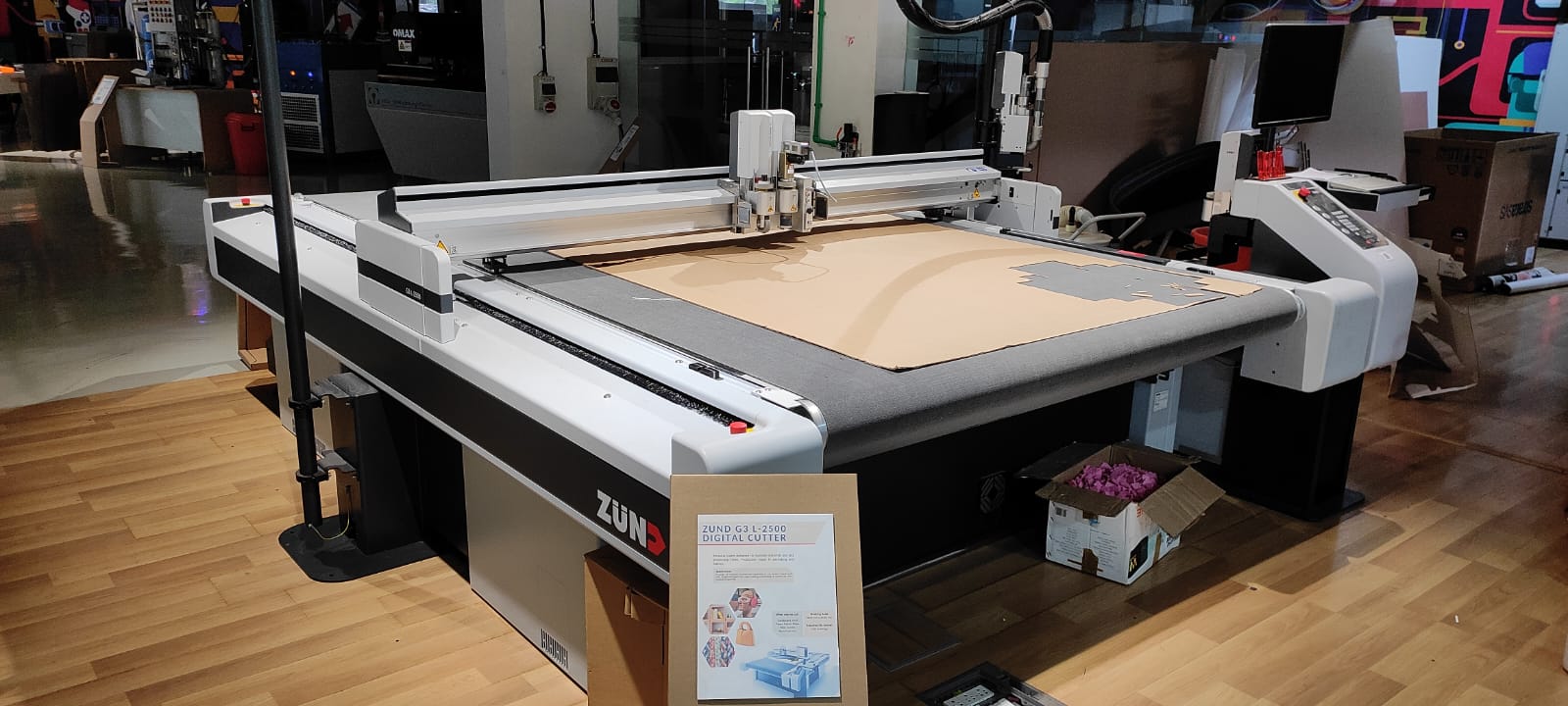

I decided to use the Zund G3 L - 2500 to cut the body for my final project. By leveraging this advanced machine, we can quickly create a custom cardboard stool designed to meet our exact needs and requirements.

Zund G3 L - 2500

The Zund G3 L - 2500 is a highly advanced cutting system that offers exceptional precision and versatility. It is widely recognized as a top-of-the-line solution for various industries, including packaging, signage, textile, and industrial manufacturing.

- Working Area: 1800 mm x 2500 mm

- Module Slots: 3 Nos( 1 Power Module, 2 Speed module)

- Materials: Card Board, Vinyl, Paper, Fabric, Glass Fiber, Acrylic, Aluminium etc.

- Applications: A range of modules provide the capability to cut, score, crease and mill. Use cases include origami/kirigami for rapid cutting-and-folding of structures with tunable properties, two sided milling for press fit furniture etc.

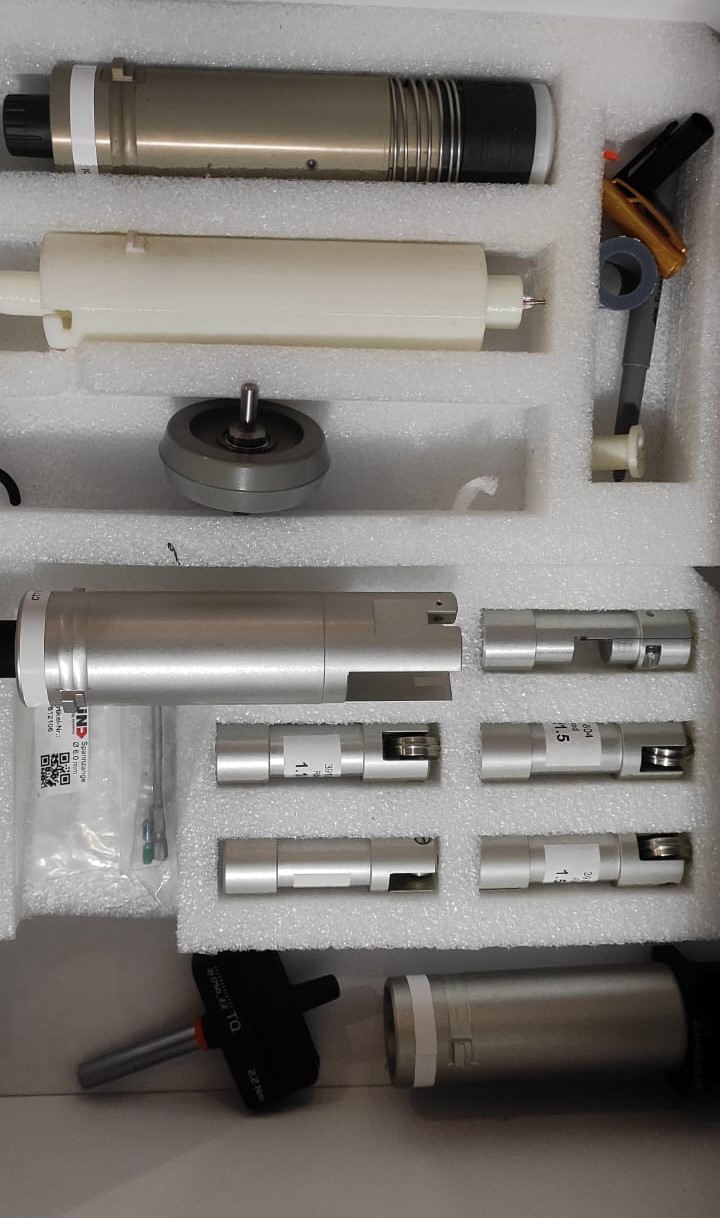

The Zund digital cutter is equipped with various tools to handle a wide range of cutting, routing, and creasing tasks. Here is a brief overview of the primary tools:

- Universal Cutting Tool (UCT): Used for through-cuts on a variety of materials.

- Kiss-Cut Tool (KCT): Ideal for cutting the top layer of laminated materials without cutting through the backing.

- Router Tool (RT): Utilized for routing rigid materials like wood, plastic, and aluminum.

- Oscillating Tool (EOT): Perfect for cutting thick and dense materials using an oscillating motion.

- Creasing Tool (CTT): Designed for creating fold lines on materials like cardboard and corrugated board.

- Perforating Tool (POT): Used for perforating materials to create tear-off lines.

- V-Cut Tool (VCT): Allows for precise V-shaped cuts, suitable for creating 3D structures from foam or cardboard.

- Drill Tool (DT): Used for drilling holes in various materials with precision.

The machine's versatility is further enhanced by its modular design, which enables easy customization and integration of additional tools and modules based on specific production needs. This flexibility ensures that the Zund G3 L - 2500 can adapt to a variety of applications and workflows.

Moreover, the Zund G3 L - 2500 incorporates advanced automation features, such as automated tool changes, material handling, and workflow optimization, which significantly increase productivity and efficiency. The machine is also equipped with user-friendly software that streamlines the design-to-production process, making it accessible to both experienced professionals and newcomers.

Rotary Knife

The primary tool used for cutting cardboard is a rotary knife, often referred to as a "carton tool" or "cardboard cutting tool." This tool features a circular blade that rotates at high speed, allowing it to cleanly and accurately cut through cardboard materials.

Creasing Tool

For creasing or scoring cardboard, the Zund employs a creasing tool, commonly known as a "creasing wheel" or "carton creasing tool." This tool consists of a sharp wheel or roller that applies pressure to the cardboard, creating a defined crease line without cutting through the material. The creasing tool is used to facilitate folding and bending of the cardboard for various applications, such as creating folds in boxes or cardboard furniture.

Integrated camera system

The camera system also enables the Zund to perform print-to-cut registration, where it detects registration marks on the printed material and aligns the cutting path accordingly.

camera captures images of the material, allowing the cutting system to analyze and align the cutting paths with the printed graphics or pre-defined markers.

Auto initialization

Auto initialization in Zund is like a smart setup process. It's a way for the cutting system to get ready on its own. It checks and adjusts things to make sure everything is working properly.

- Calibrating the cutting table

- initializing the cutting head

- establishing communication with the control software.

Machine and Software Setup

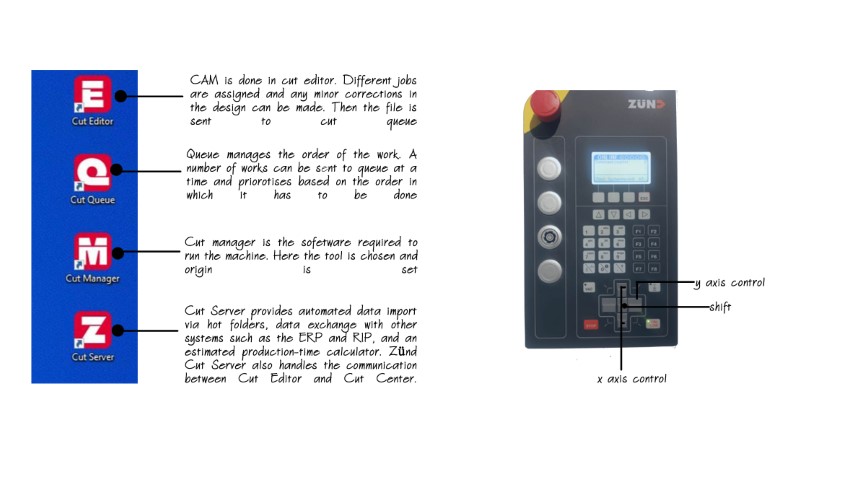

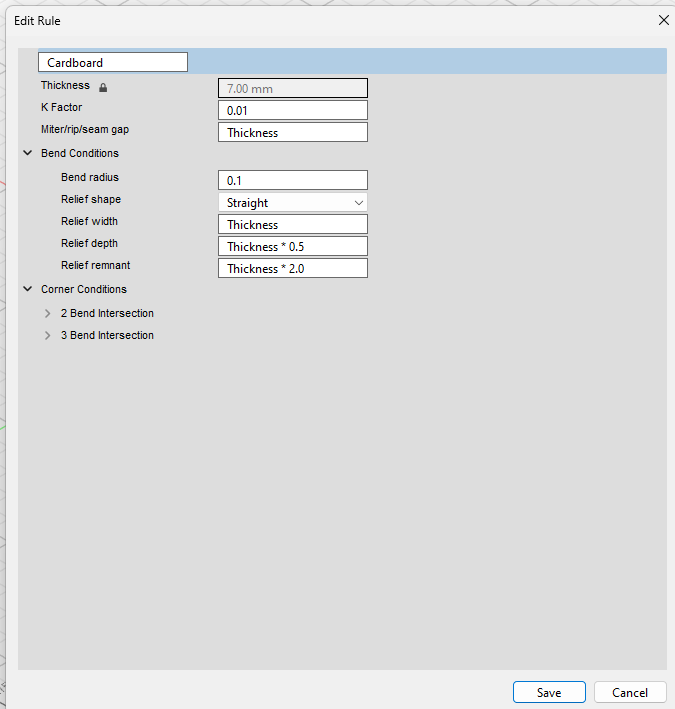

To operate the Zund, you will use three software programs: Cut Editor, Cut Queue, and Cut Centre.

- Cut Editor: This software is used for designing and creating your cutting files. It allows you to import or create designs, set up cut paths, and define cutting parameters.

- Cut Queue: This program manages and organizes your cutting jobs. It functions as a job queue, enabling you to schedule and prioritize various cutting tasks.

- Cut Centre: This is the central hub for overseeing the entire cutting production workflow.

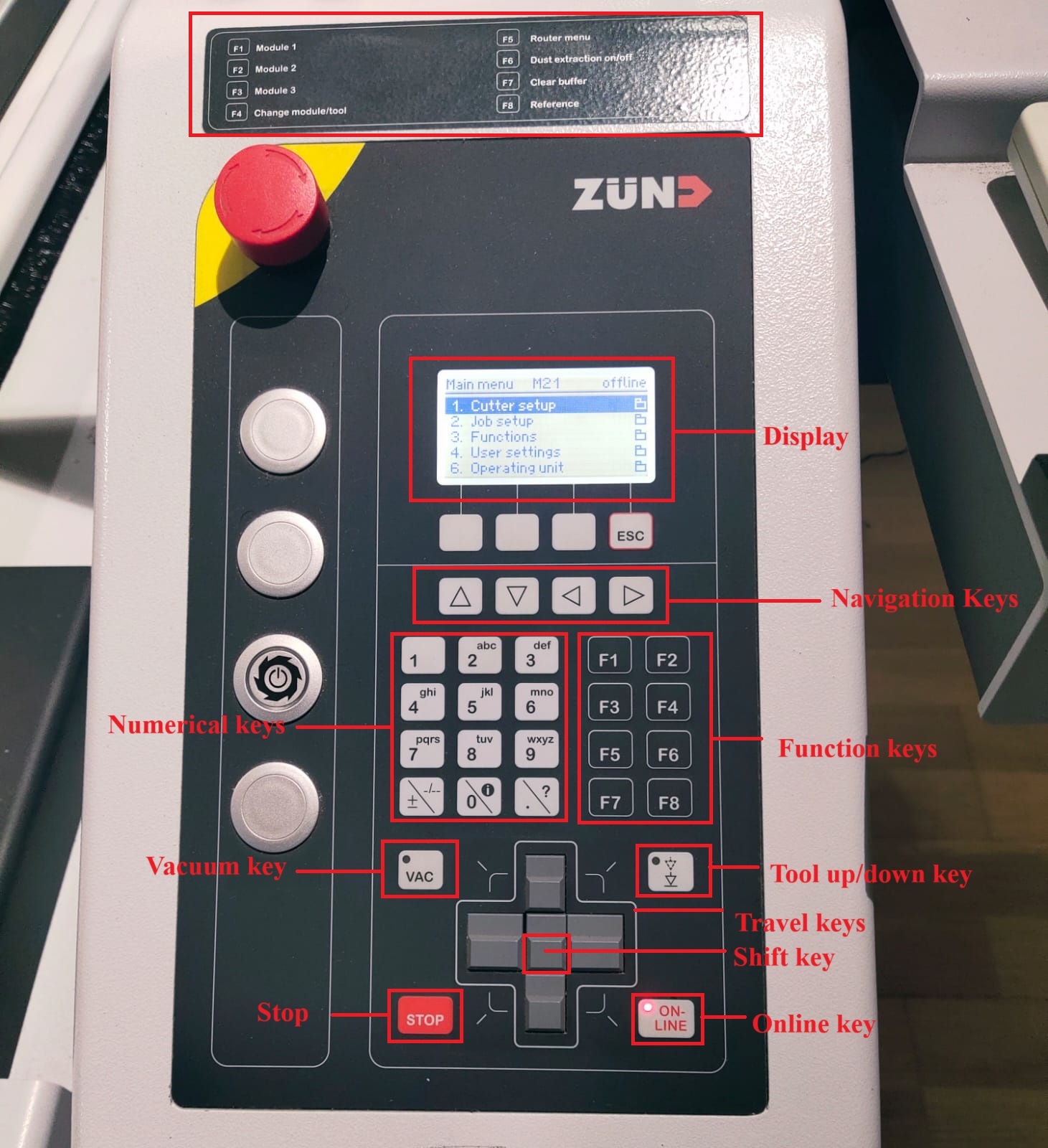

The photo below provides an overview of the Zund control panel.

Zund Cut Editor

The Zund Cut Editor software allows users to prepare cutting files, send them to the Zund machine, and control the cutting process. The software includes tools for designing and editing cutting paths, managing materials and tool settings, and optimizing cutting workflows.

.jpg)

To add your dxf file click on file then select Add job. Since the laser cutting machine was down, my final project body is need to cut in Zund

.png)

The Numerical Geometry tool in Zund Cut Editor is used to create and modify cutting paths on digital materials with precision and accuracy. This tool allows users to enter numerical values to define the exact position, size, and orientation of cutting lines, curves, and shapes.

Method Of Cutting

The method is set to Route and Drill. Route cuts involve using a router bit to cut through the material, allowing for more complex and precise shapes. Drill cuts use a drill bit to create holes or cutouts in the material. Both techniques can be combined to achieve the desired cutting results for your project.

Right-click again and select “Change method", then select “New method”.

Right-click and select “Change method", then select “New method”.

From the “method attributes”, select “Register”, select “Border: front right” from the method, and click “OK”.

.png)

.png)

.png)

.png)

Finally i have given all method of fabrication

.png)

Setting the Material

To set the material select the pen icon on the right side next to materials . I was going to cut the materials on 6 mm acrylic . click and select the OK to set the material

.png)

Press the "Send to Editor" icon to transfer the files to the Zund Cut Queue software.

The Zund Cut Queue software enables users to manage and organize their cutting jobs efficiently. With Cut Queue, you can add, delete, and modify jobs, as well as prioritize and manage the order in which they are processed. Additionally, users can view the status of each job, including details about the material, cutting parameters, and estimated cutting time.

.png)

double click on the job and cut queue will auto open cut center

.png)

So in cut center, we need to select the different tools and speed parameters for routing and drilling operation

For 2 mm, i have followed these parameters

.png)

For 4 mm bit

.png)

For 6 mm

.png)

.png)

To start the cutting process press start job button ( right bottom )

.jpeg)

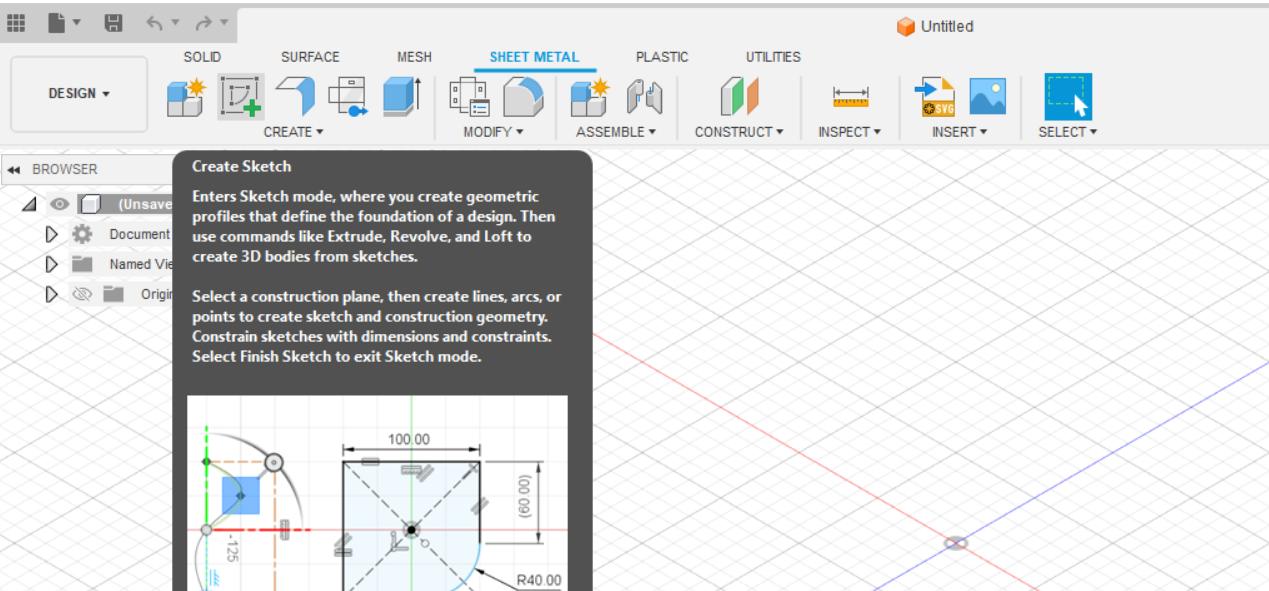

Cardboard Furniture in Fusion 360

Designing Card board in Fusion 360

Fusion 360 has great tutorials in youtube on sheet metal . follow the below tutorial to learn more .

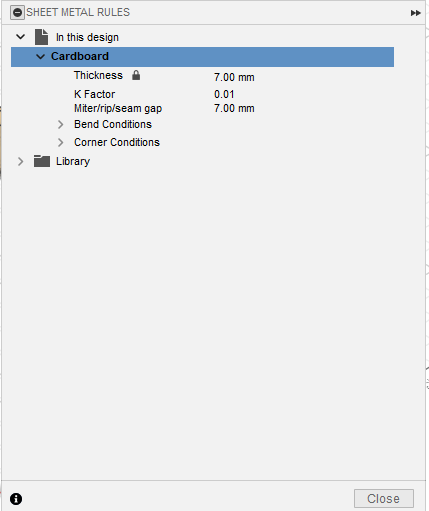

Open the sheet metal rules design window to add cardboard Rules

Click on Modify —> Sheet metal rules

Give all the Rules as shown below for 7 mm cardboard

The Flange tool in Fusion 360's sheet metal functionality is used to create bends or folded edges in sheet metal components.

Using Sketch and Flange tool I started designing the stool.

.png)

Using Height Datum and bend position determine the appropriate folding positions .

.png)

.png)

Then i have mirrored the design

.png)

Draw the front portion

.png)

Added the final appearance to the design

.png)

Unfloding

the Unfolding tool is used in the context of sheet metal design to convert a folded sheet metal part into its flat or unfolded state. It essentially "unfolds" the part to show its 2D representation, which is essential for creating manufacturing drawings and determining the flat pattern necessary for fabrication.

When working with sheet metal components that have bends, such as flanges, the Unfolding tool analyzes the geometry of the part and calculates the necessary bends and their locations. It then virtually unfolds the part, displaying it as a 2D flat pattern that represents how the sheet metal material would need to be cut and bent to recreate the original folded shape.

.png)

.png)

.png)

Then we can export it into .dxf format for cutting

Cutting on Zund

I followed the above procedure for the initialization of the machine.

Placed the cardboard over Zund

Inserted the Design file to Zund Cut Editor

.png)

.png)

Selected the material

.png)

.png)

.png)

Added the required operations and opened the design in Zund Cut Queue

.png)

.png)

Send the files to cut Center

.png)

For creasing operationd i have used the CTT1 module and CT103 creasing tool

.png)

For Cutting i have used Z21 tool

.png)

Cutting video

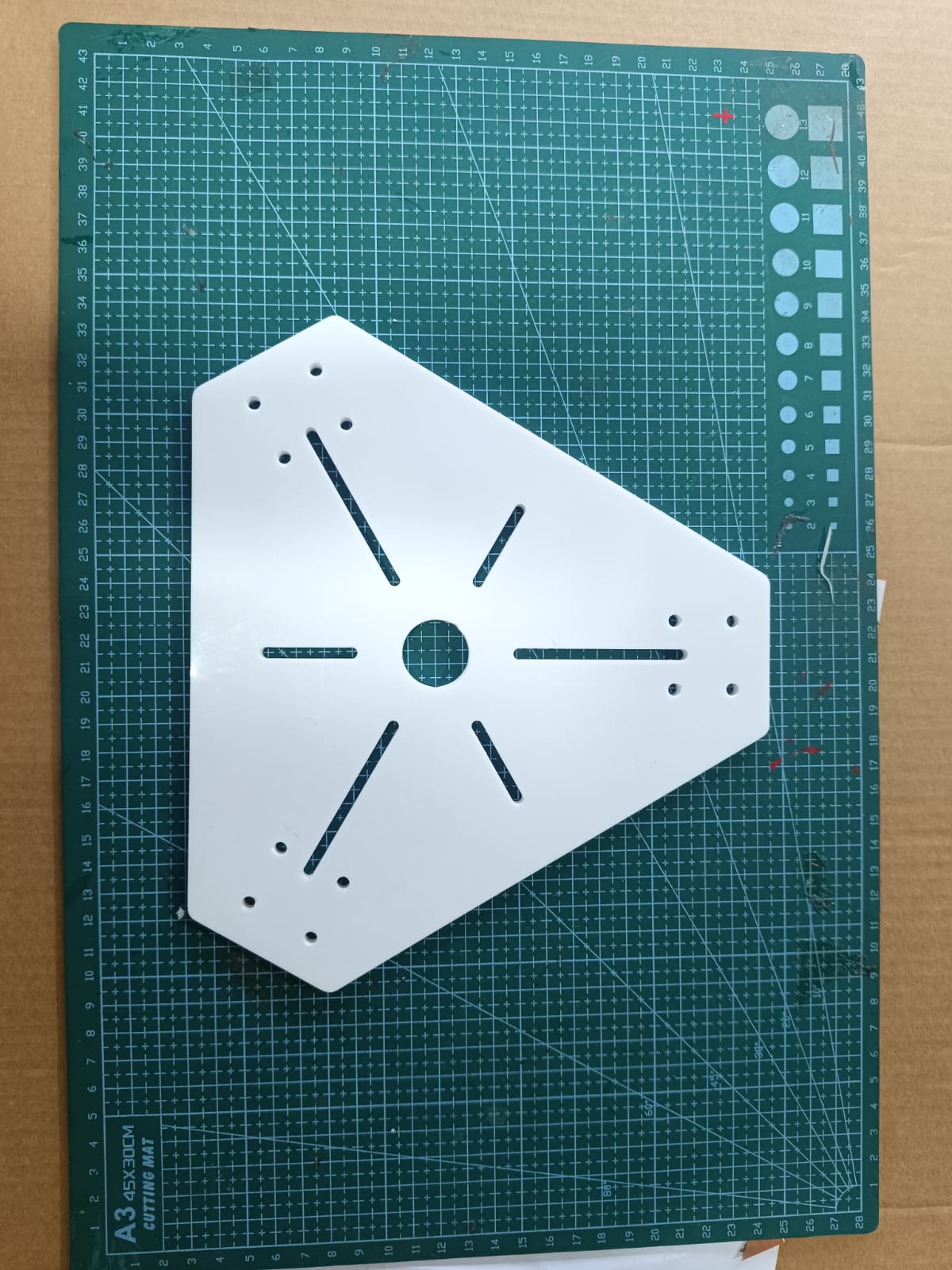

Finaaly i have assembled my stool

.jpeg)

Final result

Downloads